Patents

Literature

39results about How to "Reduce waste silk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

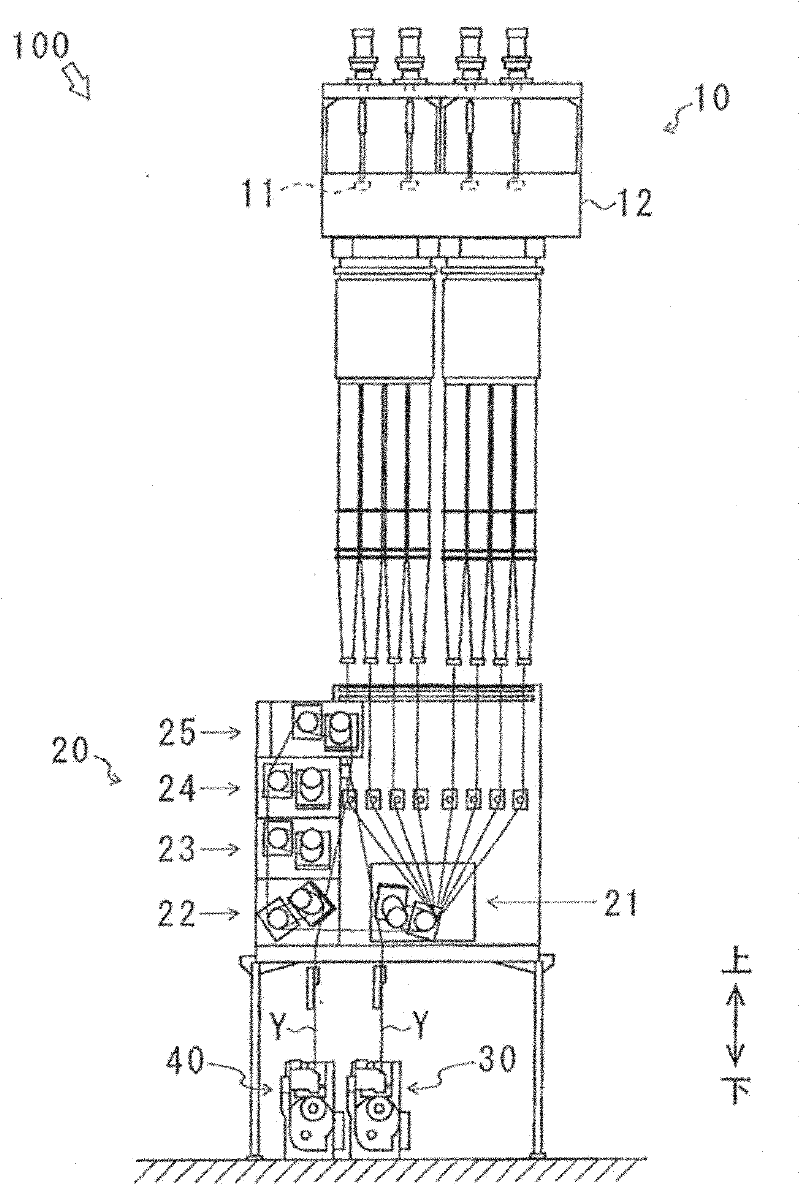

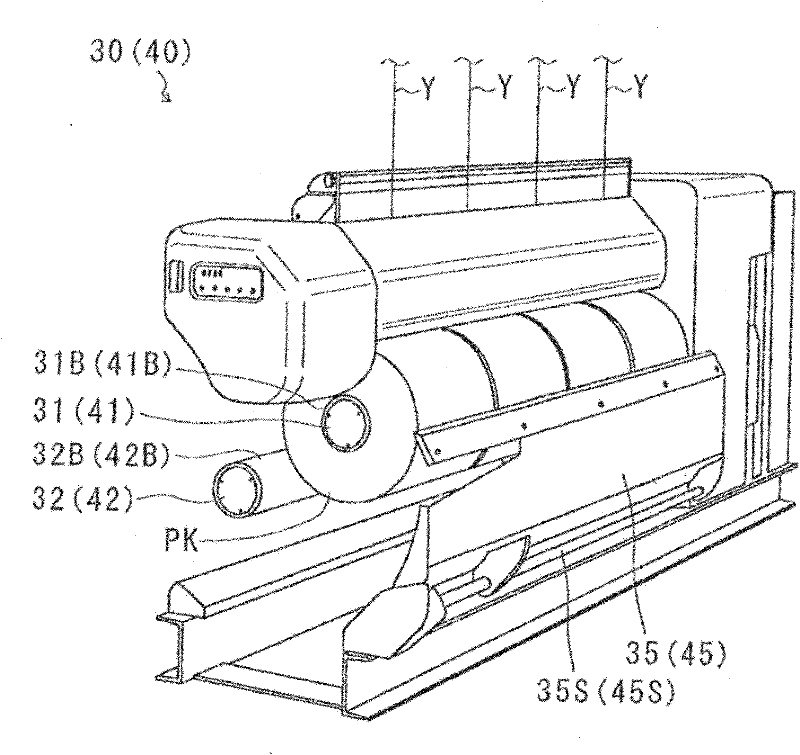

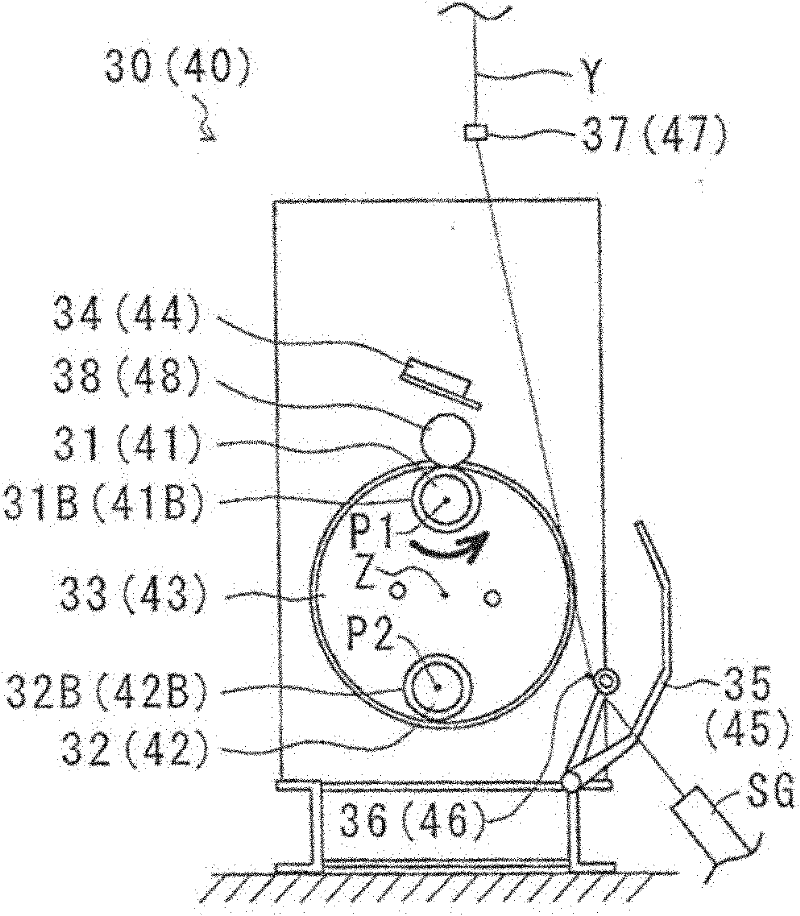

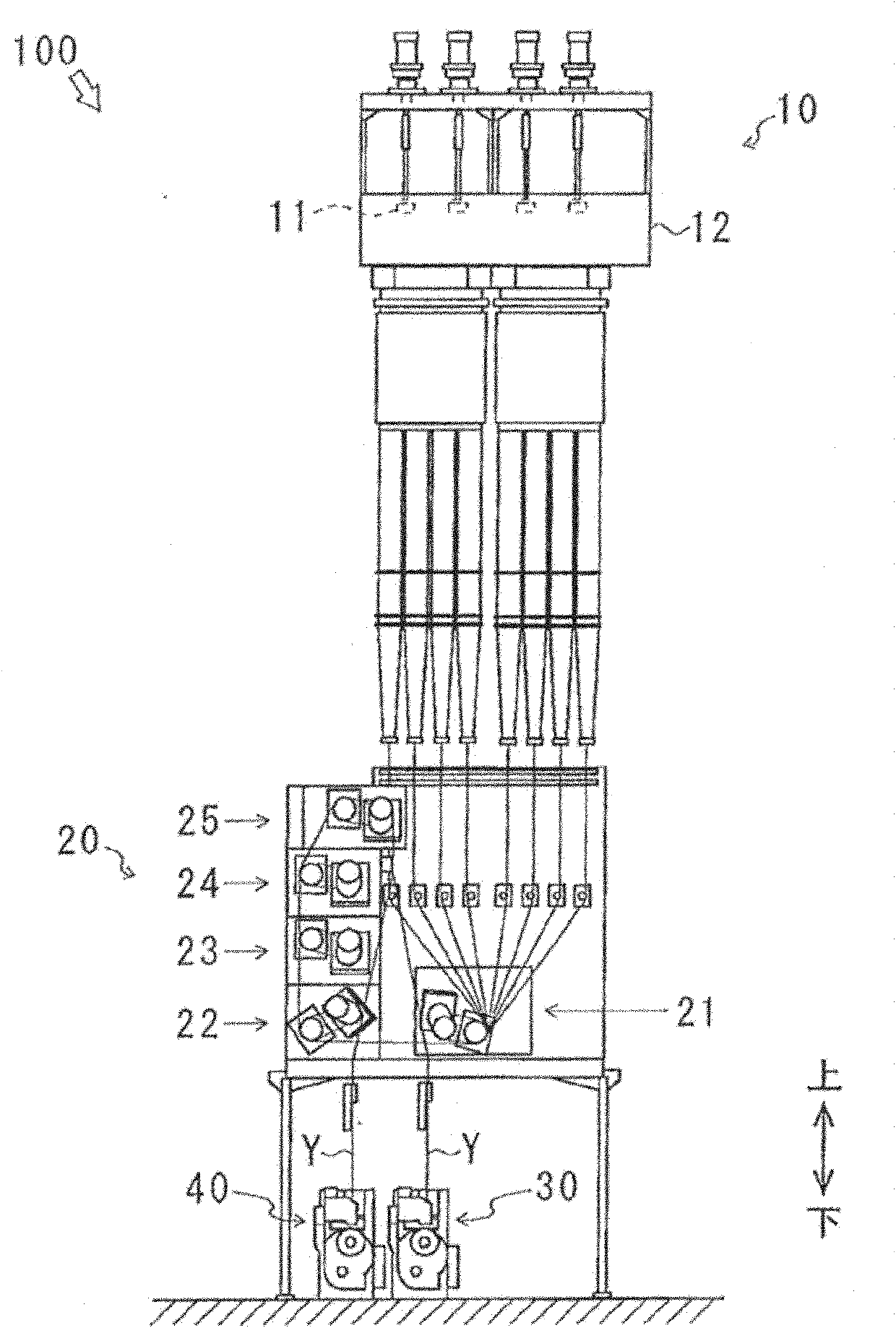

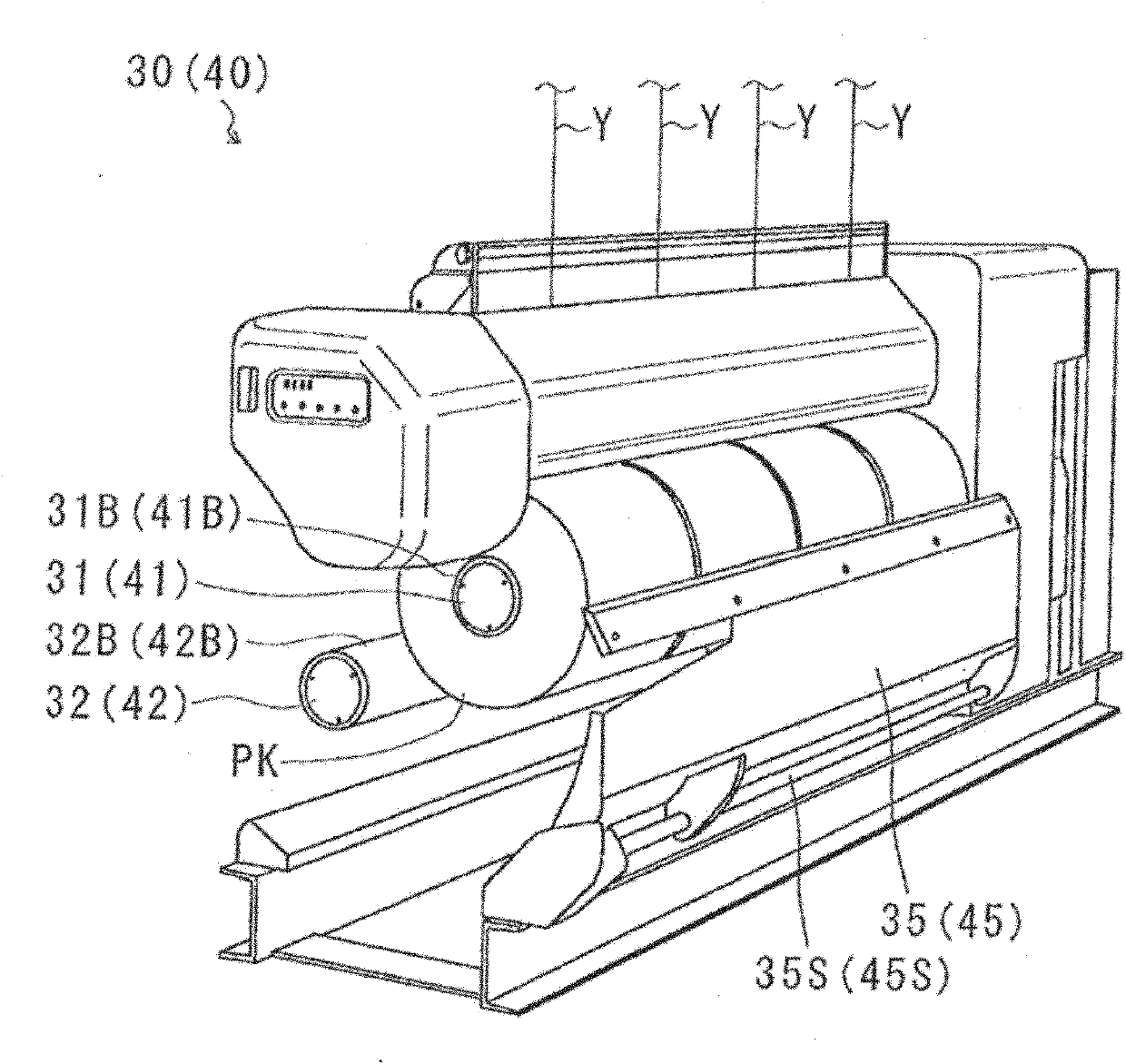

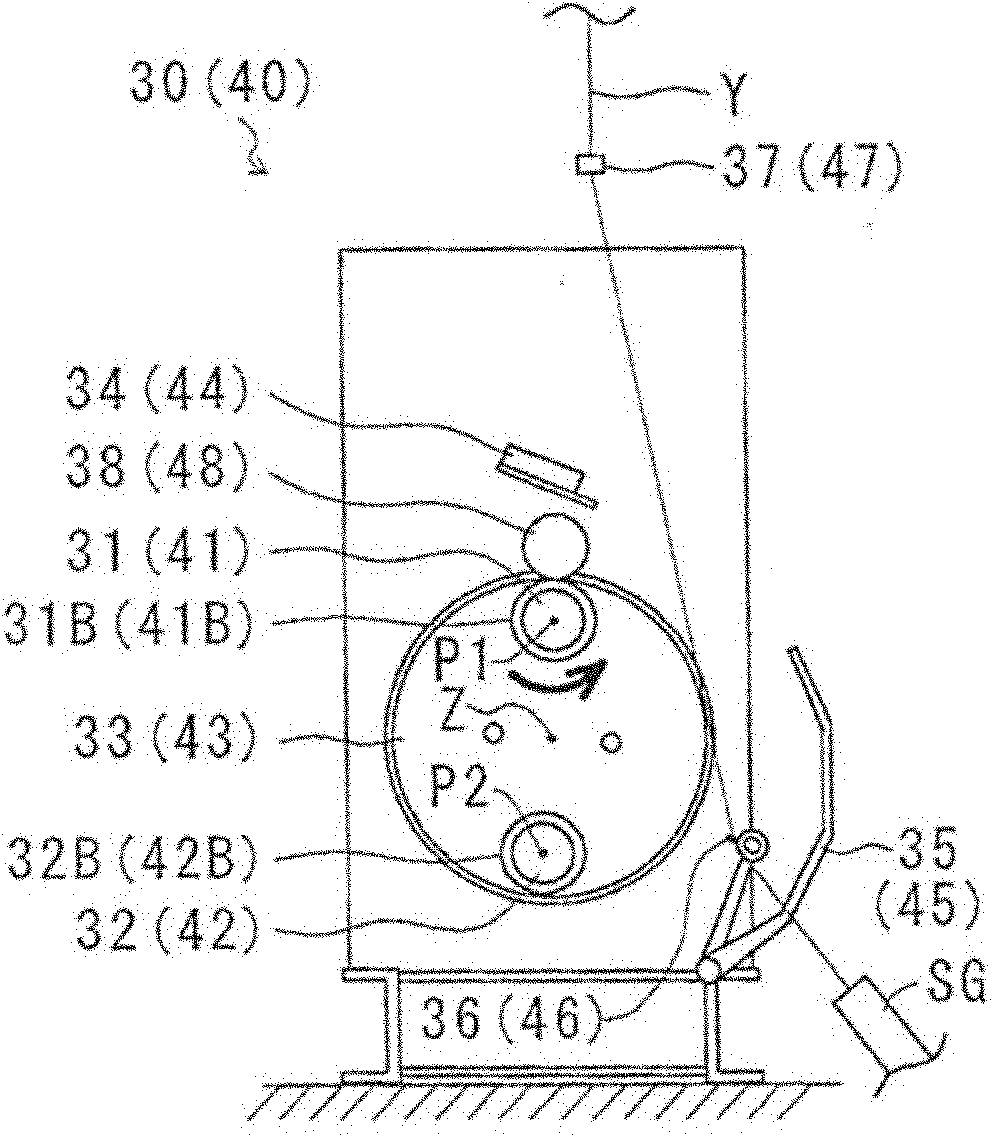

Spinning-winding apparatus and spinning-in method therein

The invention provides a spinning-winding apparatus and spinning-in method and a spinning-in method therein which may reduce the amount of waste yarns. In the spinning-winding apparatus with a drawing-out device (10), a godet roller group (20), a first winding device (30) and a second winding device (40), the first winding device (30) and the second winding device (40) are provided with first bobbin support shafts (31, 41) on which bobbins (31B, 41B) for spinning in are mounted, and second bobbin support shafts (32, 42) on which bobbins (32B, 42B) for switching silk yarns from the bobbins (31B, 41B) of the first bobbin support shafts (31, 41) are mounted, respectively; the first winding device (30) is at a spinning-in rotating speed (L) while spinning in to the bobbin (31B) of the first bobbin support shaft (31), and at a production rotating speed (H) after completing spinning-in of the bobbin (31B); and the second winding device (40) is at the production rotating speed (H) while spinning in to the bobbin of the first bobbin support shaft (41).

