Production method of valve steel 53Cr21Mn9Ni4N polishing bar

A production method and technology for polishing rods, applied in the field of iron and steel smelting, can solve the problems of dimensional tolerance, low yield of valve steel, low yield of finished products, etc., so as to reduce processing loss and energy consumption, improve dimensional accuracy control, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

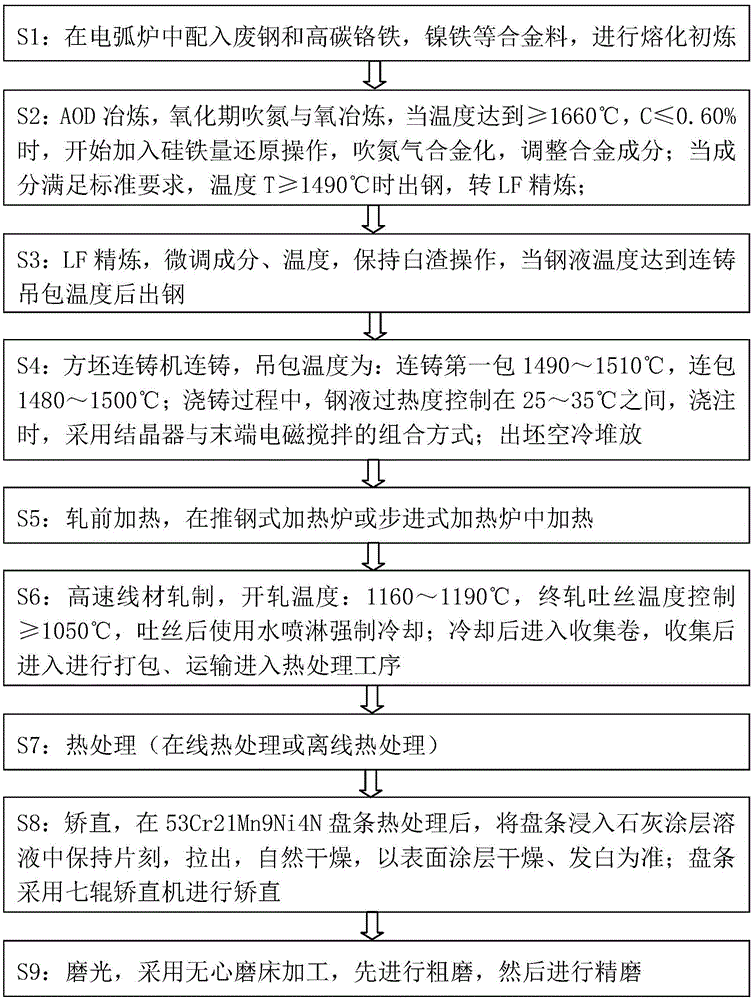

Method used

Image

Examples

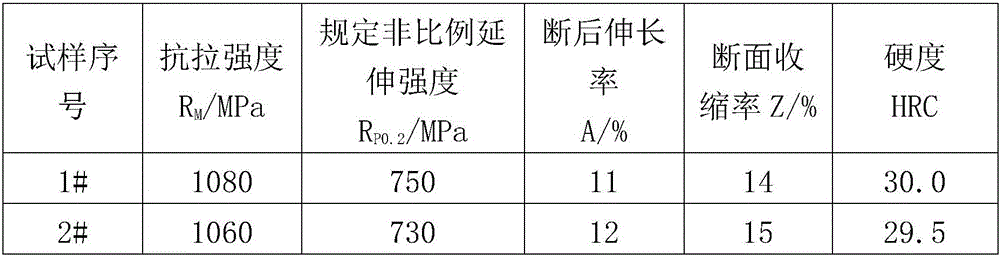

Embodiment 1

[0029] The wire rod specification for producing a furnace of 53Cr21Mn9Ni4N is φ6.7mm. Its production process is as follows: 25t electric furnace smelting→25tAOD smelting→25tLF refining→two-strand 150×150mm section billet continuous casting→heating→high-speed wire rolling→off-line heat treatment→straightening→polishing→qualified inspection→finished product into library. The specific production steps are as follows:

[0030] Step 1: Add scrap steel and high-carbon ferrochromium, ferronickel and other alloy materials into the electric arc furnace for primary melting. Tapping temperature is 1620°C, P: 0.030%;

[0031] The second step: AOD smelting, nitrogen blowing and oxygen smelting during the oxidation period. When the temperature reaches ≥1660°C and C≤0.60%, start to add ferrosilicon to reduce the operation, blow nitrogen for alloying, and adjust the alloy. When the composition meets the standard requirements, the steel is tapped when the temperature T≥1490°C, and then tran...

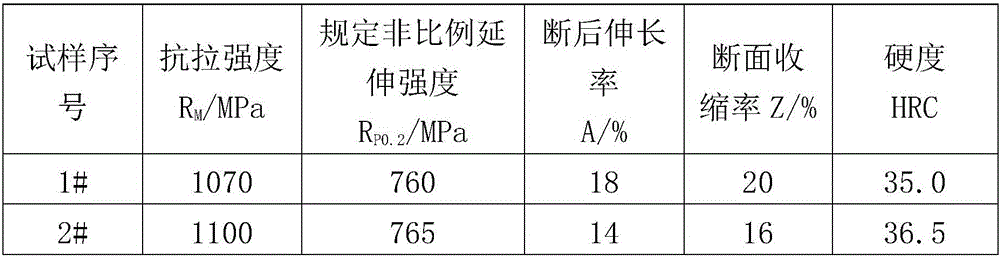

Embodiment 2

[0043] The wire rod specification for producing a furnace of 53Cr21Mn9Ni4N is φ6.5mm. Its production process is as follows: EBT electric furnace smelting→AOD smelting→LF refining→two-strand 150×150mm billet continuous casting→heating→high-speed wire rolling→on-line heat treatment→straightening→polishing→qualified inspection→finished product storage. The specific production steps are:

[0044] Step 1: Add scrap steel and high-carbon ferrochromium, ferronickel and other alloy materials into the electric arc furnace for primary melting. Tapping temperature is 1610°C, P: 0.036%;

[0045] The second step: AOD smelting, nitrogen blowing and oxygen smelting during the oxidation period. When the temperature reaches ≥1660°C and C≤0.60%, start to add ferrosilicon to reduce the operation, blow nitrogen for alloying, and adjust the alloy. When the composition meets the standard requirements and the temperature T≥1490℃, the steel is tapped and transferred to LF refining;

[0046] The th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com