Method of dearsenic by parallel circulating continuous electric formation

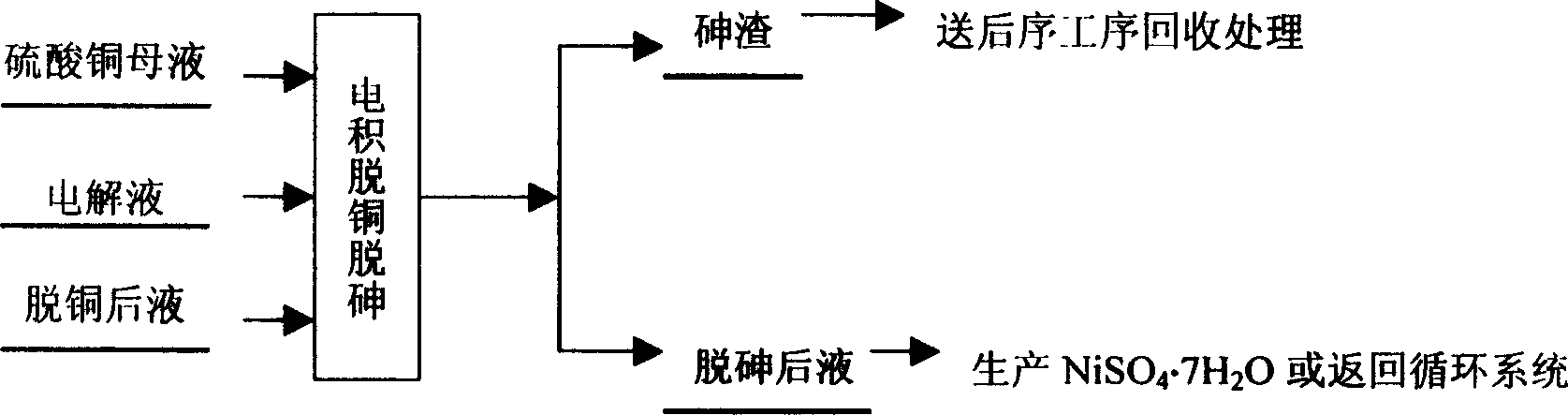

A technology of arsenic removal and electrowinning, which can be used in photography technology, instruments, photography auxiliary technology, etc., and can solve the problems of difficult control, large equipment investment, and high control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