Owner:TMT MACHINERY INC

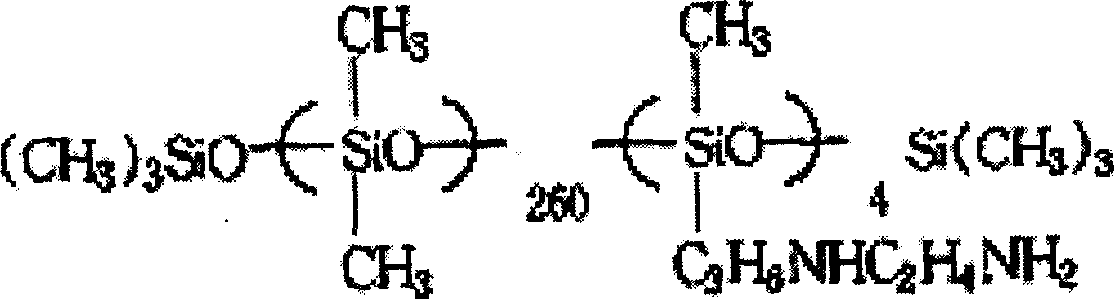

Polyester DTY fiber and preparation method thereof

ActiveCN108385195AIncrease the cross-sectional areaReduce the temperatureFilament/thread formingArtificial filament heat treatmentThermal insulationDiol

The invention relates to polyester DTY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, winding to prepare polyester POY fiber, and carrying out fiber conduction pipe, network, heating drawing, false twisting, heat setting and winding molding on the polyester POY fiber to obtain the polyester DTY fiber. According to the present invention, during the cooling, the longitudinal height is maintained, and the cross section area of the slow cooling chamber is increased while the plate surface temperature of thespinning plate is maintained by using the thermal insulation method; the material of the polyester POY fiber is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atom number of 1-5, and R4 is selected fromalkyl with a carbon atom number of 2-5; and the preparation method is simple, and the chromatic aberration [delta]E of the prepared fiber is less than 0.200.

Owner:JIANGSU HENGLI CHEM FIBER

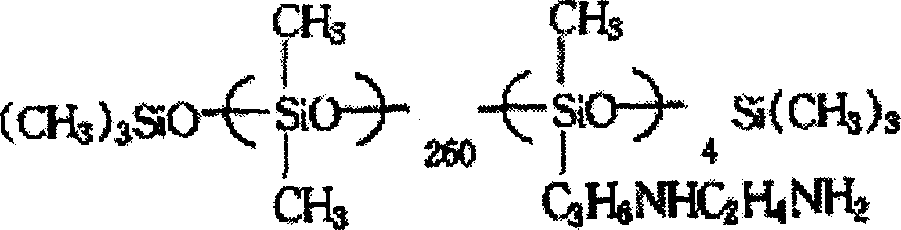

High-modulus low-shrinkage stiff cord and preparation method thereof

ActiveCN108385418AIncrease the cross-sectional areaReduce the temperatureFibre typesFilament/thread formingYarnSlow cooling

The invention relates to a high-modulus low-shrinkage stiff cord and a preparation method thereof. The preparation method comprises the following steps: performing solid-phase polycondensation-viscosity enhancement, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain high-modulus and low-shrinkage polyester industrial yarns; twisting to obtain a cord; making the cord into a high-modulus low-shrinkage stiff cord by a two-bath impregnation method, wherein during cooling, the longitudinal height is kept constant and the cross-sectional area of a slow cooling chamber is increased; meanwhile, the surface temperature of a spinneret plate is kept in a heat preserving way in the slow cooling chamber; an oiling agent contains 67.30 to 85.58 percent by weight of crown ether; during use of the oiling agent, 14 to 18 percent by weight emulsion is prepared with water. The preparation method disclosed by the invention is simple; the prepared high-modulus low-shrinkage stiff cord is made from modified polyester of which the molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain, is greater than or equal to 80N in breaking strength, and is greater than or equal to 37KN / m in cord bonding strength.

