Processing process for fried capelins

A processing technology, a technology of mulberry, applied in the fields of application, food preparation, food science, etc., can solve the problems of inability to maintain the crispy and delicious taste of mullet, short shelf life of fried mullet, and high oil content in the product, and achieve the taste And the effect of delicious prolongation, simple and practical processing technology, and low oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of processing technology of deep-fried capricorn, described processing technology comprises the following steps:

[0028] (1) Pretreatment of raw materials:

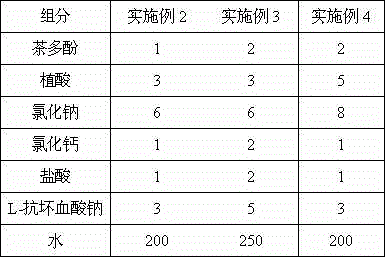

[0029] a. Wash and drain the fresh capuchin fish, soak in the soaking solution for 30-40 minutes, rinse with water for 8-10 minutes, drain and set aside;

[0030] b. Freeze the sliced bread below 0°C for about 3 hours, freeze hard, grind the frozen sliced bread into bread crumbs on a food processor, and set aside;

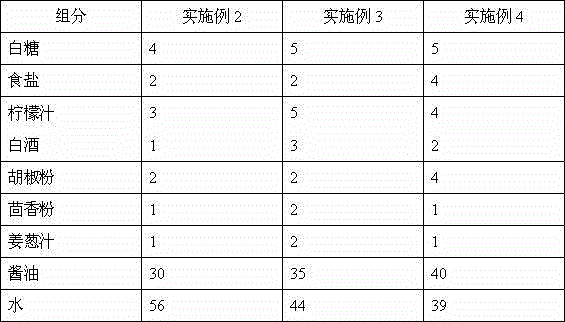

[0031] (2) Pickling: Put the capuchin fish processed in step (1) into the pickling solution for 2 to 3 hours, and set aside;

[0032] (3) Coating with flour: Coat the marinated capuchin with a layer of flour first, then a layer of egg liquid, then a layer of bread crumbs, and set aside;

[0033] (4) Vacuum frying: Put the capsicum processed in step (3) into the hot oil at a temperature of 105-110°C and vacuum-fry for 3-5 minutes;

[0034] (5) Vacuum deoiling: Centrifuge the vacuum-fried c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com