Friction stirring welding method of weld joint in step structure

A friction stir, structural weld technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of high grinding requirements of gaskets, unstable welding quality, and difficulty in pressing gaskets. Production cycle, saving time and process, effect of simplifying welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to examples.

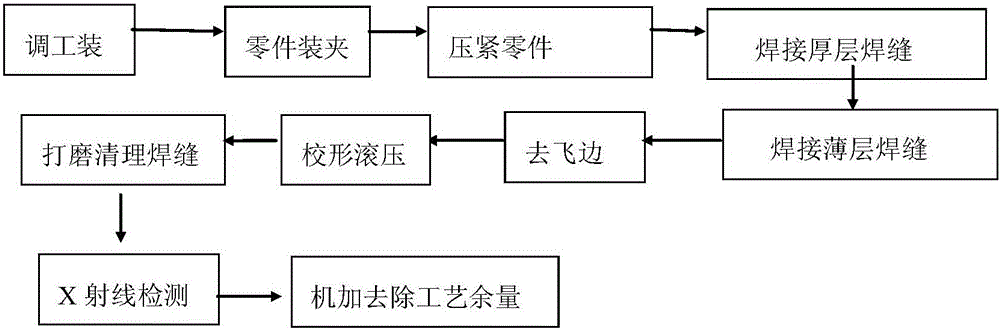

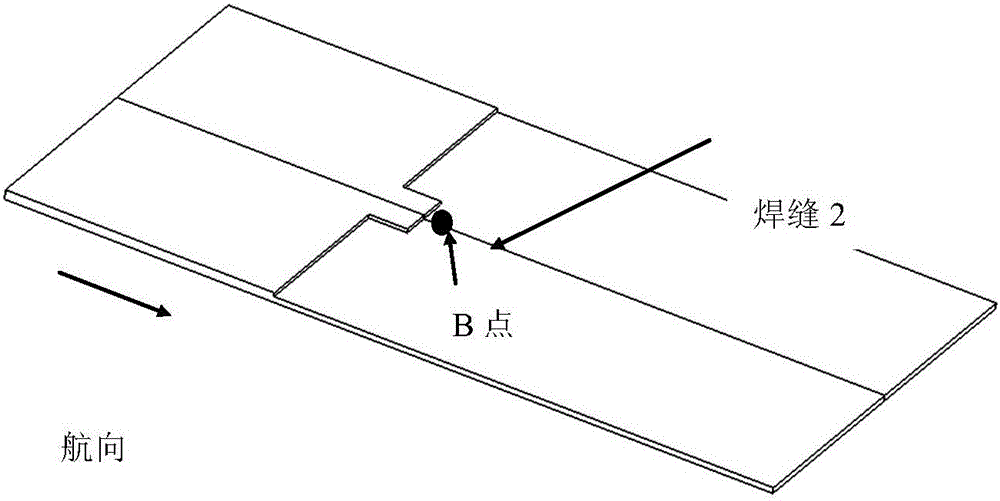

[0020] In the friction stir welding method for the welded seam of the stepped structure of the invention, a process allowance is reserved at the stepped structure. During welding, the thick layer of the stepped structure is first welded, the thick welding seam is welded, and then the process margin is milled to make it fit with the step structure. Structural thin layers are flush, and thin welds are welded from the milled weld.

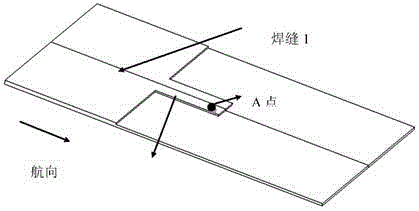

[0021] see figure 1 , the friction stir welding method of the step structure weld seam of the present invention comprises the following steps:

[0022] Step 1. Reserve welding process allowance for parts thick welding machine overtime: When parts machine overtime provides machining drawings to the machine shop, a process allowance area is reserved to solve the problem of friction stir welding of step structure of parts.

[0023] Step 2. Surface clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com