Owner:JIANGSU HENGLI CHEM FIBER

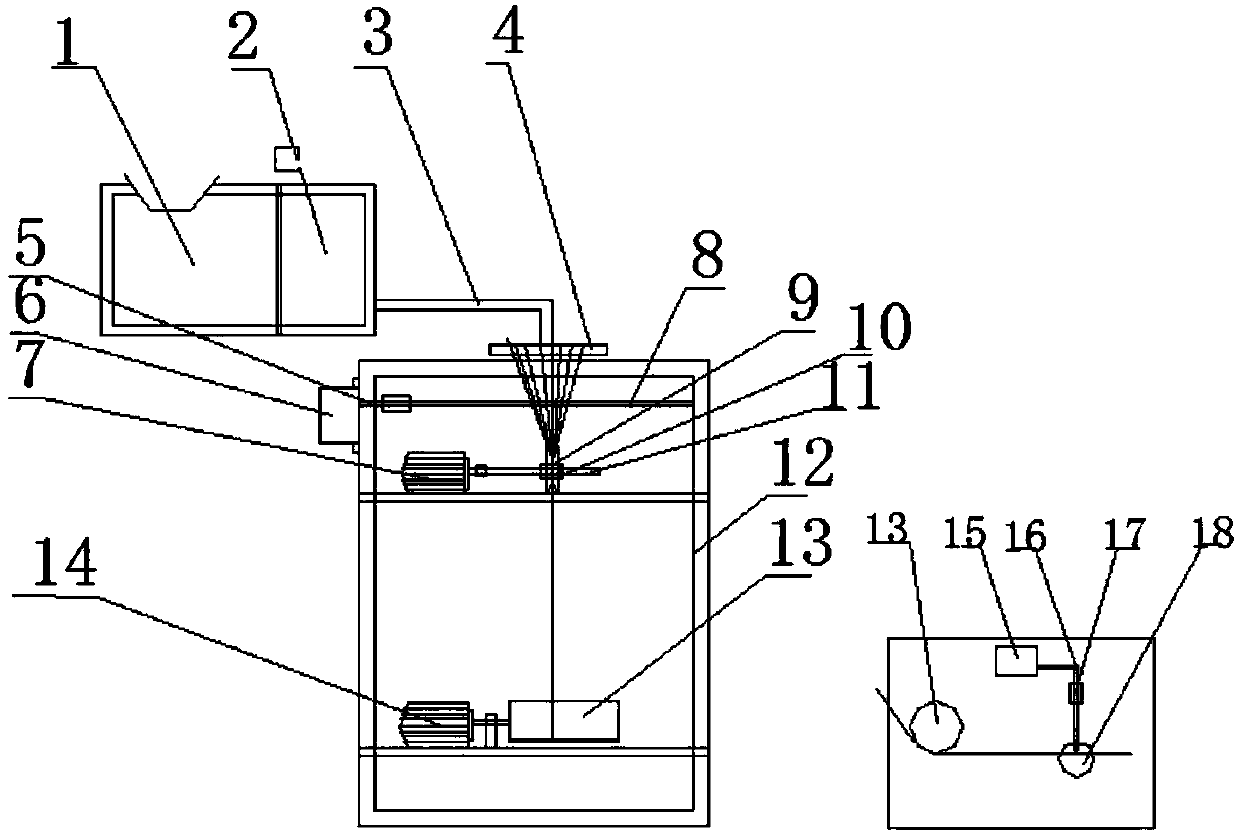

Glass fiber wire-drawing device

The invention discloses a glass fiber wire-drawing device which comprises a melting device, a wire-drawing device, an air jetting device, a bundle collection device and an oil coating device; the melting device comprises a ball-charging machine; a melting furnace is connected to one side of the ball-charging machine and is fixed above the wire-drawing device; the wire-drawing device comprises a wire-drawing rack, a bushing plate, a rotation motor, a coupler and a rotary drum; the air jetting device comprises an air pump, an air pipe, a transverse pipe and a nozzle; the air pump is arranged onthe outer side of the wire-drawing rack and is connected to the transverse pipe through the air pipe; and the transverse pipe is provided with an opening to be connected with the nozzle and is fixed to the rack and below the bushing plate. The glass fiber wire-drawing device has the beneficial effects that the temperature of wire drawing is controlled, the drawn wire is prevented from deformationdue to excessive temperature, the linear speed of the oil coating device is slowed down, and the auxiliary material is saved; and through wire drawing, the rate of produced finished products is increased, and the amount of waste wires is reduced.

Owner:SHANDONG FIBERGLASS GRP

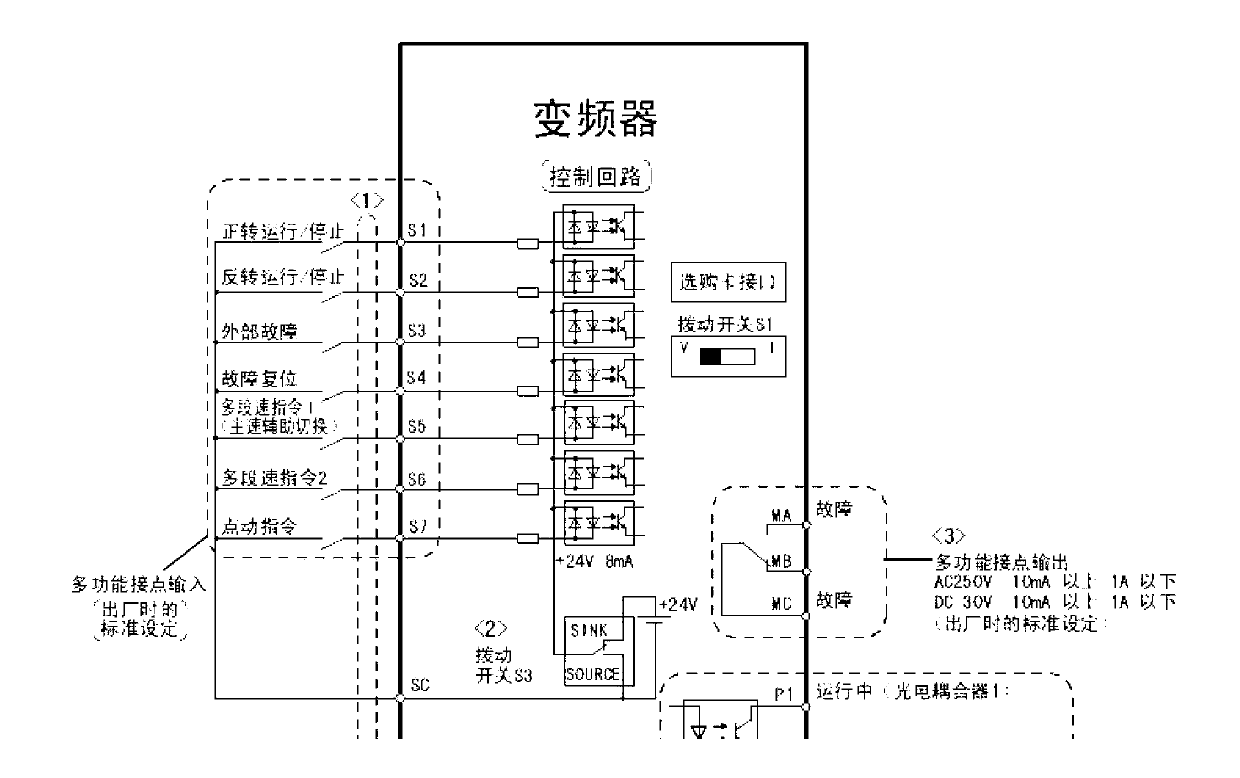

Low-speed spinning threading control system

InactiveCN103014883AReduce manufacturing costPump speed reductionSpinning head liquid feederFrequency changerLow speed

A low-speed spinning threading control system comprises a metering pump, a winder and a frequency converter, a second speed signal is added to a frequency conversion control board of the frequency converter, when a stop signal of the winder is sent, a second speed of the frequency converter is triggered, and when a start signal of the winder is sent, the frequency converter is switched to a first speed automatically. Speed switching of the frequency converter is achieved through a multispeed terminal S5. The frequency converter further comprises a metering pump operation control terminal S1 with a start-stop function, when the S1 is on and the S5 is on, the metering pump is in high-speed operation; when the S5 is off, the metering pump is in low-speed operation; and when the S1 is off, no matter the S5 is on or off, the metering pump is out of operation. The stop / start signals of the winder are sent through a relay, and contacts of the relay are connected with the multispeed terminal S5. By the aid of the low-speed spinning threading control system, when the winder brakes down to stop operation, the rotating speed of the metering pump is automatically controlled to be decreased through the signals, waste silk quantity is decreased greatly, and production cost is reduced for enterprises.

