Method for hydrogenolysis catalysis of glycerin

A technology that catalyzes the hydrogenolysis of glycerol, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve problems that do not conform to the development direction of green chemical industry, complex methods and processes, and harmful to human health, etc., to achieve Good catalytic activity and stability, simple process requirements, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Catalyst preparation:

[0015] The Cu-Zn-Ti (1:2:1) catalyst was prepared by co-precipitation method: according to the composition requirements of the catalyst, the corresponding amount of raw material Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 O and TiCl 4 Mix, add appropriate amount of water to dissolve and stir evenly. Then use two constant flow pumps to add the above mixed solution and a sufficient amount of saturated sodium carbonate solution to a beaker at a constant temperature of 75°C. Maintain sufficient stirring and adjust the flow rate of the constant flow pump to keep the pH of the reaction solution between 8 and 8.5 to form a co-precipitation mixture. After the precipitation is complete, age overnight. The resulting precipitate was washed, decanted, suction filtered, and distilled water was used repeatedly until the conductivity was less than 2mS / m. The samples were dried at 120°C for 12h and calcined at 450°C for 2h to make the catalyst precursor. Th...

Embodiment 2

[0025] With embodiment 1, but change the ratio of Cu-Zn-Ti in the catalyst to be respectively 1: 2: 2, 2: 2: 1, 2: 2: 2, 1: 0: 1, the obtained results are shown in Table 2 respectively, table 3, Table 4, Table 5.

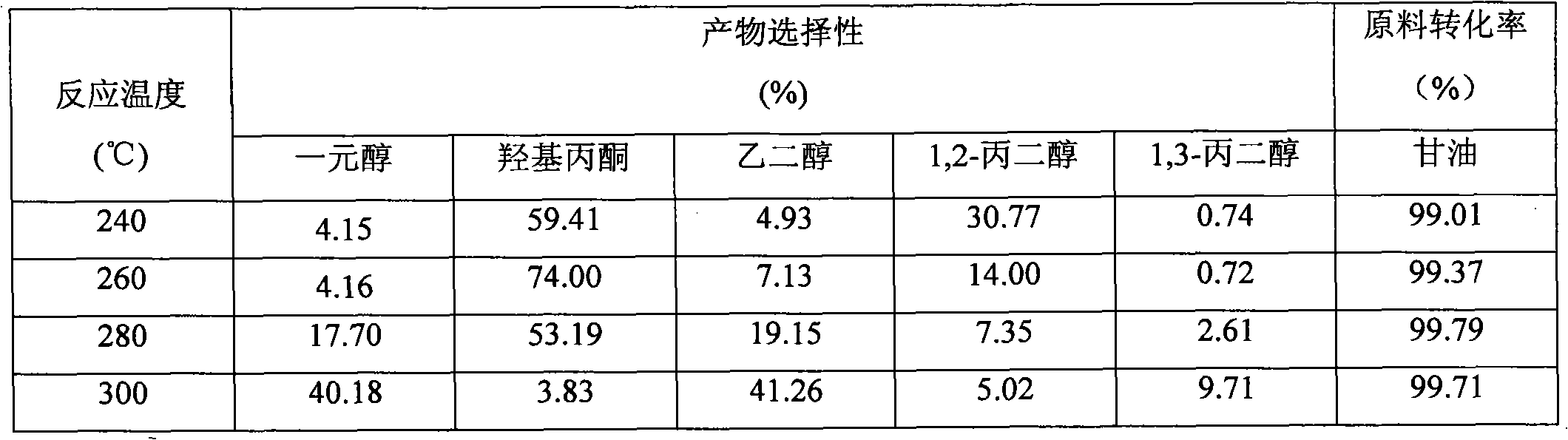

[0026] Table 2 Under normal pressure, the product selectivity and the conversion rate of raw material glycerol of Cu-Zn-Ti (1:2:2) gas-phase catalytic hydrogenolysis reaction of glycerol at different reaction temperatures

[0027]

