Automatic fried dough twist shaping machine

A twist machine and forming mechanism technology, which is applied to dough forming machinery or equipment, dough twisting machinery, baking, etc., can solve the problem that the power mechanism of the twist machine is not perfect enough to form industrialized large-scale production, and the twist machine cannot Continuous operation and other problems, to achieve the effect of neat and beautiful appearance, consistent appearance and size, convenient disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

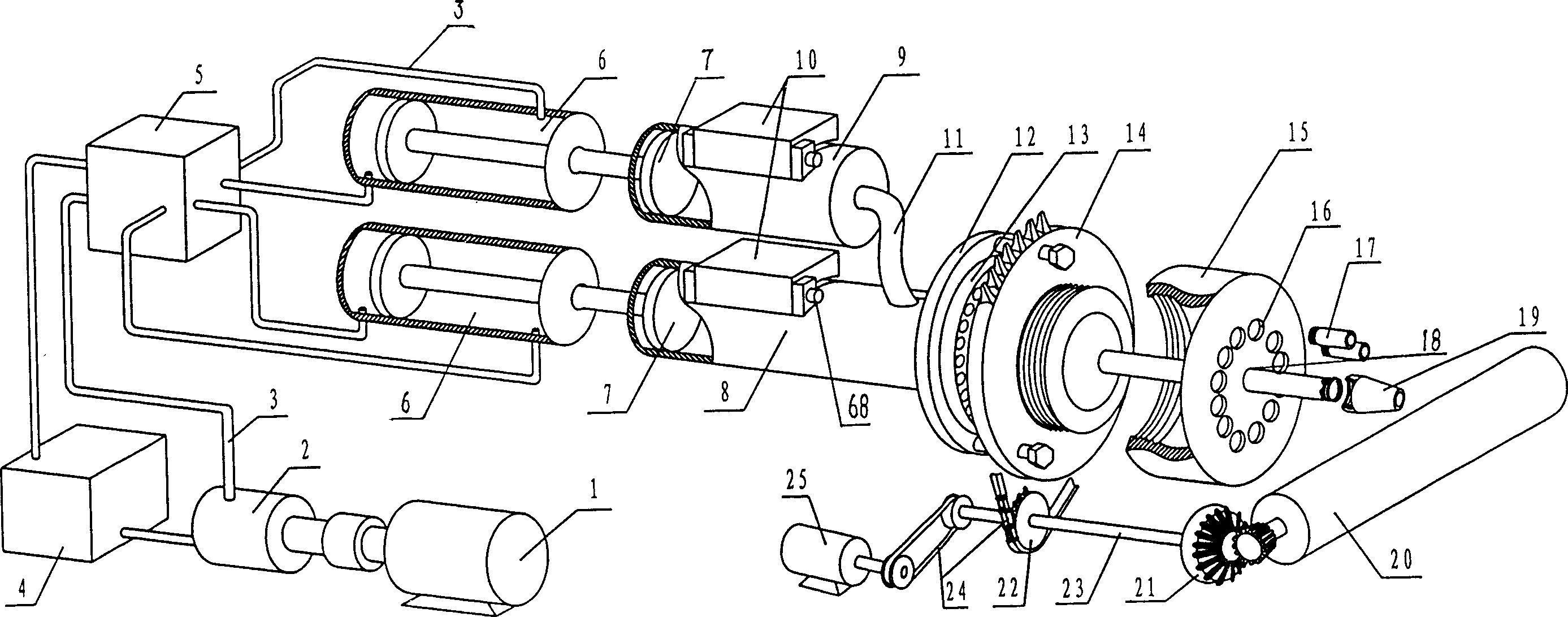

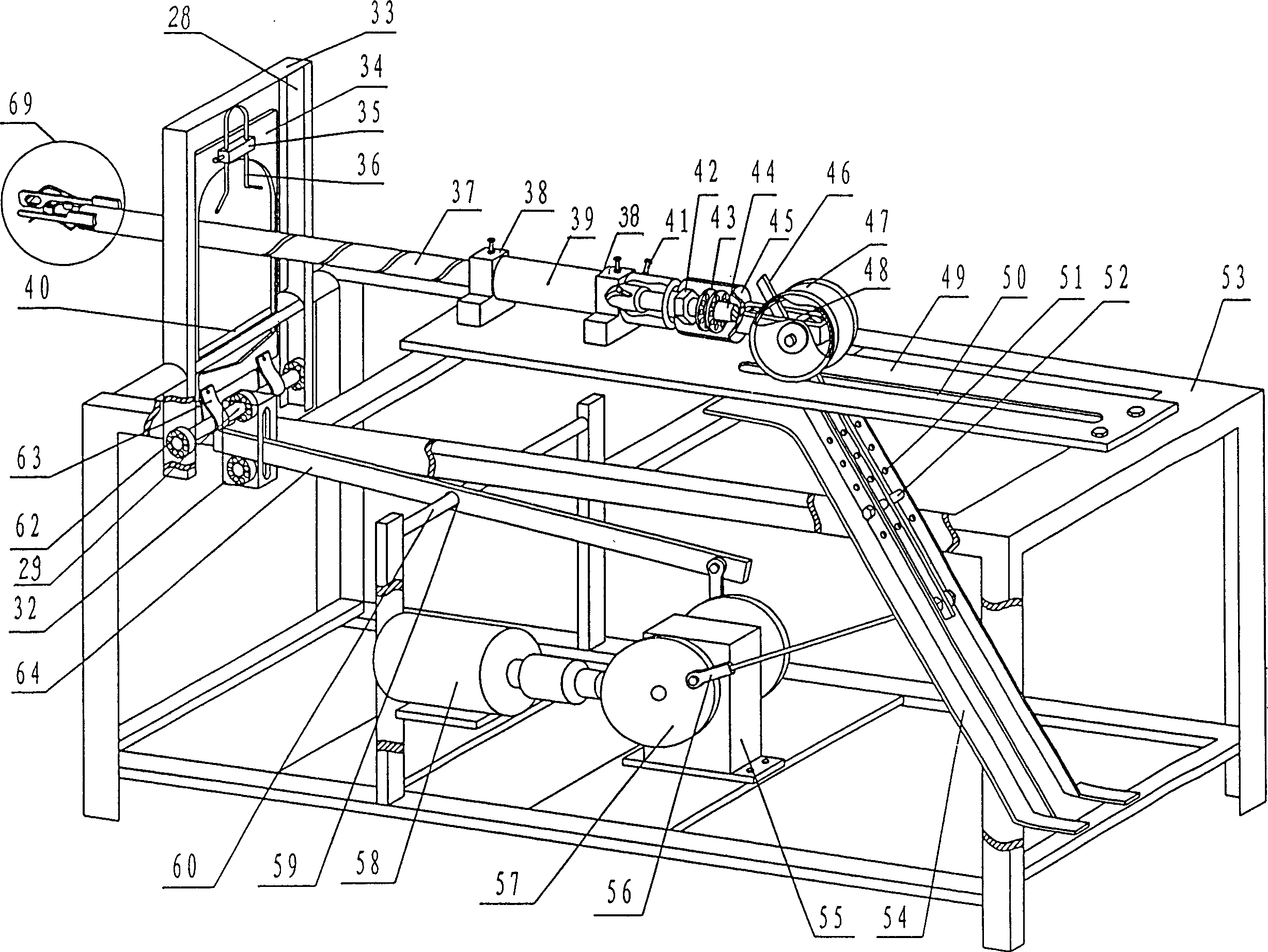

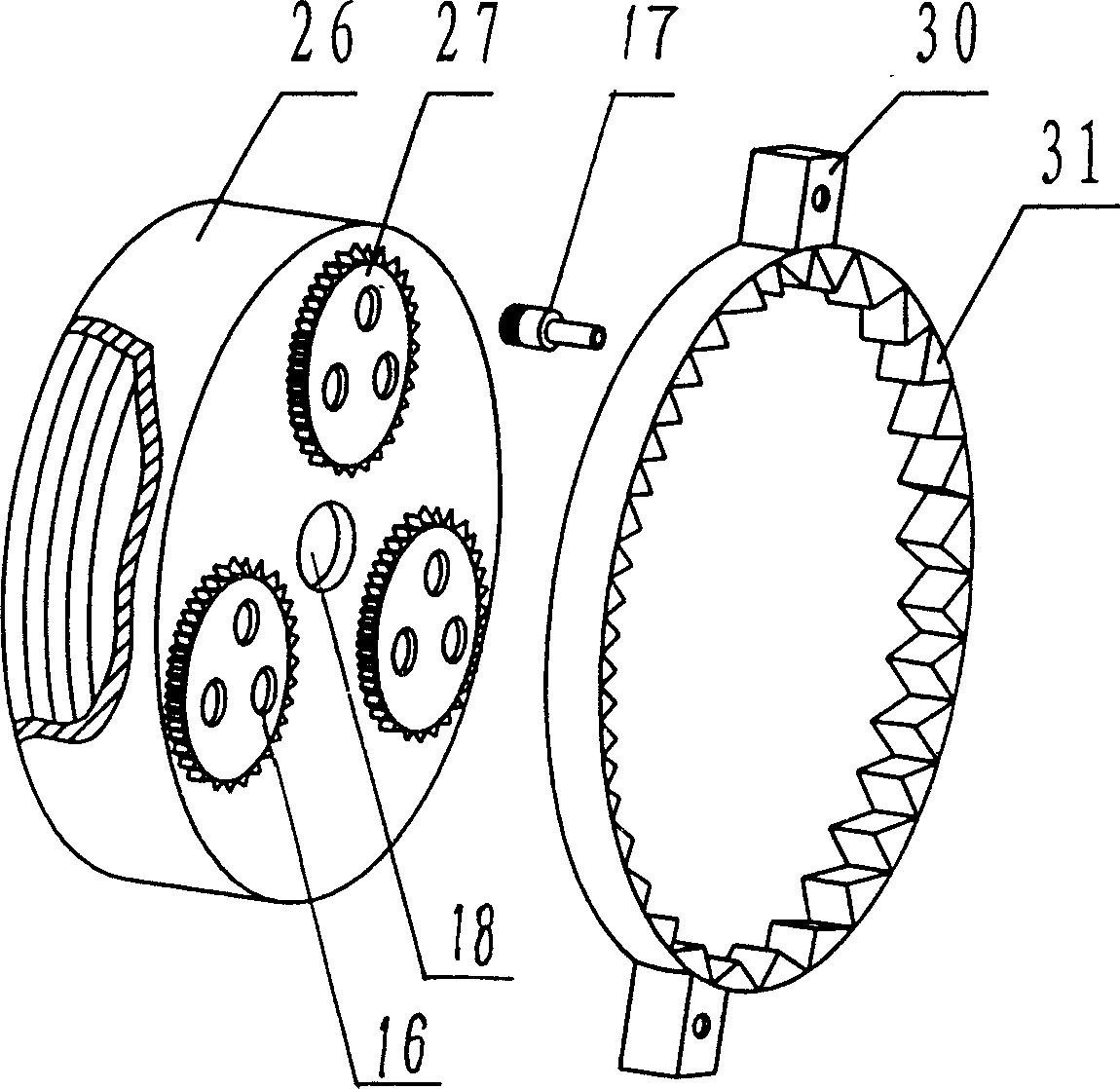

[0012] like Figure 1 to Figure 4 As shown, the twist machine includes a hydraulic power mechanism and a roll-forming mechanism. The hydraulic power mechanism is connected to the oil pump 2 by the motor 1 and connected to the oil tank 4 and the oil delivery controller 5 through the oil pipe 3. Oil is supplied to two hydraulic cylinders 6 arranged in parallel. The rolling forming mechanism includes a primary forming mechanism and a secondary forming mechanism. The primary forming mechanism is provided with a stuffing cylinder 9 and a dough cylinder 8, and the dough cylinder 9 discharge end is provided with a synthetic disc, which is formed by a bearing 13. Bottom cover 12, synthetic disc rotating wheel 14 and disc surface cover 15 are connected in the same axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com