Method and device for deodorizing light oil product through dissolved oxygen

A technology of light oil and dissolved oxygen, which is applied in the direction of refining with oxygen-containing compounds, can solve the problems of hindering deodorization reaction, product yield reduction, oil color deepening, etc., to slow down oxidation side reactions, reduce processing losses, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

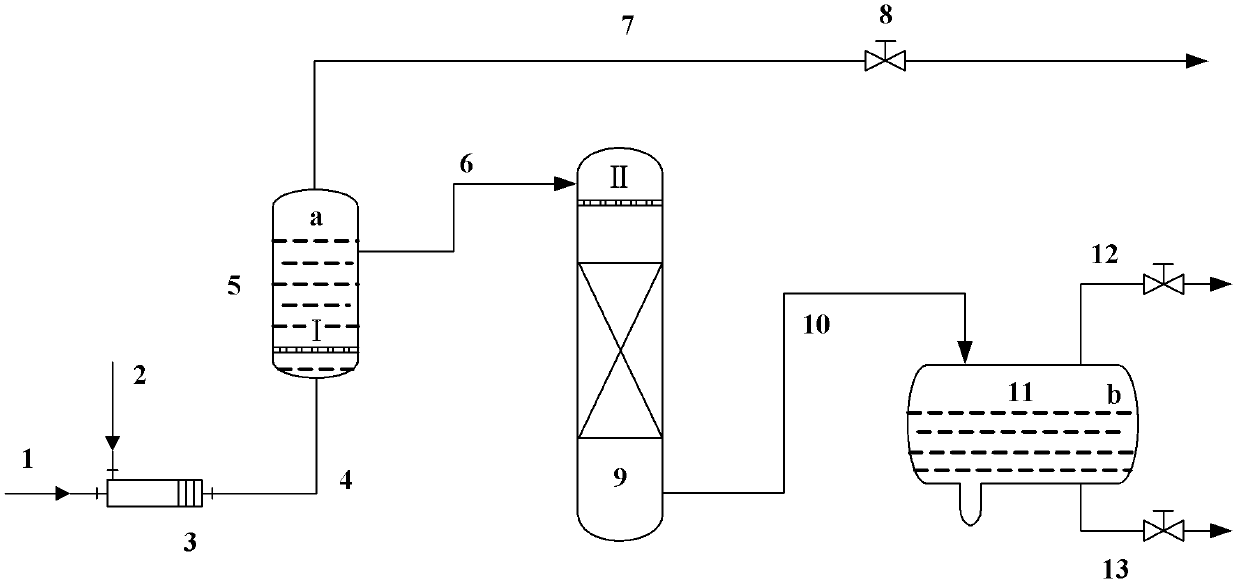

[0037] Take 10 mL of 20-30 mesh copper molecular sieve catalyst (trade name RCu-01, provided by Sinopec Catalyst Branch) and fill it in the reactor. After heating to the reaction temperature, inject the light oil to be deodorized together with air into the oxygen-dissolving container , and then injected into a fixed bed reactor for deodorization reaction. The light oil product to be deodorized is an aviation jet fuel A (density 0.7842g / cm 3 , the distillation range is 142-224°C, and its mercaptan sulfur content is 75μg / g. The deodorization reaction conditions are: temperature 90°C, pressure 0.5MPa, volume liquid hourly space velocity 2.0h -1 , the tail gas passes through the back pressure fine-tuning valve and then enters the precision wet gas flow meter for reading, so as to maintain the same pressure in the entire reaction system, that is, to maintain the same pressure in the reactor and the post-reaction product collector. The air flow rate is 20mL / h.

Embodiment 2

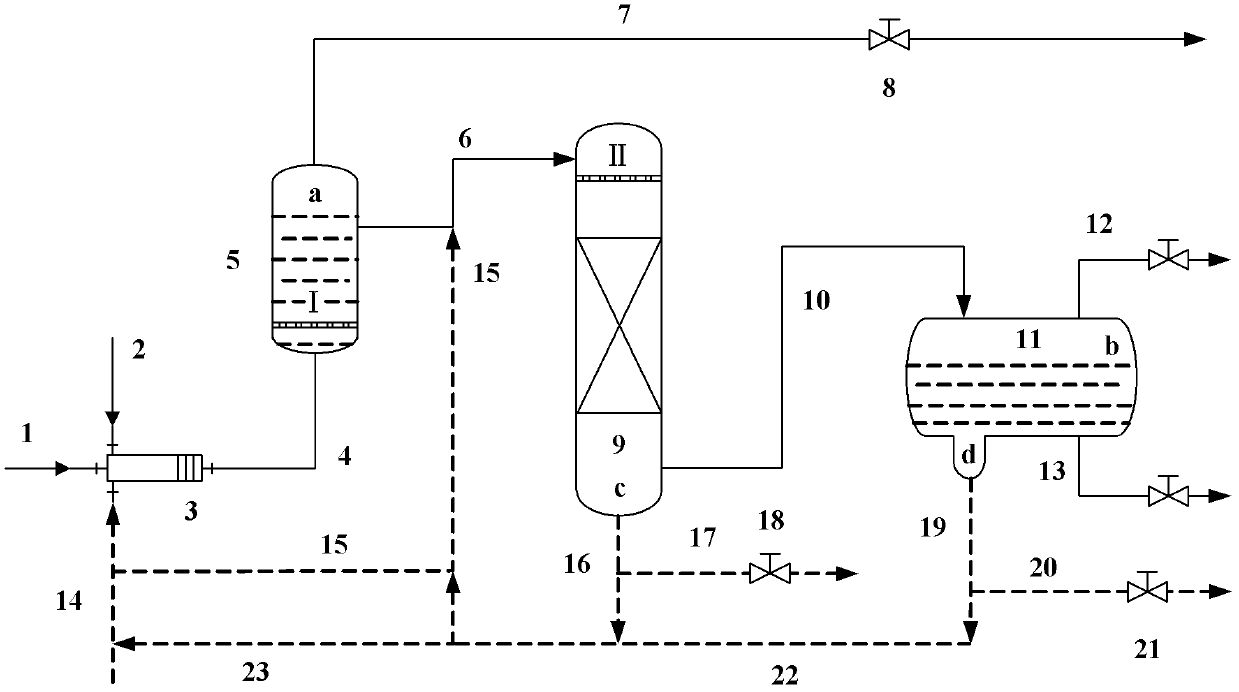

[0045] according to figure 2 As shown in the diagram of the device, a simulated micro-reflector device was assembled in the laboratory. Take 10mL of 20-30 mesh metal phthalocyanine catalyst (activated carbon supported sulfonated cobalt phthalocyanine, the mass fraction of sulfonated cobalt phthalocyanine is 1%) and put it in the reactor. After heating to the reaction temperature, put the deodorized light oil Together with the air, it is passed into the deodorization device for deodorization reaction. The light oil product to be deodorized is certain catalytic cracking gasoline (density 0.7332g / cm 3 , the distillation range is 33~196℃, and its mercaptan sulfur content is 35μg / g). The deodorization reaction conditions are: temperature 40°C, pressure 0.5MPa, volume liquid hourly space velocity 2.0h -1 , the tail gas passes through the back pressure fine-tuning valve and then enters the precision wet gas flow meter for reading, so as to maintain the same pressure in the entire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com