Hot-fin heater exchanger

A heat exchanger and heat fin technology, applied in the field of heat fin plate heat exchanger and heat exchanger, can solve the problems of inability to withstand high temperature, high pressure, difficult space layout, large volume, etc., and achieve low cost and large heat transfer area. , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

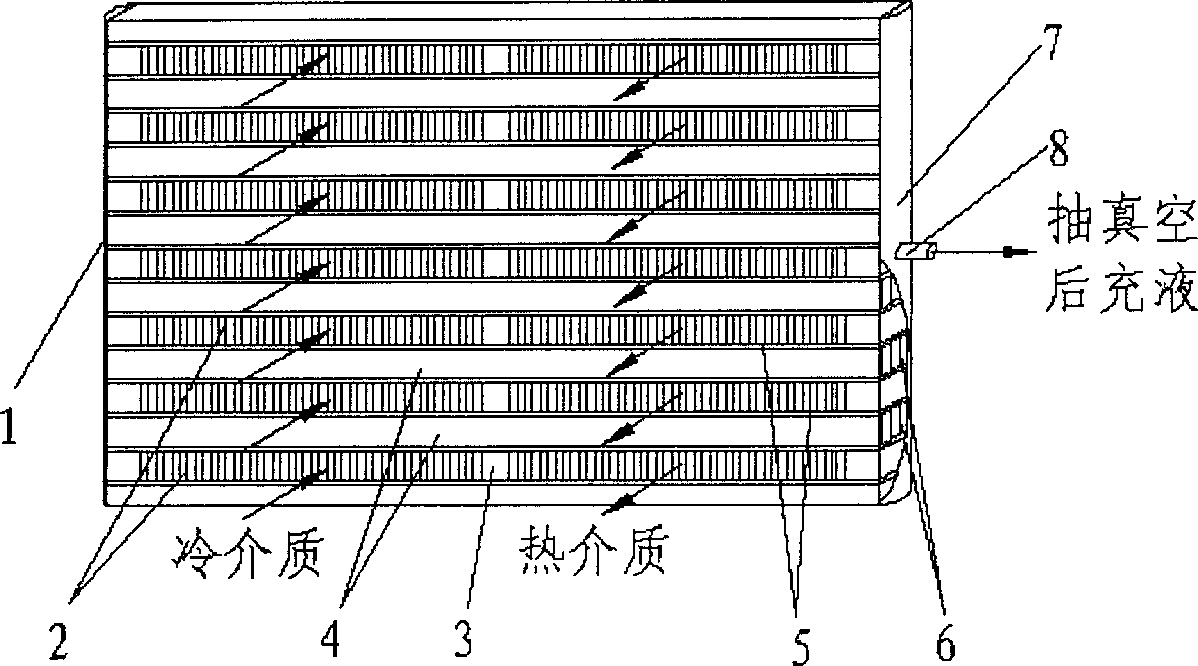

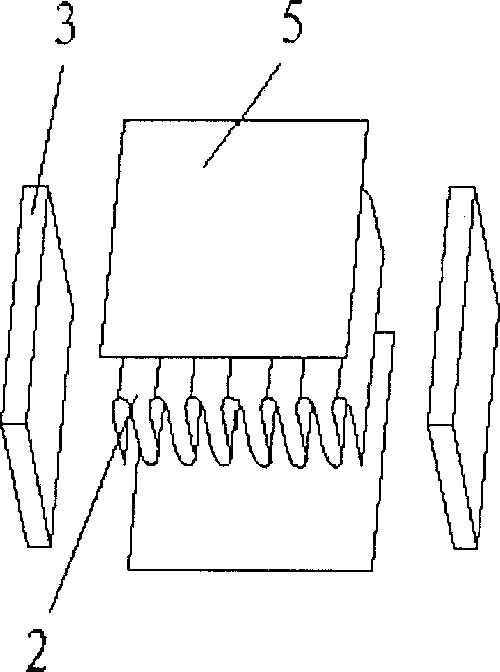

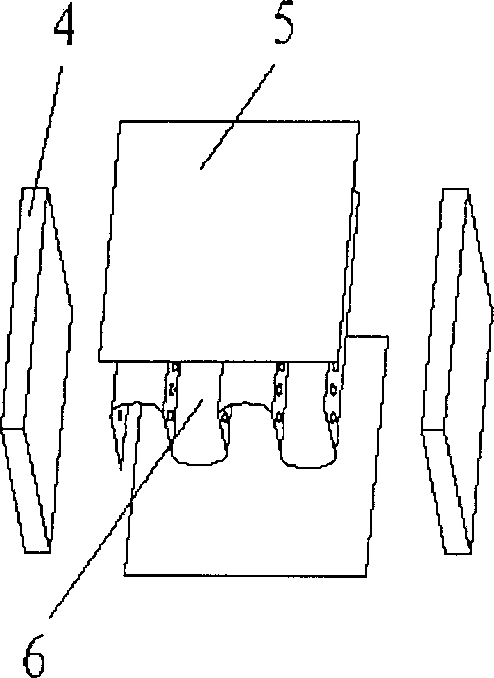

[0013] Refer to attached Figure 1-6 , The main structure of the hot-fin plate heat exchanger has two parts: the head 1, 7 and the core. The heads 1 and 7 are arranged on both sides of the vacuum liquid-filled channel, and one side of the head 7 is provided with a connecting pipe 8 for vacuumizing the vacuum liquid-filled channel and filling it with working liquid. The core body is made of several plate-fin channels and vacuum liquid-filled channels stacked at intervals and vacuum brazed. The plate-fin channel is provided with partitions 5 up and down, seals 3 are provided on both sides, and fins 2 are provided in the channel. Each plate-fin channel is divided into two juxtaposed hot medium channels and cold medium channels by a strip 3 to realize the countercurrent flow of hot fluid and cold fluid. Both the hot medium channel and the cold medium channel have fins, and the upper and lower sides of the fins 2 are provided with partitions 5 (sealed partitions), and the sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com