Tensile RTP and manufacturing method thereof

A manufacturing method, tensile technology, applied in the direction of pipes, rigid pipes, pipes/fittings/fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

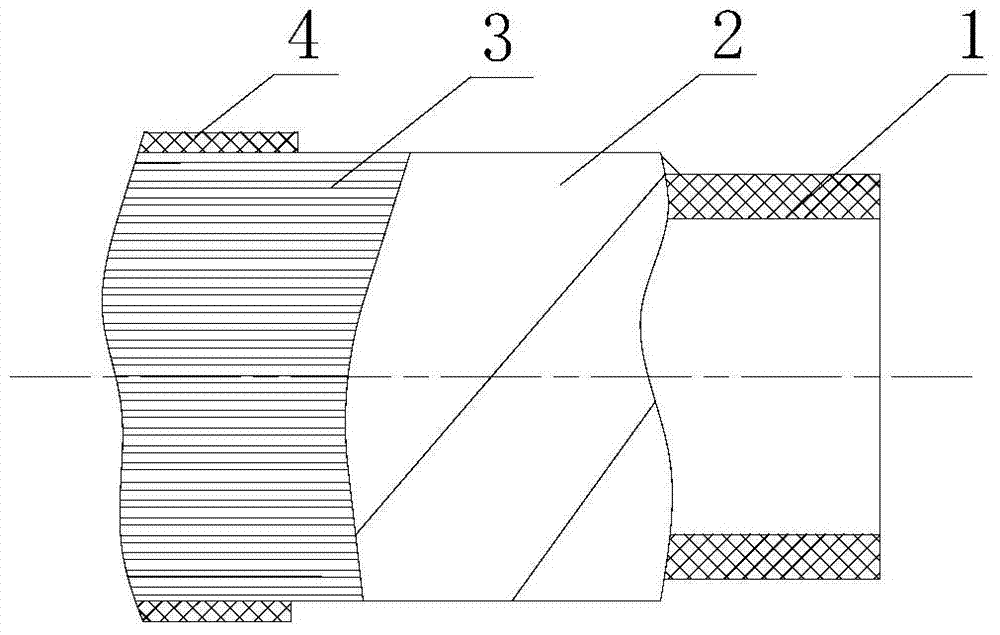

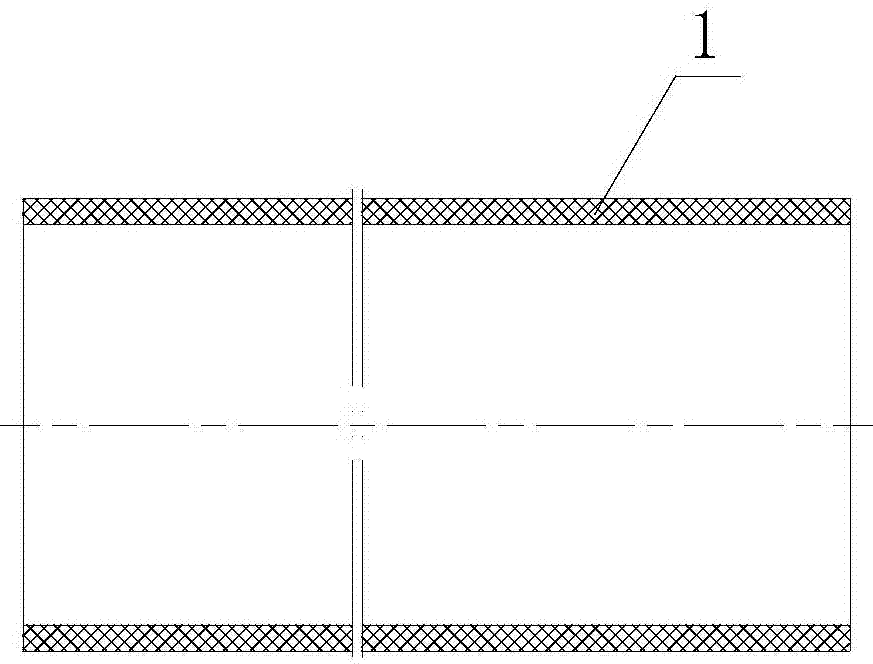

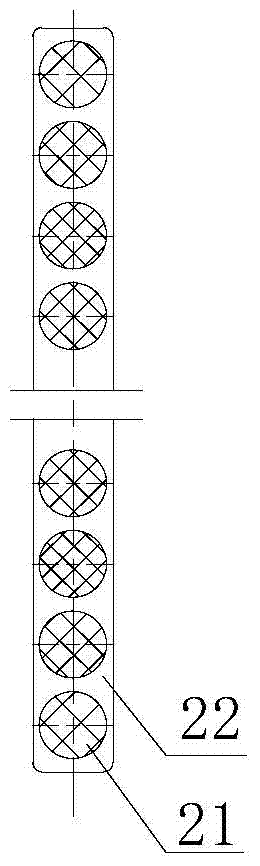

[0031] The tensile RTP pipe of the present embodiment has a structure such as figure 1 and figure 2 As shown, it includes the inner tube 1 and the reinforcement layer 2 wound on the inner tube 1. The reinforcement layer 2 is composed of two winding tapes wound on the outer wall of the inner tube 1 from opposite directions at a predetermined winding angle, wherein the winding angle is 54.7 °. The reinforcing layer 2 wraps the protective layer 4, and a tensile layer 3 is provided between the reinforcing layer 2 and the protective layer 4. The tensile layer 3 is composed of a group of pre-tensioned axial fiber ropes 8 uniformly distributed in the circumferential direction. The fiber ropes 8 Pre-tensioned by a tensioner, the pre-tensioned stress of the fiber rope 8 is 200 Newtons, and the pre-tensioned fiber rope 8 is evenly arranged on the outer surface of the reinforcement layer 2 along the axial direction of the pipeline through the pay-off frame 5, and the pre-tensioned Th...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the reinforcing layer 2 is composed of two winding tapes wound on the outer wall of the inner tube 1 from opposite directions at a predetermined winding angle, wherein the winding angle is 50°; the tensile layer is formed The fiber rope 8 of 3 is pre-tensioned by the tensioner, the pre-tension stress of