Owner:JIANGSU CHALLEN FIBER S&T

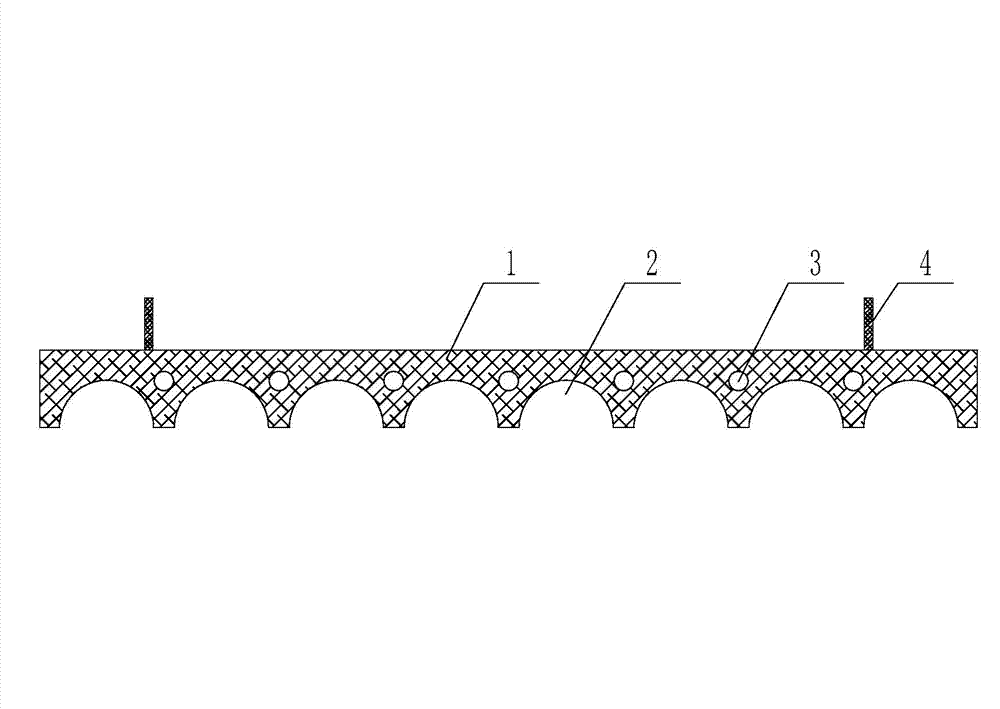

Network distributor gas supply pipeline network system

ActiveCN102345176AImprove networkImprove uniformityConjugated synthetic polymer artificial filamentsMonocomponent polyesters artificial filamentBuffer tankEconomic benefits

The invention discloses a network distributor gas supply pipeline network system, comprising at least two levels of network air pressure air pressure stabilizing devices, wherein, each level of network air pressure air pressure stabilizing device is provided with a plurality of buffer tanks, one end of each buffer tank is communicated with an air inlet and the other end is communicated with at least two air outlets, the level one network air pressure air pressure stabilizing device is provided with a buffer tank, each air outlet of each buffer tank in each level of network air pressure air pressure stabilizing device is respectively communicated with the air inlet of one buffer tank in the next level of network air pressure air pressure stabilizing device, and each air outlet of each buffer tank in the last one level of network air pressure air pressure stabilizing device is respectively communicated with the network distributor. The network distributor gas supply pipeline network system is a multi-level multi-branch system, air flow is subject to buffer through multiple buffer tanks, so that the air pressure is more stable, the degree of network and network uniformity of filaments and mixed filaments are increased, the winding tension is stabilized, end breaking and waste filaments are reduced, the production state is improved, and the product quality, production efficiency and economic benefit are improved.

Owner:XUZHOU SILK FIBER TECH

Filament drawing and winding device

ActiveCN102839436ALower the altitudeReduce infrastructure costsNew-spun product collectionArtificial thread manufacturing machinesEconomic benefitsEngineering

The invention discloses a filament drawing and winding device, falling into the technical field of chemical fiber mechanical manufacturing. The device comprises a frame, a drawing apparatus located at the upper part of the frame, and a winding apparatus located at the lower part of the frame. The drawing apparatus includes a mounting panel vertically arranged at the upper part of the frame; a preprocessing part and a drawing part are sequentially distributed along the filament tow circulating direction on the mounting panel; the length directions of a filament inlet and a filament outlet of the preprocessing part are parallel to the axial direction of the drawing part; and at least one network part is arranged on the circulating path of the filament tow between the preprocessing part and the winding apparatus. The inventive device improves the filament quality, saves the labor cost for spinning, eliminates potential safety hazards, shortens the stringup time, improves the spinning production capacity, reduces stringup waste filaments, shortens the equipment mounting period, saves mounting costs, can obtain economic benefits in advance, and saves the manufacturing cost of equipment and the capital construction cost of factory building.

