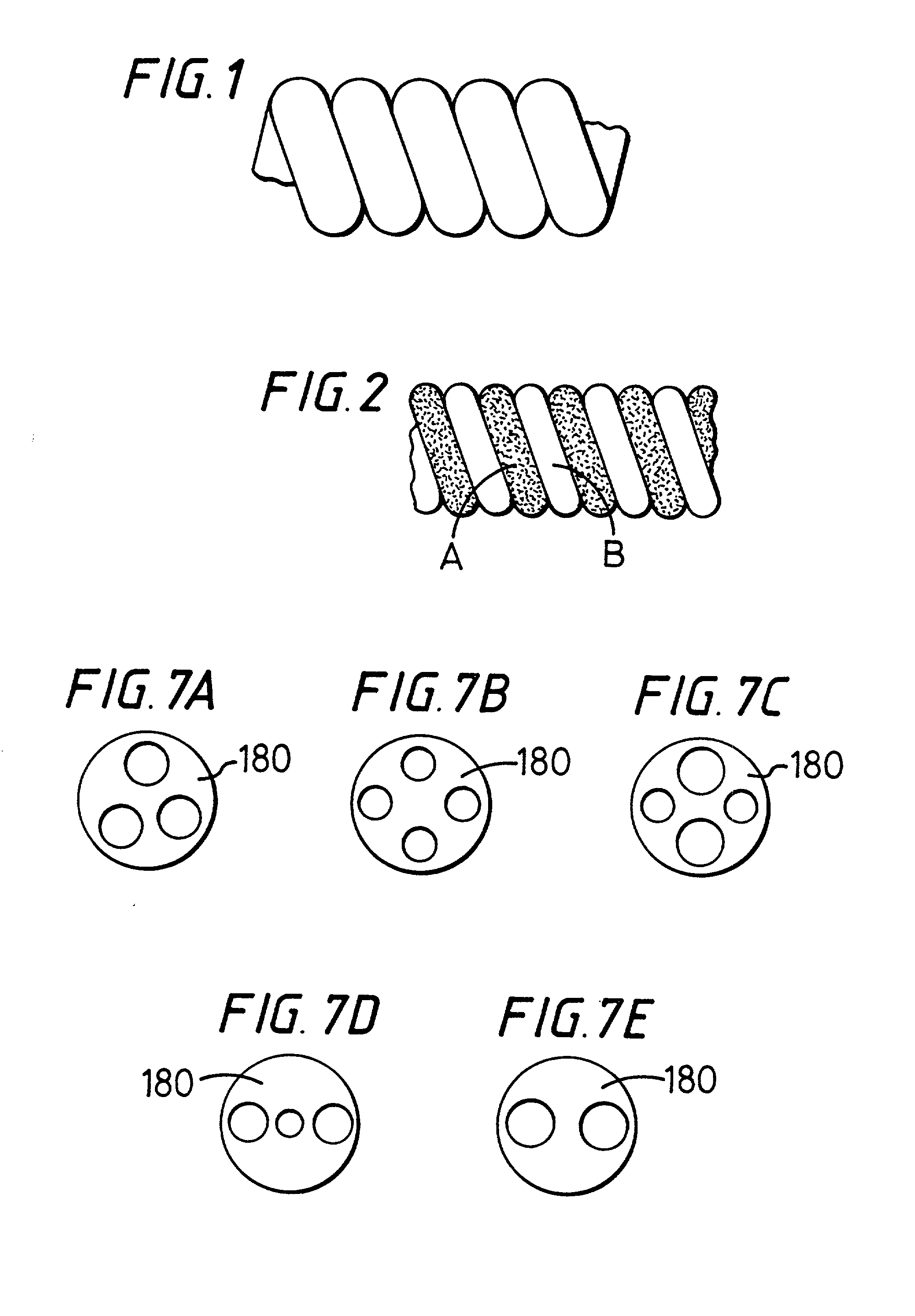

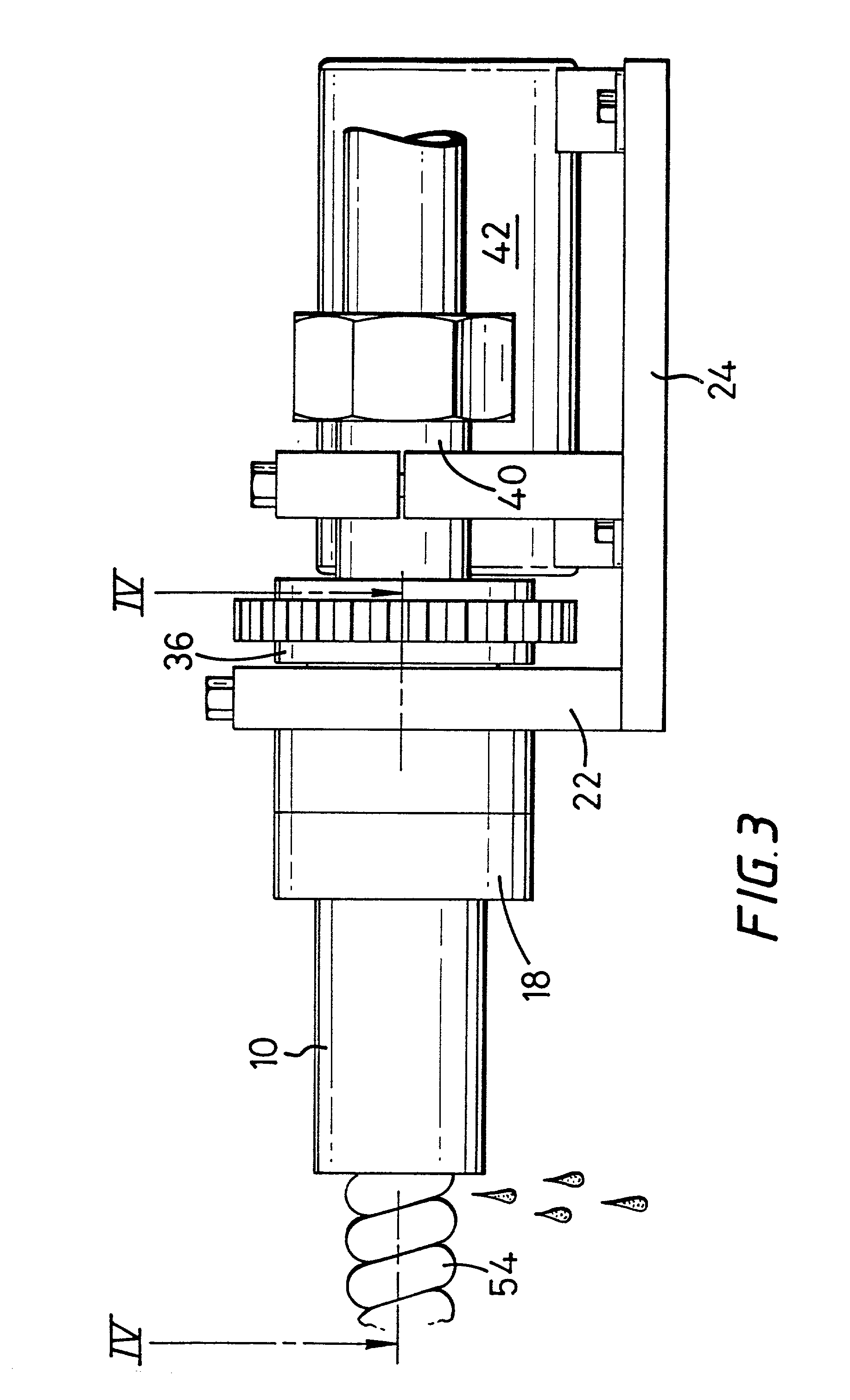

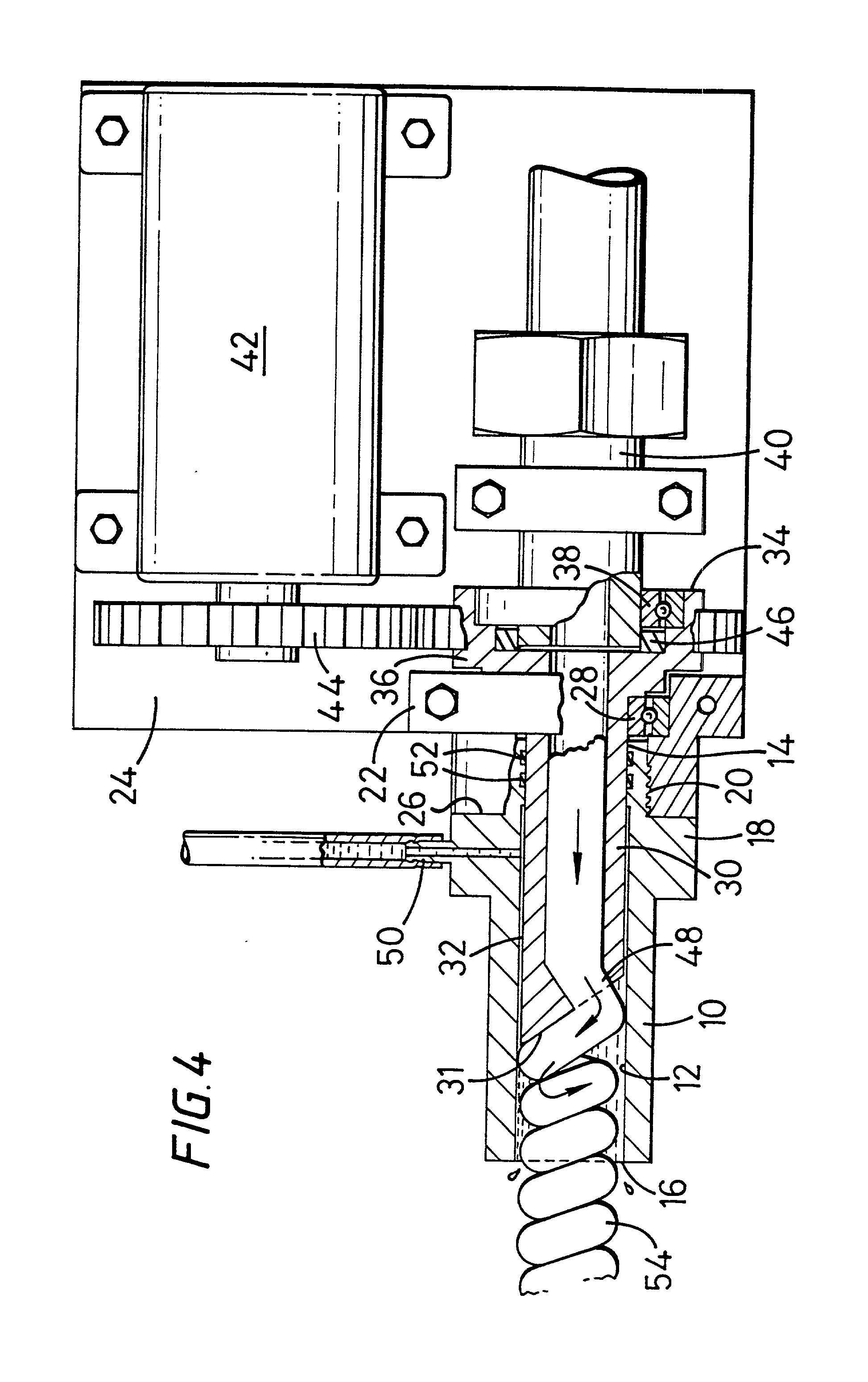

Method and apparatus for making an helical food product

a technology of helical protein and production method, which is applied in the direction of food preservation, baking, containers, etc., can solve the problems of inability to manufacture continuous products, inability to re-anneal, and inadvertently miss surface areas,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Four product mixes were prepared to the following recipes:

