Preparation method of organosilicon auxiliary agent

A technology of organosilicon additives and solvents, which is applied in the field of preparation of organosilicon additives, can solve the problems of stable product quality, adverse effects on human health, difficulty in achieving performance, and waste of resources, and achieve stable and efficient raw material conversion. The effect of stable rate and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

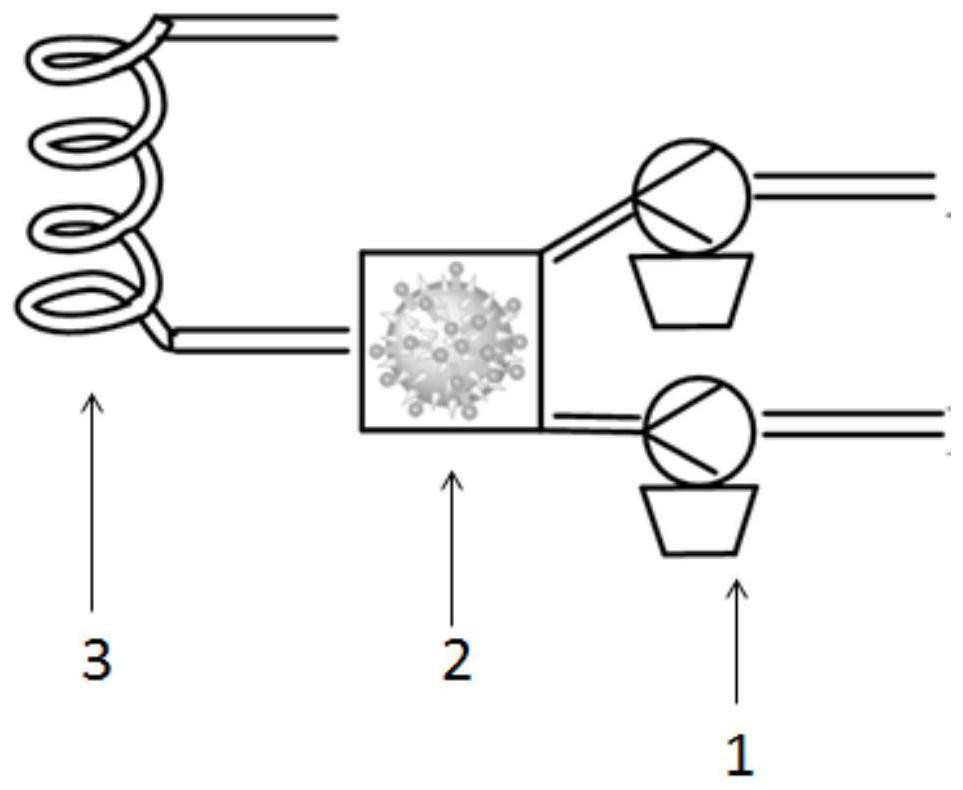

[0045] (1) The feed pump module 1, the mixer module 2, and the heat exchange reaction module 3 of the continuous flow tubular reactor are figure 1 The structures shown are connected sequentially, and the inner diameter of the continuous flow reactor in this embodiment is 1 mm. The temperature of the circulation system of the heat exchange reaction module 3 is set at 240° C., and the preheating time is 30 minutes, so that the heat exchange reaction module 3 is in a temperature equilibrium state.

