High-performance light-weight aggregate concrete and preparation method thereof

A lightweight aggregate concrete and lightweight aggregate technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as slump loss

Inactive Publication Date: 2014-03-05

HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

View PDF2 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

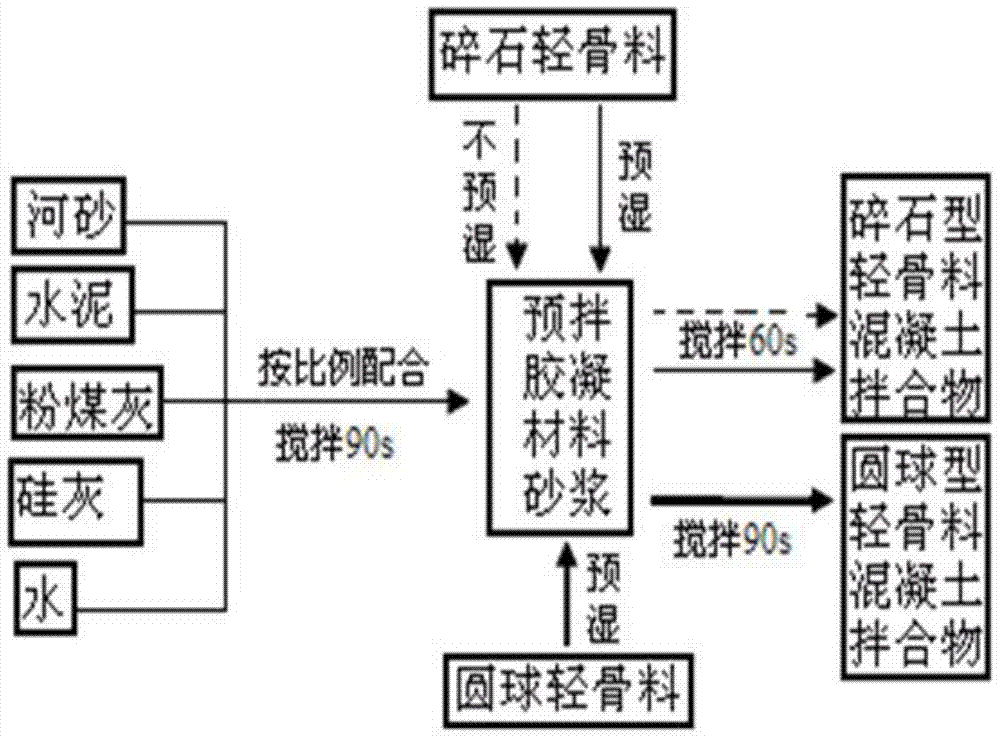

[0013] Aiming at the deficiencies in the prior art, the object of the present invention is to provide a high-light aggregate concrete and its preparation method to improve the working performance of lightweight aggregate concrete, reduce the floating of light aggregate, and solve the problem of slump loss

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

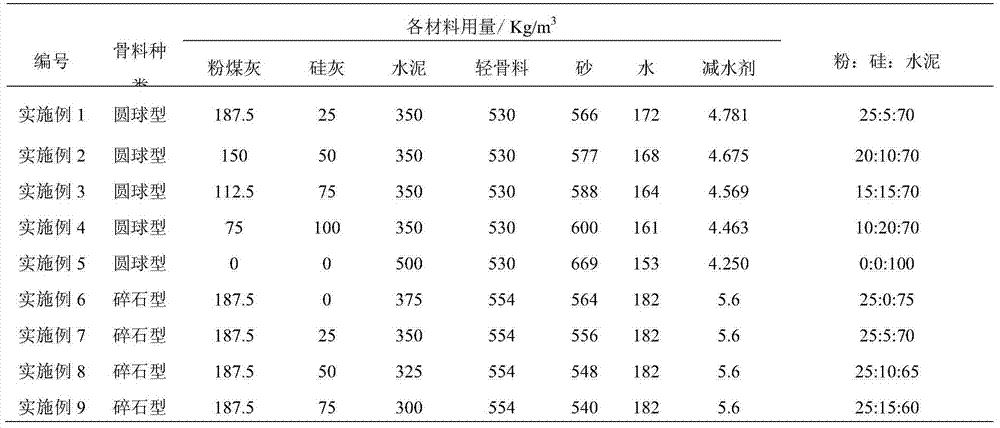

[0038] The raw material ratio of embodiment 1-9 is with reference to table 1

[0039] The raw material proportioning of embodiment 1-9

[0040]

[0041] The preparation methods all adopt the preparation methods disclosed in the present application.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

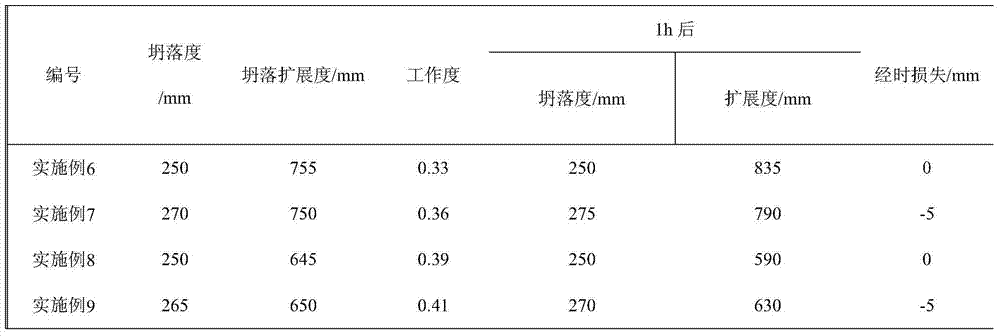

The invention discloses high-performance light-weight aggregate concrete and a preparation method thereof. When aggregate is rubble type light-weight aggregate, the concrete contains the following components in parts by weight: 187.5 parts of coal ash, 0-75 parts of silica ash, 300-375 parts of cement, 554 parts of light-weight aggregate, 540-564 parts of sand, 182 parts of water and 5.6 parts of a water reducing agent; when the aggregate is spherical light-weight aggregate, the concrete contains the following components in parts by weight: 0-187.5 parts of coal ash, 0-100 parts of silica ash, 530 parts of light-weight aggregate, 566-669 parts of sand, 153-172 parts of water and 4.25-4.781 parts of a water reducing agent. The slump loss in 1 hour of the prepared high-fluidity light-weight aggregate is smaller than 15 mm, no light-weight aggregate floats upwards, and the compressive strength is higher than 65.0 MPa.

Description

technical field [0001] The invention belongs to the field of inorganic non-metal, and in particular relates to a high-light aggregate concrete and a preparation method thereof. Background technique [0002] High Performance Concrete (HPC) is a new concept of concrete proposed by some developed countries based on the durability design of concrete structures in the late 1980s and early 1990s. It takes durability as the primary design index. This concrete It is possible to provide a service life of more than 100 years for infrastructure projects. China defines high-performance concrete in the "Technical Regulations for the Application of High-Performance Concrete" (CECS207-2006) as: it is produced using conventional materials and processes, has various mechanical properties required by concrete structures, and has high durability, high workability and high volume. stable concrete. [0003] Different from traditional concrete, high-performance concrete is a new type of high-te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/00C04B18/08

CPCY02W30/91

Inventor 麻建锁元敬顺薛斌黄洪亮丛晓红

Owner HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com