Owner:BEIJING CHONGLEE MACHINERY ENG

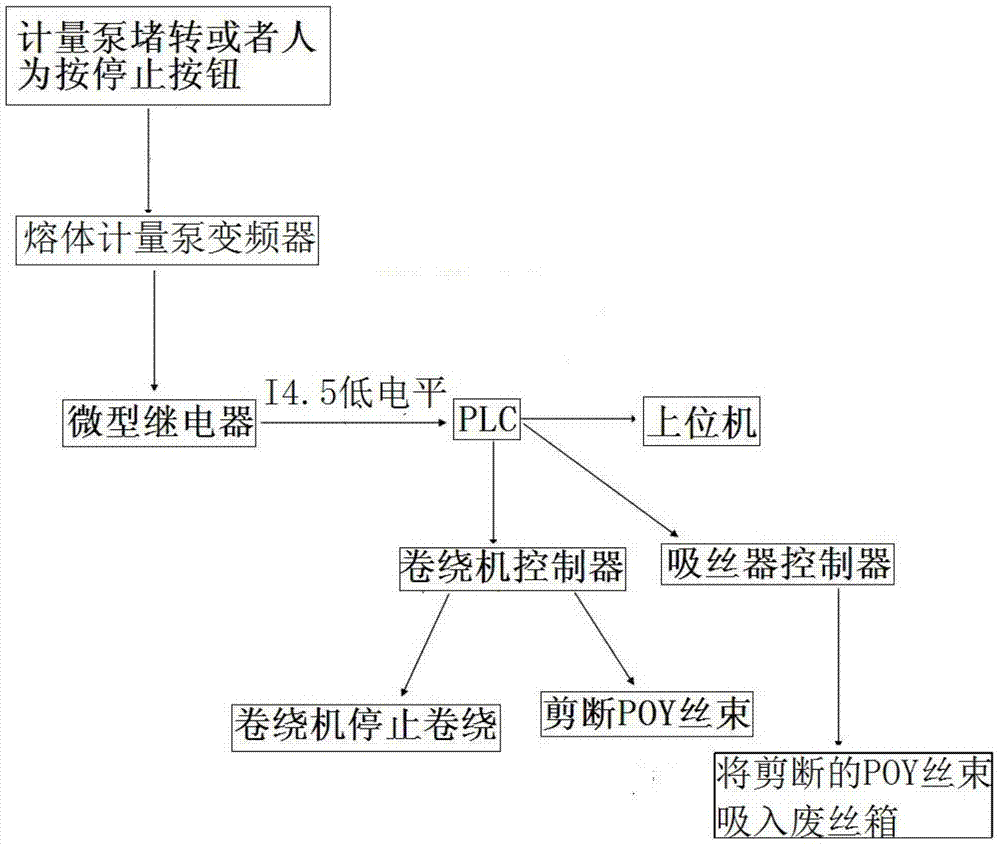

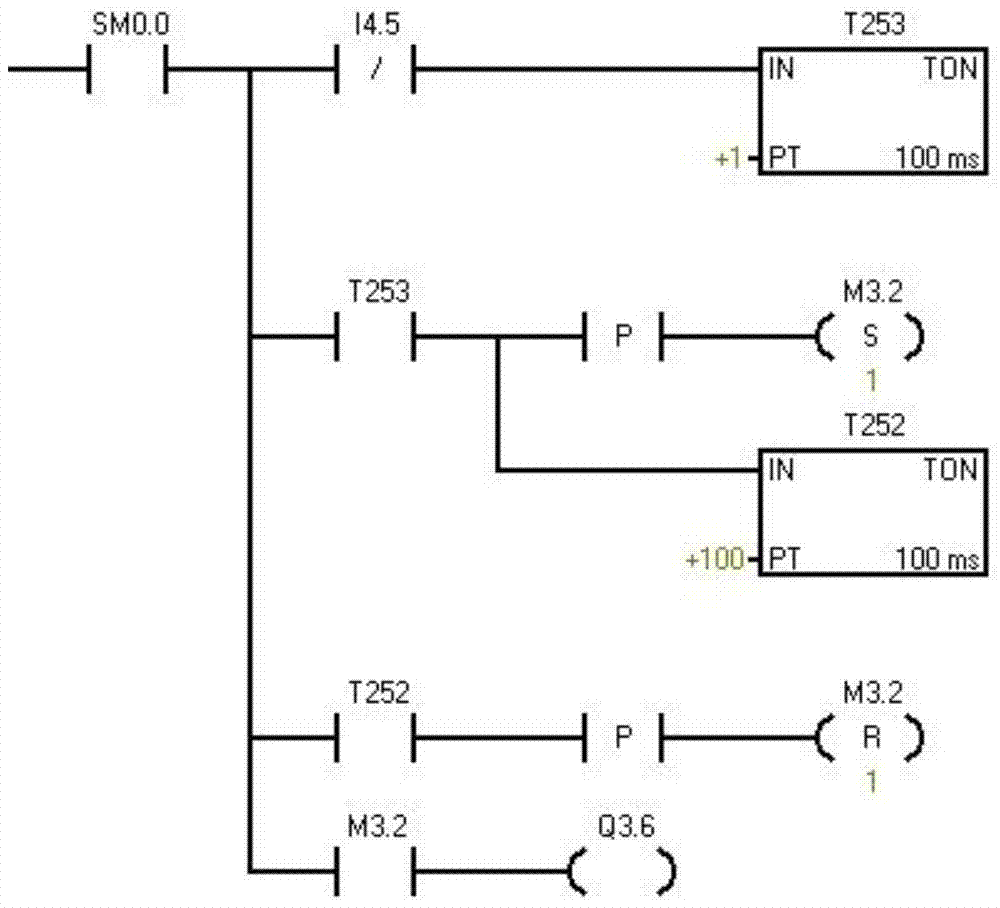

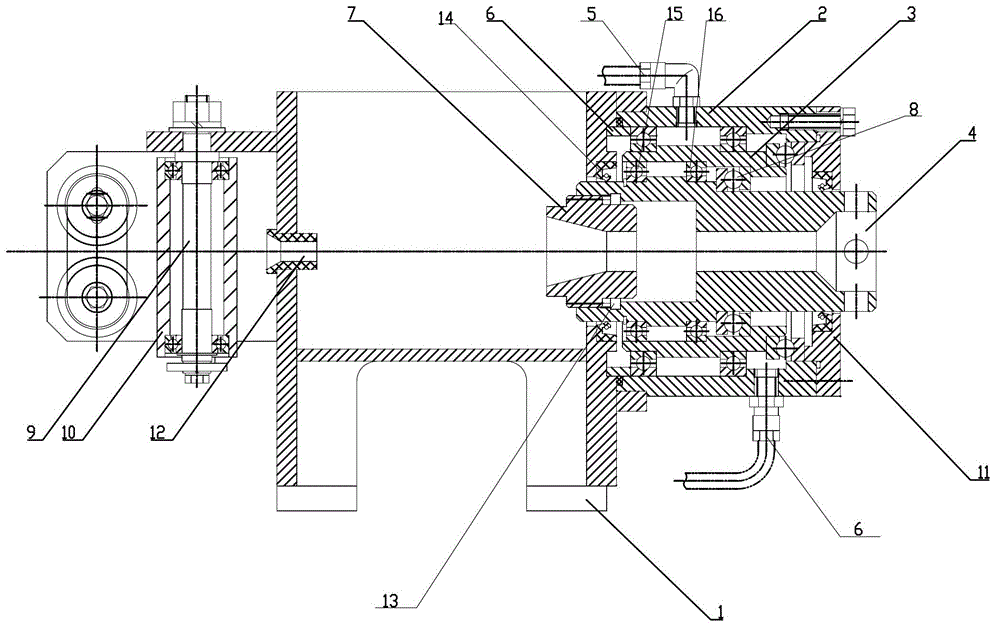

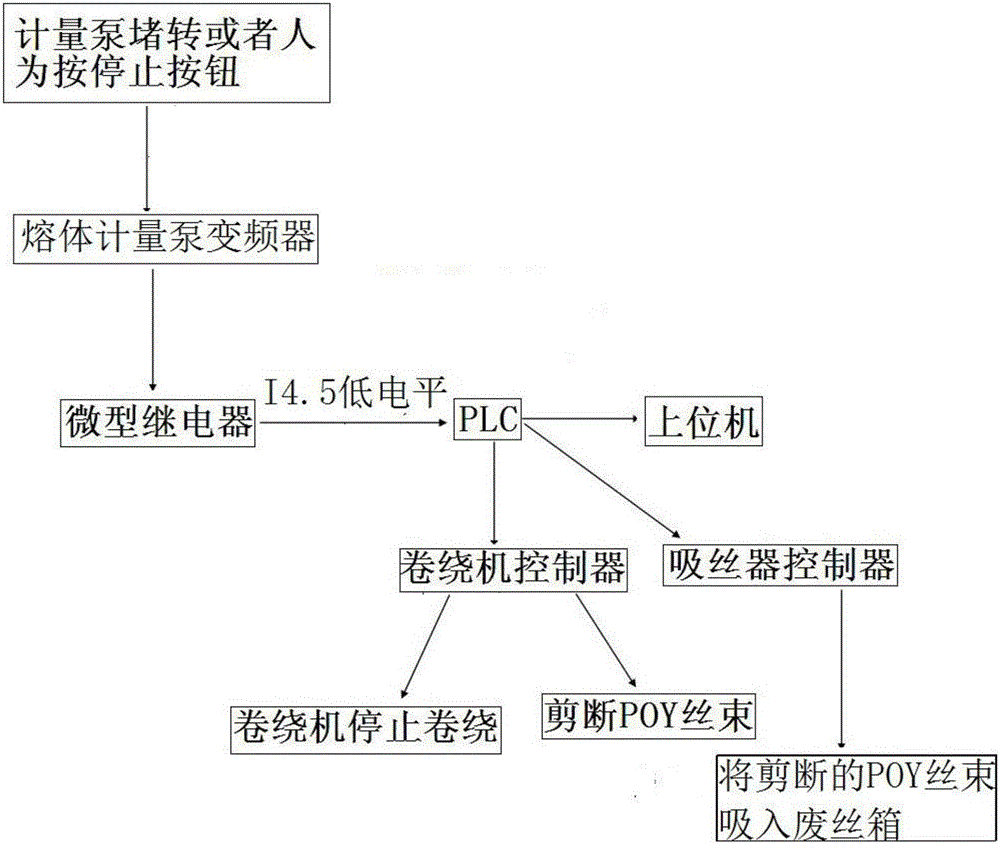

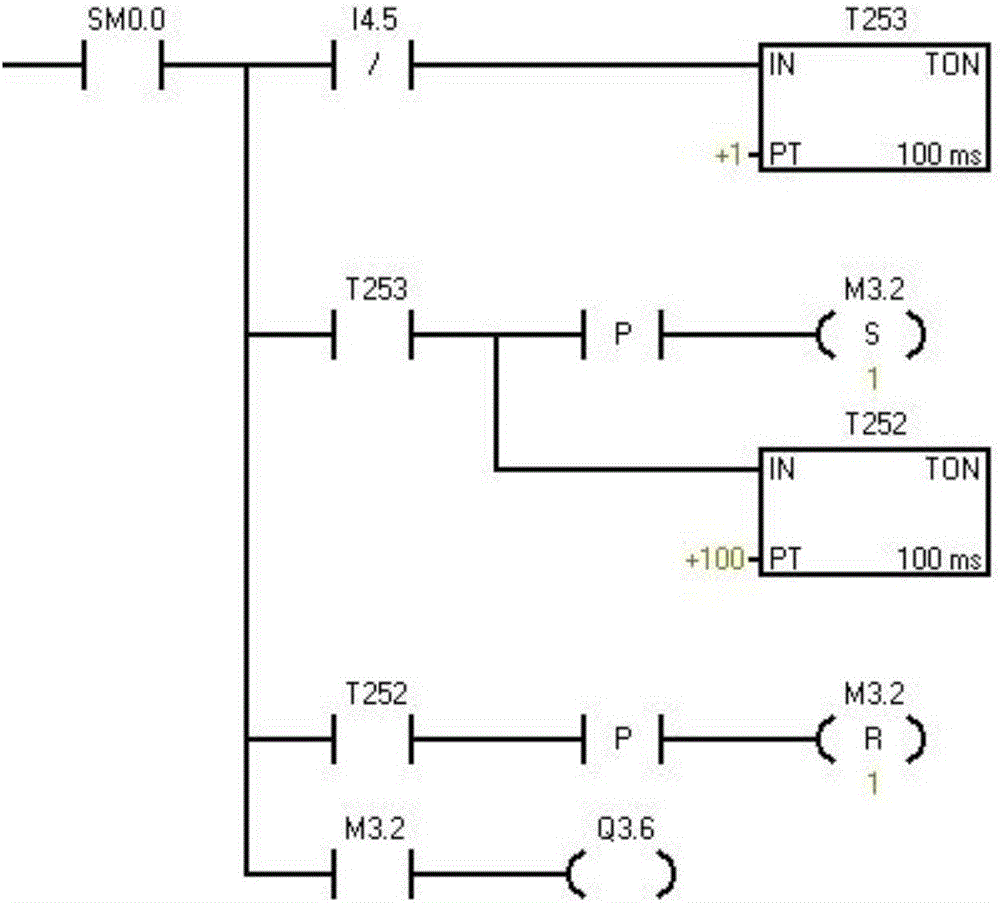

Control method for preventing POY (Pre-Oriented Yarn) fineness from generating midway variation

