Low-carbon olefin catalyst made through dehydrogenation of low-carbon alkane and use method of low-carbon olefin catalyst

A technology of low-carbon olefins and low-carbon alkanes, applied in the field of catalysts, can solve problems such as low activity and decreased selectivity, and achieve uniform distribution and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

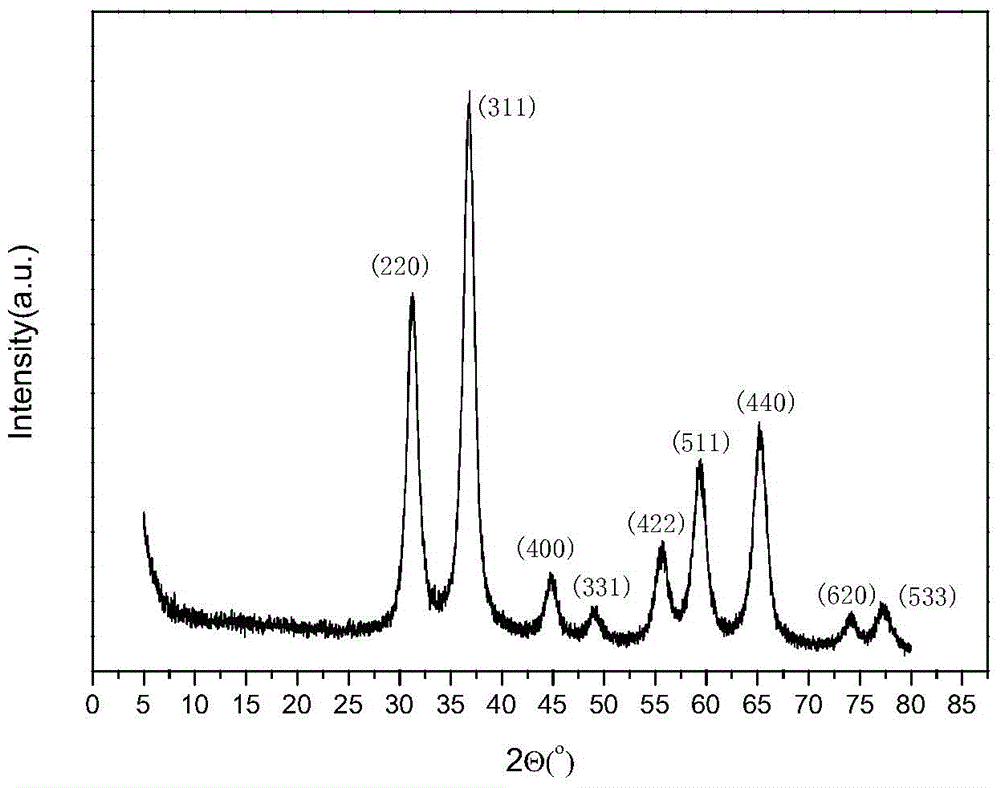

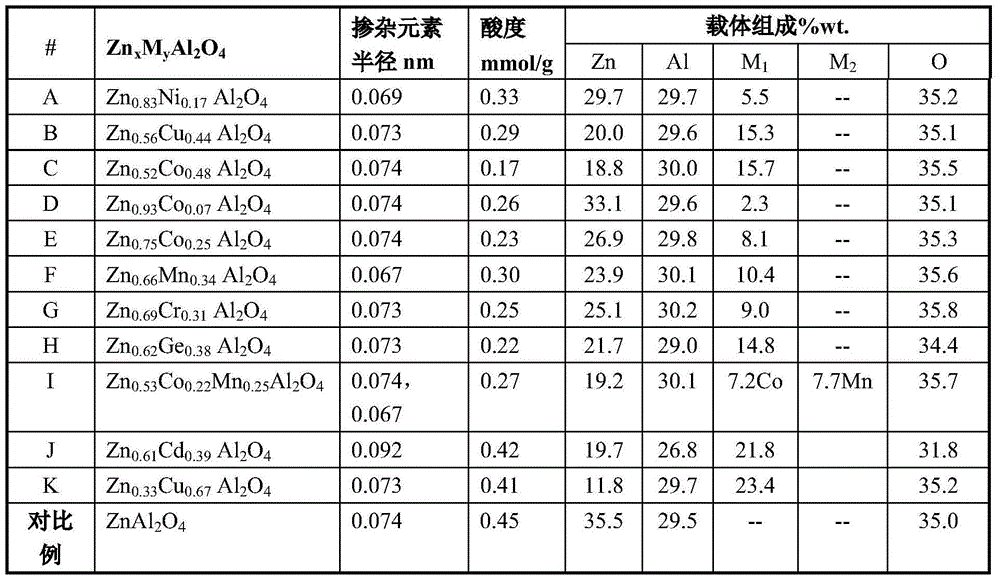

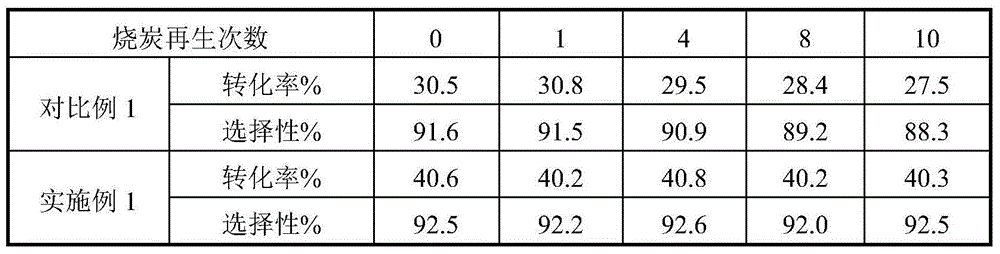

[0034] Get 754.56g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 245.81g zinc nitrate (Zn(NO3 ) 2 6H 2 O), 48.44g nickel nitrate (Ni(NO 3 ) 2 6H 2 O) be dissolved in 2000ml of deionized water; at 25°C, under vigorous stirring, slowly add 15% ammonia by weight dropwise to the mixed aqueous solution to form a precipitate, control the pH value to 6.5, and filter the precipitate at room temperature overnight , washed, dried at 110°C, crushed, sieved, and calcined at 720°C for 18 hours to obtain a composite zinc aluminate carrier. XRD characterization (see figure 1 ) shows that the carrier has a typical spinel structure with a pore volume of 0.34cm 3 / g, specific surface area 86m 2 / g. The carrier composition and acidity are shown in Table 1.

[0035] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2 O, 0.16g) and an aqueous ...

Embodiment 2

