Knotting system for a dough strand

a technology of knotting system and dough strand, which is applied in the direction of dough treatment, dough strip twisting machine, baking, etc., can solve the problems of huge technical challenge in the manufacture of knotted dough products, in particular pretzels, and achieve the effect of increasing the distance from the stationary stop and building up the tension in the dough strand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] German patent application serial number 102004001792.1, having a filing date of 12 Jan. 2004, the above claimed priority application, is incorporated in this application by reference.

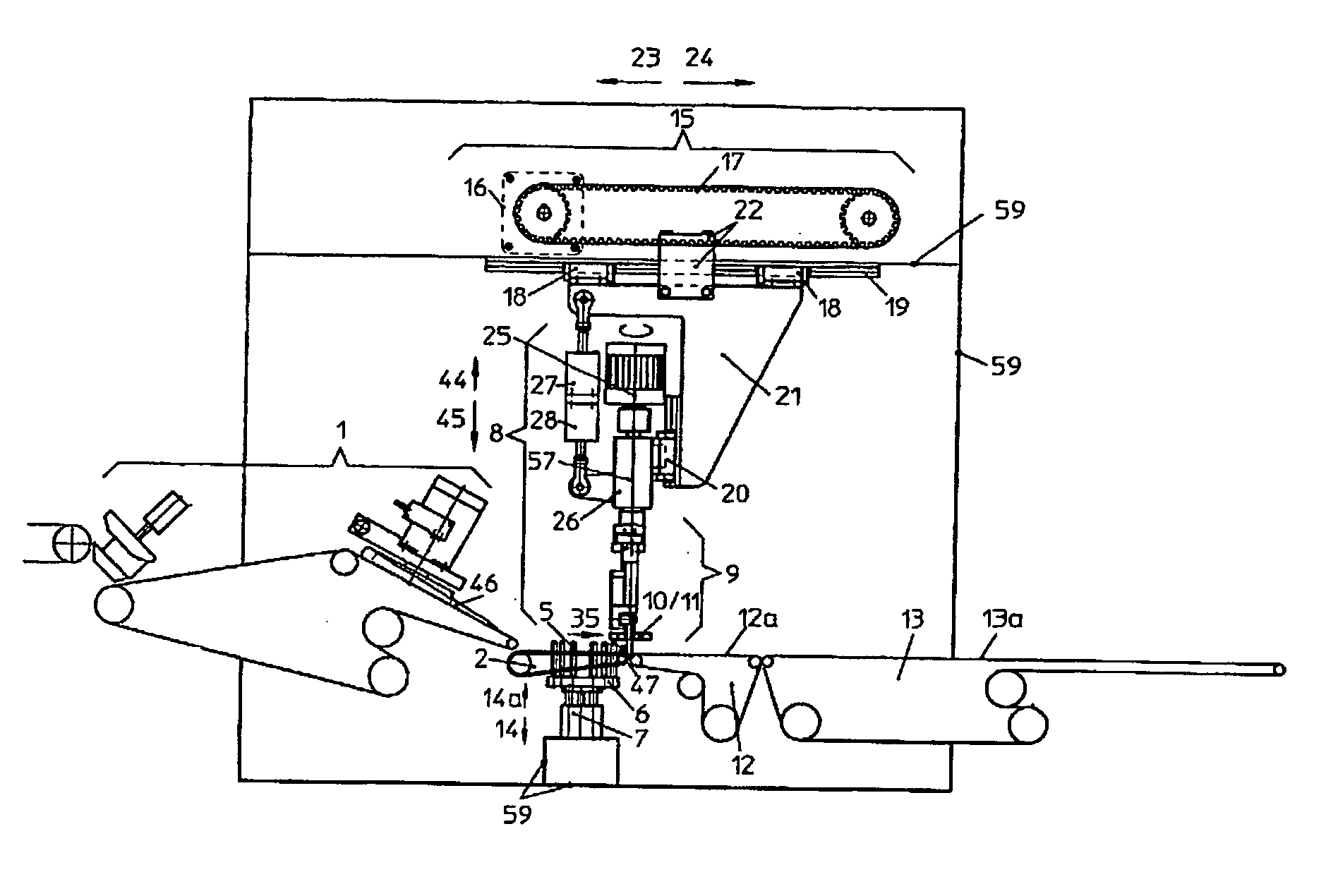

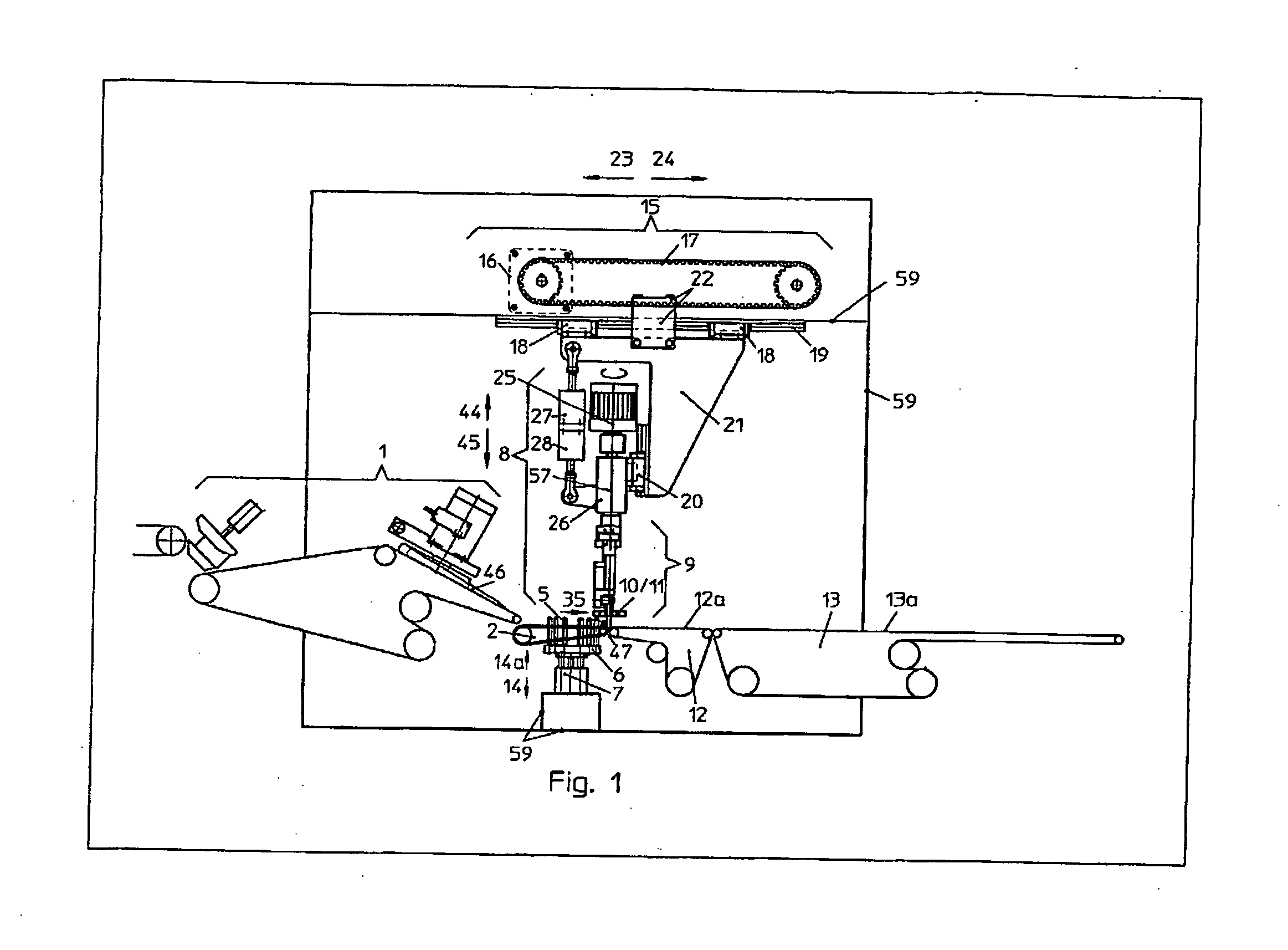

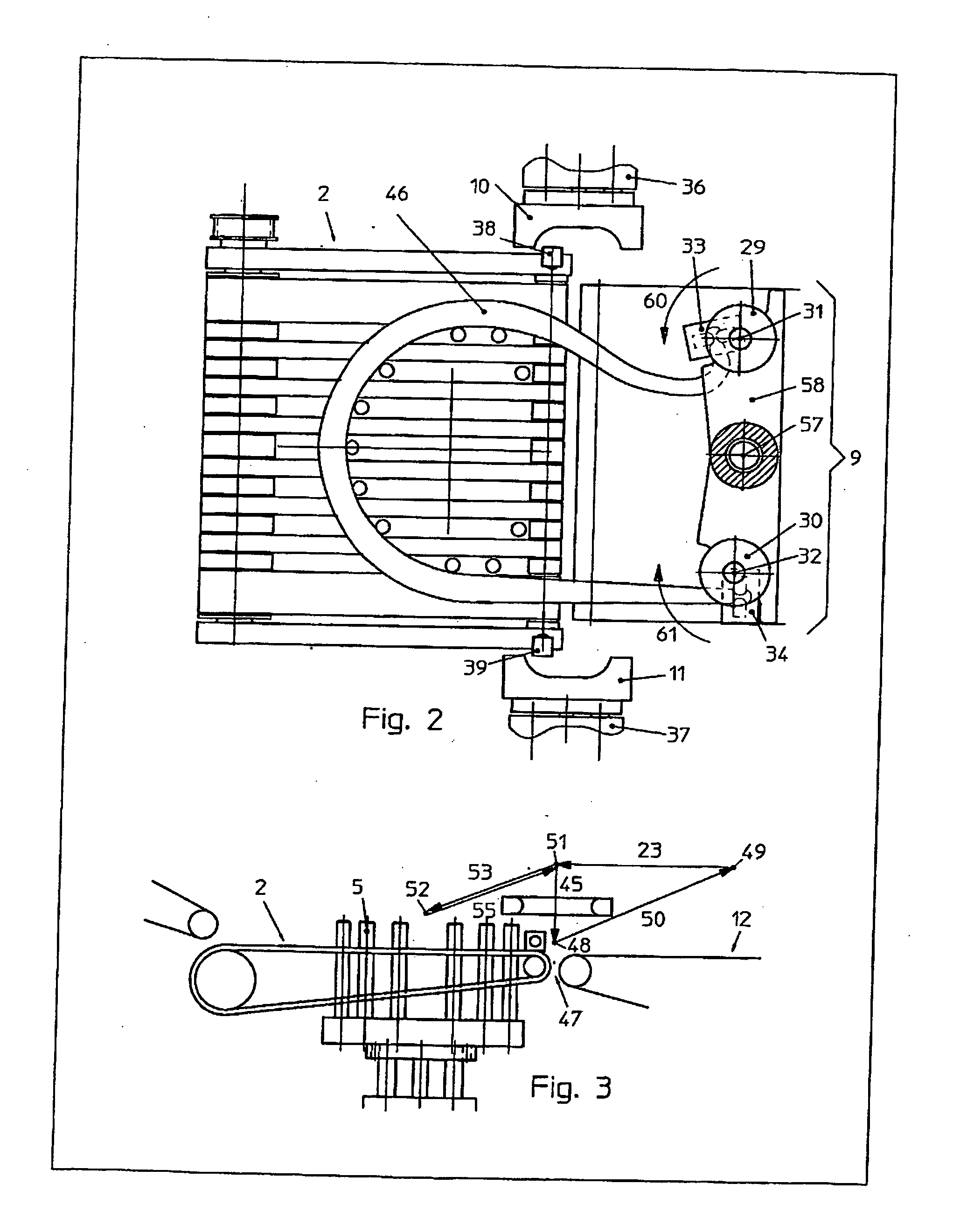

[0063] The pretzel manufacturing apparatus comprises a feed device 1, with which dough strands curved in a U-shape are prepared and fed to a shaping table 2; the shaping table itself 2, on which by using a tying device 8 the dough strands curved in a U-shape are tied into pretzels; and an intermediate table 12 and a discharge table 13 for conveying the tied pretzels away.

[0064] The sequence of the method for manufacturing pretzels is briefly as follows: A straight dough strand (not shown) is fed into the feed device 1 by means of a further conveyor belt, the dough strand being disposed horizontally and perpendicular in its longitudinal extension to the feed direction. The feed device 1 forms the straight dough strand into a dough strand 46 curved in a U-shape, whose free dough strand ends are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com