ActiveCN103488119AReduce the problem of denier shrinkageIncrease the full volume rateArtificial thread manufacturing machinesProgramme control in sequence/logic controllersWinding machineControl system

The invention provides a control method for preventing POY (Pre-Oriented Yarn) fineness from generating midway variation. The method provides a control system for preventing the POY fineness from generating the midway variation. The system comprises a melt metering pump frequency converter for controlling a rotary speed of a melt metering pump, a winding machine controller for controlling a winding machine to operate and a PLC (Programmable Logic Controller), wherein the melt metering pump frequency converter is connected with the melt metering pump for spinning POY; the winding machine controller is connected with the winding machine for spinning the POY; the melt metering pump frequency converter and the winding machine controller are connected with the PLC respectively. According to the control method, the problems that the POY metering pump has faults and manual faulty operation is not found in time to cause that the POY middle fineness becomes small can be reduced greatly; therefore, the problem that the dyeing is not uniform, caused by the fineness, and the amount of waste silks are reduced.

Owner:JIANGSU CHALLEN FIBER S&T

High strength polyester industrial filament and preparation method thereof

ActiveCN108130616AIncrease the cross-sectional areaReduce the degree of cokingNew-spun product collectionArtificial filament heat treatmentCooling chamberStructural formula

The invention relates to a high strength polyester industrial filament and a preparation method thereof. Modified polyester is subjected to solid phase polycondensation tackifying, melting, metering,extrusion, cooling, oiling, stretching, heat setting and winding to obtain the high strength polyester industrial filament; during cooling, the vertical height is kept unchanged and the cross sectionarea of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the way of heat preservation; a molecular chainof the modified polyester consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branched chain, and diol with the branched chain has the following structural formula defined in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3 , R3 is selected from alkyl with thecarbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5. The fracture strength of the prepared high strength polyester industrial filament is more than or equal to8.1 cN / dtex. The method is simple and reasonable, and the prepared industrial filament has the advantages of high breaking strength and good mechanical properties.

