Catalyst for 1,3-dihydroxyacetone prepared from glycerin and preparation method thereof

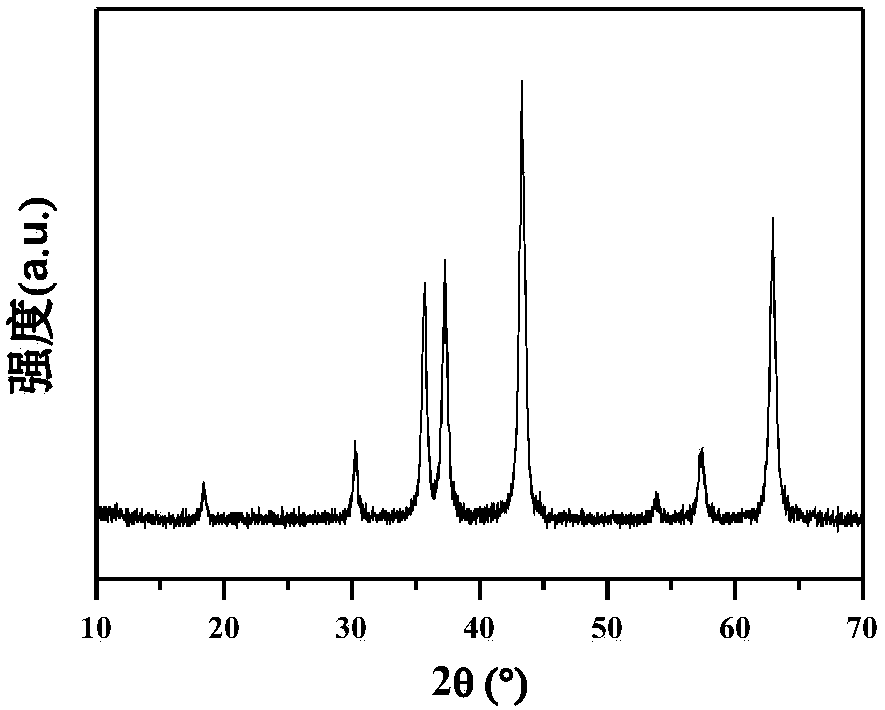

A dihydroxyacetone and catalyst technology, applied in the field of catalysis, can solve the problems of Au sintering and particle size, easy loss of precious metal utilization rate, unfavorable Au dispersion, etc., and achieves good glycerol conversion rate, good stability, and mild reaction process conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A. Add 0.1894gGa(NO 3 ) 3 ·5H 2 O, 4.4624gZn (NO 3 ) 2 ·6H 2 O and 2.0001gCr(NO 3 ) 3 9H 2 O was dissolved in 150 mL deionized water to prepare solution A. Weigh 1.0600gNa 2 CO 3 Dissolve 1.2000g NaOH in 150mL deionized water to prepare solution B.

[0028] Pour solutions A and B into a rotating liquid film reactor at the same time and mix quickly, the speed is 4000rpm, the gap between the stator and the rotor is 15μm, nucleation takes 180 seconds; the suspension after nucleation is kept in a water bath at 80°C for 20h, Naturally cooled to room temperature; the obtained precipitate was washed with deionized water and centrifuged until neutral, and dried at 60 °C for 12 h to obtain Ga 0.15 -Zn 3 Cr 1 -LDH. The calcined product Ga 2 o 3 / Zn 3 Cr 1 o 4.5 .

