Trace dual-tube needle valve

A double-tube needle and trace technology, which is applied to multi-port valves, valve devices, mixers, etc., can solve the problems of difficult to control the accuracy of polyurethane glue feeding, poor product performance and appearance quality, affecting the ratio and mixing effect, etc. The effect of ideal mixing effect, consistent appearance and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

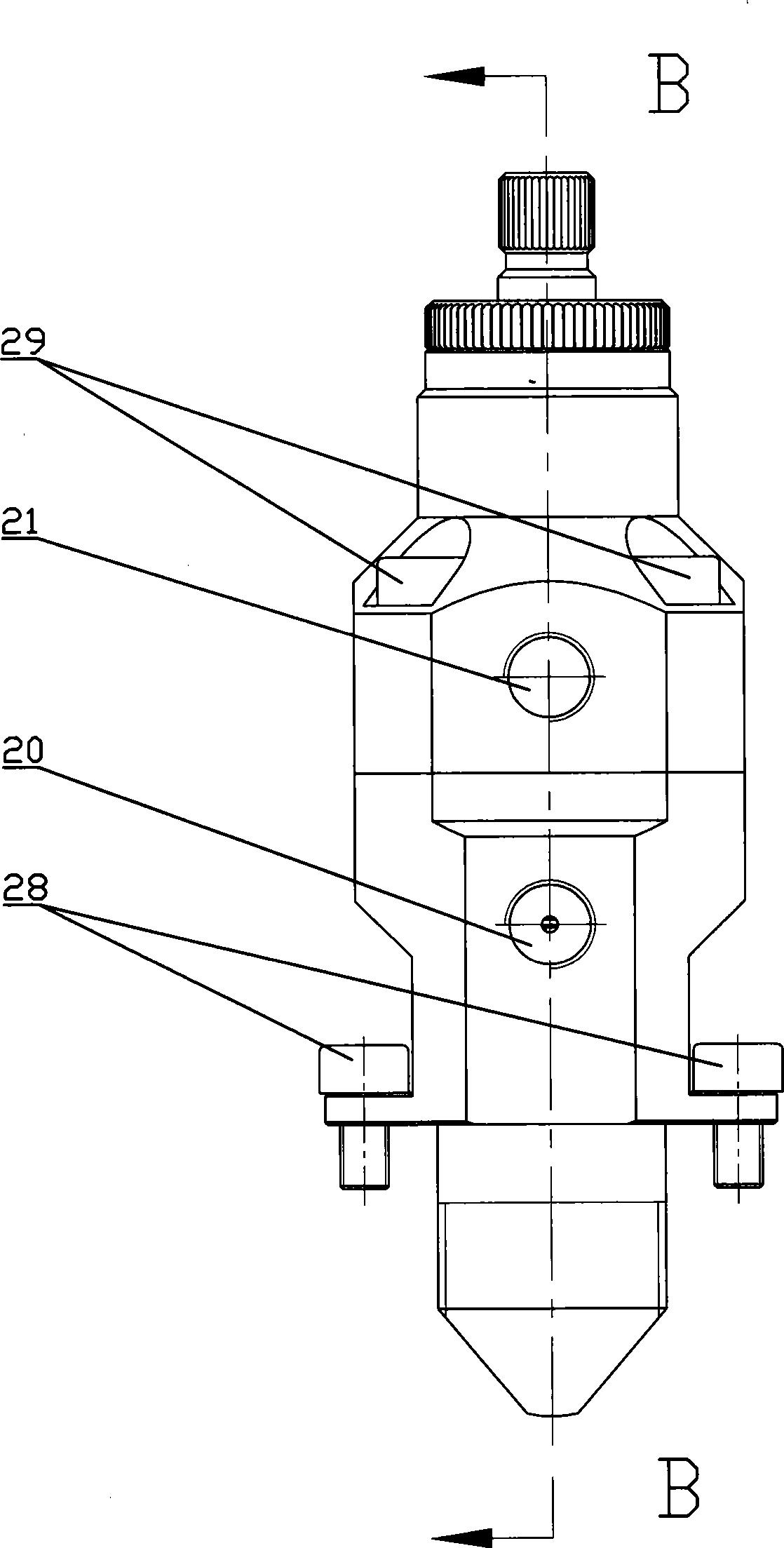

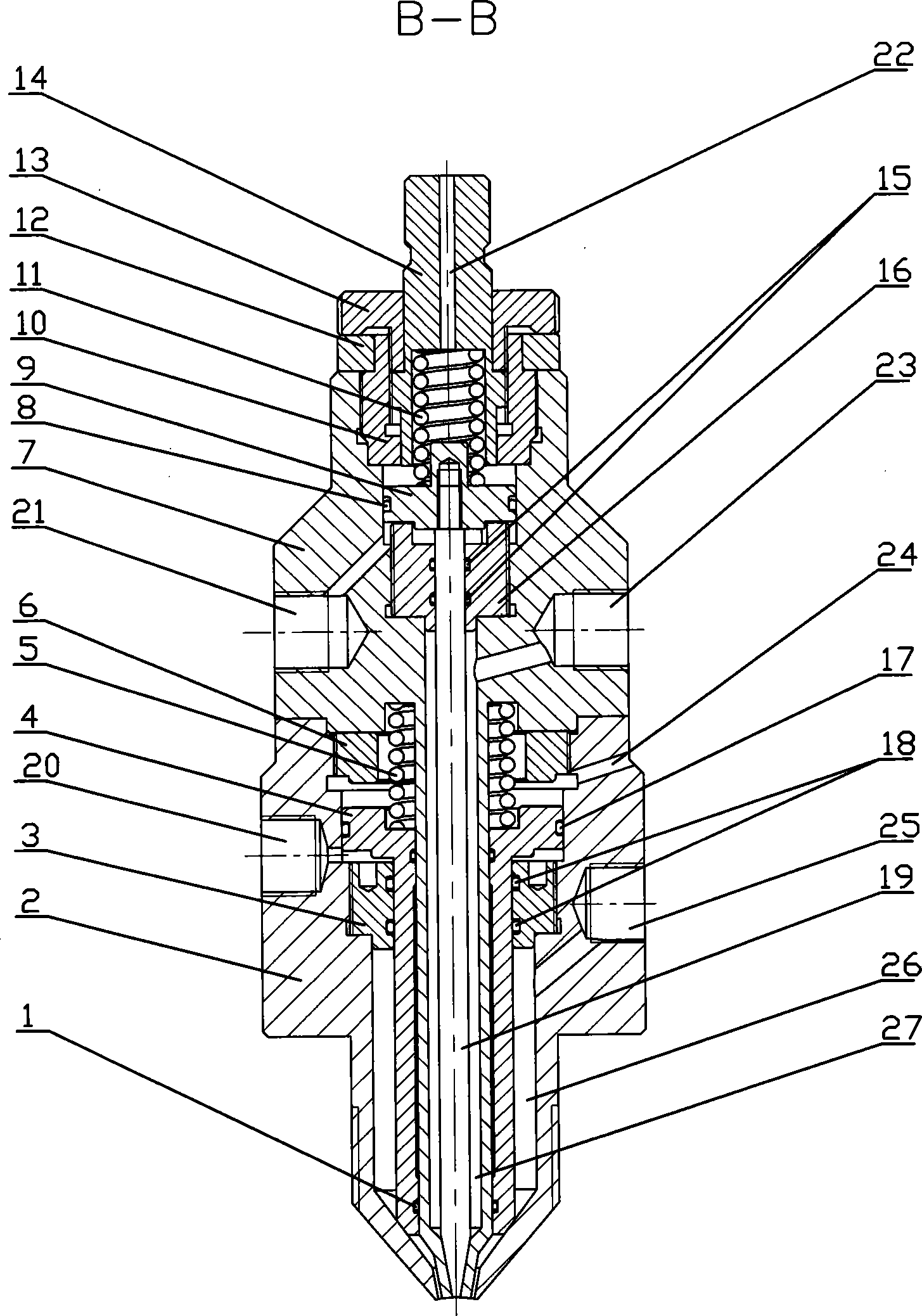

[0010] Specific implementation mode one: as figure 1 , 2 As shown, the micro double-tube needle valve includes a needle valve seat 2, a sealing plug 3, a piston A4, a spring A5, a retaining ring 6, a valve body 7, a piston B9, an inner sleeve 10, a spring B11, a gasket 12, an adjustment Nut 13, adjusting screw 14, seal head 16, valve needle 19, valve body 7 and needle valve seat 2 are fixedly connected by screw B29, retaining ring 6 and sealing plug 3 are fixed in needle valve seat 2 by threads respectively, piston A4 The piston part is installed between the retaining ring 6 and the sealing plug 3, the spring A5 is installed between the valve body 7 and the piston A4, the piston A4 can move up and down, the outer tapered surface of the lower end of the piston A4 and the lower end of the needle valve seat 2 The taper fits to seal and is used to close or open the A glue channel 26; the inner sleeve 10 and the head 16 are installed in the upper part of the valve body 7 with thre...

specific Embodiment approach 2

