Sub-cylinder type rotary cylinder static pressure fried dough twist making machine

A twist machine and rotary cylinder technology, which is applied in the direction of dough twisting machinery, etc., can solve the problems of leakage and heat generation of the twist machine, and achieve the effect of reducing the failure rate, improving the quality, and preventing the damage of the internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

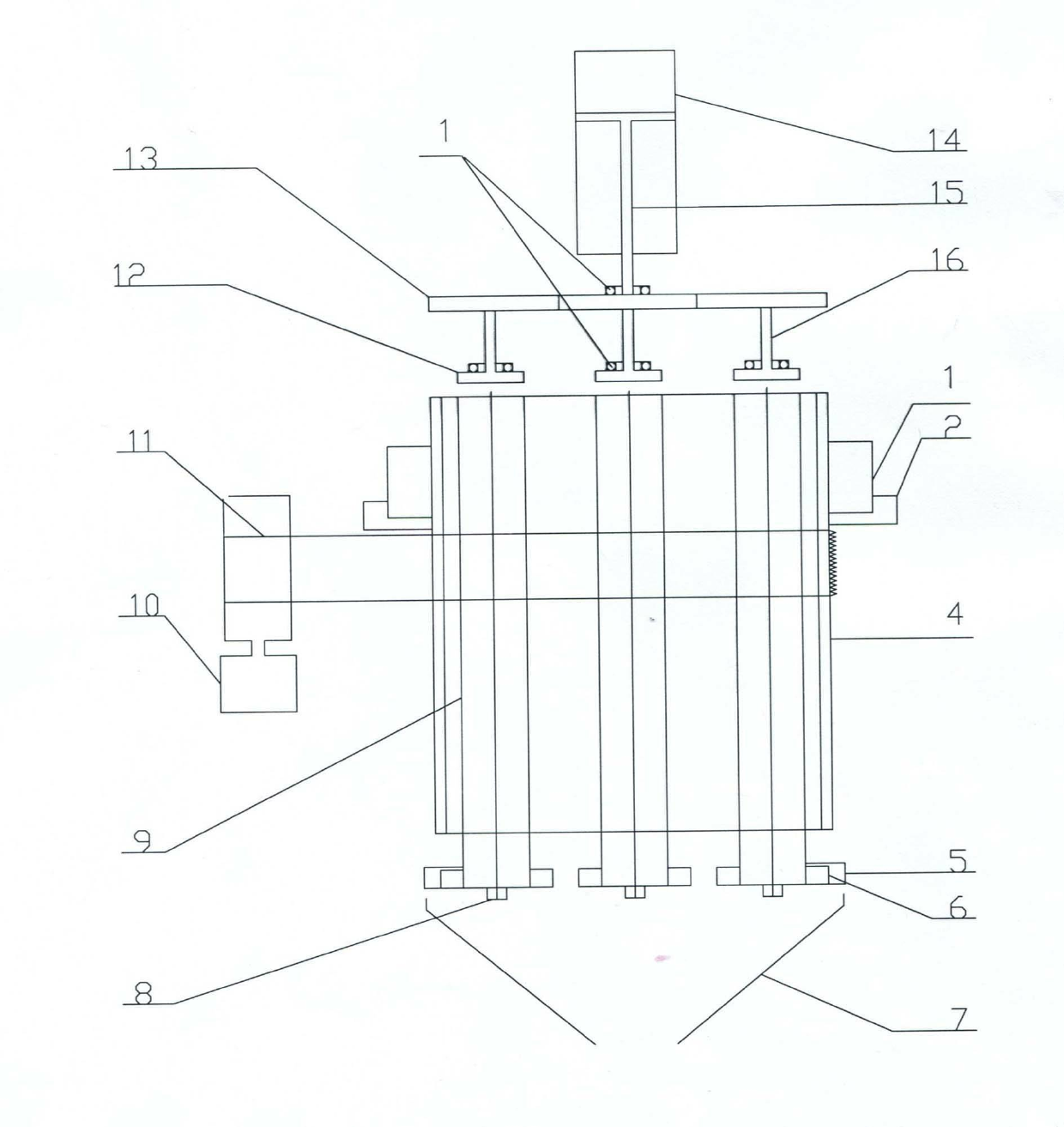

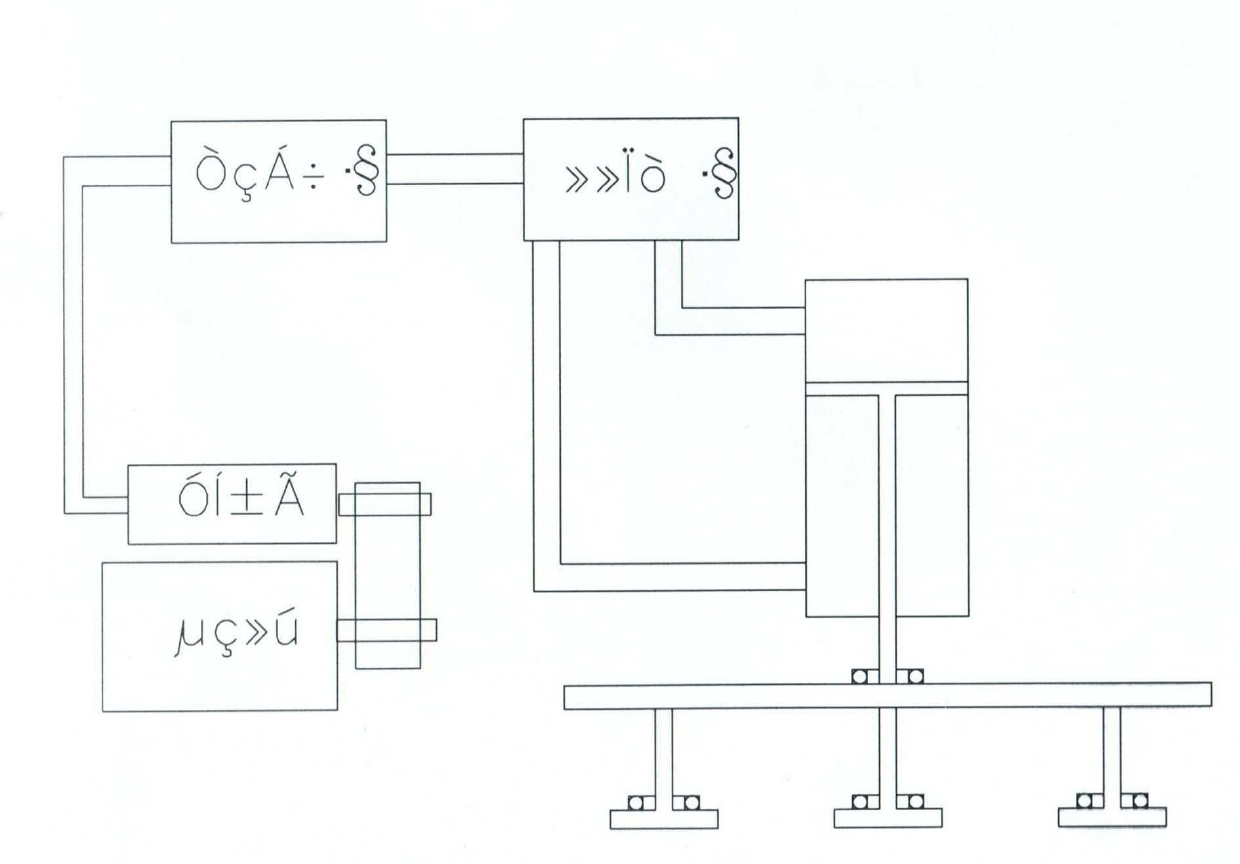

