Catalyst for VOCs catalytic combustion and its preparation method

A technology of catalytic combustion, catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing a catalyst for catalytic combustion of VOCs, comprising:

[0040] A) Mixing the aqueous solution of lanthanum-containing compound with CeO 2 Mixed, La-CeO was obtained by the first roasting 2 catalyst;

[0041] B) the La-CeO 2 The catalyst is mixed with an aqueous solution of a cobalt-containing compound, and after a second calcination, Co / La-CeO 2 catalyst;

[0042] C) the Co / La-CeO 2 The catalyst is mixed with water, polyvinyl alcohol and colloidal alumina to obtain a slurry;

[0043] D) mixing the honeycomb ceramic substrate with the slurry for coating, and then firing the coated honeycomb ceramic substrate for the third time to obtain a catalyst for catalytic combustion of VOCs.

[0044] The present invention has no special limitation on the preparation method of the aqueous solution of the lanthanum-containing compound, and the preparation method of the aqueous solution well known to those skilled in ...

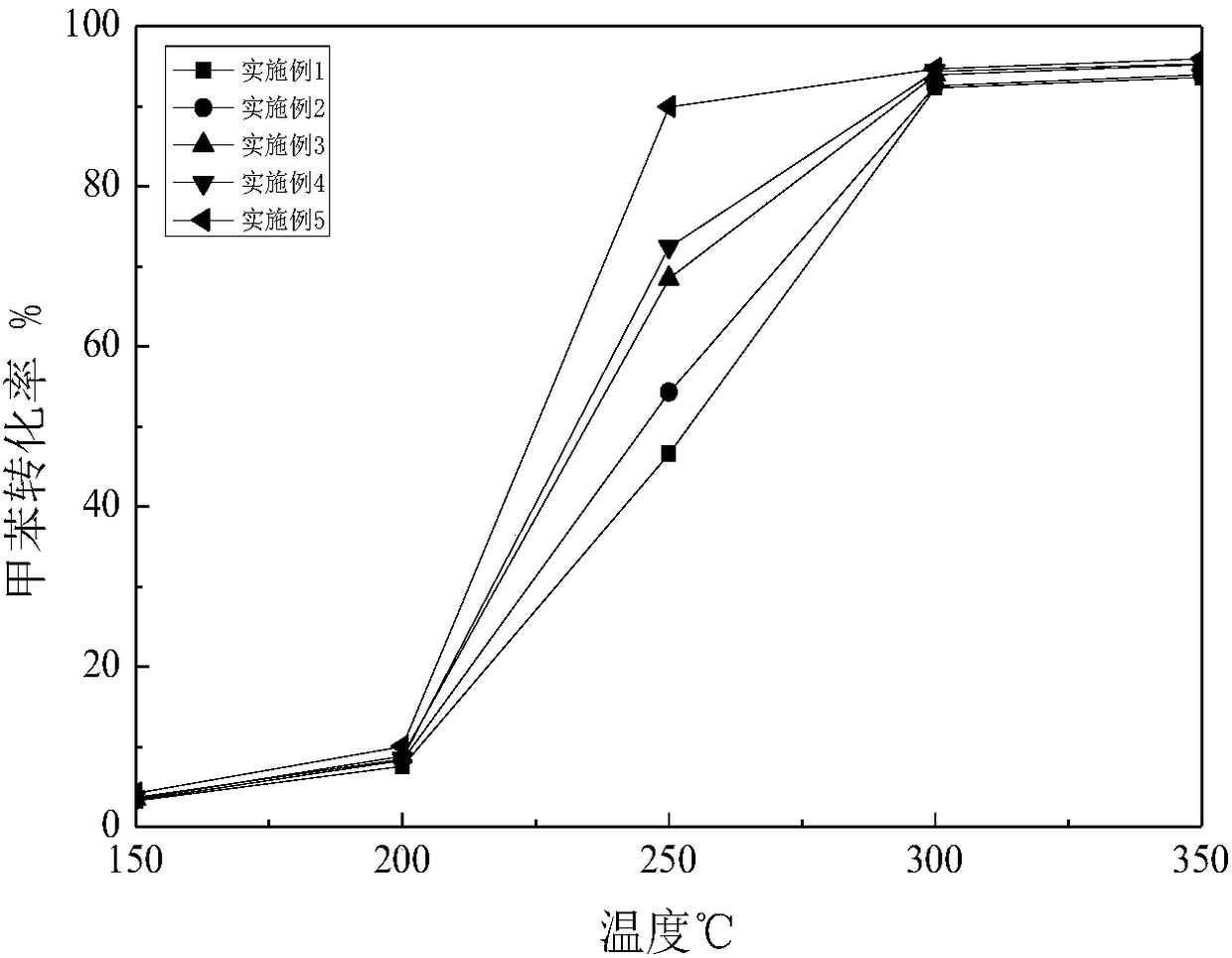

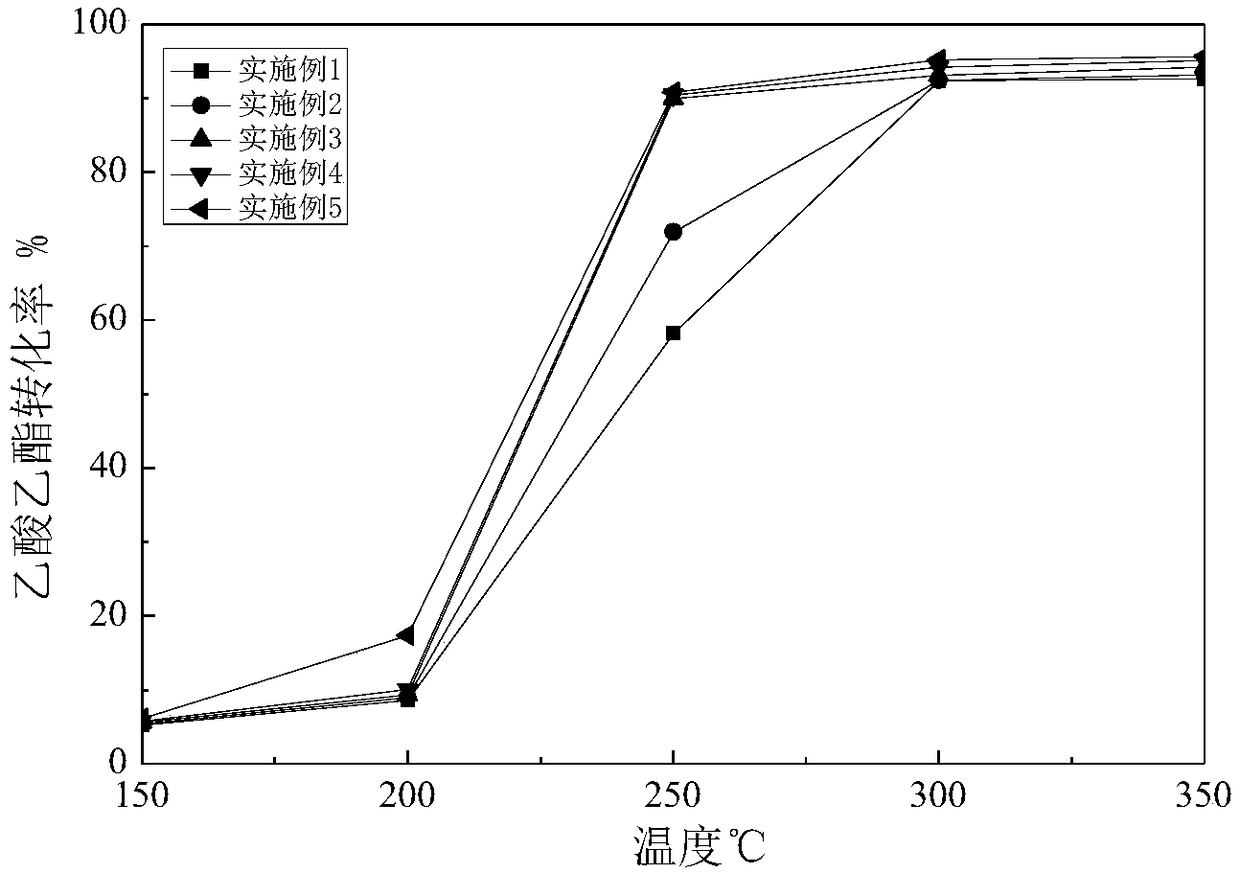

Embodiment 1

[0074] (1) 0.1655g La(NO 3 ) 3 ·6H 2 O was dissolved in 100ml of distilled water and stirred until completely dissolved to form an aqueous solution of the lanthanum-containing compound.

[0075] (2) Take 1g CeO 2 The powder is mixed with the aqueous solution obtained in (1), stirred by a magnetic stirrer at room temperature for 1 h, impregnated for 8 h, evaporated at 50 °C, dried at 100 °C for 2 h, calcined at 350 °C for 4 h, and ground to obtain La-CeO 2 powder. The La-CeO 2 In the catalyst, the mass fraction of La is 5%.

