Biomass-based carbon material supported nano-nickel catalyst, preparation method and application thereof

A biomass carbon and catalyst technology, applied in the direction of physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of low metal dispersion and achieve benefits for large Large-scale production and industrial application, avoiding resource waste, and evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Catalyst preparation:

[0044] (1) Take 2.619g of nickel sulfate hexahydrate, dissolve it in 100mL of deionized water, and prepare 0.1mol / L solution A.

[0045] (2) After the bagasse is dried and pulverized, 10 g is put into a flat-bottomed flask filled with 100 mL of 0.2 mol / L nitric acid solution, soaked overnight, then the mixture is cleaned with deionized water until the supernatant pH=7, and then Put into a drying oven and dry at 110° C. for 12 hours to obtain solid B. Get biochar and take 5.9375g.

[0046] (3) Put solid B and solution A in a beaker, stir in the beaker, then transfer to a hydrothermal reaction kettle for hydrothermal carbonization reaction, and then wash several times with deionized water. Obtain suspension D.

[0047] (4) Get the suspension obtained in step (3) and place it in a magnetic stirrer, with a rotating speed of 150r / min, slowly add sodium borohydride solution dropwise, and the concentration of the borohydride ion in the sodium borohyd...

Embodiment 2

[0059] Catalyst preparation:

[0060] (1) Take 5.815g of nickel nitrate hexahydrate and dissolve it in 100mL of deionized water to prepare solution A with a concentration of 0.20mol / L.

[0061] (2) After drying and pulverizing the corn stalks, take 10 g and put it into a flat-bottomed flask filled with 100 mL of 0.2 mol / L nitric acid solution, soak overnight, then wash the mixture with deionized water until the supernatant pH=7, and then Put into a drying oven and dry at 110° C. for 12 hours to obtain solid B. Get 9.3g of biochar

[0062] (3) Put solid B and solution A in a beaker, stir in the beaker, then transfer to a hydrothermal reaction kettle for hydrothermal carbonization reaction, and then wash several times with deionized water. get suspension

[0063] (4) Get the suspension obtained in step (3) and place it in a magnetic stirrer, at a speed of 200r / min, slowly add sodium borohydride solution dropwise, and the concentration of the borohydride ion in the sodium boro...

Embodiment 3

[0069] Catalyst preparation:

[0070] (1) Dissolve 8.304g of nickel nitrate hexahydrate in 100mL of deionized water, stir until completely dissolved, and prepare solution A with a concentration of 0.4mol / L.

[0071] (2) After crushing the peanut shells, take 20 g and put it into a flat-bottomed flask containing 100 mL of 0.2 mol / L sulfuric acid solution, soak overnight, then wash the mixture with deionized water until the supernatant pH=7, and then put it into a drying box B was obtained as a solid after drying at 110°C for 12 hours. Obtain biochar 16.875g.

[0072] (3) Put solid B and solution A in a beaker, stir in the beaker, then transfer to a hydrothermal reaction kettle for hydrothermal carbonization reaction, and then wash several times with deionized water. Obtain suspension D.

[0073](4) Get the suspension obtained in step (3) and place it in a magnetic stirrer, at a speed of 250r / min, slowly add sodium borohydride solution dropwise, and the concentration of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

