Preparation method of battery-grade manganese sulfate

A manganese sulfate, battery-grade technology, applied in the field of preparation of battery-grade manganese sulfate, can solve the problems of corrosion, many processes, and high energy consumption, and achieve the effects of improving quality, reducing requirements, saving energy and auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

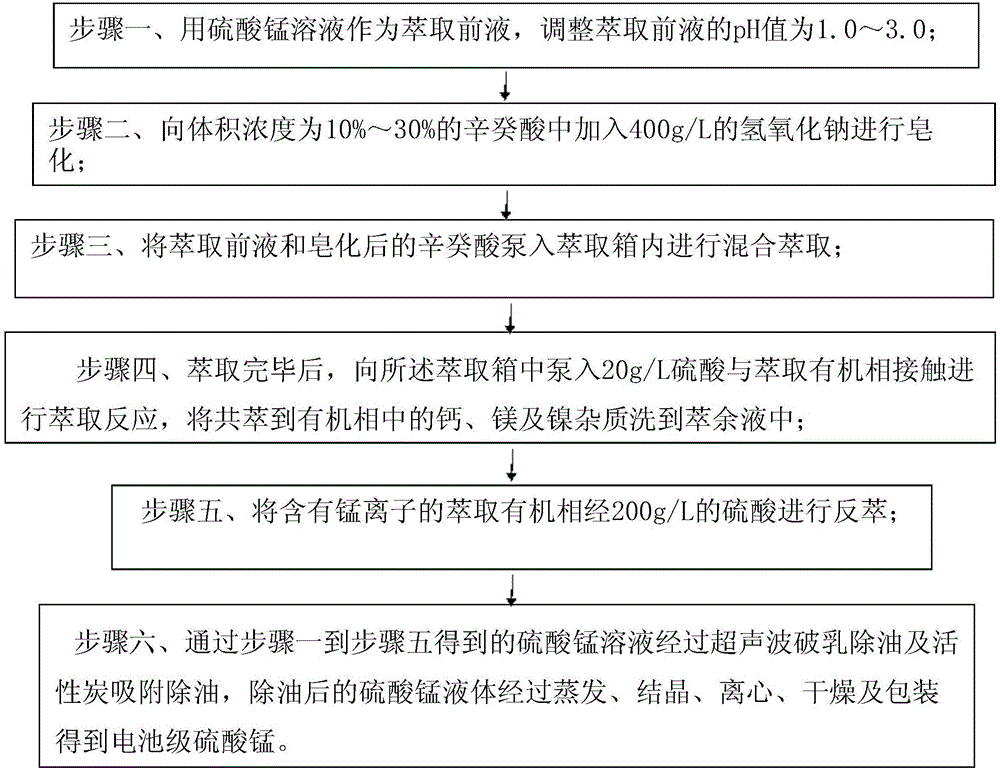

Method used

Image

Examples

Embodiment 1

[0019] Step 1. Select pre-extraction solution

[0020] Use manganese sulfate solution as the pre-extraction liquid, adjust the pH value of the pre-extraction liquid to be 1.5, wherein the element content in the pre-extraction liquid is: Ni: 0.01g / L, Mn: 113g / L, Zn: 0.3g / L, Cu: 0.66g / L, Ca:0.39g / L, Mg:0.005g / L;

[0021] Step 2, saponification of extractant octadecanoic acid

[0022] Octydecanoic acid adds the sodium hydroxide of 400g / L to the octadecanoic acid that volume concentration is 30% and carries out saponification, and saponification rate is controlled at 54%;

[0023] Step 3. Extraction

[0024] Use a pump to pump the pre-extraction liquid and the saponified octadecanoic acid into the extraction box to mix, and the extraction reaction occurs. The extraction temperature is 30°C to 50°C, and the extraction ratio is 5:1. Turn on the stirring paddle and control the speed of the stirring paddle at 260 rpm;

[0025] Step 4. Washing

[0026] After the extraction is comp...

Embodiment 2

[0031] Step 1. Select pre-extraction solution

[0032] Use manganese sulfate solution as the pre-extraction liquid, adjust the pH value of the pre-extraction liquid to be 1.72, wherein the element content in the pre-extraction liquid is: Ni: 0.03g / L, Mn: 120g / L, Zn: 0.55g / L, Cu: 2.5g / L, Ca:0.44g / L, Mg:0.008g / L;

[0033] Step 2, saponification of extractant octadecanoic acid

[0034] Be that the sodium hydroxide of 400g / L is added in the octadecanoic acid that volume concentration is 10% carries out saponification, and saponification rate is controlled at 45%;

[0035] Step 3. Extraction

[0036] Pump the pre-extraction liquid and the saponified octadecanoic acid into the extraction box for mixed extraction. The extraction temperature is 30°C-50°C, the extraction ratio is 5.5:1, and the stirring paddle is turned on. The speed of the stirring paddle is controlled at 100 rpm ;

[0037] Step 4. Washing

[0038] After the extraction is completed, pump 20g / L sulfuric acid into ...

Embodiment 3

[0043] Step 1. Select pre-extraction solution

[0044] Use manganese sulfate solution as the pre-extraction liquid, adjust the pH value of the pre-extraction liquid to be 1.0, wherein the element content in the pre-extraction liquid is: Ni:0.04g / L, Mn:115g / L, Zn:0.38g / L, Cu: 3.0g / L, Ca:0.38g / L, Mg:0.008g / L;

[0045] Step 2, saponification of extractant octadecanoic acid

[0046] Add the sodium hydroxide of 400g / L to carry out saponification in the octadecanoic acid that volume concentration is 20%, saponification rate is controlled at 50%;

[0047] Step 3. Extraction

[0048] Pump the pre-extraction liquid and the saponified octadecanoic acid into the extraction box for mixed extraction. The extraction temperature is 30°C-50°C, the extraction ratio is 6:1, the stirring paddle is turned on, and the speed of the stirring paddle is controlled at 300 rpm ;

[0049] Step 4. Extract organic washing

[0050]After the extraction is completed, pump 20g / L sulfuric acid into the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com