[0076] (3) 0.5493g Co(CH 3 COO) 2 4H 2 O was dissolved in 100ml of distilled water and stirred until completely dissolved to form an aqueous solution containing cobalt compounds.

[0077] (4) Take 1gLa-CeO 2 The powder is mixed with the aqueous solution obtained in (3), stirred by a magnetic stirrer at room temperature for 1 h, impregnated for 8 h, evaporated at 50 °C, dried at 100 °C for 2 h, calcined at 350 °C for 3 h, and ground to obtain Co / L...

Embodiment 2

[0083] (1) 0.1483g La(CH 3 COO) 3 4H 2 O was dissolved in 100ml of distilled water and stirred until completely dissolved to form an aqueous solution of the lanthanum-containing compound.

[0084] (2) Take 1g CeO 2 The powder is mixed with the aqueous solution obtained in (1), stirred by a magnetic stirrer at room temperature for 2 hours, impregnated for 10 hours, evaporated at 60°C, dried at 110°C for 4 hours, calcined at 450°C for 5 hours, and ground to obtain La-CeO 2 powder. The La-CeO 2 In the catalyst, the mass fraction of La is 5%.

[0085] (3) 0.8944g Co(CH 3 COO) 2 4H 2 O was dissolved in 100ml of distilled water and stirred until completely dissolved to form an aqueous solution containing cobalt compounds.

[0086] (4) Take 1gLa-CeO 2 The powder is mixed with the aqueous solution obtained in (3), stirred by a magnetic stirrer at room temperature for 2 hours, impregnated for 10 hours, evaporated at 60°C, dried at 110°C for 4 hours, calcined at 450°C for 4 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com