Semi-continuous casting device for preparation of aluminum matrix composites

An aluminum matrix composite material, semi-continuous technology, applied in the field of semi-continuous casting equipment for the preparation of aluminum matrix composite materials, can solve the problem of high difficulty in accurately controlling the addition ratio of reinforcements, achieve the effect of reducing the involvement of oxide film and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

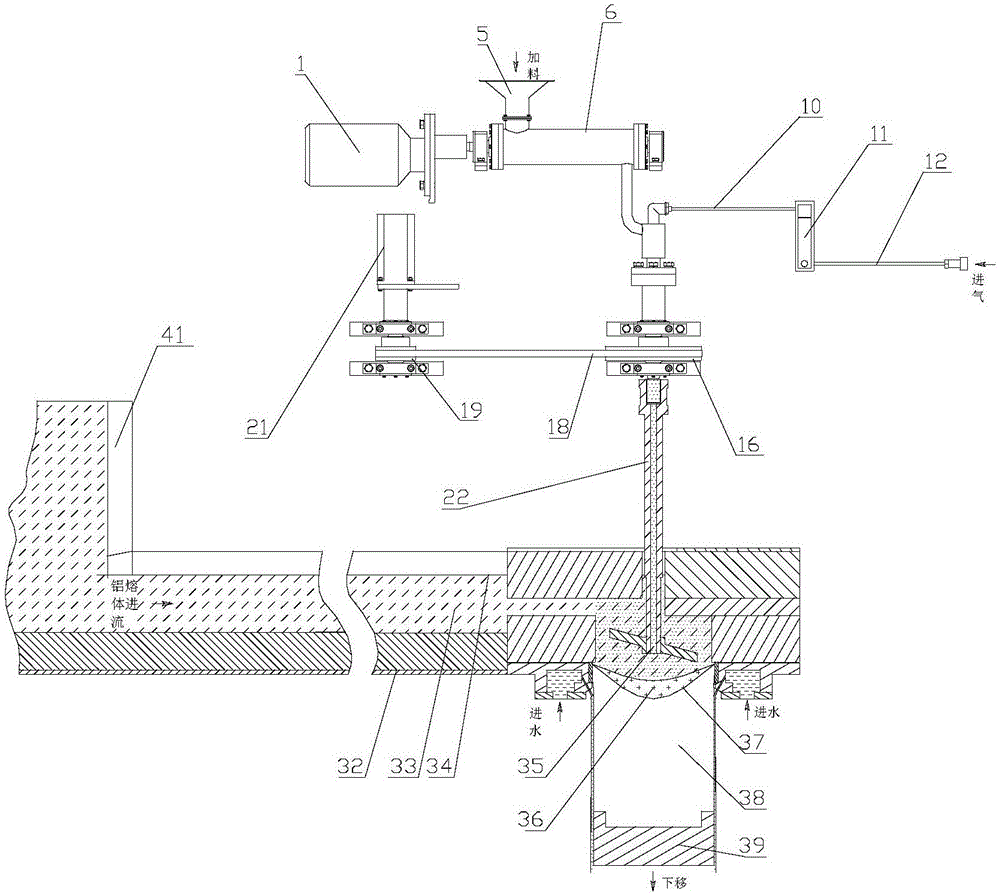

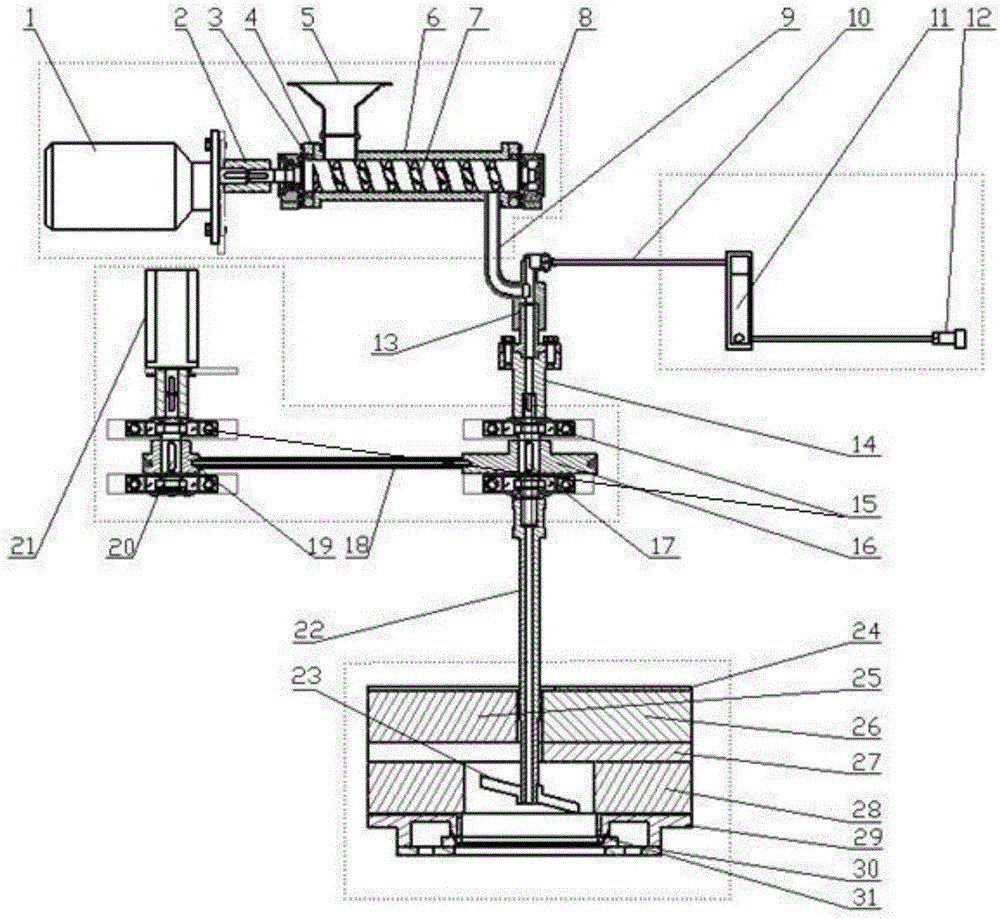

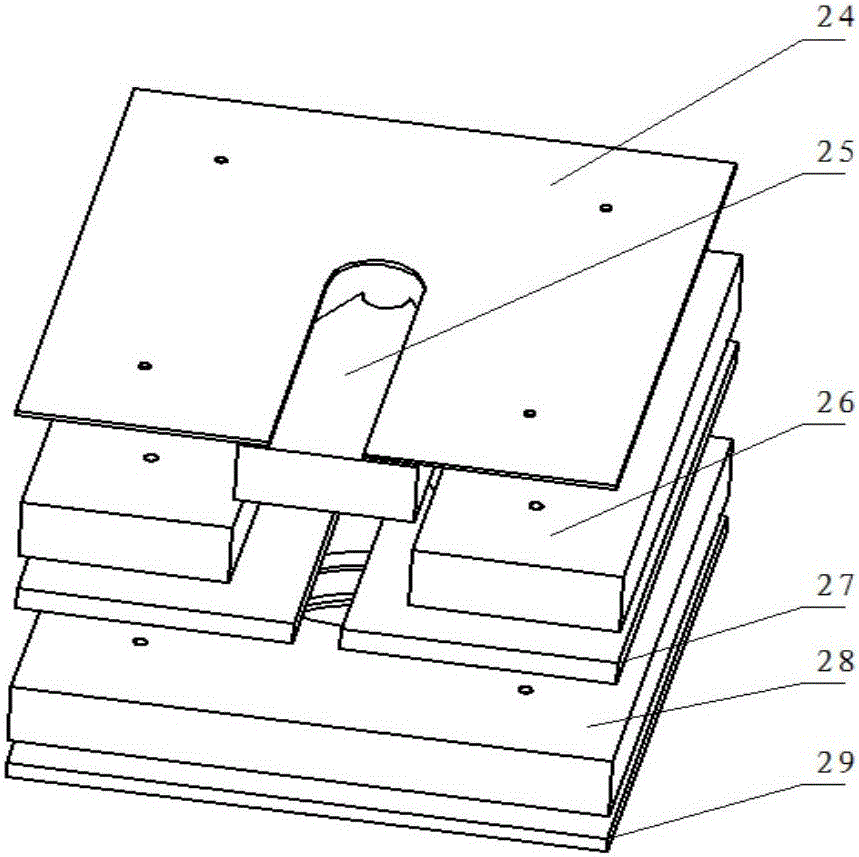

[0025] Such as figure 1 As shown, the semi-continuous casting device for preparing aluminum-based composite materials in the present invention includes a smelting and holding furnace 41, a stirring device, a holding device, a crystallizer, a feeding device, an air supply device, a rotating drive device, a connecting mechanism, and a launder 32. A melt outlet is provided at the bottom of one of the side walls of the holding furnace 41 , and a flow control valve is provided at the melt outlet for convenience in controlling the flow of the melt. There is a passage in the heat preservation device, the entrance of the passage is located at the front side of the heat preservation device, the outlet of the passage is located at the lower side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com