Application of gluconobacter oxydans in preparing 1,3-dioxyacetone

A technology of Gluconobacter oxydans and oxidizing glucose, applied in the fields of fermentation engineering and enzyme engineering, can solve the problems of increasing process difficulty and cost, being unable to tolerate high-concentration glycerol, unfavorable for industrialized production, etc., and achieving the effect of facilitating separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

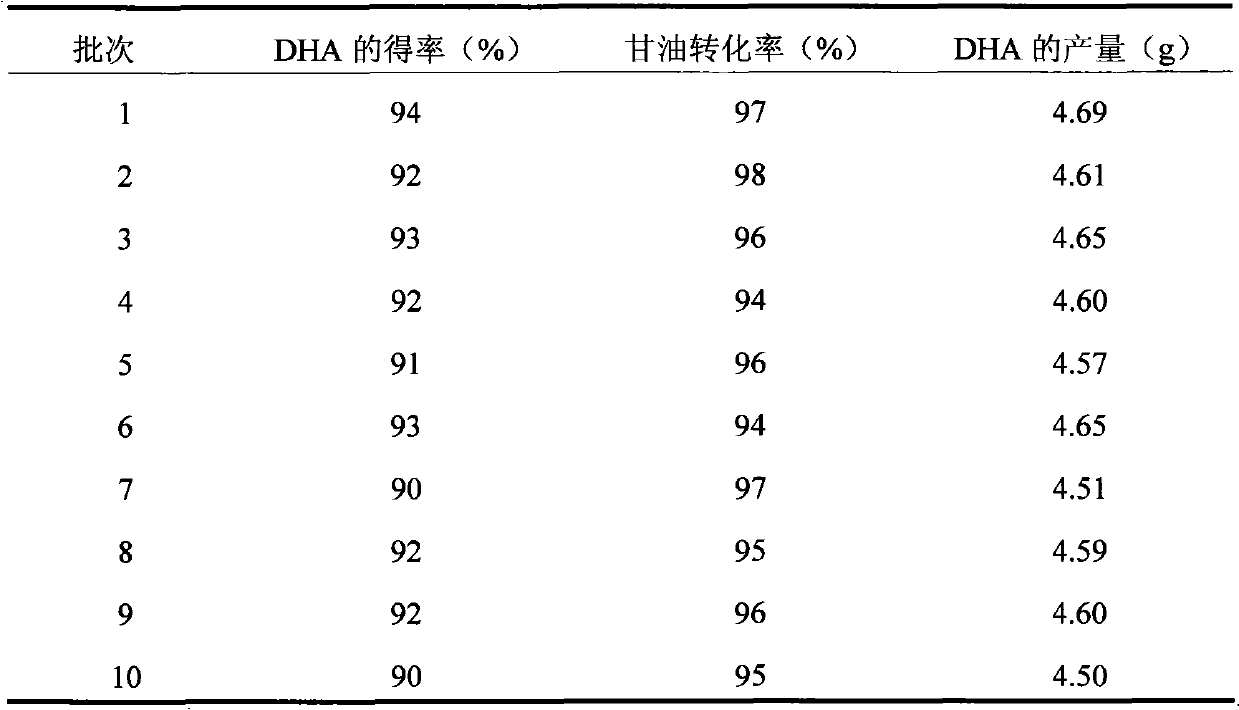

Examples

Embodiment 1

[0031] Incline medium: glucose 30g / L, yeast extract 5g / L, beef extract 3g / L, agar 20g / L.

[0032] Fermentation medium (same as shake flask medium): sorbitol 10g / L, glycerin 40g / L, yeast extract 5g / L, beef extract 3g / L, MgSO 4 ·7H 2 O 0.5g / L, CaCO 3 0.5g / L, the initial pH is 5.0, and sterilized at 121°C for 15min.

[0033] Cultivate Gluconobacter oxydans CGMCC No.2709 on the slant medium at 30°C for 24 hours, then use an inoculation loop to connect a ring of bacteria from the slant to the shake flask medium, cultivate at 30°C for 24 hours, and spin the shaker flask at 200r / min, centrifuge Collect the thalli in the fermentation broth, transform with free cells, weigh 1.5g of centrifuged wet cells and add them to 10mL of 100g / L glycerin solution (the amount of cells added is calculated by converting 1L of 100g / L glycerol solution per 150g of cells) , under the condition of 30° C., transform on a shaking table at 200 r / min for 24 h, and measure the conversion rate of the substr...

Embodiment 2

[0035] The medium composition is the same as in Example 1. Cultivate Gluconobacter oxydans CGMCC No.2709 on a slant medium at 30°C for 24 hours, and then use an inoculation loop to connect a ring of bacteria from the slant to the shake flask medium, cultivate at 28°C for 30 hours, and centrifuge at 120r / min. Collect the thalli in the fermentation broth, wash twice with pH7.0 potassium phosphate buffer, weigh 1.5 g of centrifuged wet cells and add them to 10 mL of 160 g / L glycerol solution (the amount of cells added is calculated as 1 L of 160 g / L per 150 g of cells). L of glycerol solution), under the condition of 28°C, convert and produce DHA in a shaking table at 120r / min, convert for 48h, measure the conversion rate of the substrate and the concentration of the product after the reaction finishes. The conversion rate of glycerol was 97%, and the concentration of DHA was 154g / L. Example 3:

Embodiment 3

[0036] The medium composition is the same as in Example 1. Cultivate Gluconobacter oxydans CGMCC No.2709 in the slant medium at 30°C for 24 hours, then use an inoculation loop to connect a ring of bacteria from the slant to the shake flask medium, cultivate at 32°C for 40 hours, and spin the shaker flask at 220r / min, centrifuge Collect the thalli in the fermentation broth, wash twice with pH7.0 potassium phosphate buffer, weigh 1.5 g of centrifuged wet cells and add them to 10 mL of 200 g / L glycerin solution (the amount of cells added is 1 L of 200 g / L per 150 g of cells) L of glycerol solution), under the condition of 30°C, convert and produce DHA in a shaking table at 200r / min, convert for 60h, measure the conversion rate of the substrate and the concentration of the product after the reaction finishes. The conversion rate of glycerol was 90%, and the yield of DHA was 166.2 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com