Catalyst filling method for decomposing hydrogen sulfide, and method for decomposing hydrogen sulfide

A catalyst, hydrogen sulfide technology, applied in separation methods, chemical instruments and methods, sulfur compounds, etc., can solve the problems of unstable hydrogen sulfide conversion rate, low hydrogen sulfide conversion rate, etc., achieving simple operation, low preparation cost, high The effect of hydrogen sulfide conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

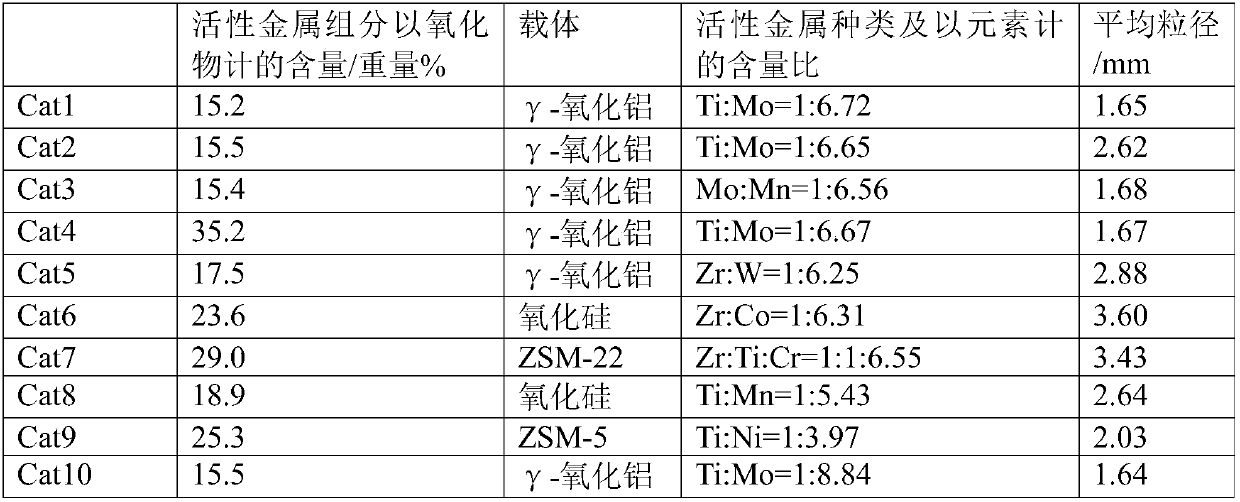

[0029] Regarding the specific implementation of the decomposition catalyst A, preferably, in the decomposition catalyst A, the active metal component is a mixture of the first component and the second component, and the first component is Ti, the second component is selected from at least one of V, Cr, Mo, W, Mn, Fe, Co, Ni, Pd, Pt, Cu, Ag, Zn and Cd.

[0030] More preferably, in the decomposition catalyst A, the second component is at least one selected from Mo, W, Mn, Co, Ni and Cr.

[0031]Preferably, in the decomposition catalyst A, in the mixture containing the first component and the second component, the content of the first component in terms of elements is 7 to 35% by weight, and the The content of the second component in terms of elements is 65 to 93% by weight; more preferably, in the decomposition catalyst A, in the mixture containing the first component and the second component, the second component The content of one component in terms of elements is 12-30% by w...

