Assembly line for automatically packaging solar heat collection shuttle

A technology of solar heat collection and assembly line, which is applied in the field of energy harvesting equipment manufacturing, can solve the problems of no heat collection shuttle covering production equipment, etc., and achieve the effect of good packaging effect, simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

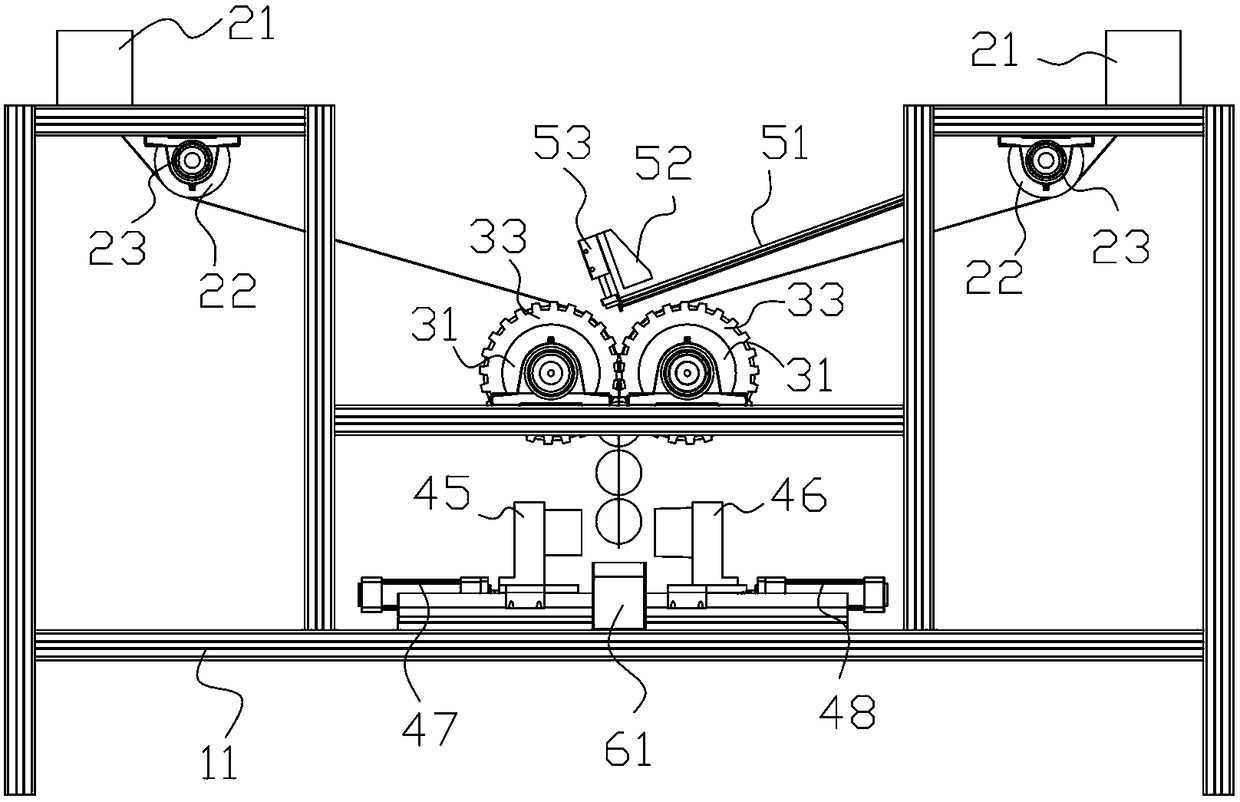

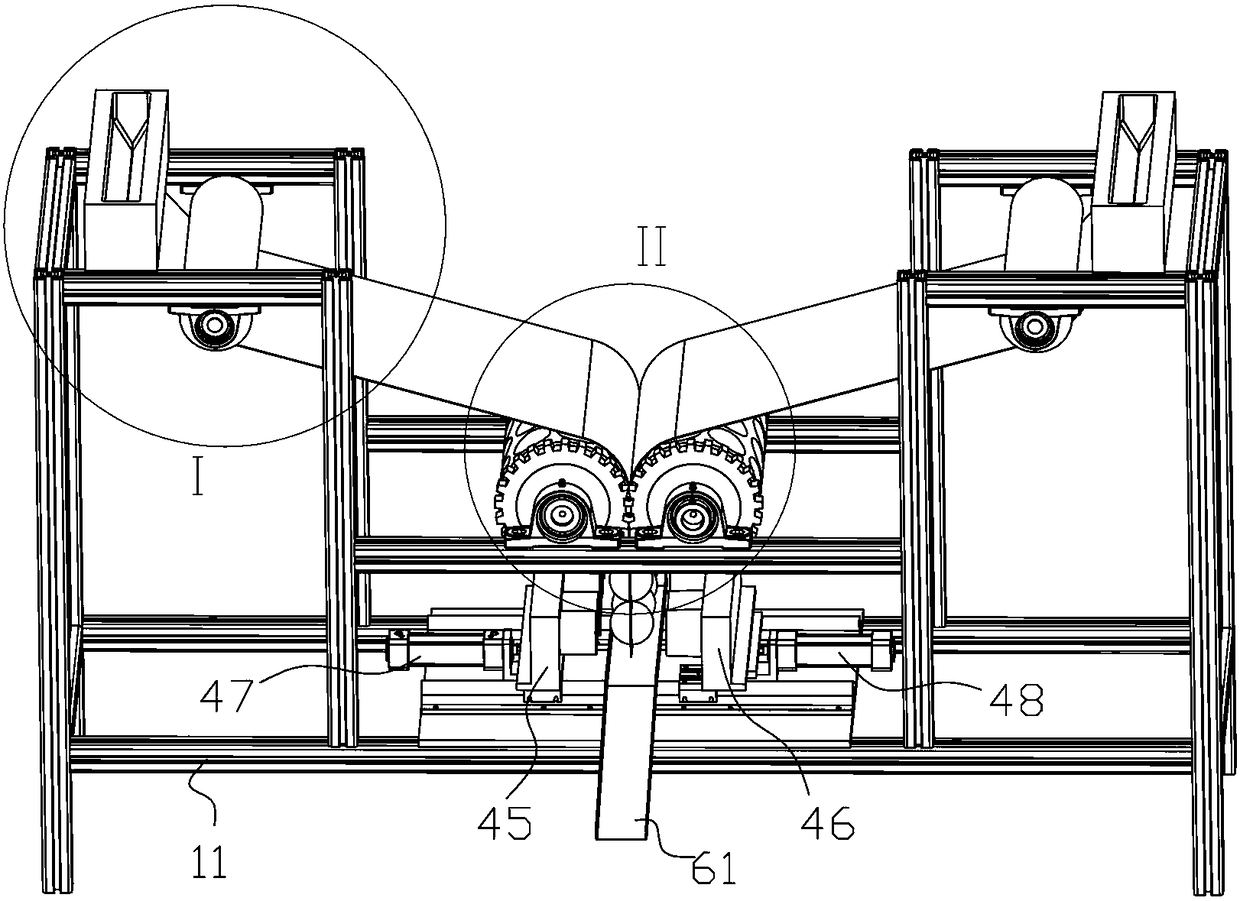

[0033] Such as Figure 1 to Figure 14 As shown, an assembly line for automatically encapsulating solar heat collector shuttles described in this embodiment includes a plurality of encapsulating mechanisms b arranged side by side, and one side of the encapsulating mechanism b is provided with a conveyor belt a for transporting finished products .

[0034] Coating mechanism b comprises a concave frame 11 and two film feeding devices, and the two film feeding devices are respectively located at the two ends of the frame 11, and the film feeding device includes a film extrusion die 21 and a film forming Roller 22, the two ends of described film extruding mold 21 are fixed on described frame 11, and the two ends of described film forming roller 22 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com