One-pot or one-step method for preparing diesel oil or aviation kerosene

A technology for aviation kerosene and diesel oil, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oils, etc. It can solve problems such as hydrogenation or hydrodeoxygenation catalyst poisoning, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

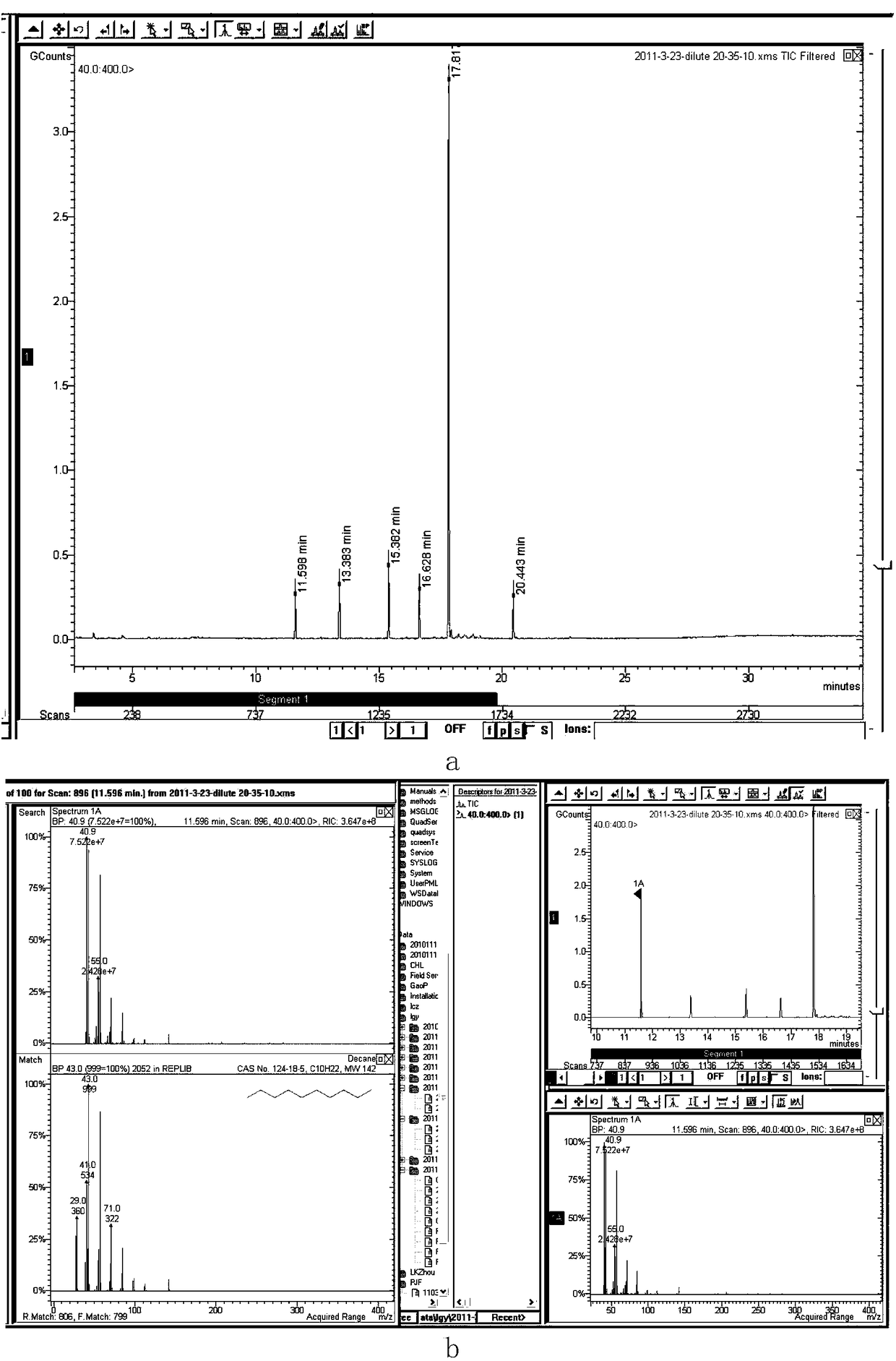

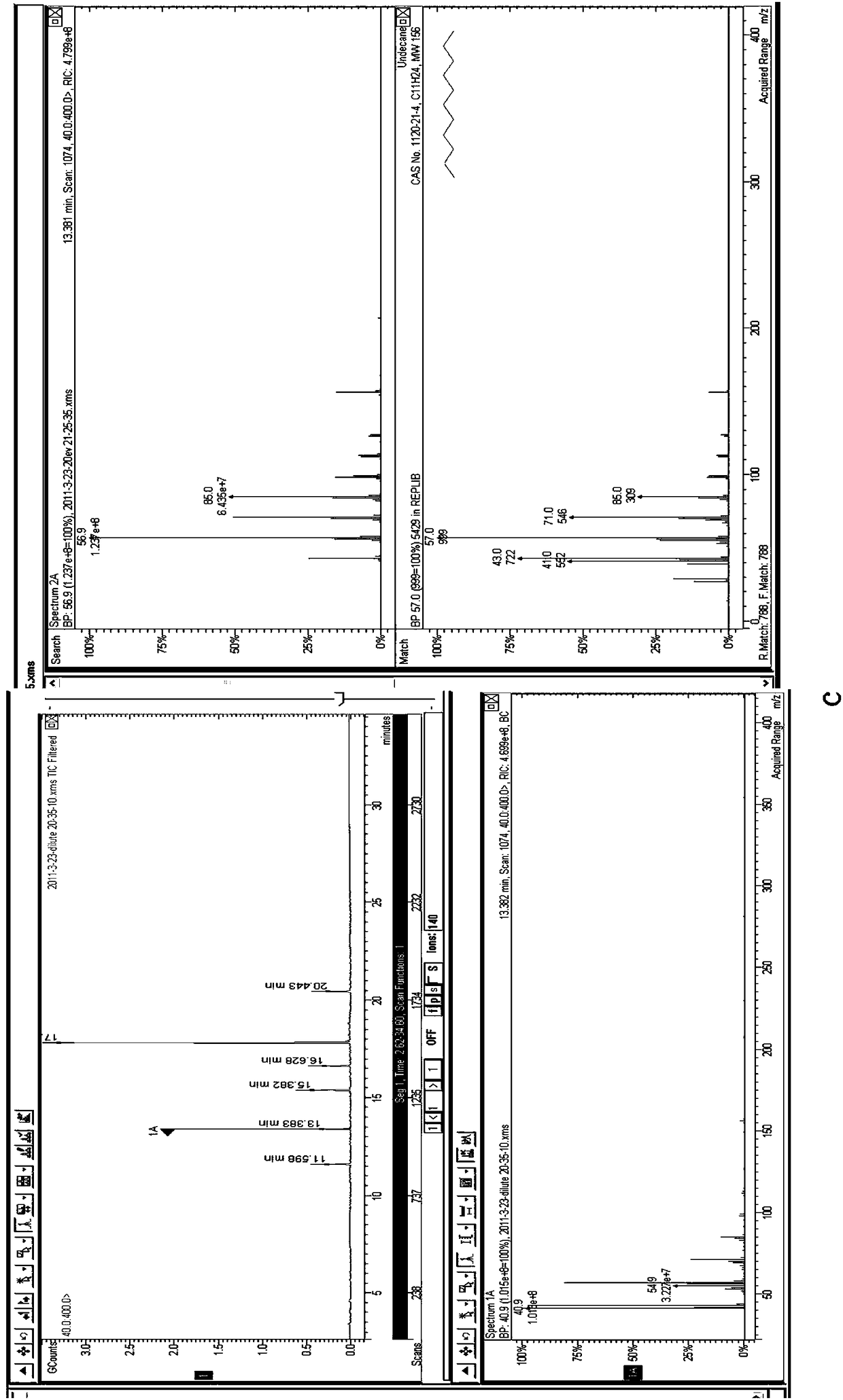

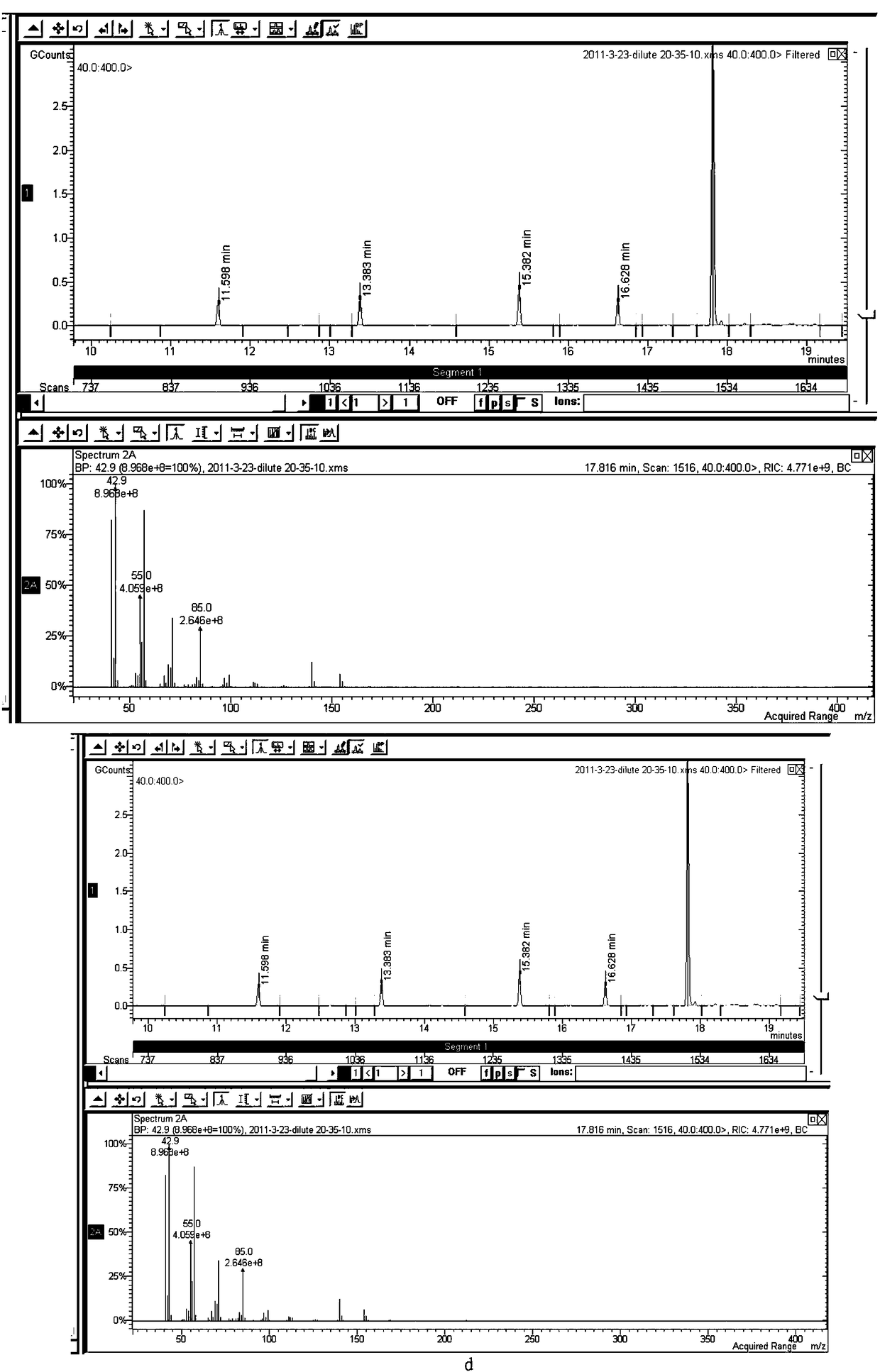

Image

Examples

Embodiment

[0043] 1. Preparation of catalyst:

[0044] 1) Preparation of solid acid catalyst: Nafion and Amberlyst resins are commercial catalyst products purchased directly.

[0045] The activated carbon used in the present invention is pretreated by immersing in nitric acid with a mass concentration of 20-50% at 80° C. for 24 hours. Mix activated carbon (AC) or mesoporous carbon (MC) with concentrated sulfuric acid (95%) at a mass ratio of 1:15, raise the temperature to 250°C under nitrogen protection, keep it for 24h, filter it, and wash it with 80°C hot water several times, then washed with deionized water until neutral, and dried overnight at 120°C. Zirconium phosphate (ZrP) catalyst is mixed with 1mol / L zirconium oxychloride and ammonium dihydrogen phosphate aqueous solution at a volume ratio of 2:1, and the obtained precipitate is washed and filtered repeatedly, dried at 120°C for 10h, and then dried at 400°C Under roasting 4h. The sulfonated alumina is mixed with γ-Al2O3 and 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com