Copper catalyst for preparing isopropyl benzene by alpha, alpha-dimethyl benzyl alcohol hydrogenolysis and preparation method thereof

A technology of dimethyl benzyl alcohol and copper catalysts, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, and can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

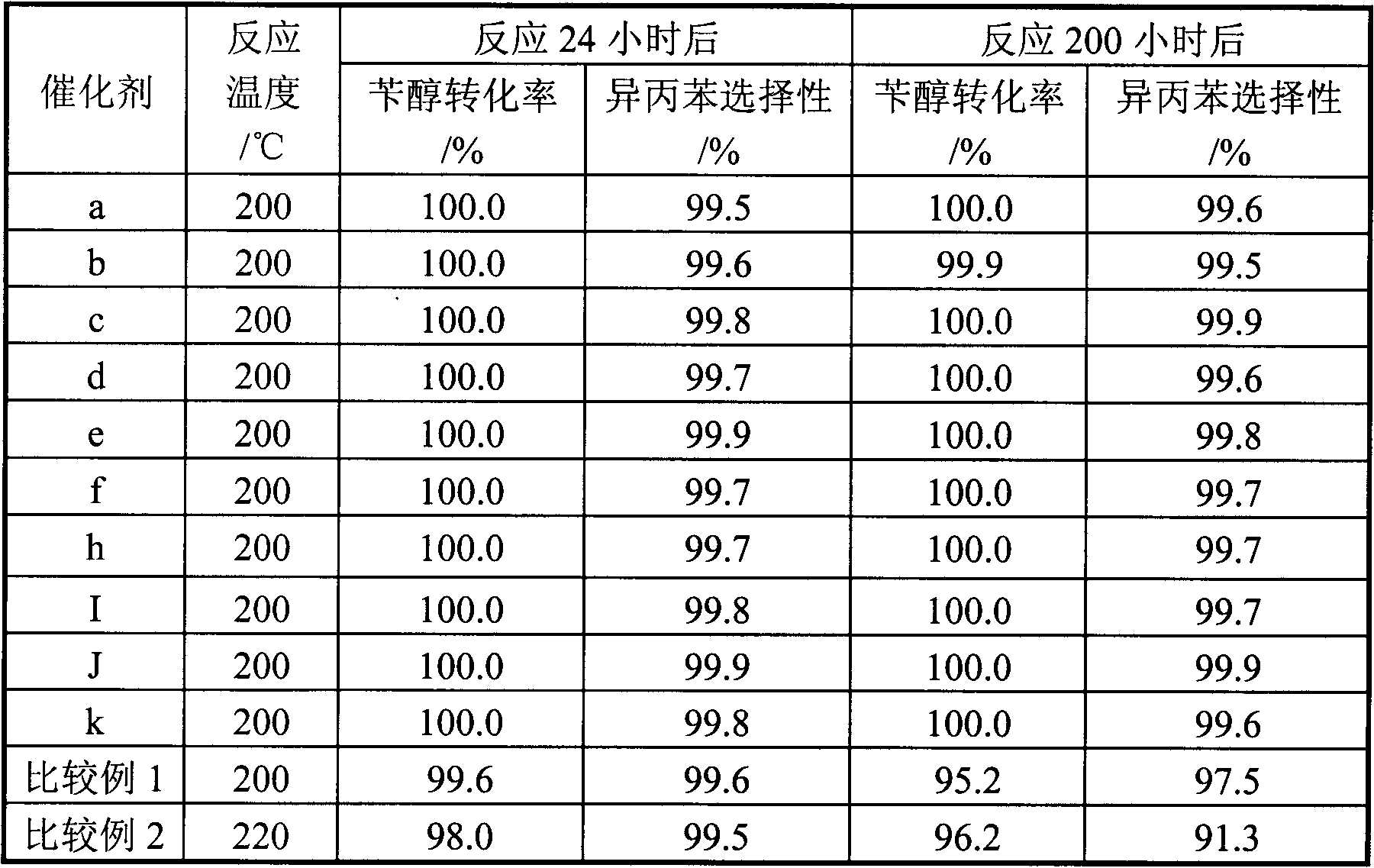

Examples

Embodiment 1

[0018] Mix the required amount of alumina and water to make slurry to obtain slurry I, drop the required amount of copper nitrate, zinc nitrate and manganese nitrate mixed solution and sodium carbonate aqueous solution into the slurry A at the same time for co-precipitation, the precipitation temperature is 70 ° C , control the pH value of the solution to 6.5, after the precipitation is completed and age at 70°C for 2 hours, then the precipitate is washed, filtered and dried at 120°C for 4 hours, and roasted at 400°C for 4 hours, and baked with 2% graphite of solid weight, After 10% of the water phase is mixed, the compression molding obtains the catalyst a (the composition of the catalyst is 55.0%CuO-20.0%ZnO%-24.0%Al in weight percent 2 o 3 -1.0%MnO 2 ).

Embodiment 2

[0020] Catalyst b (catalyst composition is 20.0%CuO-50.0%ZnO-25.0%Al in weight percent 2 o 3 -5.0%MnO 2 ), the precipitation temperature is 80° C., the pH value of the control solution is 8.0, and all the other steps and parameters are the same as in Example 1.

Embodiment 3

[0022] Catalyst c (the composition of catalyst is 30.0%CuO-20.0%ZnO%-45.0%Al in weight percent 2 o 3 -1.5%MnO 2 -3.5%TiO 2 ), the precipitation temperature is 90° C., the pH value of the control solution is 8.0, and all the other steps and parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com