High-strength beta-SiAlON ceramic and pressureless sintering preparation method thereof

A high-strength, ceramic technology, applied in the field of high-strength β-SiAlON ceramic materials and its pressureless sintering preparation, to achieve the effect of reducing raw material loss and processing loss, reducing processing difficulty, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

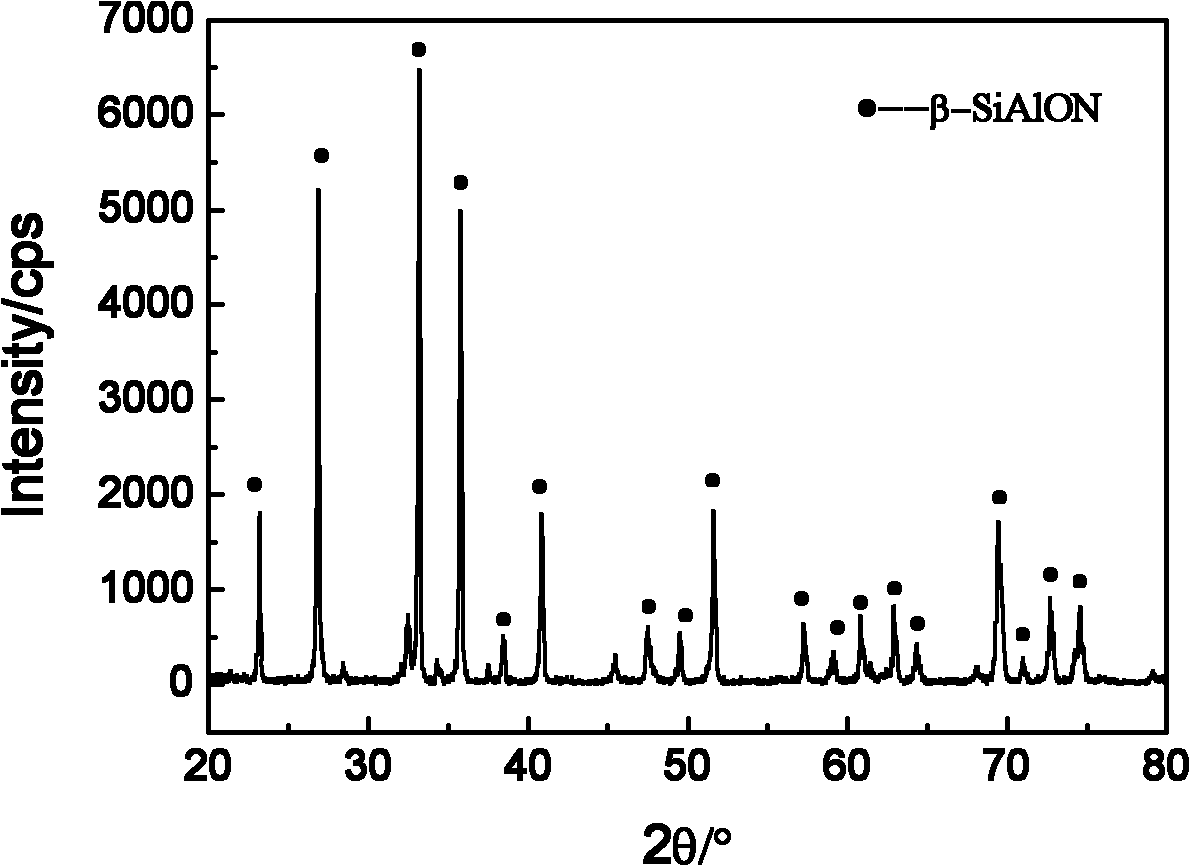

Image

Examples

Embodiment 1

[0032] Doped with yttrium oxide, using silicon nitride, aluminum nitride and aluminum oxide powder as raw materials. According to the molecular formula Si 6-z Al z O z N 8-z Calculate the mass percentage of silicon nitride, aluminum nitride, and aluminum oxide in the raw material powder when 1.6<z<2.5, and then weigh the yttrium oxide powder at 4% of the total mass of the above powder, and place the weighed powder in Anhydrous ethanol is used as the dispersion medium in the polytetrafluoroethylene tank, and silicon nitride balls are used as the ball milling medium for 24 hours. After drying, the mixed slurry is put into a metal mold and molded under a pressure of 40 MPa. The blank is placed in a graphite mold spread with graphite paper and SiAlON powder, and β- is prepared by the pressureless sintering process described above. The SiAlON ceramic material is processed with a diamond cutting machine, grinder and polishing machine to obtain ceramic material samples for performance...