[0013] Specific implementation mode two: as figure 1 , 2 As shown, in the present embodiment, the micro double tube needle valve also includes II air inlet 20, I air inlet 21, through hole A22, glue inlet B23, through hole B24, glue inlet A25, A glue The channel 26 is located in the center of the B glue channel 27, the glue inlet B23 communicates with the B glue passage 27, the glue inlet A25 communicates with the A glue passage 26, the II air inlet 20, the I air inlet 21, the glue inlet A25 and The glue inlets B23 are respectively provided with connecting threads. When the polyurethane B enters the glue inlet B23, the compressed air enters the I air inlet 21, the piston B9 and the valve needle 19 move upward, and the taper surface at the lower end of the valve needle 19 and the valve body The lower cone surface of 7 is separated, polyurethane B flows out from the lower end of valve body 7, when the air inlet 21 of I is not ventilated, piston B9 is under the action of spring ...

specific Embodiment approach 3

[0014] Specific implementation mode three: as figure 2 As shown, in this embodiment, the micro-volume double-tube needle valve also includes a sealing ring B8 set on the piston B9, a sealing ring D17 set on the piston A4, a sealing ring A1 installed on the lower end of the piston A4, and a sealing ring installed on the piston A4. The sealing ring C15 on the sealing head 16 and the sealing ring E18 installed on the sealing plug 3 are made of solvent-resistant materials such as polyurethane or polytetrafluoroethylene or rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com