Low-carbon olefin platinum catalyst made through dehydrogenation of low-carbon alkane

A technology for low-carbon olefins and low-carbon alkanes, applied in the field of catalysts, can solve the problems of low catalyst activity and decreased selectivity, and achieve the effects of uniform distribution and high dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

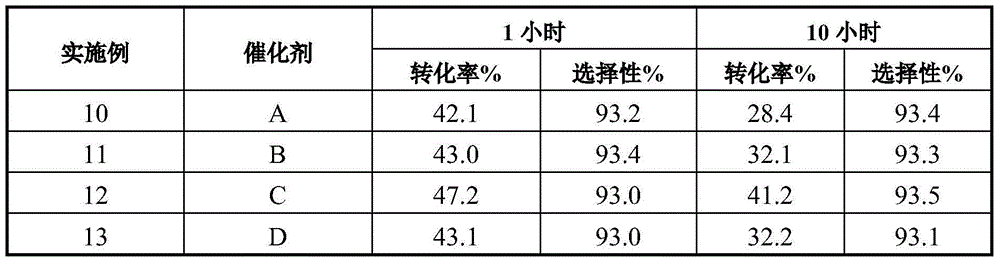

Examples

Embodiment 1

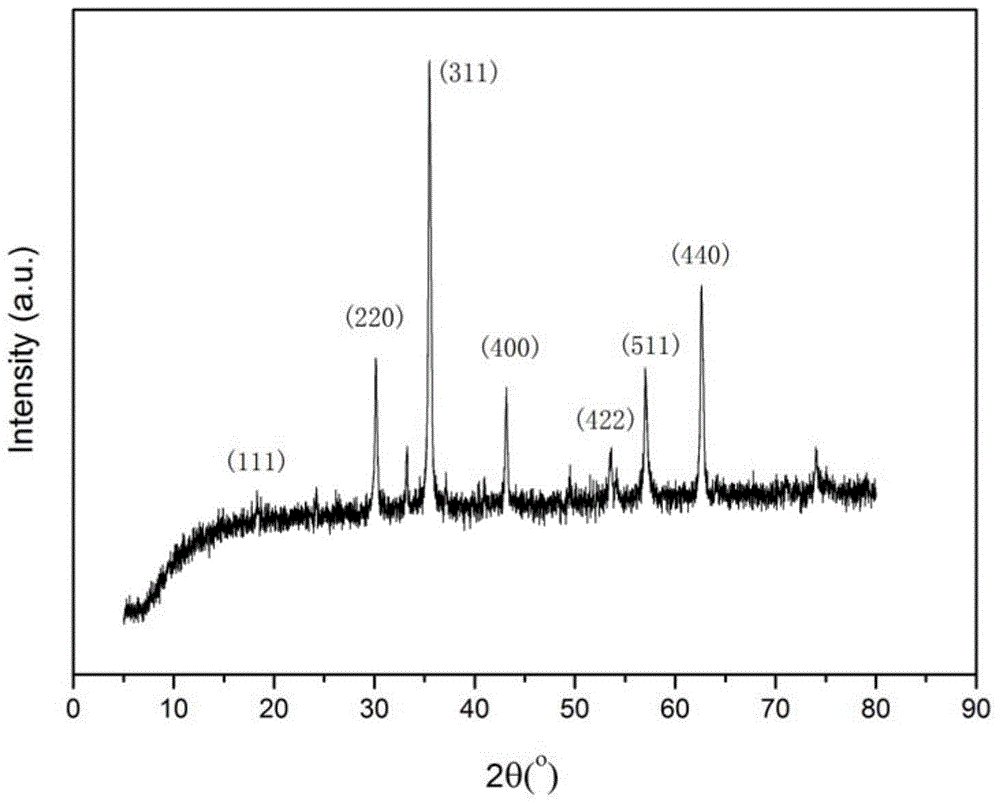

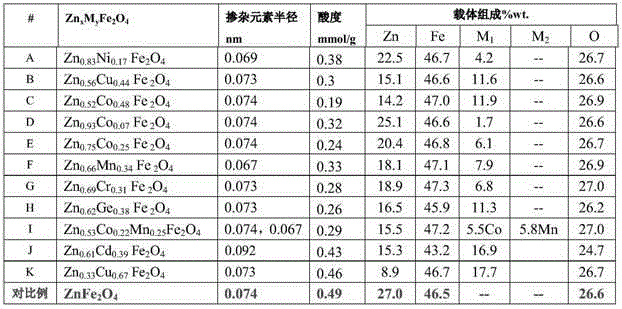

[0032] Get 807.14g ferric nitrate (Fe(NO 3 ) 3 9H 2 O), 247.62g zinc nitrate (Zn(NO 3 ) 2 6H 2 O), 48.29g nickel nitrate (Ni(NO 3 ) 2 6H2 O) Dissolve in 2000ml of deionized water; at 25°C, under vigorous stirring, slowly add 5% wt. ammonia water dropwise to the mixed aqueous solution, control the pH value to be about 7.5, and form a precipitate, leave the precipitate overnight at room temperature, filter , washed, dried at 120°C, crushed, sieved, and calcined at 700°C for 16 hours to obtain a composite zinc ferrite carrier. XRD characterization shows that the carrier has a spinel structure with a pore volume of 0.29cm 3 / g, specific surface area 76m 2 / g. The carrier composition and acidity are shown in Table 1.

[0033] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2 O, 0.16g) and an aqueous solution (10ml) of s...

Embodiment 2

[0036] Get 809.6g ferric nitrate (Fe(NO 3 ) 3 9H 2 O), 167.51g zinc nitrate (Zn(NO 3 ) 2 6H 2 O), 107.22g copper nitrate (Cu(NO 3 ) 2 3H 2 O) be dissolved in 2000ml deionized water; at 25 DEG C, under vigorous stirring, slowly add 10% ammoniacal liquor dropwise in this mixed aqueous solution, form precipitation, control pH value to be about 7.8, will precipitate at room temperature overnight, filter, Washing, drying at 100°C, crushing, sieving, and calcining at 750°C for 8 hours to obtain a composite zinc ferrite carrier. XRD characterization shows that the carrier has a spinel structure with a pore volume of 0.39cm 3 / g, specific surface area 86m 2 / g. The carrier composition and acidity are shown in Table 1.

[0037] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2 O, 0.16g) and an aqueous solution (10ml) of so...

Embodiment 3

[0040] Get 808.64g ferric nitrate (Fe(NO 3 ) 3 9H 2 O), 154.65g zinc nitrate (Zn(NO 3 ) 2 6H 2 O), 139.32g cobalt nitrate (Co(NO 3 ) 2 6H 2 O) be dissolved in 2000ml deionized water; at 26 DEG C, under vigorous stirring, 20% ammoniacal liquor is slowly added dropwise in this mixed aqueous solution, forms precipitation, controls pH value to be about 8.8, with precipitation overnight at room temperature, filter, Washing, drying at 100°C, crushing, sieving, and roasting at 750°C for 5 hours to obtain a composite zinc ferrite carrier. XRD characterization shows that the carrier has a spinel structure with a pore volume of 0.35cm 3 / g, specific surface area 55m 2 / g. The carrier composition and acidity are shown in Table 1.

[0041] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2 O, 0.16g) and an aqueous solution (10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com