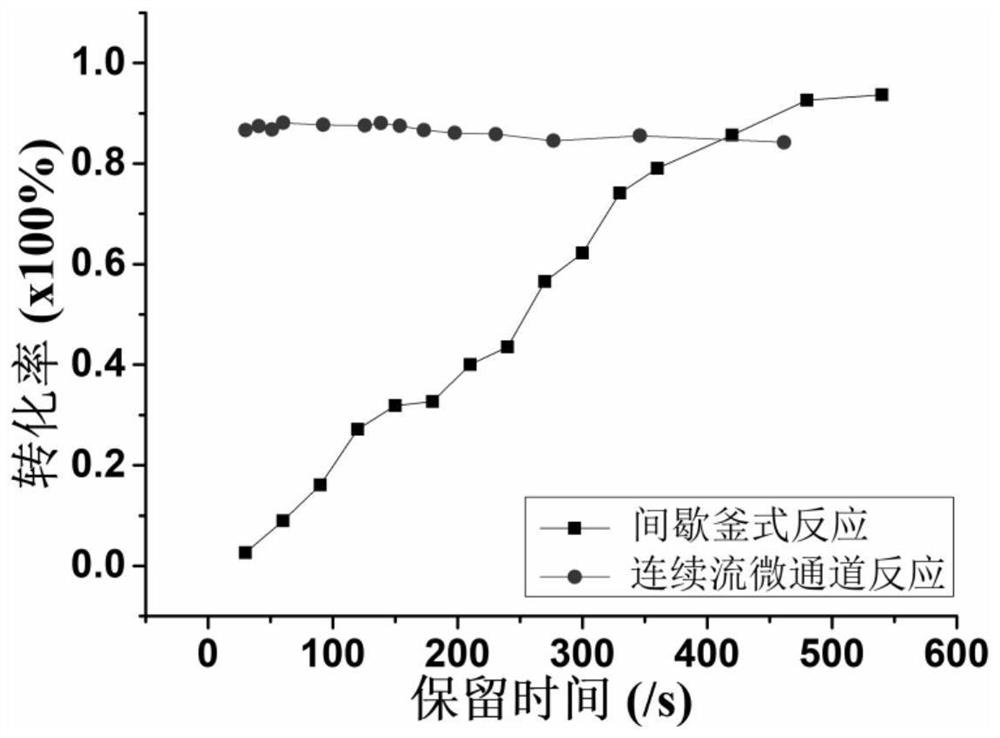

[0046] (2) Set the flow rate of the feed pump to control the mixture of hydrogen-containing silicone oil and catalyst (the molecular weight of hydrogen-containing silicone oil is about 1200, and the active hydrogen content is about 0.17wt%; the catalyst is chloroplatinic acid hydrate, and the consumption is the total mass of the mixture The flow rate of 0.01%) is 1.1mL / min, and the flow rate of allyl monoethylene glycol ether is 0.2mL / min, which can be adjusted according to this ratio...

Embodiment 2

[0050] (1) The continuous flow reactor used in this example is the same as in Example 1. The temperature of the circulation system of the heat exchange reaction module 3 is set at 230° C., and the preheating time is 30 minutes, so that the heat exchange reaction module 3 is in a temperature equilibrium state.

[0051] (2) Set the flow rate of the feed pump to control the mixture of hydrogen-containing silicone oil and catalyst (the molecular weight of hydrogen-containing silicone oil is about 1200, and the active hydrogen content is about 0.17wt%; the catalyst is chloroplatinic acid hydrate, and the consumption is the total mass of the mixture 0.01% of ) flow rate is 2.0mL / min, and the flow rate of 3-buten-1-ol is 0.3mL / min, which can be adjusted according to this ratio according to the needs of residence time.

[0052] (3) After the two streams of materials are mixed by the mixer module 2, they enter the heat exchange reaction module 3 for reaction, and the reaction temperatur...

Embodiment 3

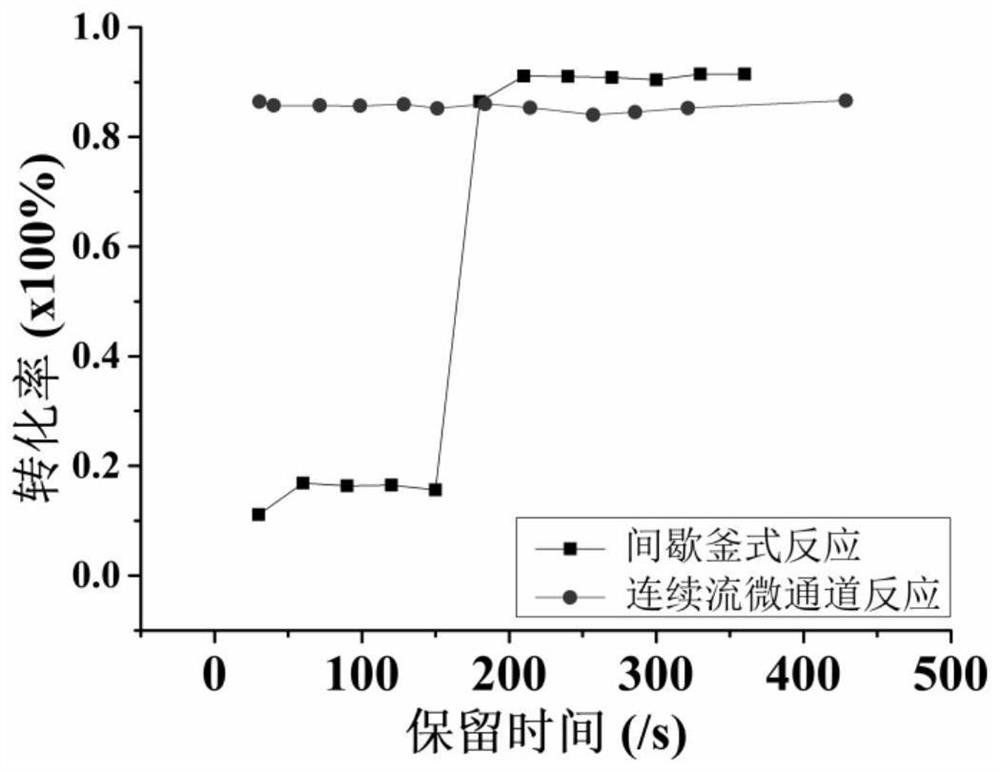

[0055] (1) The continuous flow reactor used in this example is the same as in Example 1, and the temperature of the circulation system of the heat exchange reaction module 3 is set to 200° C., and the preheating time is 30 minutes, so that the heat exchange reaction module 3 is in a temperature equilibrium state.

[0056] (2) Set the flow rate of the feed pump to control the mixture of hydrogen-containing silicone oil and catalyst (the molecular weight of hydrogen-containing silicone oil is about 1200, and the active hydrogen content is about 0.17wt%; the catalyst is Castel platinum catalyst, and the consumption is the total mass of the mixture The flow rate of 0.02%) is 2.0mL / min, and the flow rate of dodecene is 0.8mL / min, which can be adjusted according to this ratio according to the needs of the residence time.

[0057] (3) After the two streams of materials are mixed by the mixer module 2, they enter the heat exchange reaction module 3 for reaction. The reaction temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com