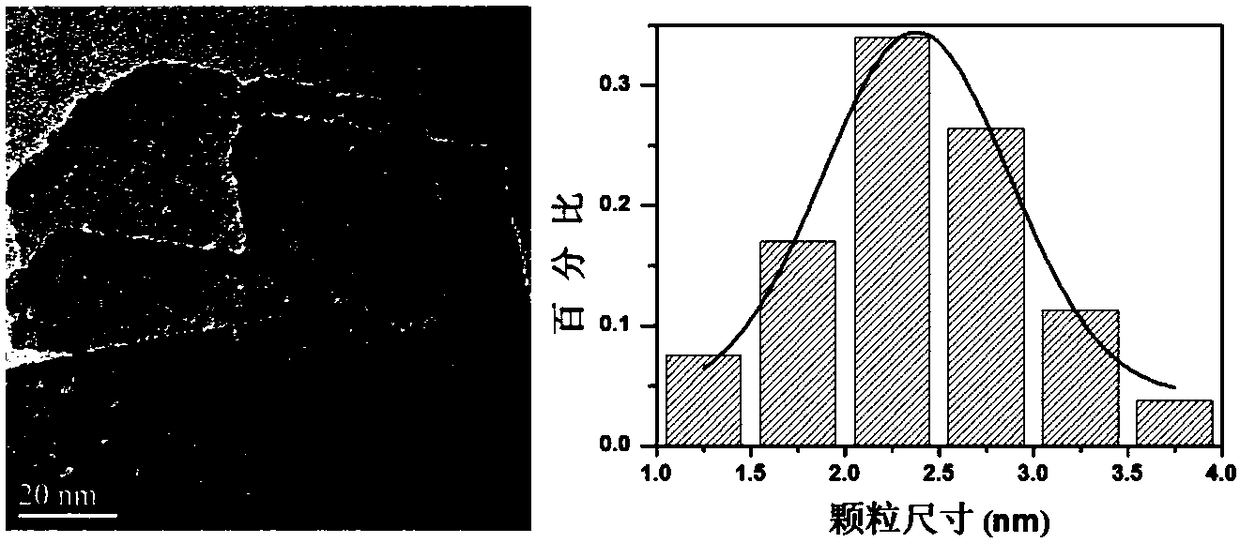

[0029] B. Weigh 1.0000g of Ga from step A 2 o 3 / Zn 3 Cr 1 o 4.5 Place in 80mL of deionized water, stir, add 4.06mL of 50mmol / L HAuCl 4 Solution, and then use 3mol / L urea to adjust the pH of t...

Embodiment 2

[0031] A. Add 0.1894gGa(NO 3 ) 3 ·5H 2 O, 5.9499gZn (NO 3 ) 2 ·6H 2 O and 2.0001gCr(NO 3 ) 3 9H 2 O was dissolved in 150mL deionized water to prepare solution A, and weighed 2.1200gNa 2 CO 3 Dissolve 1.2000g NaOH in 150mL deionized water to prepare solution B. Pour solutions A and B into a rotating liquid film reactor at the same time and mix quickly, the speed is 4000rpm, the gap between the stator and the rotor is 15μm, nucleation takes 180 seconds; the suspension after nucleation is kept in a water bath at 80°C for 20h, Naturally cooled to room temperature; the obtained precipitate was washed with deionized water and centrifuged until neutral, and dried at 60 °C for 12 h to obtain Ga 0.15 -Zn 4 Cr 1 -LDHs. The calcined product Ga 2 o 3 / Zn 4 Cr 1 o 4.0 .

[0032] B. Weigh 1.0000g of Ga from step A 2 o 3 / Zn 4 Cr 1 o 4.0 Place in 80mL of deionized water, stir, add 3.50mL of 50mmol / L HAuCl 4 solution, and then use 1mol / L NaOH solution to adjust the pH...

Embodiment 3

[0034] A. Add 0.0426gRuCl 3 , 5.9499gZn (NO 3 ) 2 ·6H 2 O and 2.0001gCr(NO 3 ) 3 9H 2 O was dissolved in 150mL deionized water to prepare solution A, and weighed 2.1200gNa 2 CO 3 Dissolve 1.2000g NaOH in 150mL deionized water to prepare solution B. Pour solutions A and B into a rotating liquid film reactor at the same time and mix quickly, the speed is 4000rpm, the gap between the stator and the rotor is 15μm, nucleation takes 180 seconds; the suspension after nucleation is kept in a water bath at 80°C for 20h, Naturally cooled to room temperature; the obtained precipitate was washed with deionized water and centrifuged until neutral, and dried at 60°C for 12h to obtain Ru 0.03 -Zn 4 Cr 1 -LDHs. Calcined at 700 °C for 6 h at a heating rate of 5 °C / min to obtain the roasted product RuO 2 / Zn 4 Cr 1 o 3.9 .

[0035] B. Weigh 1.0000g of RuO from step A 2 / Zn 4 Cr 1 o 3.9 Place in 80mL of deionized water, stir, add 3.20mL of 50mmol / L HAuCl 4 solution, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com