Synthesis method of nano Y zeolite, synthesized nano Y zeolite and application

A synthesis method and nanotechnology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve serious problems, high cost, environmental pollution, etc., reduce production costs, simplify manufacturing processes, Environmentally green friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to one aspect of the present invention, it relates to a method for synthesizing nano Y zeolite. The method comprises the steps of:

[0033] a) contacting the aluminum source with a sodium hydroxide solution to obtain an aluminum source solution; the contact temperature is 50-95°C;

[0034] b) contacting the silicon source with a sodium hydroxide solution to obtain a silicon source solution; the contact temperature is 70-100°C;

[0035] c) contacting the aluminum source solution with the silicon source solution in an ice-water mixing bath to obtain a mixture;

[0036] d) crystallizing the mixture to obtain the nano Y molecular sieve.

[0037] According to one aspect of the present invention, a) step, with Na 2 O, Al 2 o3 and H 2 In terms of O, in the aluminum source solution, Na 2 O: Al 2 o 3 :H 2 The molar ratio of O is 2-18:1:10-50.

[0038] According to one aspect of the present invention, b) step, with Na 2 O, SiO 2 and H 2 In terms of O, in th...

Embodiment 1

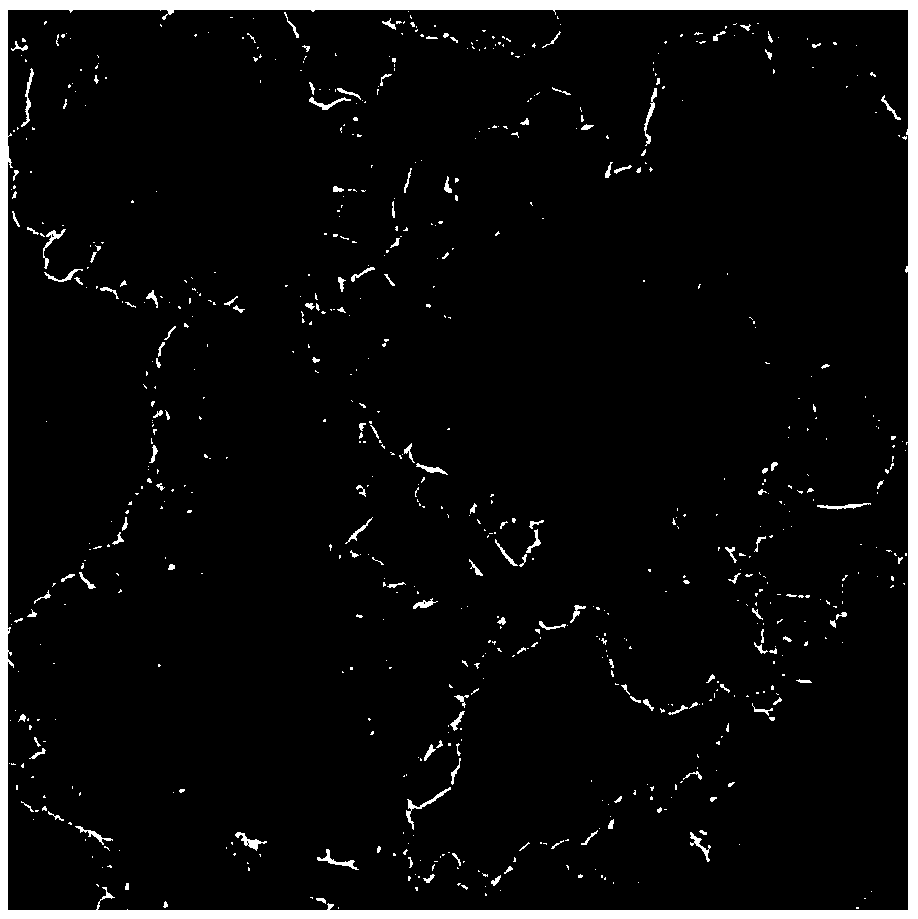

[0054] First, configure the aluminum source solution, weigh 20g of NaOH and dissolve it in 40g of water, add 1.9g of aluminum powder, stir in a 60°C water bath for 10min, and then place it in an ice-water mixing bath. Next, configure the silicon source solution, weigh 16g NaOH and dissolve it in 59g water, add 75g silica sol, heat at 100°C for 10min to fully dissolve, and place the solution in an ice-water mixed bath environment after it becomes transparent. Slowly drop the aluminum source solution into the silicon source solution and stir for 24 hours to obtain a mixture. Then the mixture was warmed up to 50°C and allowed to stand still for crystallization for 50 hours. The product was washed with water until the pH value of the washing solution was less than 10, filtered, and dried at 80°C for 12 hours to obtain nano Y zeolite, whose morphology was determined by figure 1 Note that the average grain size is 10 nm. The catalyst was named Cat-1, and the molar ratio of silica ...

