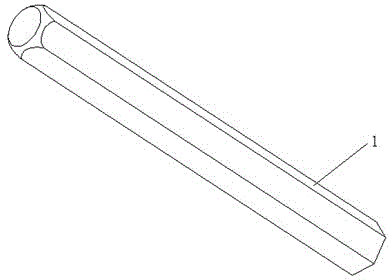

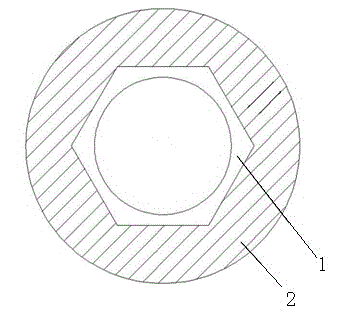

Screw and powder injection molding method thereof

A technology of injection molding and powder, which is applied in the direction of engine components, other manufacturing equipment/tools, turbines, etc., can solve the problems of high processing costs, tool wear, poor finish, etc., and achieve simplified processing procedures, reduced steps, and low porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

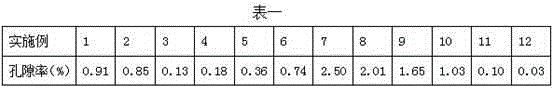

Examples

Embodiment 1

[0058] (1) Mix 100 parts of carbonyl iron powder with a particle size of 20 μm and 200 parts of binder to form a homogeneous feed. The binder is composed of 50 parts of paraffin wax and 50 parts of low-density polyethylene.

[0059] (2) An insert is preset inside the mold of the injection molding machine, and the mold temperature is 30°C; the mixed feed is put into the injection molding machine for injection molding to obtain an injection molded blank; the injection temperature is 150°C, and the injection pressure is 5Mpa.

[0060] (3) Put the injection molding blank in the furnace, heat at 200°C for 1 hour, and dewax;

[0061] (4) Under the protective atmosphere of hydrogen, pre-fire the dewaxed injection molded billet. The pre-fired temperature is 200°C for 180min, 300°C for 120min, and 600°C for 100min to remove the remaining bond in the injection molded billet. agent components; then raise the temperature to 1000°C, keep it warm for 2 hours, and pre-fire to obtain a calcin...

Embodiment 2

[0064] (1) Mix 100 parts of carbonyl nickel powder with a particle size of 10 μm and 150 parts of binder to form a homogeneous feed. The binder consists of 20 parts of polypropylene, 10 parts of paraffin wax, 68 parts of carnauba wax, 1 part stearic acid.

[0065] (2) An insert is preset inside the mold of the injection molding machine, and the mold temperature is 50°C; put the mixed feed into the injection molding machine for injection molding to obtain an injection molded blank; the injection temperature is 180°C, and the injection pressure is 15Mpa.

[0066] (3) Put the injection molding blank in the furnace, heat it to 170°C, keep it for 1 hour, and dewax it;

[0067] (4) Under an argon protective atmosphere, pre-burn the dewaxed injection molded billets at 250°C for 60 minutes; (2) 400°C for 80 minutes; (3) 700°C for 100 minutes to remove the injection molding The remainder of the binder component in the billet; then the temperature is raised to 900°C, kept for 2 hours, ...

Embodiment 3

[0070] (1) Mix 100 parts of carbonyl tungsten powder powder with a particle size of 1 μm and 100 parts of binder to form a homogeneous feed. The binder consists of 10 parts of ethylene-vinyl acetate copolymer, 79 parts of paraffin, and 10 parts of Brazilian Palm wax, 1 part stearic acid.

[0071] (2) An insert is preset inside the mold of the injection molding machine, and the mold temperature is 80°C; put the mixed feed into the injection molding machine for injection molding to obtain an injection molded blank; the injection temperature is 200°C, and the injection pressure is 35Mpa.

[0072] (3) Put the injection molding blank in the furnace, heat it to 170°C, keep it for 10 hours, and dewax it;

[0073] (4) Under the protective atmosphere of argon, pre-fire the dewaxed injection molded billet. The pre-fired temperature is 300 ° C for 30 minutes; 500 ° C for 60 min; Binder components;

[0074] (5) Under an argon protective atmosphere, sinter the pre-sintered billet at 2200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com