Asynchronous punching process for coated conductive foam

A conductive foam and coated technology, applied in the field of coated conductive foam asynchronous punching process, can solve the problems of low efficiency, accelerated update cycle, insufficient market supply, etc., to improve production assembly efficiency and reduce process loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

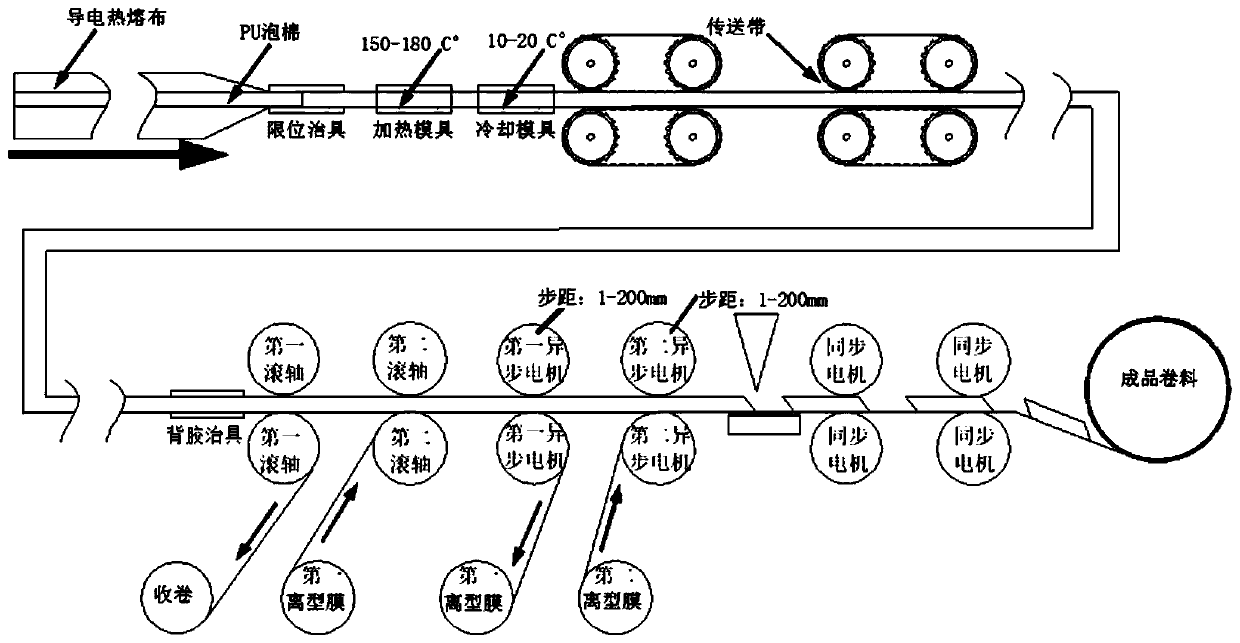

[0019] An asynchronous punching process of coated conductive foam, comprising the following steps:

[0020] S1, molding, the conductive hot-melt cloth and PU foam are sequentially inserted into the limit fixture, heating mold and cooling mold of the conductive foam molding machine; the temperature of the heating mold is set to 150 ° C, and the set temperature of the cooling mold is 10°C; Pull out the wrapped conductive foam through the conveyor belt;

[0021] S2. The conductive foam passes through the adhesive jig, the first roller drives the winding to remove the self-contained release paper, and the second roller drives the first release film to bond the conductive foam;

[0022] S3, the first asynchronous motor rewinds the first release film; the step distance of the first asynchronous motor is 1 mm;

[0023] S4. The second asynchronous motor drives the second release film to be laminated with the conductive foam, and the step distance of the second asynchronous motor is 1...

Embodiment 2

[0027] An asynchronous punching process of coated conductive foam, comprising the following steps:

[0028] S1, molding, the conductive hot-melt cloth and PU foam are sequentially inserted into the limit fixture, heating mold and cooling mold of the conductive foam molding machine; the temperature of the heating mold is set to 180 ° C, and the set temperature of the cooling mold is 20°C; Pull out the wrapped conductive foam through the conveyor belt;

[0029] S2. The conductive foam passes through the adhesive jig, the first roller drives the winding to remove the self-contained release paper, and the second roller drives the first release film to bond the conductive foam;

[0030] S3, the first asynchronous motor rewinds the first release film; the step distance of the first asynchronous motor is 200mm;

[0031] S4. The second asynchronous motor drives the second release film to be laminated with the conductive foam, and the step distance of the second asynchronous motor is ...

Embodiment 3

[0035] An asynchronous punching process of coated conductive foam, comprising the following steps:

[0036] S1, molding, the conductive hot-melt cloth and PU foam are sequentially inserted into the limit fixture, heating mold and cooling mold of the conductive foam molding machine; the temperature of the heating mold is set to 160 ° C, and the set temperature of the cooling mold is 15°C; Pull out the wrapped conductive foam through the conveyor belt;

[0037] S2. The conductive foam passes through the adhesive jig, the first roller drives the winding to remove the self-contained release paper, and the second roller drives the first release film to bond the conductive foam;

[0038] S3, the first asynchronous motor rewinds the first release film; the step distance of the first asynchronous motor is 100mm;

[0039] S4. The second asynchronous motor drives the second release film to be laminated with the conductive foam, and the step distance of the second asynchronous motor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com