Processing process of semi-steel cable outer conductor

A processing technology and outer conductor technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problem that semi-rigid cables cannot be continuously produced in large lengths, and achieve obvious price advantages, stable performance, and improved manufacturing processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

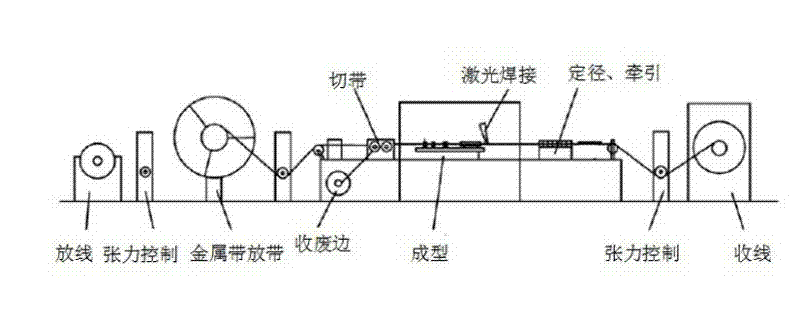

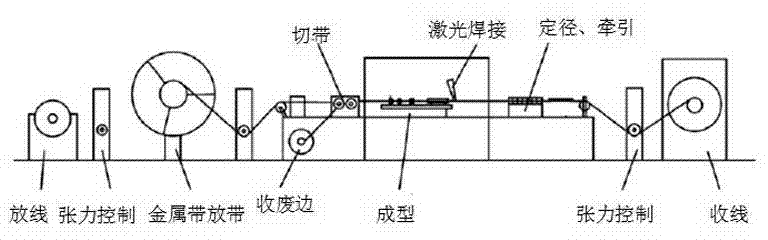

[0017] Taking the pure copper outer conductor semi-rigid RF cable RG402 as an example, the specific process steps are as follows, see figure 1 ,

[0018] S1: First, install the pushed and qualified Φ2.98mm core wire on the pay-off frame, and adjust the pay-off tension to 10N for stable control of production. The core wire includes an inner conductor and an insulating layer;

[0019] S2: Put the pure copper strip with a width of 12mm and a thickness of 0.2mm on the strip rack, adjust the tension of the strip to 15N, and trim the copper strip. Turn on the laser welding machine for welding debugging. During the debugging process, ensure that the copper strips are trimmed neatly, without flashes or burrs. The output power of the machine is controlled at 1.05 ~ 1.35KW, and the debugging production speed is controlled at about 10m / min;

[0020] S3: After welding and debugging, insert the Φ2.98mm core wire into the pure copper strip for cladding, forming, welding and sizing. Among ...

Embodiment 2

[0023] Taking tinned copper outer conductor semi-rigid RF cable RG402 as an example, the specific process steps are as follows, S1: First, install the pushed and inspected Φ2.98mm core wire on the pay-off frame, and adjust the pay-off tension to 20N for production stable control, the core wire includes an inner conductor and an insulating layer;

[0024] S2: Put the tinned copper strip with a width of 14mm and a thickness of 0.4mm on the tape rack, adjust the tension of the tape to 30N, and trim the tinned copper strip. After trimming, the tinned copper strip has a width of 12mm, and then passes through the speaker The mold is formed, and the laser welding machine is turned on for welding debugging. During the debugging process, it is ensured that the trimming of the tinned copper strip is neat, without flashes and burrs. For defects such as pinholes and perforations, the output power of the laser welding machine is controlled at 1.05-1.35KW, and the debugging production speed...

Embodiment 3

[0027] Taking the silver-plated copper outer conductor semi-rigid RF cable RG402 as an example, the specific process steps are as follows, S1: First, install the pushed and inspected Φ2.98mm core wire on the pay-off frame, and adjust the pay-off tension to 15N for production stable control, the core wire includes an inner conductor and an insulating layer;

[0028] S2: Put the silver-plated copper strip with a width of 13mm and a thickness of 0.3mm on the tape rack, adjust the tension of the tape to 23N, and trim the silver-plated copper strip. After trimming, the width of the silver-plated copper strip is 11.5mm, and then pass The speaker mold is formed, and the laser welding machine is turned on for welding debugging. During the debugging process, ensure that the trimming of the silver-plated copper strip is neat, without flashes and burrs. As well as defects such as pinholes and perforations, the output power of the laser welding machine is controlled at 1.05-1.35KW, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com