Embodiment 2

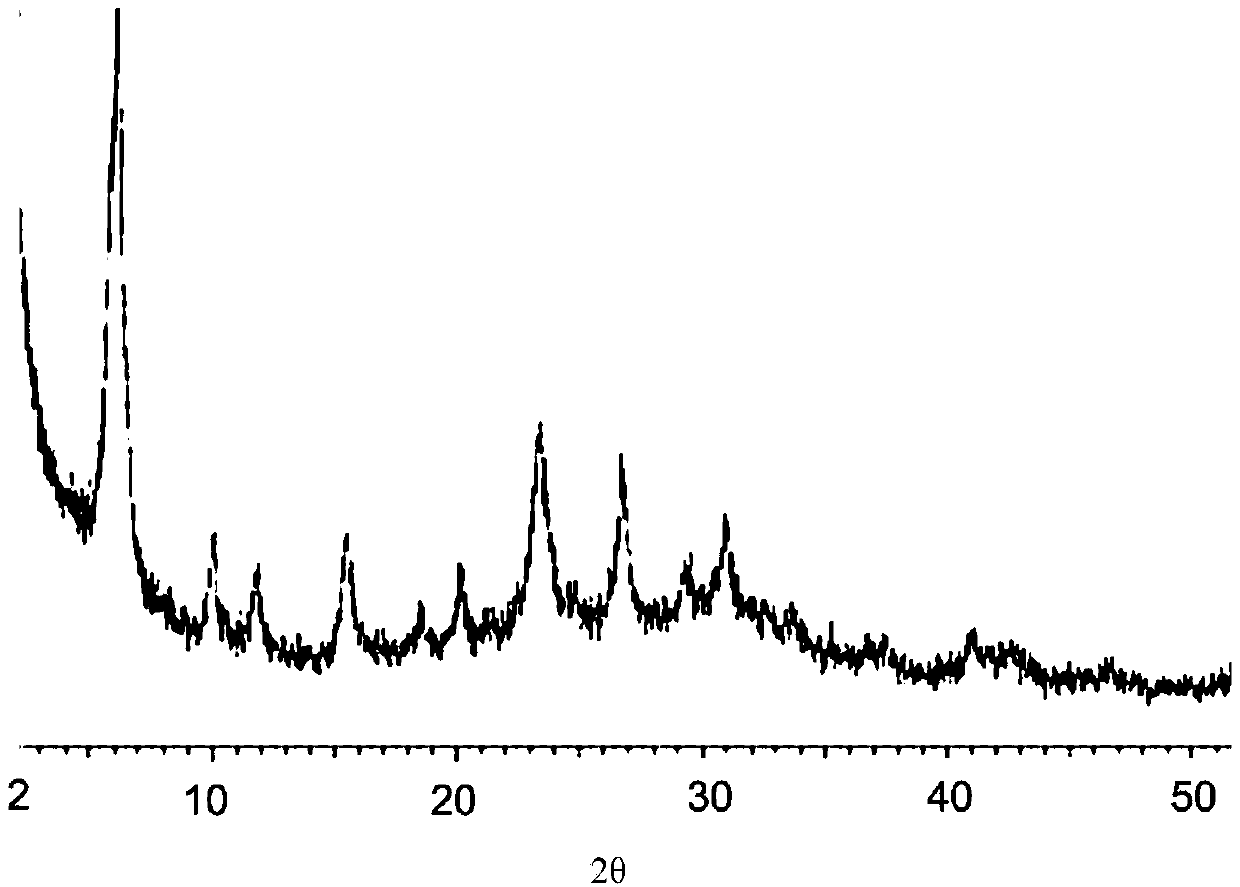

[0057] First, configure the aluminum source solution, weigh 18g of NaOH and dissolve it in 38g of water, add 3.6g of alumina powder, stir in a water bath at 80°C for half an hour, and then place it in an ice-water mixing bath. Next, configure the silicon source solution, weigh 16g NaOH and dissolve it in 59g water, add 75g silica sol, heat at 100°C for 10min to fully dissolve, and place the solution in an ice-water mixed bath environment after it becomes transparent. Slowly drop the aluminum source solution into the silicon source solution and stir for 24 hours to obtain a mixture. Then the mixture was warmed up to 60°C and allowed to stand for crystallization for 45 hours. The product was washed with water until the pH value of the washing solution was less than 10, filtered, and dried at 80°C for 12 hours to obtain nano Y zeolite, whose morphology was determined by figure 2 Note that the average grain diameter is 30 nm. The catalyst was named Cat-2, and the molar ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com