Embodiment 1

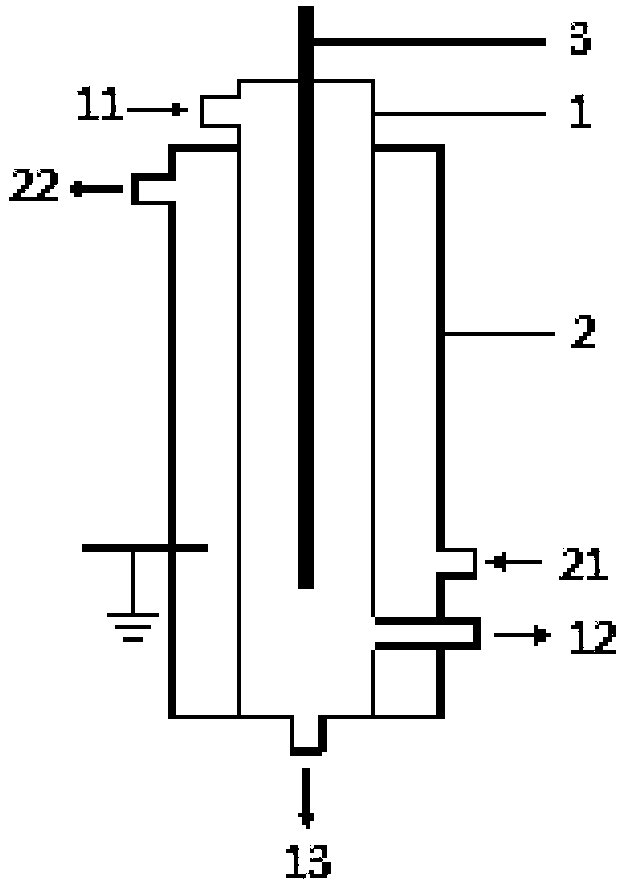

[0048] Example uses figure 1 The shown low-temperature plasma reactor carries out the decomposition reaction of hydrogen sulfide, specifically, figure 1 The structure of the low temperature plasma reactor shown is:

[0049] The reactor includes:

[0050] An inner cylinder 1, the inner cylinder is respectively provided with a reactor inlet 11, a gas product outlet 12 and a liquid product outlet 13, wherein all side walls of the inner cylinder are formed by a barrier medium, and the material forming the barrier medium It is hard glass, and in each test, a total of 200mL of the aforementioned catalysts are filled in the inner cylinder of the reactor, and the loading types of the catalysts are as shown in Table 2;

[0051] An outer cylinder 2, the outer cylinder is nested outside the inner cylinder, and the outer cylinder is respectively provided with a heat transfer medium inlet 21 and a heat transfer medium outlet 22;

Embodiment 2

[0065] This embodiment is carried out using a method similar to that of embodiment 1, except that the discharge conditions in this embodiment are: voltage 17.9kV, frequency 7.8kHz, current 0.75A.

[0066] And the conditions of the decomposition reaction are as follows: the reaction temperature is 65° C., the reaction pressure is 0.06 MPa, and the average residence time of the reactants in the low-temperature plasma reactor is 17.5 s.

[0067] All the other are the same as in Example 1.

[0068] The results of this example are listed in Table 3.

[0069] table 3

[0070]

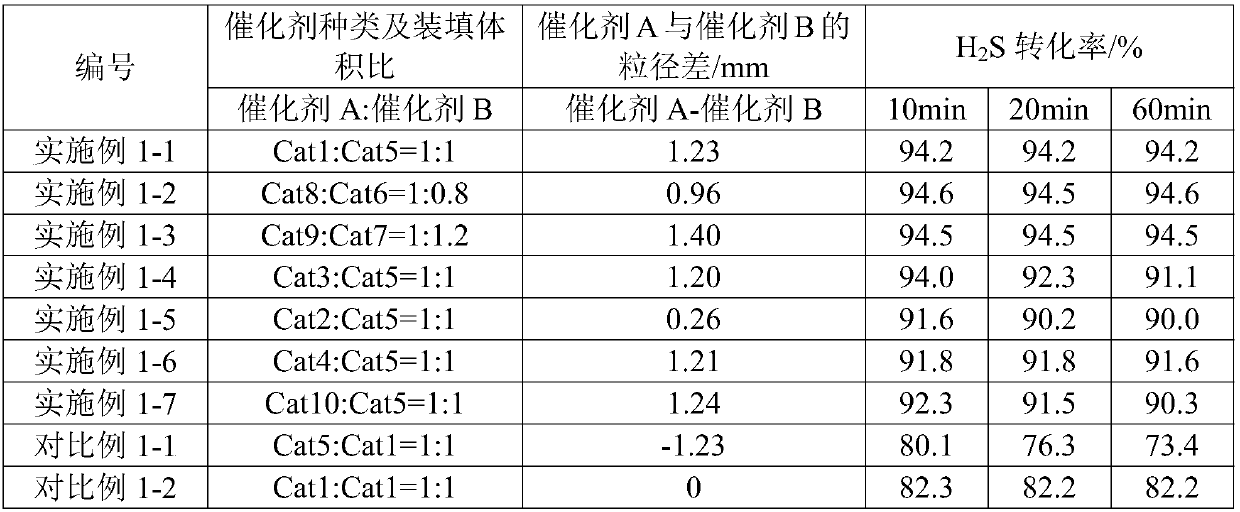

[0071] It can be seen from the results in Table 2 and Table 3 that when the catalyst for decomposing hydrogen sulfide provided by the present invention is used in the decomposition reaction of hydrogen sulfide, the conversion rate of hydrogen sulfide is significantly improved.

[0072] Moreover, the catalyst for decomposing hydrogen sulfide provided by the present invention can maintain the conversion ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com