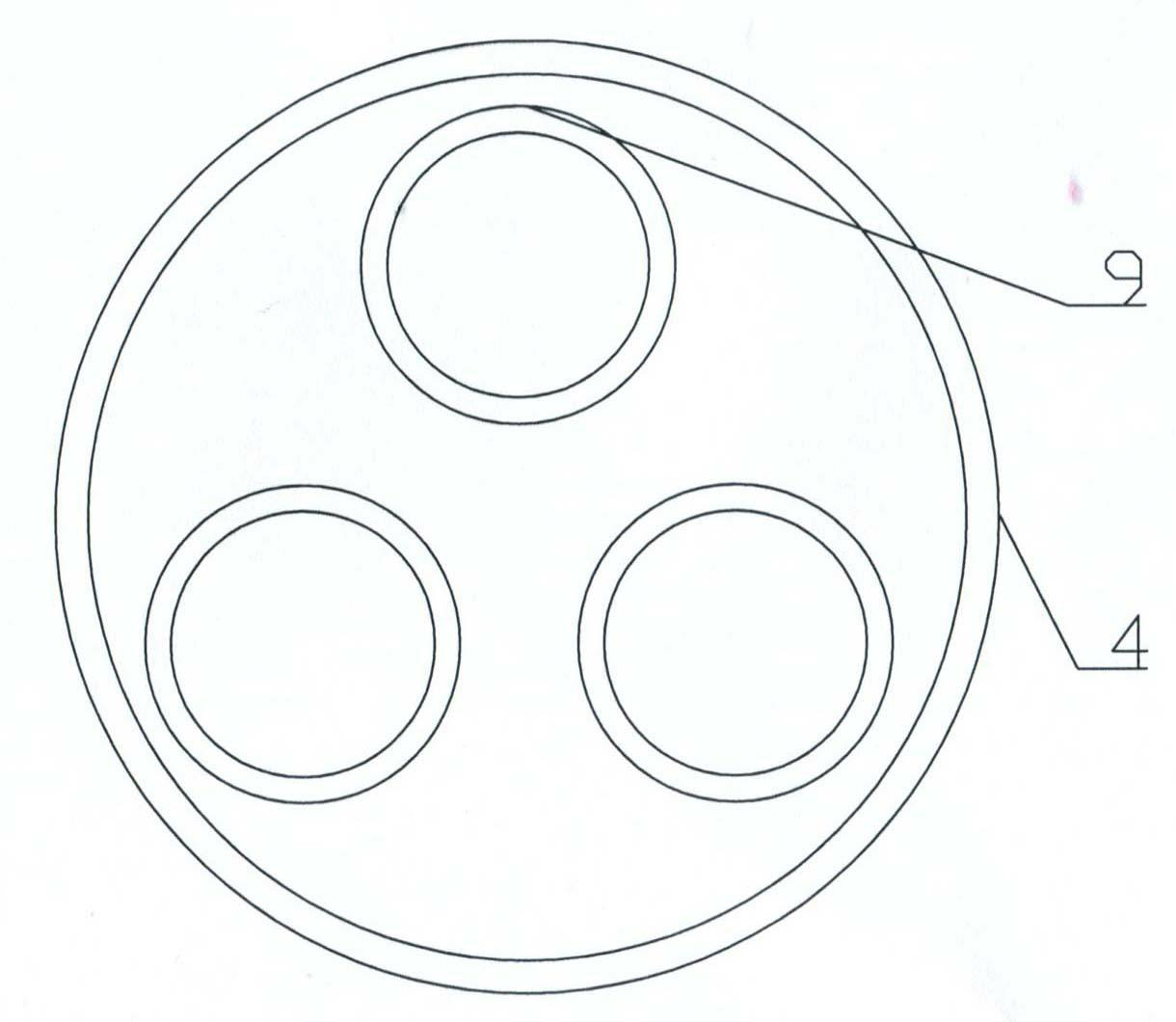

[0013] Such as figure 1 , 2 . As shown in 3, a split-cylinder rotary cylinder static pressure twist machine includes: a hydraulic-electric transmission power system and a pressing surface forming device, and the hydraulic-electric transmission power system includes: an electric motor, an oil pump, an electromagnetic reversing valve, Electromagnetic overflow valve, oil pipe, the motor drives the oil pump, the oil pump communicates with the rodless cavity of the hydraulic cylinder 14 through the right oil pipe, electromagnetic reversing valve and electromagnetic overflow valve, and the oil pump passes through the left oil pipe, electromagnetic reversing valve and electromagnetic overflow The valve communicates with the rod cavity of the hydraulic cylinder 14; the pressing surface forming device includes: bearing 1, platform 2, rotating cylinder 4, internal gear plate 5, external gear 6, twist synthesis bucket 7, forming die 8, rotating surface Cylinder 9, rotary pressing sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com