Method for selectively preparing acraldehyde and hydroxy-acetone

A technology of hydroxyacetone and acrolein, which is applied to the new preparation field of supported catalysts, can solve the problems of insufficient selectivity and stability, worrying about catalyst stability, and easy coking of catalysts, so as to reduce the cost of separation and treatment, and the preparation is simple and easy to operate. , the preparation process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

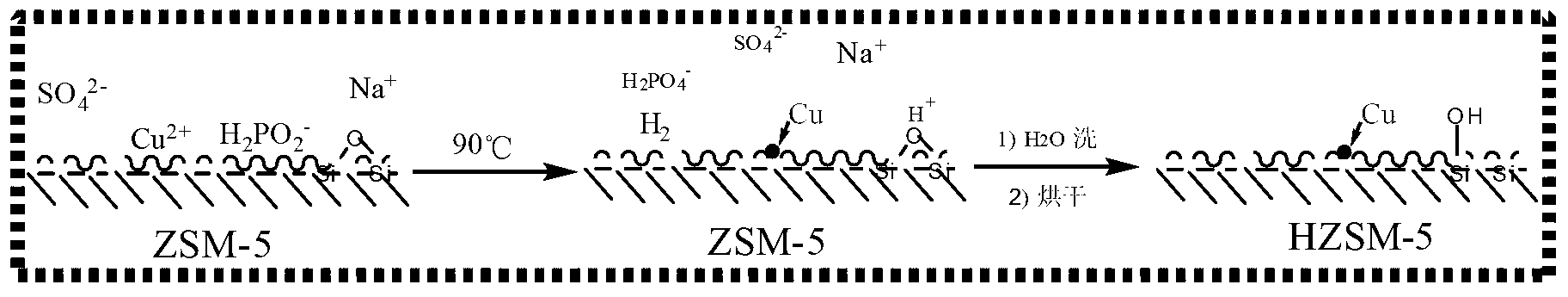

[0032] Weigh 2.3g of ZSM-5 molecular sieve into the flask, then add 0.72g of copper sulfate pentahydrate and 0.85g of sodium dihydrogen hypophosphite (slightly excessive), and finally add 20mL of water, and let stand at room temperature for 1 hour . Then heated in a constant temperature water bath at 90°C with vigorous stirring until the reaction was complete. The precipitate was filtered, washed, dried and calcined at 300°C for 3h under the protection of nitrogen. Catalyst samples were prepared after cooling.

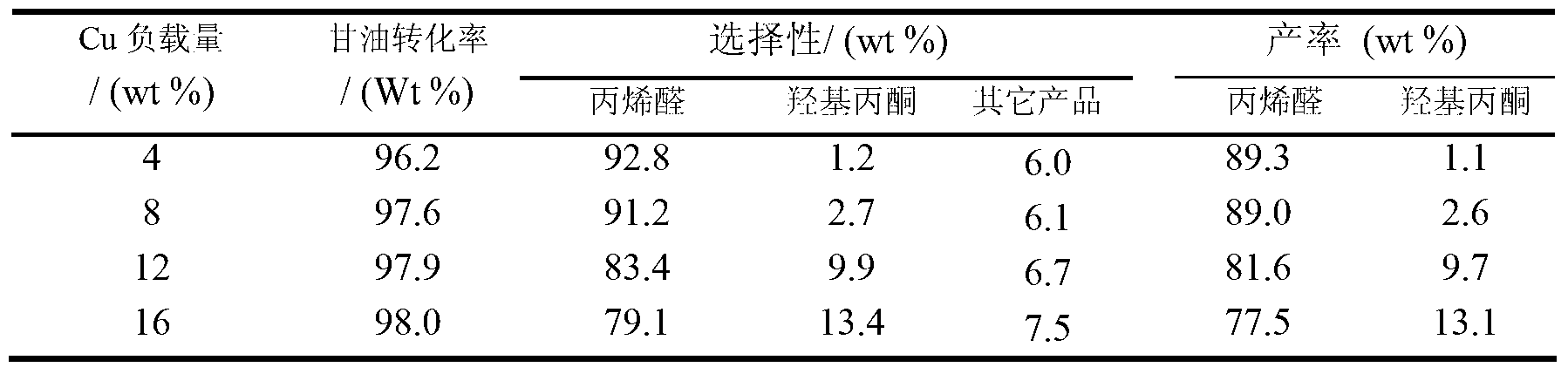

[0033] Table 1

[0034]

[0035] Weigh 0.2g of Cu / HZSM-5 molecular sieve catalysts with different loads into a 75ml reaction kettle, add 5g of glycerin, place in an extremely hot constant temperature magnetic stirrer with silicone oil, adjust the temperature to 200°C, and keep stirring at constant temperature for 2h. After the reaction is over, the product is poured into a centrifuge test tube, centrifuged and stored in an airtight manner, and analyzed by gas chr...

Embodiment 2)

[0037] Catalyst preparation is the same as the catalyst preparation part in Example 1.

[0038] Weigh 0.2g of Cu / HZSM-5 molecular sieve catalyst with 8wt% loading at different calcination temperatures in a 75ml reaction kettle, add 5g of glycerin, place it in an extremely hot constant temperature magnetic stirrer with silicone oil, adjust the temperature to 200°C, Keep stirring at constant temperature for 2h. After the reaction is over, the product is poured into a centrifuge test tube, centrifuged and stored in an airtight manner, and analyzed by gas chromatography. The results are shown in Table 2.

[0039] Table 2

[0040]

Embodiment 3)

[0042] Catalyst preparation is the same as the catalyst preparation part in Example 1.

[0043] Weigh 0.2g of 8wt% loaded Cu / HZSM-5 molecular sieve catalyst roasted at 300°C in a 75ml reaction kettle, add 5g of glycerin, place in an extremely hot constant temperature magnetic stirrer with silicone oil, and adjust to the desired Temperature, keep stirring at constant temperature for 2h. After the reaction is over, the product is poured into a centrifuge test tube, centrifuged and stored in an airtight manner, and analyzed by gas chromatography. The results are shown in Table 3.

[0044] table 3

[0045]

[0046]

[0047] nd- indicates that the component was not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com