Machine for making double-stranded farci fried dough twists

A technology of stuffing twist machine and forming mechanism, which is applied in the direction of dough twisting machine, baking, dough forming and cutting combination, etc. It can solve the problems of difficult operation, manual production, difficulty in adapting, etc., and achieve the degree of automation High, reduced twist quality, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided according to the present invention are described in detail as follows:

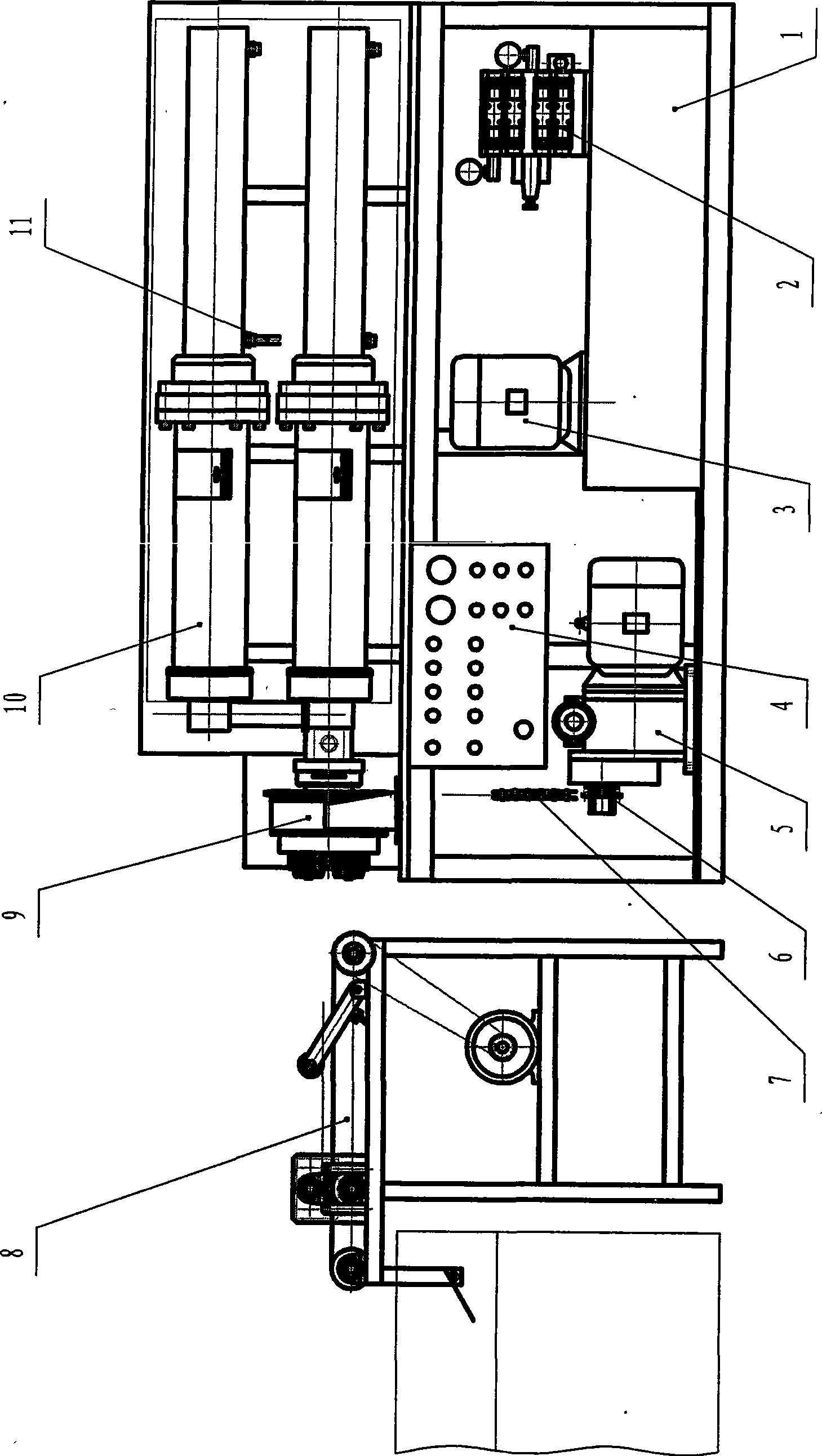

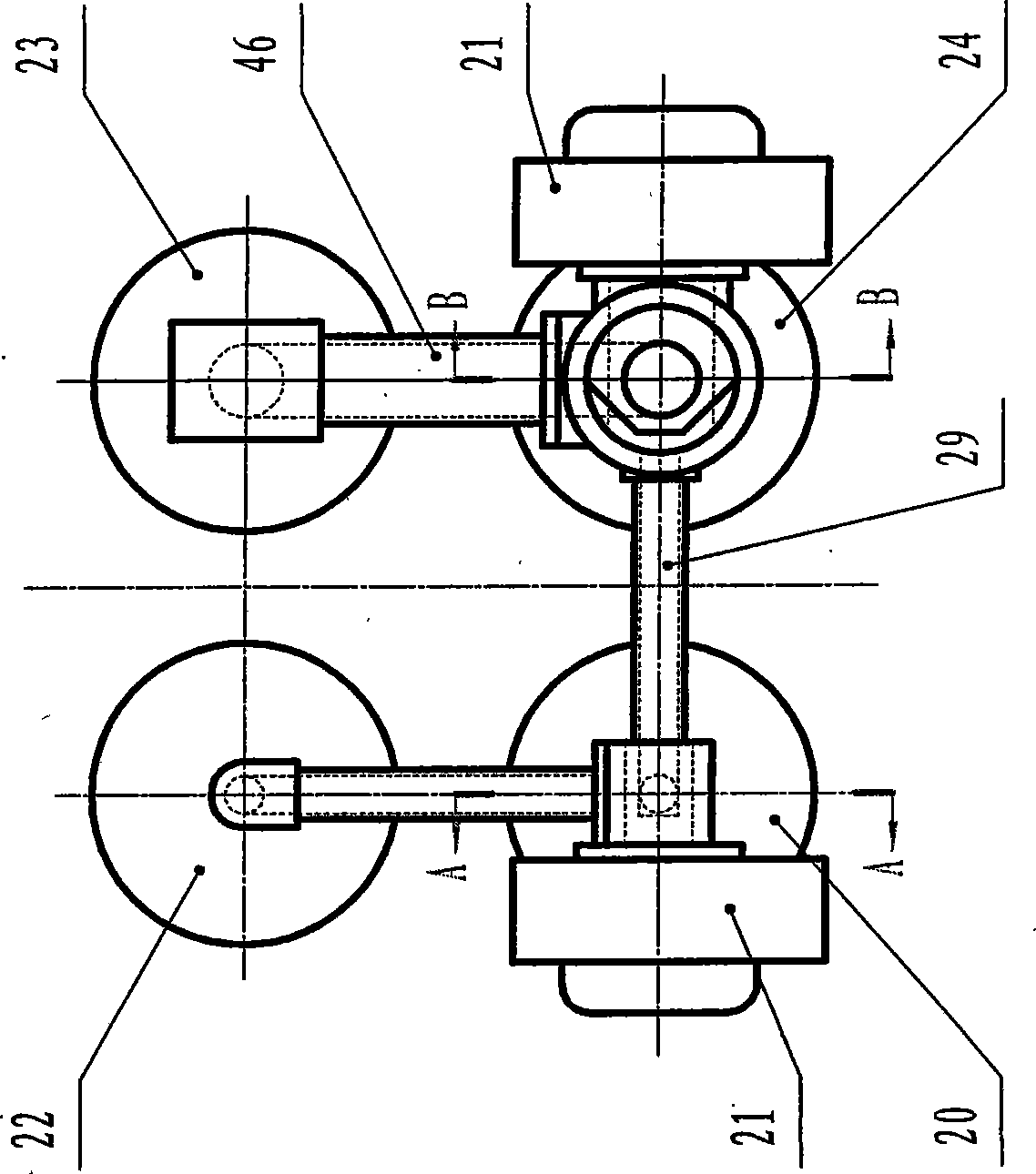

[0038] Such as Figure 1-Figure 12 As shown, it includes a PLC program controller and the operating device controlled by it; it is characterized in that: the operating device is composed of a hydraulic four-cylinder fully automatic feeding mechanism 10, a forming mechanism 9, a conveyor belt, and a shaping and cutting mechanism 8;

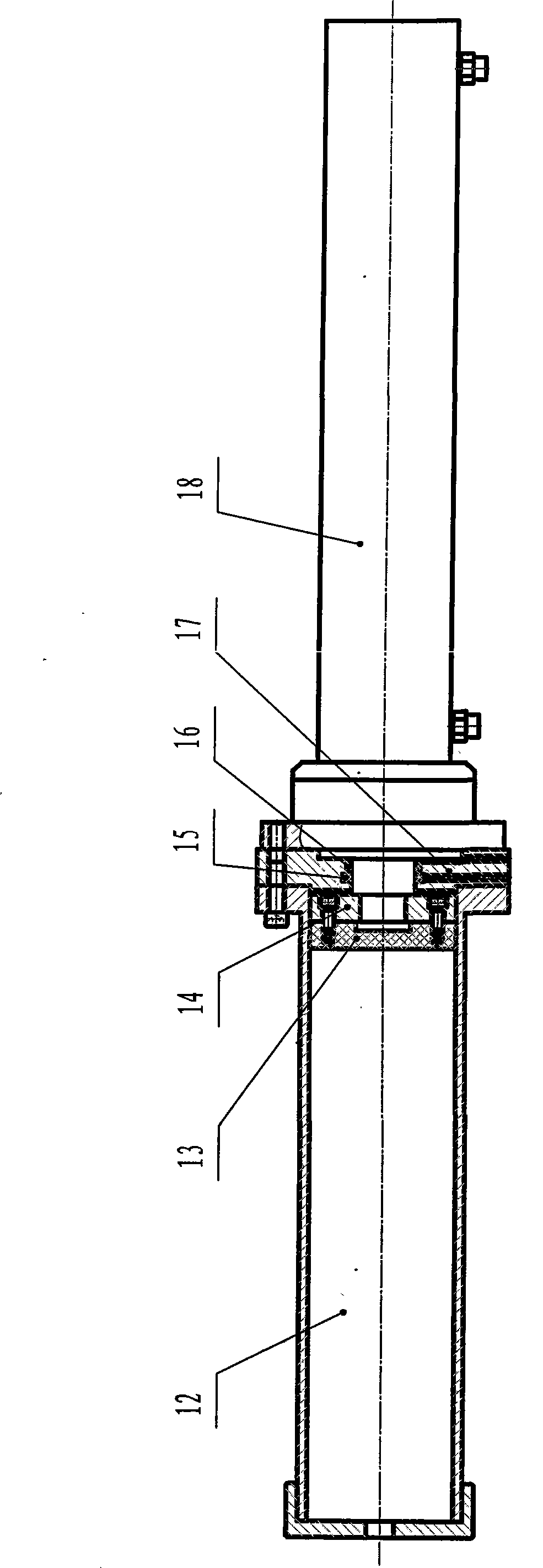

[0039]The hydraulic four-cylinder automatic feeding mechanism 10 is composed of a dough cylinder, a filling cylinder and a hydraulic power unit; Push plate base 14, double sealing device 17 including PA type hydraulic dustproof ring 15, felt oil seal 16, hydraulic cylinder 18 are formed; Cover and lock pin, its end face is equipped with a hydraulic cylinder 18 respectively, at the front end of the piston rod of the hydraulic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com