1 Example 1 Example 2 Example 3 Example 4 Recipe % % % % 25.75Frozen Fresh MST.sup.1 51.5 -- 51.5 Fresh 25.75 Port Fat 16.5 -- 16.5 10.00 Rusk 13.5 -- 8.0 8.00 Ice 12.5 9.24 16.0 12.70 Pork Belly 3.5 --3.5 3.50 Seasoning 2.5 -- 2.5 2.50 Collagen Fibre -- -- 2.0 --Whey Protein -- -- -- 1.00 Concentrate Soya Protein -- -- -- 0.80 Isolate Water -- -- -- 4.00 Palm Oil -- 5.80 -- 4.00 Calcium Carbonate -- -- -- 2.00 Rehydrated TVP.sup.2 -- 19.81 -- --2:1 dry Tapioca Starch -- 4.00 -- --Chicken Flavouring -- 0.96 -- --Salt -- 0.97 -- --Herb Extract -- 0.02 -- --GW Pepper -- 0.05 -- --Sodium Caseinate -- 1.63 -- --Skimmed Milk -- 2.00 -- -- Powder Skin -- 10.00 -- --Red Trims -- 10.00 -- -- Oyster Meat -- 20.52 -- --Baardered White -- 15.00 -- --Trims 100.00% 100.00% 100.00% 100.00% Post Mix Temperature +4.degree. +4.degree. +7.degree. C. +5.6.degree. C. .sup.1MST = Mechanically separated turkey .sup.2TVP = Textured vegetable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com