Steamed bun making method and steamed bun making machine

A production method and technology of a steamed bread machine are applied in the directions of food preparation, baking, dough fermenter, etc., which can solve the problems of incomplete fermentation, poor taste and color of steamed bread, and high labor cost, and achieve complete fermentation and improved surface color. Feel and taste, mixed evenly and completely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

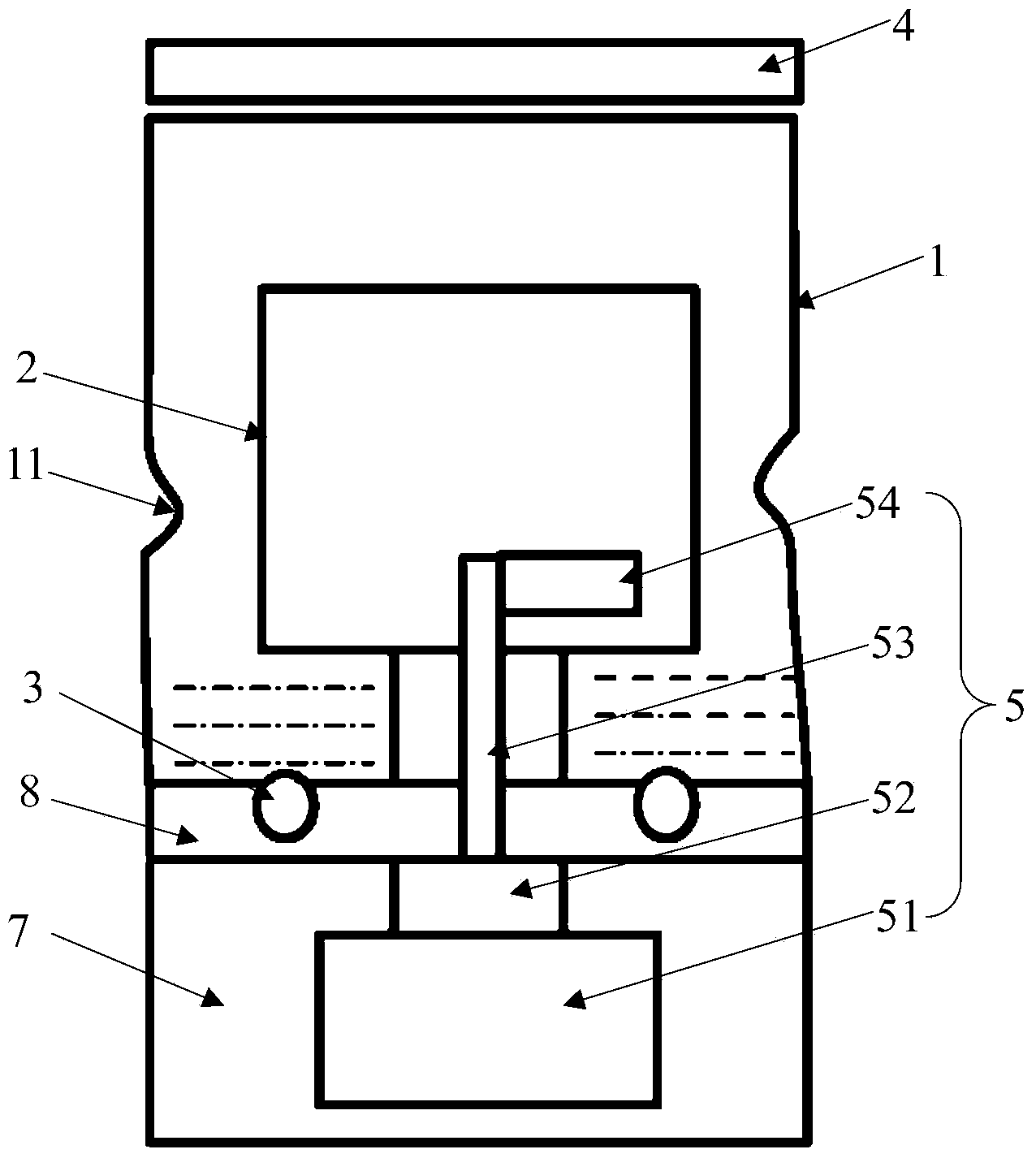

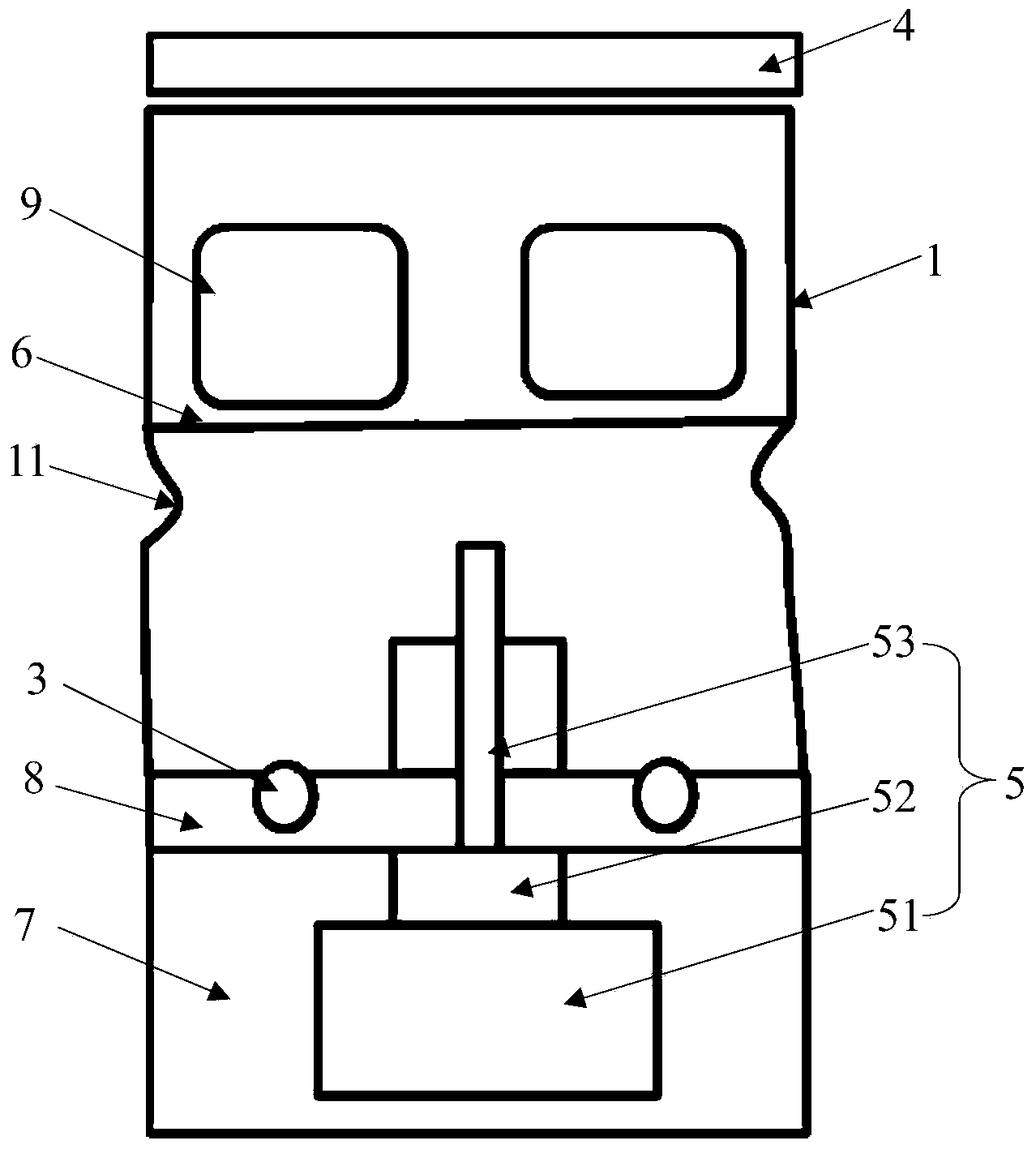

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0026] A method for making steamed buns of the present invention comprises the following steps:

[0027] First, add the raw materials needed for steamed buns into the steamed bun barrel, add water to the outer barrel, simulate the way of kneading dough by hand, turn on the heating device at the bottom of the outer barrel to preheat the steamed bun barrel, and at the same time mix the ingredients at different stirring speeds to form Dough, and let the dough ferment, preheating and variable mixing speed greatly increase the speed of mixing and fermenting, so that the raw materials are mixed evenly and the dough is fermented completely;

[0028] When the dough is fermented, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com