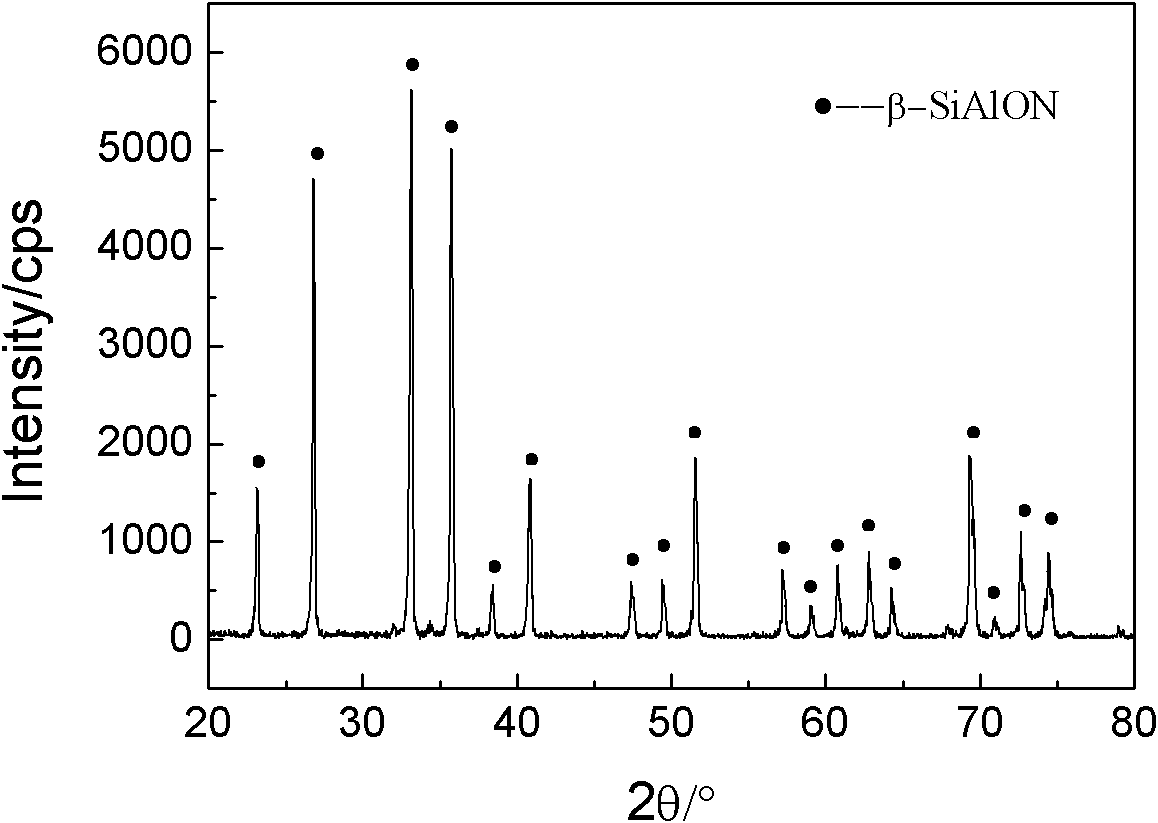

Embodiment 2

[0034] In this embodiment, the content of yttrium oxide is 2wt%, and the other composition and preparation method are the same as the β-SiAlON composition of the first embodiment.

Embodiment 3

[0036] In this embodiment, the content of neodymium oxide is 3wt%, and the other composition and preparation method are the same as the β-SiAlON composition of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com