Reactor used for semiconductor single crystal material vapor phase epitaxy growth

A technology of single crystal material and vapor phase epitaxy, which is applied in the direction of polycrystalline material growth, single crystal growth, crystal growth, etc., can solve the problems of growth thickness and thickness uniformity difference, low pass rate, interference with crystal growth, etc., to ensure Effects of epitaxial growth rate, residence time extension, and conversion rate assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

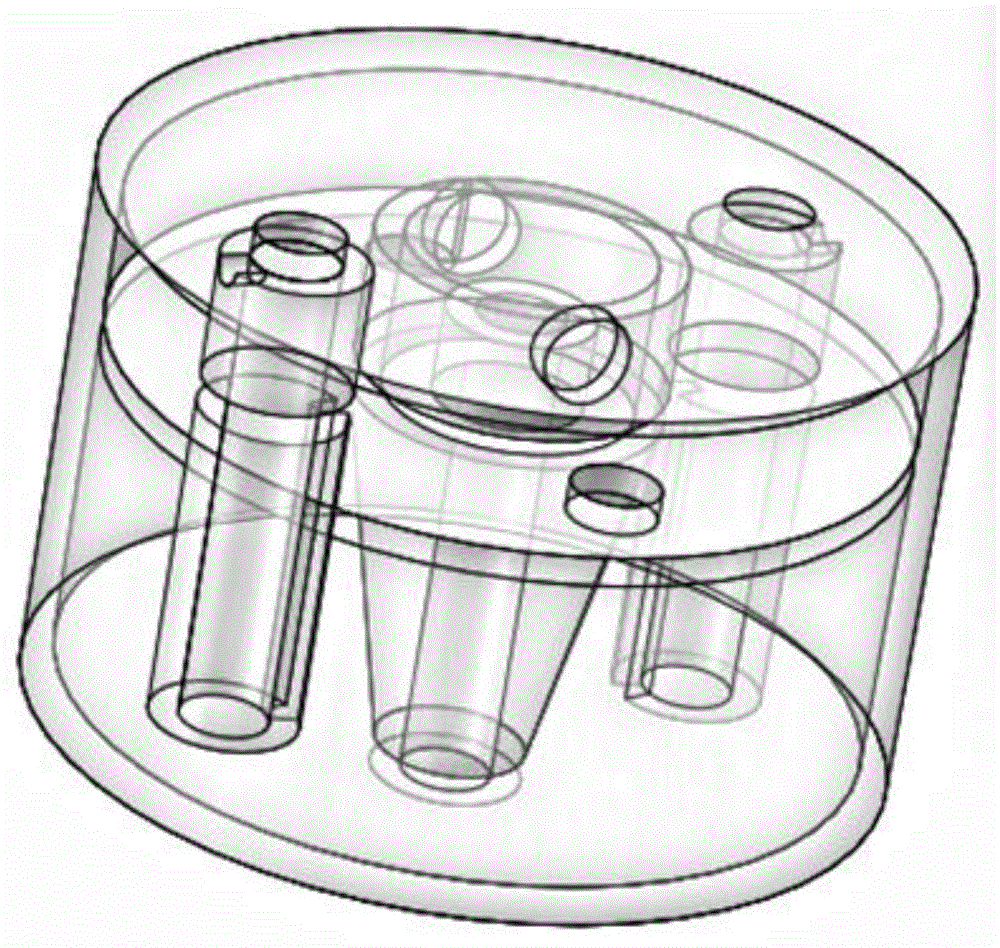

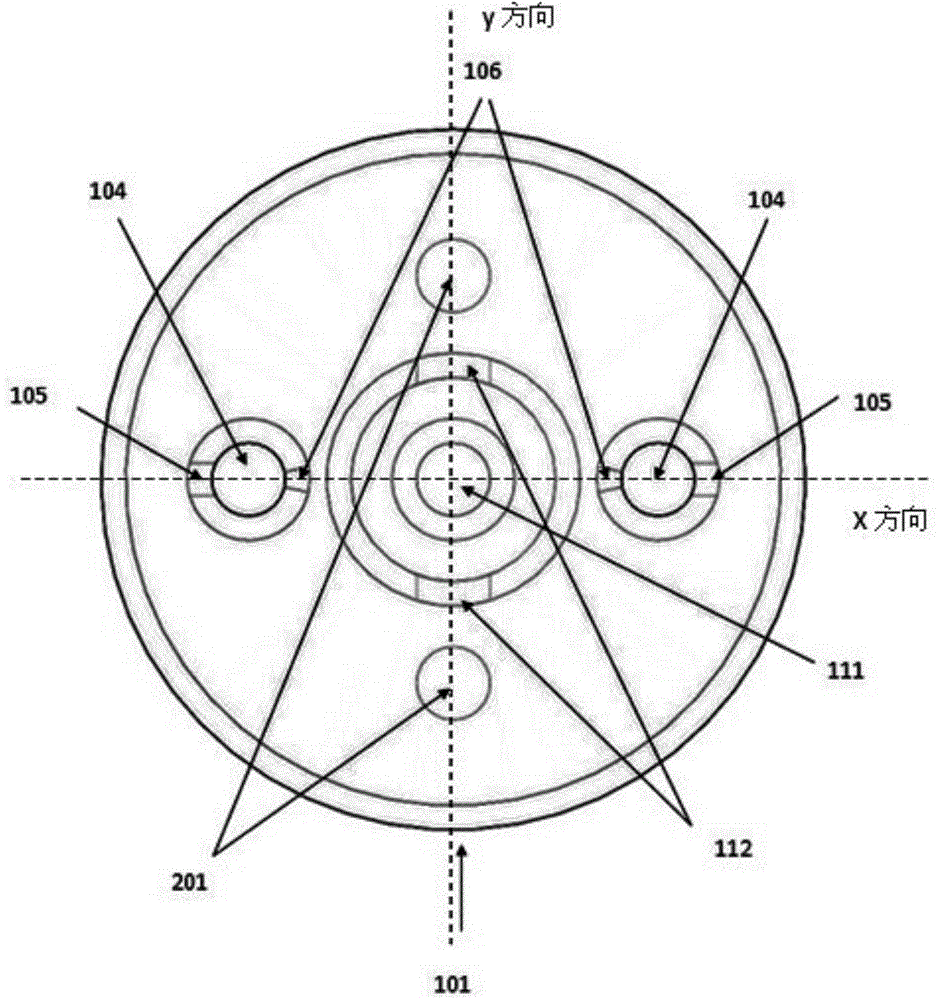

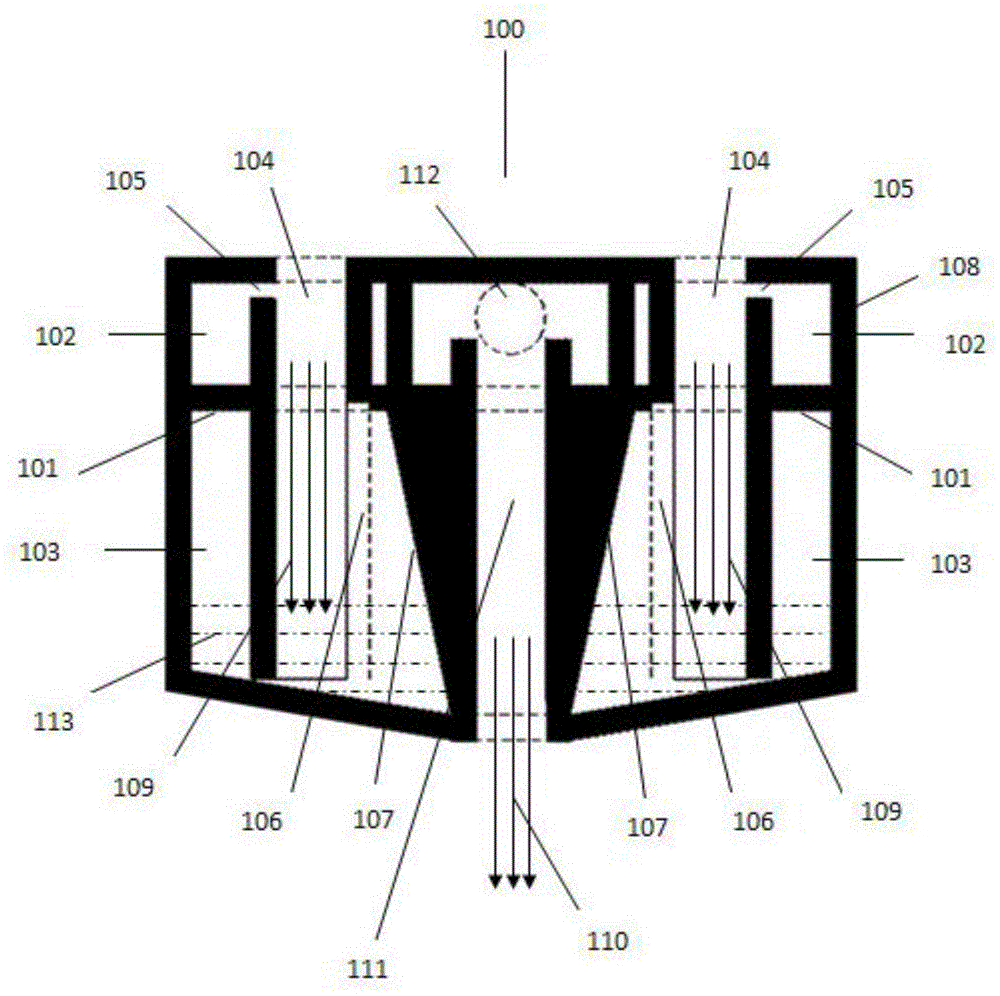

[0025] The reactor 100 for vapor phase epitaxy provided by the present invention (such as figure 2 , image 3 , Figure 4 (shown) includes: a baffle 101, an air inlet pipe 104, an inverted trapezoidal circular platform 107, a first air outlet 201, a second air outlet 112, a metal-containing precursor output pipe 111, and a reactor outer wall 108;

[0026] The baffle 101 divides the reactor into an upper space 102 and a lower space 103; two circular first air outlets 201 are arranged symmetrically on the baffle 101; the halide gas or halogen gas reacts with the metal source to generate a metal-containing precursor Objects 110 flow into the upper space 102 through the air outlet 201; two air intake pipes 104 extend from the upper space 102 to the bottom of the lower space 103. The size of the inner diameter of the air inlet pipe 104 can be determined according to the requirements of the process; the air inlet pipe 104 is connected with an external gas source, and the metal so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com