[0038] Get 755.30g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 167.51g zinc nitrate (Zn(NO 3 ) 2 6H 2 O), 108.10g copper nitrate (Cu(NO 3 ) 2 6H 2 O) be dissolved in 2000ml deionized water; at 20 DEG C, under vigorous stirring, the ammoniacal liquor of 16%wt. is slowly added dropwise in this mixed aqueous solution, forms precipitation, and the pH value of control is 7.5, and after precipitation overnight at room temperature, Filter, wash, dry at 100°C, pulverize, sieve, and bake at 700°C for 10 hours to obtain a composite zinc aluminate carrier. XRD characterization shows that the carrier has a typical spinel structure with a pore volume of 0.32cm 3 / g, specific surface area 80m 2 / g. The carrier composition and acidity are shown in Table 1.

[0039] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2 O, 0.16g) and an aq...

Embodiment 3

[0042] Get 753.33g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 154.65g zinc nitrate (Zn(NO 3 ) 2 6H 2 O), 139.69g cobalt nitrate (Co(NO 3 ) 2 6H 2 O) be dissolved in 2000ml deionized water; at 20 DEG C, under vigorous stirring, the ammoniacal liquor of 20%wt. is slowly added dropwise in this mixed aqueous solution, forms precipitation, and the pH value of control is 7.4, and after precipitation overnight at room temperature, Filter, wash, dry at 100°C, pulverize, sieve, and bake at 750°C for 5 hours to obtain a composite zinc aluminate carrier. XRD characterization shows that the carrier has a typical spinel structure with a pore volume of 0.35cm 3 / g, specific surface area 51m 2 / g. The carrier composition and acidity are shown in Table 1.

[0043] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2 O, 0.16g) and an aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com