the fiber rope 8 is 180 Newton, and the pre-tensioned fiber rope 8 is evenly arranged on the reinforcement layer 2 along the pipeline axis direction through the pay-off frame 5 The outer surface, and the circumferential interval of the pretensioned fiber rope 8 is 6mm, so that the protective layer 4 of the RTP pipe can be bonded to the reinforcing layer 2, and the tensile layer 3 can better withstand the axial pressure.

[0036] In the tensile RTP pipe manufacturing method of this embodiment, a spiral winding machine is used to wind two high-strength winding tapes from opposite directions at a winding angle o...

Embodiment 3

[0038] The difference between this embodiment and Embodiment 1 is that the reinforcement layer 2 is composed of two winding tapes wound on the outer wall of the inner tube 1 from opposite directions at a predetermined winding angle, wherein the winding angle is 60°; the tensile layer is formed The fiber rope 8 of 3 is pre-tensioned by a tensioner, and the pre-tension stress of the fiber rope 8 is 220 Newtons. The pre-tensioned fiber rope 8 is evenly arranged on the reinforcement layer 2 along the pipeline axis direction through the pay-off rack 5 The outer surface, and the circumferential interval of the pretensioned fiber rope 8 is 2mm, so that the protective layer 4 of the RTP pipe can be bonded to the reinforcing layer 2, and the tensile layer 3 can better withstand the axial pressure.

[0039] In the tensile RTP pipe manufacturing method of this embodiment, a spiral winding machine is used to wind two high-strength winding tapes on the outer wall of the inner pipe 1 from op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com