Glass fiber wire-drawing device

A glass fiber and wire drawing technology, which is applied in the field of glass fiber drawing devices, can solve the problems of increasing the production cost of glass fiber products, insufficient utilization of auxiliary materials, and a large number of raw materials, and achieves the effects of improving the yield, reducing waste wire, and preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

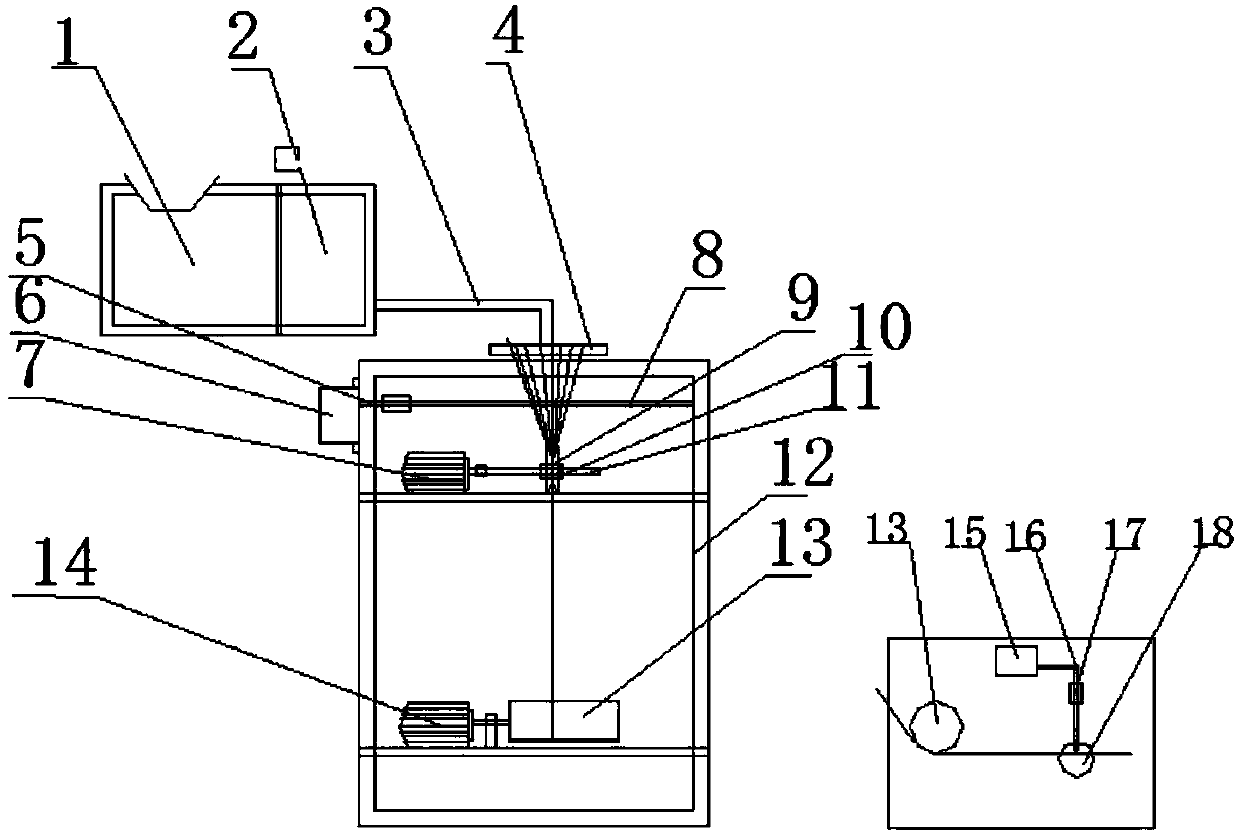

[0016] In order to make the present invention easier to understand clearly, the present invention will be further explained in conjunction with the accompanying drawings.

[0017] A glass fiber drawing device includes a melting device, a wire drawing device, an air jet device, a clustering device, and an oiling device.

[0018] The melting device includes a ball adding machine 1, one side of the ball adding machine 1 is connected to a melting furnace 2, and the melting furnace 2 is fixed above the wire drawing device, and the wire drawing device includes a wire drawing frame 12, a bushing 4. Rotate the motor 14, the shaft coupling and the drum 13. The drain plate 4 is connected to the melting furnace 2 through the pipeline 3 and is located at the top of the drawing support 12. A bottom plate is provided under the drawing support 12. The rotating motor 14 is fixed on the base plate, the output shaft of the rotating motor 14 is connected with the large main shaft through a coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com