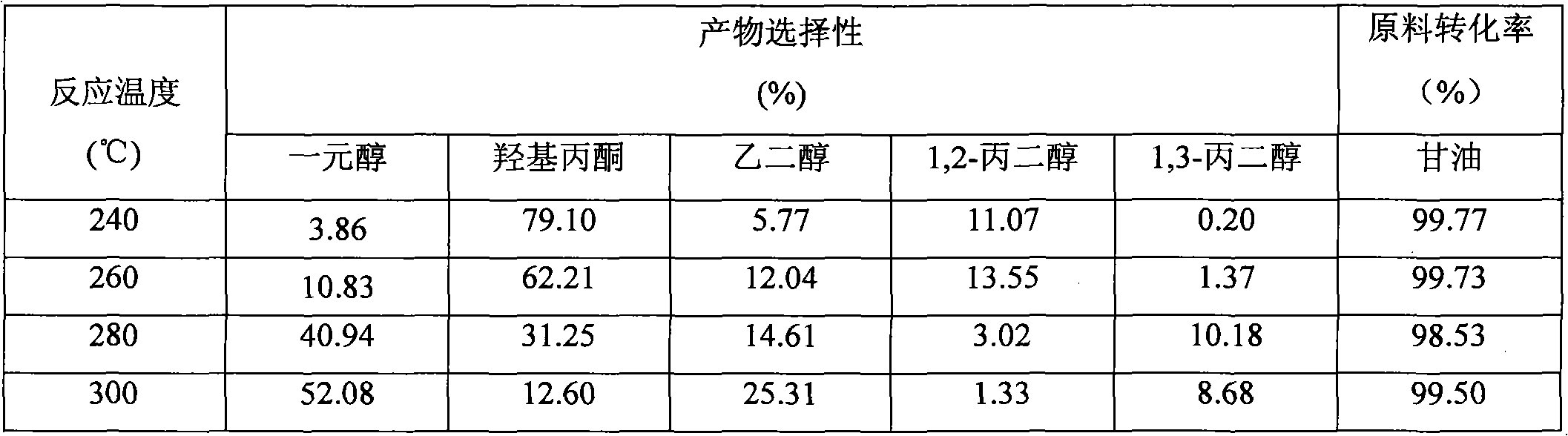

[0028] Table 3 Under normal pressure, the product selectivity and the conversion rate of raw material glycerol in the gas phase catalytic hydrogenolysis of Cu-Zn-Ti (2:2:1) at different reaction temperatures

[0029]

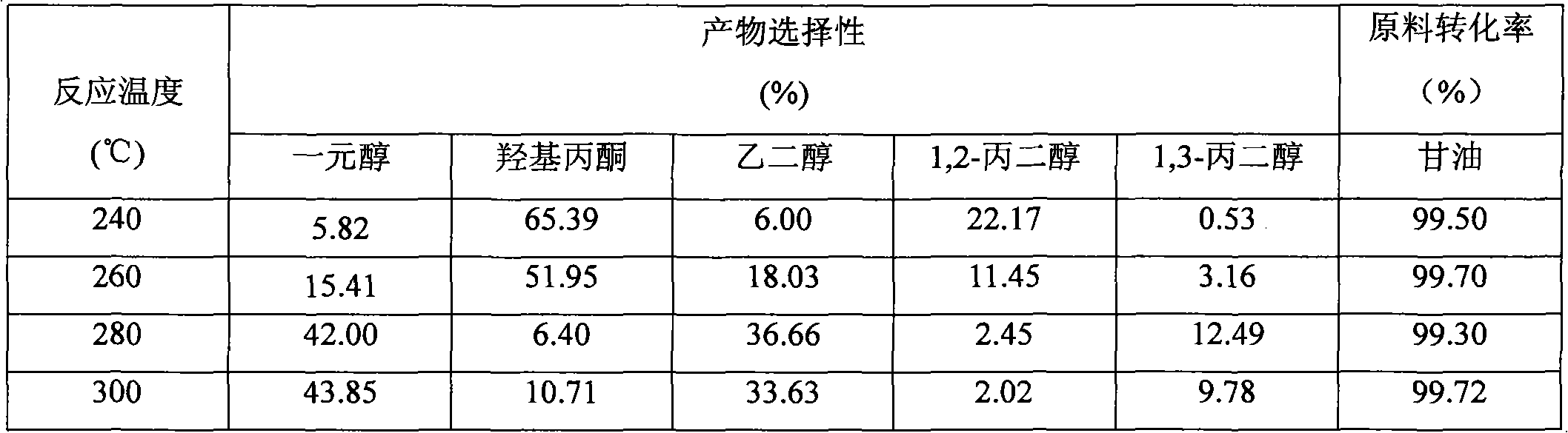

[0030] Table 4 Atmospheric pressure, Cu-Zn-Ti (2:2:2) gas-phase catalytic hydrogenolysis reaction product selectivity of glycerol and conversion rate of raw material glycerol at different reaction temperatures

[0031]

[0032] Table 5 Under normal pressure, product selectivity and conversion rate of raw material...

Embodiment 3

[0040] With embodiment 1, but use raw material Zr(NO 3 ) 4 ·5H 2 O instead of TiCl 4 , to prepare Cu-Zn-Zr catalyst, and use this catalyst to catalyze the gas-phase hydrogenolysis reaction of glycerol. The results are shown in Table 6.

[0041] Table 6 Under normal pressure, the product selectivity and the conversion rate of raw material glycerol in the gas-phase catalytic hydrogenolysis of Cu-Zn-Ti (1:2:1) at different reaction temperatures

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com