Process for treating oxidized exhaust gas

A technology for oxidizing tail gas and process, which is applied in chemical industry, incinerator, steam condensation, etc. It can solve the problems of increased energy consumption, increased energy consumption, and high one-time investment, and achieves the effects of low operating cost, simple process, and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

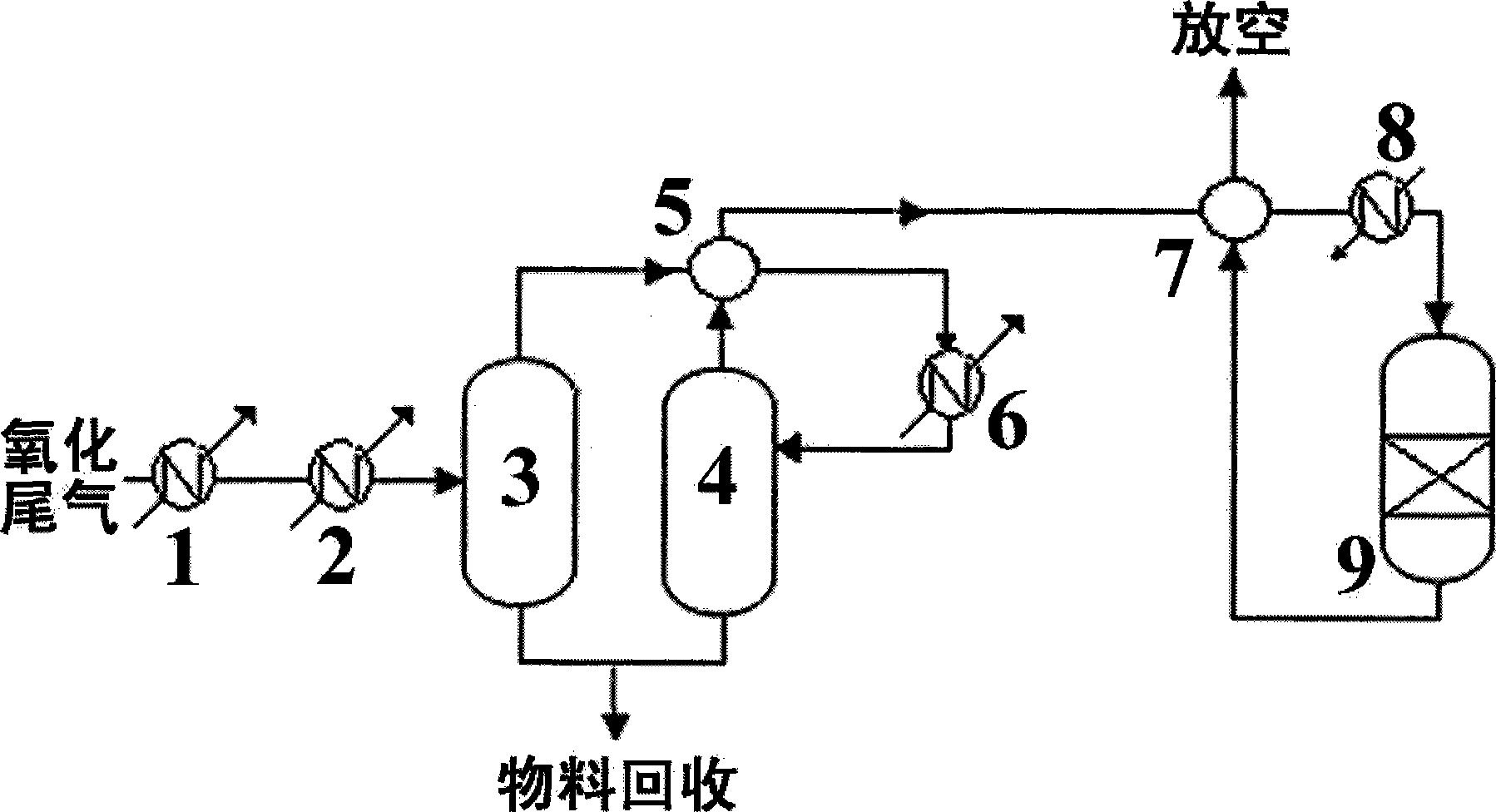

Image

Examples

Embodiment 1

[0023] The tail gas of phenol and acetone produced by a certain enterprise contains 10000mg / m of cumene 3 (in addition to entrained liquid phase), cumene hydroperoxide 0.01wt%, benzene 300mg / Nm 3 , Toluene 30mg / Nm 3 , Non-methane total hydrocarbons 45×10 4 mg / Nm 3 , the tail gas temperature is 80~100℃, the flow rate is 19000Nm 3 / h; the temperature after the heat exchange in the heat recovery heat exchanger (1) is 60-70°C, and the temperature is 25-40°C after cooling with cooling water in the cooler (2), and then enters the first gas-liquid separation tank for gas Liquid separation, the uncondensed gas discharged from the top, after being cooled by the heat exchanger (5), the temperature is 15-25°C, and further cooled by the deep cooler (6), the temperature is 1.4°C, after that, it enters the second gas-liquid The separation tank (4) performs gas-liquid separation, and the uncondensed gas discharged from the top of the second gas-liquid separation tank first passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com