Pure iron smelting method

A smelting method and pure iron technology, which is applied in the field of ferrous metal smelting, can solve the problems of inability to remove various impurities in converter steelmaking smoke and dust, large investment in production equipment, complicated process flow, etc. It is easy to achieve smelting scale, stable product quality, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

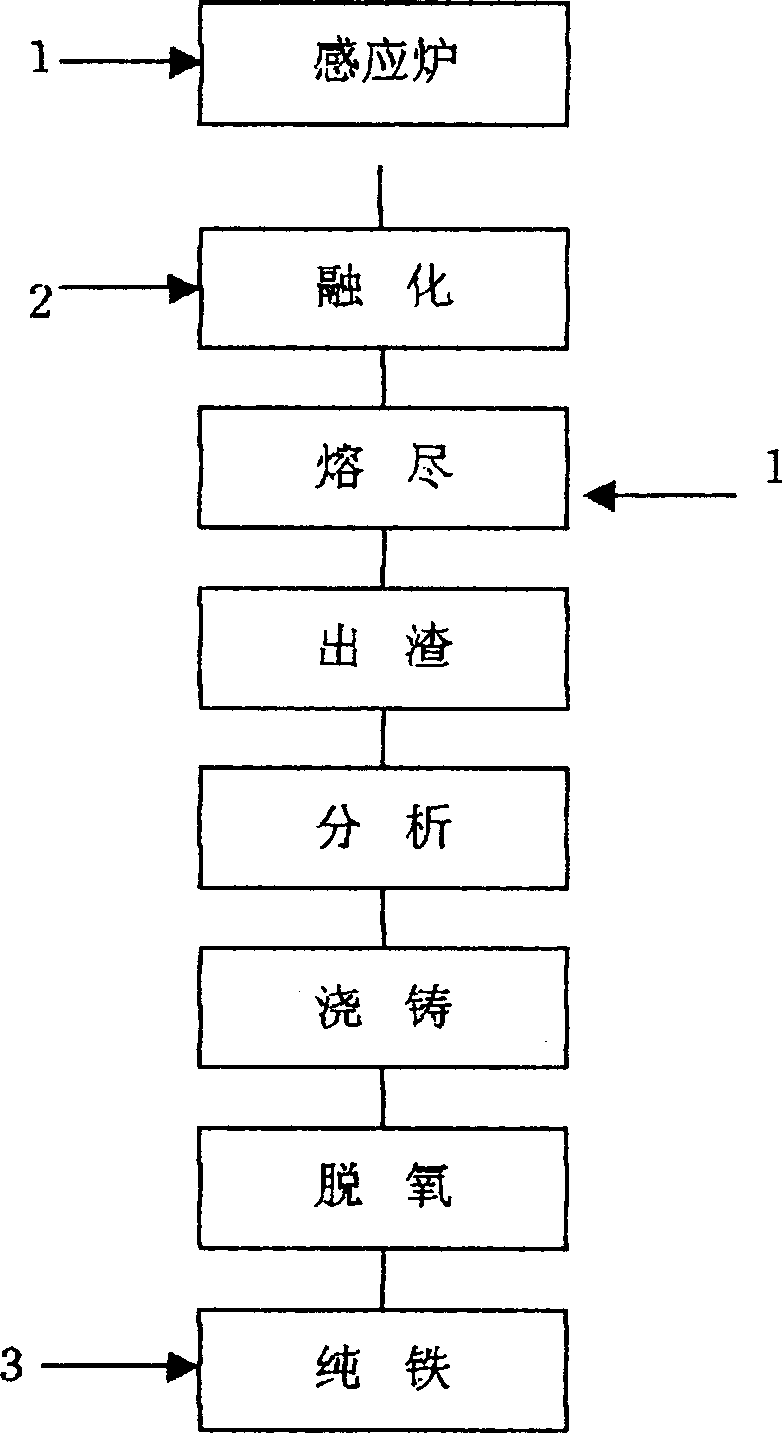

[0034] A pure iron smelting method of the present invention, its process flow diagram is as shown in the accompanying drawing.

[0035] Raw materials: 540kg of converter steelmaking dust. Slagging material: soda ash (NaHCO 3 ) 4.0kg, quicklime (CaO) 4kg, namely NaHCO 3 :CaO=1:1. Deoxidizer: aluminum bar 3kg. Smelting equipment: a medium frequency induction furnace with a total capacity of 700kg. There are 10 steel ingot molds and one ladle for injection molding.

[0036] Smelting process:

[0037] Firstly, put 270kg of converter steelmaking dust into the intermediate frequency induction furnace, turn on the electricity to raise the temperature, and when the materials start to melt, add 2.0kg of quicklime and 2.0kg of soda ash into the intermediate frequency induction furnace, continue to turn on the electricity to heat up, so that the materials in the furnace are melted. Stir continuously during the cooking process. After about 20 minutes, the materials in the furnace ar...

Embodiment 2

[0041] A pure iron smelting method of the present invention, its process flow diagram is as shown in the accompanying drawing.

[0042] Raw materials: 230kg of scrap steel, 230kg of converter steelmaking dust, that is, the weight ratio of converter steelmaking dust: scrap steel=1:1. Slagging material: CaO 9.0kg, NaHCO 3 4.5kg, namely CaO: NaHCO 3 =2:1. Deoxidizer: aluminum bar 3kg. Smelting equipment: 1 industrial frequency induction furnace with a total capacity of 500kg.

[0043] Smelting process:

[0044] Impurities

Embodiment 3

[0046] A pure iron smelting method of the present invention, its process flow diagram is as shown in the accompanying drawing.

[0047] Raw materials: 225 kg of steel scrap, 265 kg of dust from converter steelmaking, that is, the weight ratio of dust from converter steelmaking: scrap steel = 1.177:1. Slagging material: NaHCO 3 4.0kg, CaO 12kg, namely NaHCO 3 :CaO=1:3. Deoxidizer: aluminum bar 3kg. The smelting equipment is basically the same as in Embodiment 2.

[0048] Smelting process:

[0049] Take 25kg of scrap steel, 65kg of converter steelmaking dust, 4.5kg of CaO, NaHCO 3 Add 1.0kg into the furnace respectively, turn on the electricity to raise the temperature, and the materials in the furnace are melted in about 20 minutes, and the slag is removed.

[0050] Impurities

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com