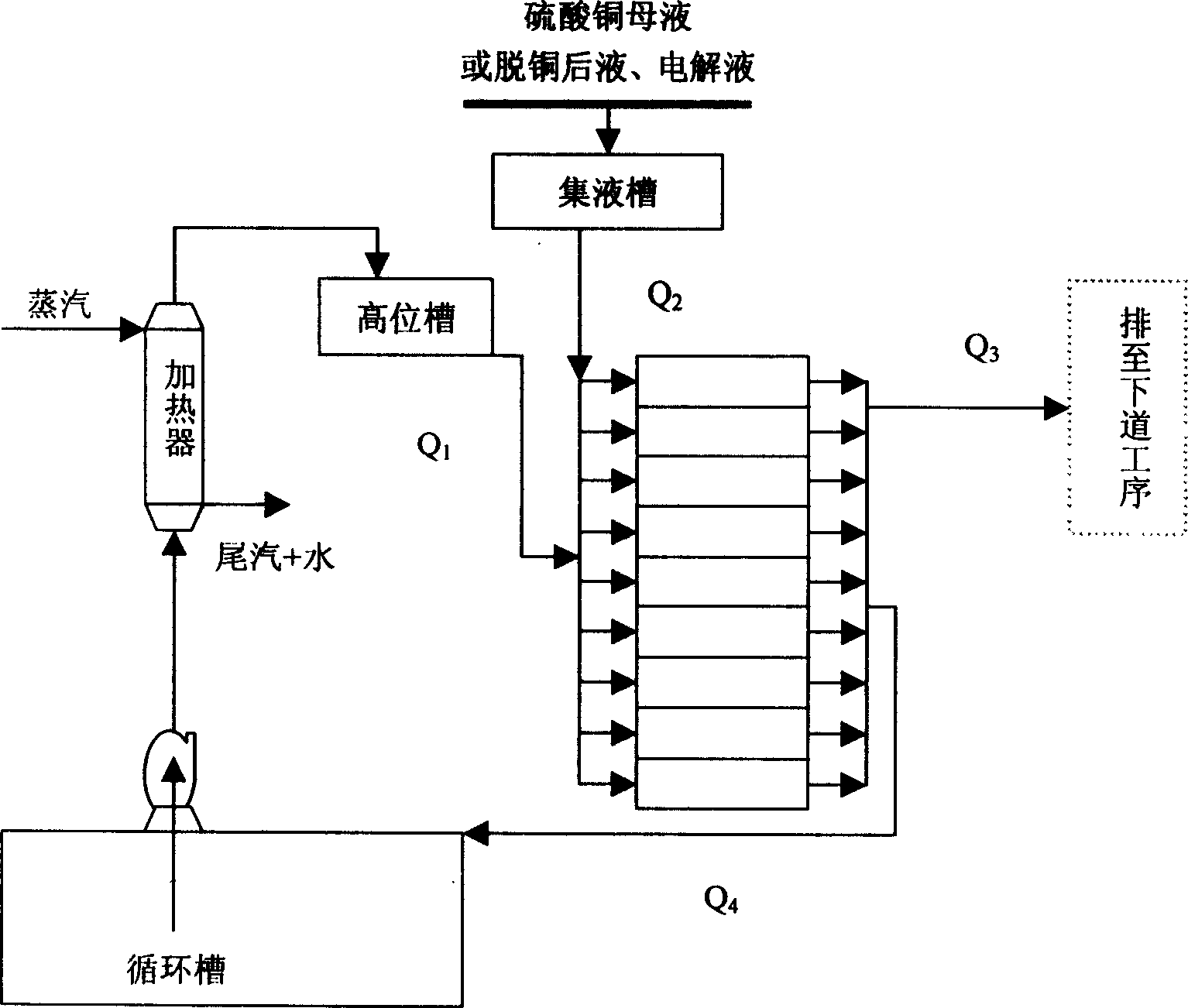

Method used

Image

Examples

Embodiment 1

[0036] Example 1: The supplement liquid contains: Cu=31.51g / L, As=19.94g / L, Cu:As=1.580:1. Supply fluid flow rate 4.2m 3 / h. The circulating fluid temperature is 63°C. There are 24 electrowinning arsenic removal tanks. Arsenic removal current 10.0KA. The composition of end point solution Cu=0.97g / L, As=1.86g / L. The composition of arsenic slag is Cu=38.40%, As=19.85, and the ratio of copper to arsenic is Cu:As=1.935:1.

Embodiment 2

[0037] Example 2: The replenishment liquid contains: Cu=23.37g / L, As=13.18g / L, Cu:As=1.773:1. Supply fluid flow rate 4.2m 3 / h. The circulating fluid temperature is 62°C. There are 24 electrowinning arsenic removal tanks. The arsenic removal current is 9.0KA. The composition of end point solution Cu=1.48g / L, As=1.39g / L. The composition of arsenic slag is Cu=33.61%, As=18.22%, and the ratio of copper to arsenic is Cu:As=1.845:1.

Embodiment 3

[0038] Example 3: The replenishment liquid contains: Cu=22.03g / L, As=12.54g / L, Cu:As=1.757:1. Supply fluid flow rate 4.0m 3 / h. The circulating fluid temperature is 62°C. There are 24 electrowinning arsenic removal tanks. The arsenic removal current is 9.0KA. The composition of end point solution Cu=1.09g / L, As=1.28g / L. The composition of arsenic slag is Cu=32.10%, As=17.01%, and the ratio of copper to arsenic is Cu:As=1.887:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com