Hydrodechlorination palladium-carbon catalyst and preparation method

A palladium carbon catalyst, hydrodechlorination technology, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of short life, easy loss of active components, poor selectivity, etc., to achieve Long life, stable selectivity, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

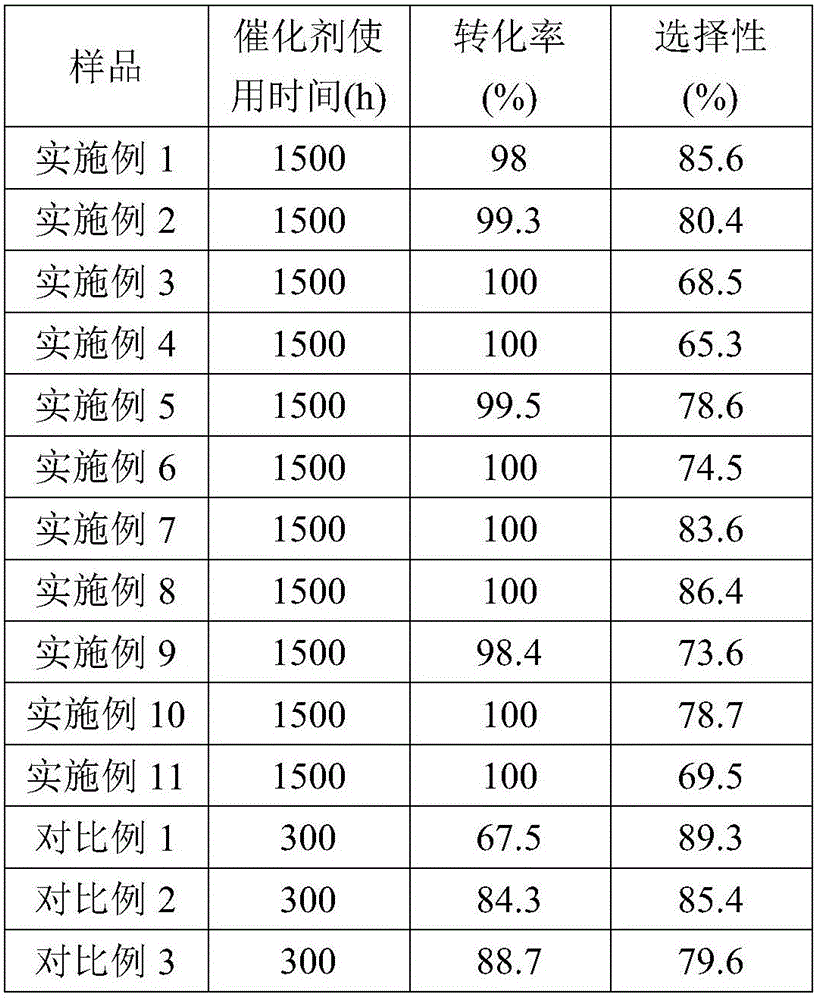

Examples

Embodiment 1

[0030] The mass percent composition of the palladium carbon catalyst prepared in this example is: Pd content 0.5%, Re content 0.5%, Cl content 0.5%, and the rest is activated carbon carrier. Among them, Pd is the active component, Re and Cl are additives, and the specific surface area of the carrier activated carbon is 800m 2 / g. The preparation method of this catalyst is as follows:

[0031] (1) Under the water bath condition of 60 ℃, the mass concentration of activated carbon is 10% HNO 3 After treatment, it was washed with desalted water until neutral, and then dried at 110°C for 10 hours for use.

[0032] (2) Add the activated carbon obtained in step (1) to the perrhenic acid aqueous solution, immerse it in a water bath at 30°C for 5h, then dry it at 110°C for 2h, and then calcinate it under a nitrogen atmosphere at 400°C for 4h to obtain the supported Rhenium activated carbon.

[0033] (3) Configure palladium chloride aqueous solution, and adjust the pH of the palla...

Embodiment 2

[0035] The palladium-carbon catalyst prepared in this example has a mass percent composition of 0.8% Pd, 1.0% Re, and 1.5% Cl, and the rest is an activated carbon carrier. Among them, Pd is the active component, Re and Cl are additives, and the specific surface area of the carrier activated carbon is 900m 2 / g. The preparation method of this catalyst is as follows:

[0036] (1) Under the water bath condition of 70 ℃, the mass concentration of activated carbon is 20% HNO 3 Treated in neutral for 12h, washed with desalted water to neutral after treatment, and then dried at 110°C for 10h for use.

[0037] (2) The activated carbon obtained in the step (1) is added to the ammonium perrhenate aqueous solution, immersed in an equal volume in a water bath at 40°C for 8h, then dried at 110°C for 3h, and then calcined for 5h under a nitrogen atmosphere at 500°C to obtain Activated carbon loaded with rhenium.

[0038] (3) Configure palladium chloride aqueous solution, and adjust th...

Embodiment 3

[0040]The mass percent composition of the palladium carbon catalyst prepared in this example is that the Pd content is 1.5%, the Re content is 2%, and the Cl content is 3%, and the carrier is activated carbon. Among them, Pd is the active component, Re and Cl are additives, and the specific surface of the carrier activated carbon is 1000m 2 / g. The preparation method of this catalyst is as follows:

[0041] (1) Under the water bath condition of 80 ℃, the mass concentration of activated carbon is 30% HNO 3 Treated in neutral for 15h, washed with desalted water to neutral after treatment, and then dried at 110°C for 10h for use.

[0042] (2) The activated carbon obtained in step (1) is added to an aqueous solution of potassium perrhenate, immersed in an equal volume in a water bath at 60°C for 10h, then dried at 110°C for 4h, and then calcined for 6h under a nitrogen atmosphere at 600°C to obtain Activated carbon loaded with rhenium.

[0043] (3) Configure palladium chloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com