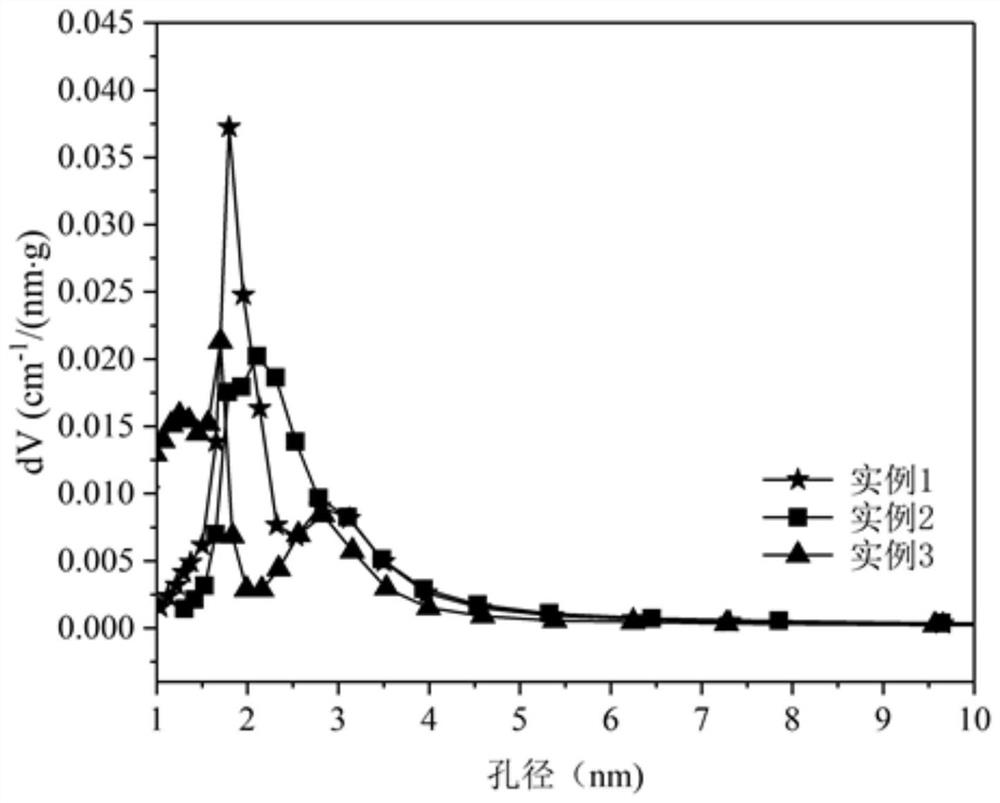

| pore size | aaaaa | aaaaa |

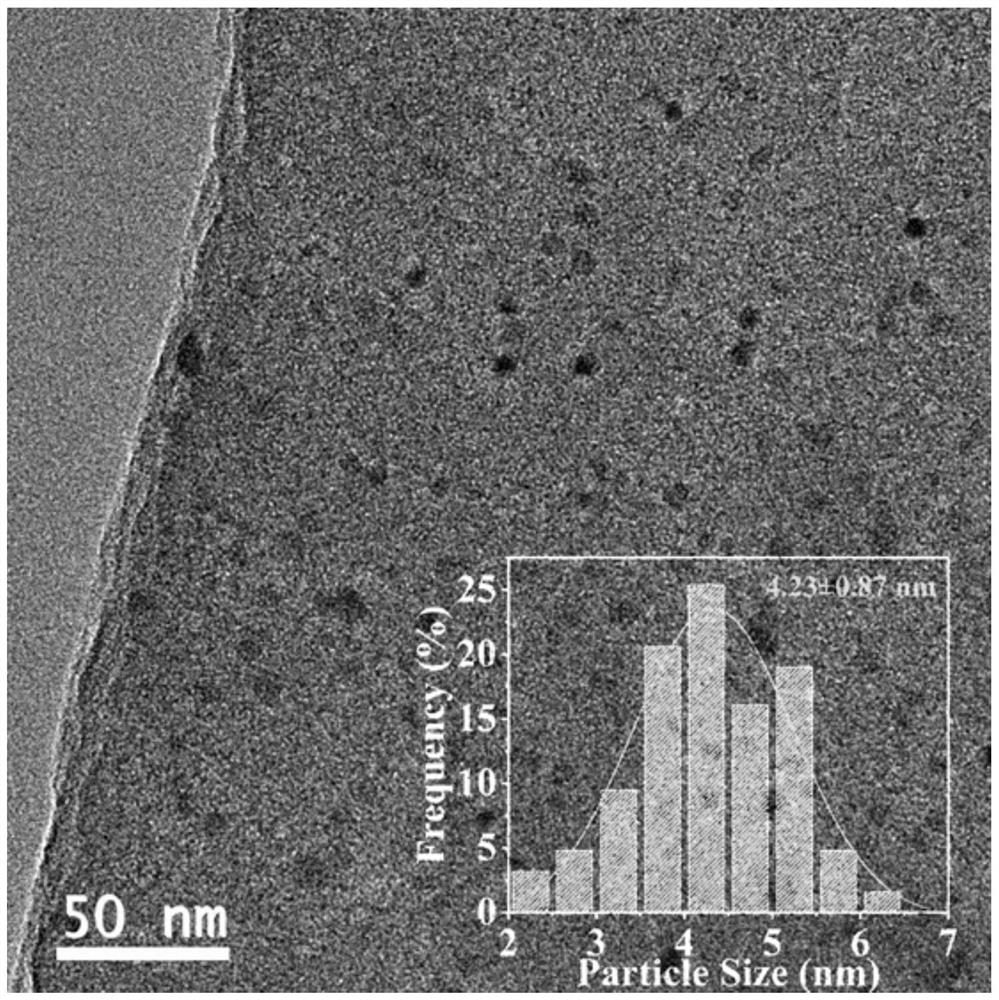

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com