Oxidation method for tert-butyl alcohol

A technology of tert-butanol and oxidant, which is applied in chemical instruments and methods, preparation of peroxygen compounds, chemical recovery, etc., can solve the problem of oxidant conversion rate, oxidant effective utilization rate, target oxidation product selectivity reduction, catalyst activity and selectivity fluctuation. It is suitable for large-scale application, stabilizes the oxidant conversion rate, and reduces the difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

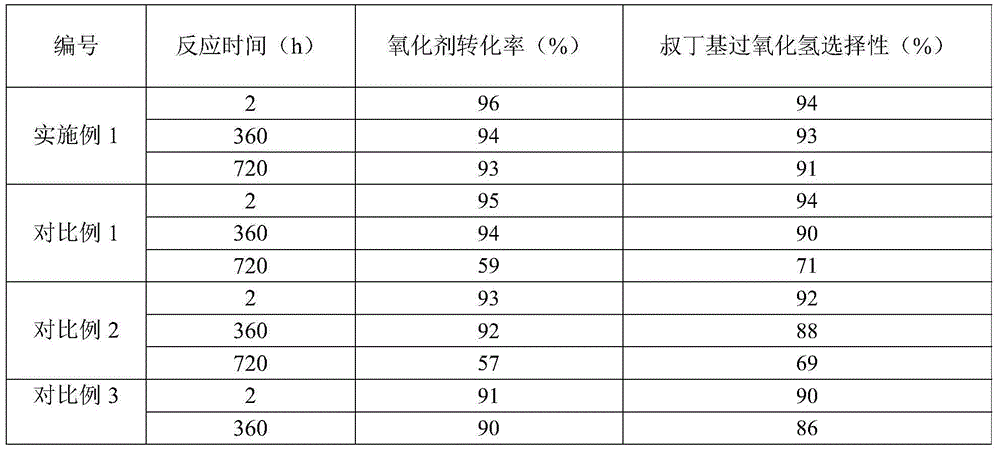

[0073] The reaction is carried out in two miniature fixed-bed reactors connected in series, wherein each reactor is filled with a catalyst bed with a circular cross-section and an equal diameter. Based on the flow direction of the liquid material, the first upstream The ratio of the inner diameter of the first catalyst bed in the first reactor to the inner diameter of the second catalyst bed in the downstream second reactor is 2:1, and the first catalyst bed is filled with a hollow titanium-silicon molecular sieve ( A spherical catalyst with a volume average particle size of 500 μm and a catalyst density of 0.70 g / cm 3 ), the second catalyst bed is filled with titanium-silicon molecular sieve TS-1 (a spherical catalyst with a volume average particle diameter of 500 μm and a density of 0.76 g / cm 3 ), the weight ratio of hollow titanium-silicon molecular sieve to titanium-silicon molecular sieve TS-1 is 2:1.

[0074] tert-butanol, hydrogen peroxide (provided in the form of 30% ...

Embodiment 2

[0088] Adopt the method identical with embodiment 1 to oxidize tert-butanol, difference is, the molding titanium-silicon molecular sieve TS-1 in the second catalyst bed uses the same amount of molding titanium-silicon molecular sieve Ti-MCM-41 (volume average particle diameter is 500μm spherical catalyst with a density of 0.61g / cm 3 )replace.

[0089] The results are listed in Table 1 for reaction times of 2 hours, 360 hours and 720 hours.

Embodiment 3

[0091] Adopt the same method oxidation tert-butanol as embodiment 1, difference is, the molding titanium-silicon molecular sieve TS-1 in the second catalyst bed layer in the second reactor uses an equivalent amount of molding titanium-silicon molecular sieve Ti-Beta ( A spherical catalyst with a volume average particle size of 500 μm and a density of 0.77 g / cm 3 )replace.

[0092] The results are listed in Table 1 for reaction times of 2 hours, 360 hours and 720 hours.

[0093] Table 1

[0094]

[0095]

[0096] Comparing the data of Example 1 with Comparative Examples 1-3, it can be seen that when the hollow titanium-silicon molecular sieve is used in combination with the titanium-silicon molecular sieve, and the hollow titanium-silicon molecular sieve is located upstream of the titanium-silicon molecular sieve, the liquid mixture flows through the hollow The superficial velocity of the titanium-silicon molecular sieve is lower than the superficial velocity of the tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com