Owner:JIANGSU HENGLI CHEM FIBER

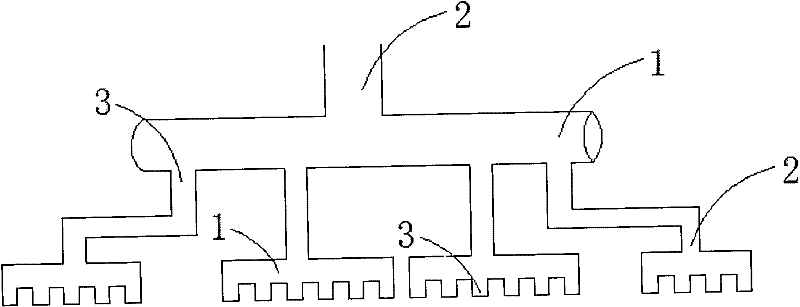

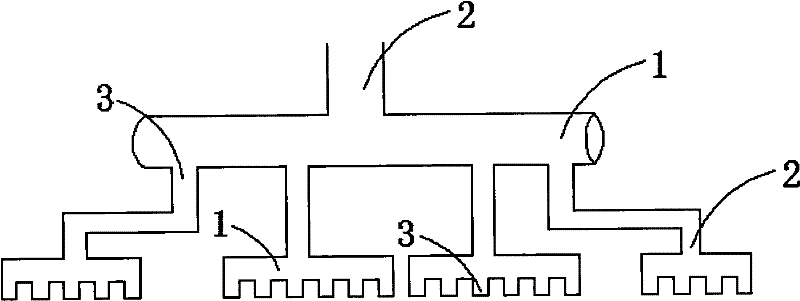

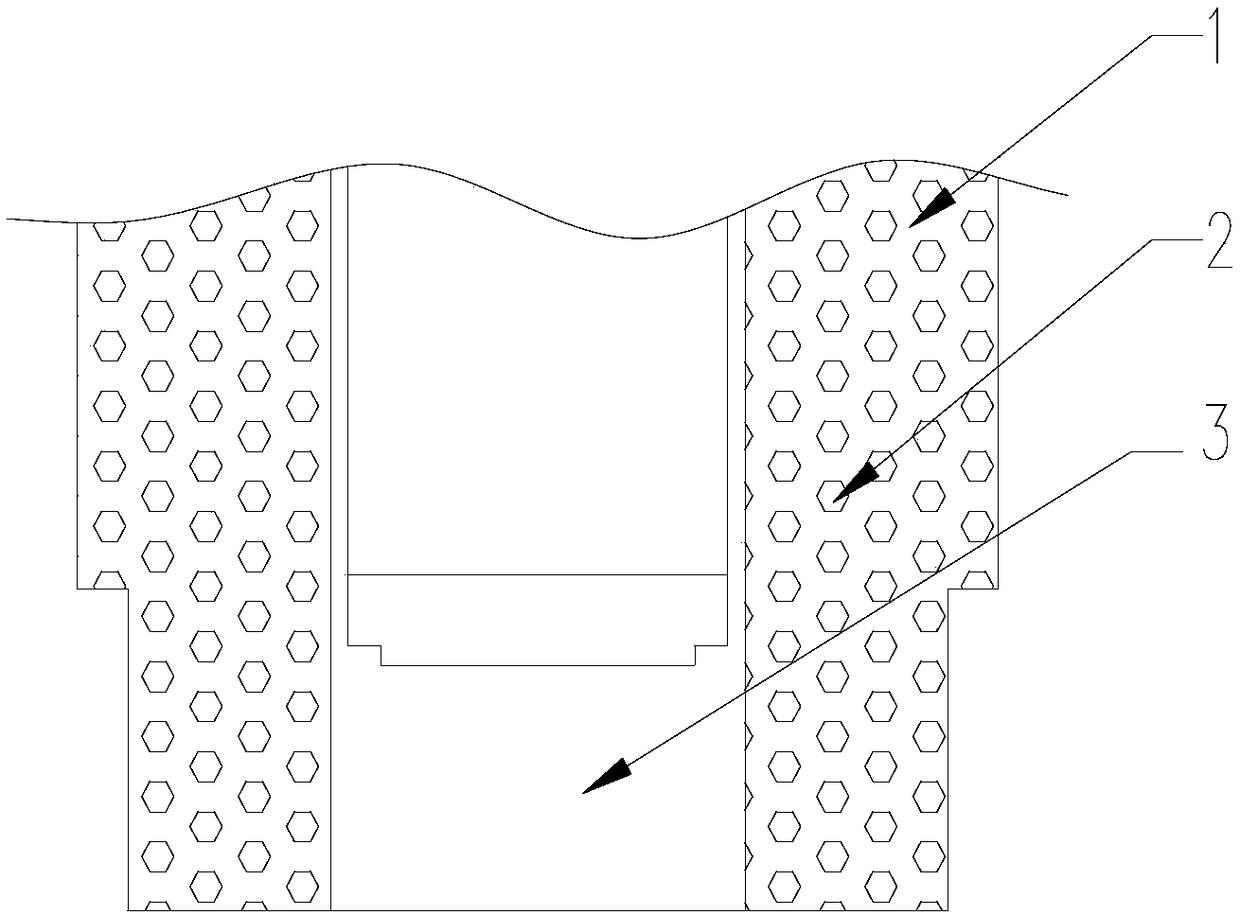

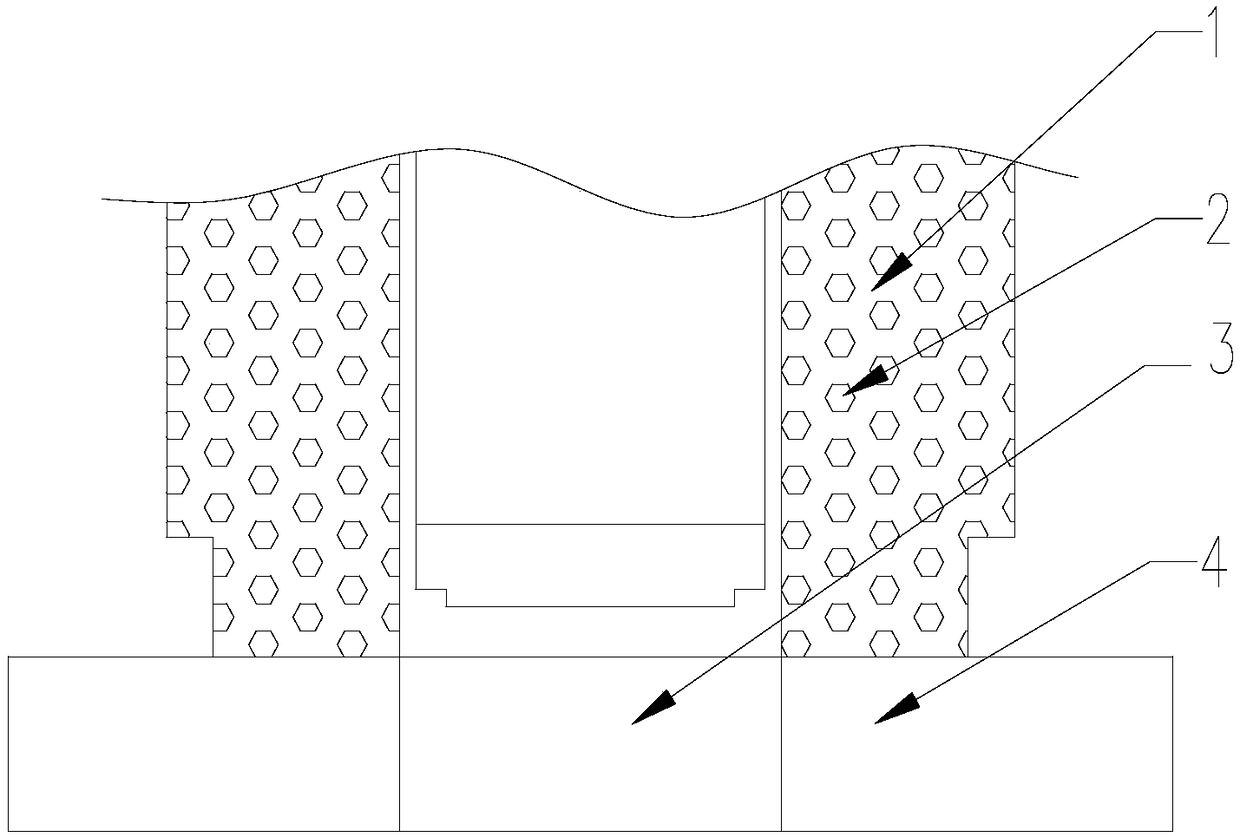

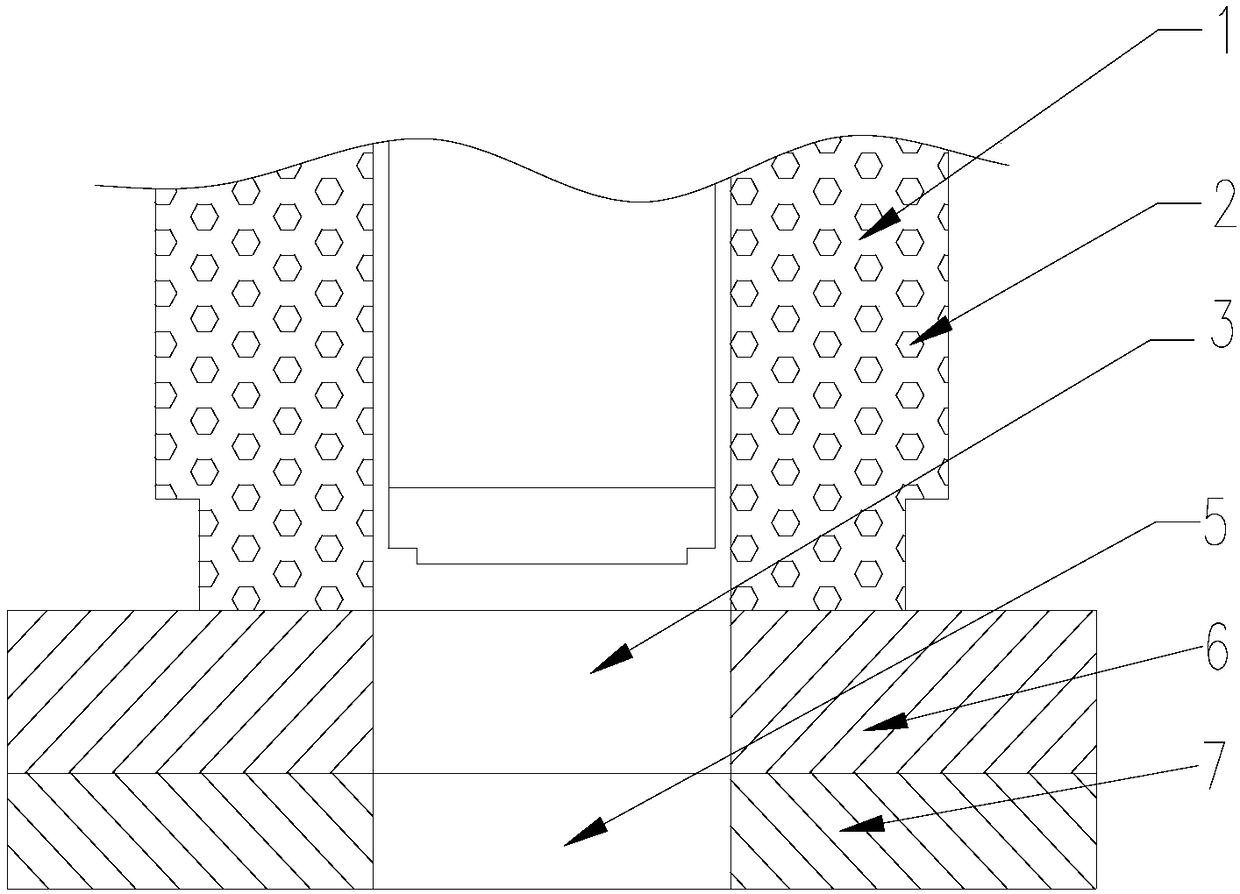

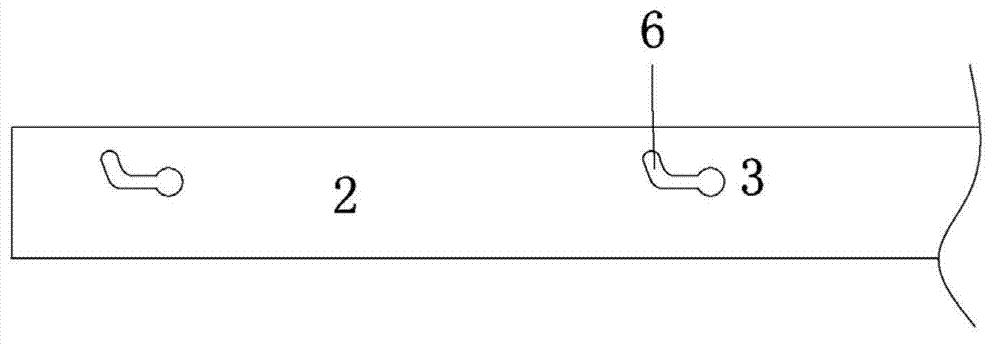

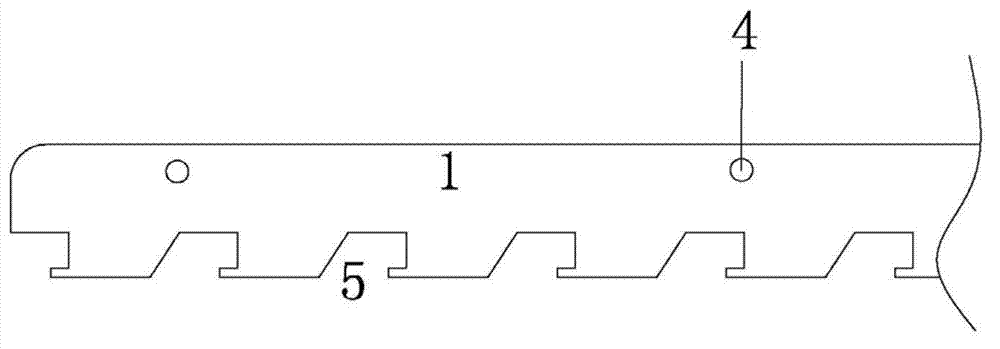

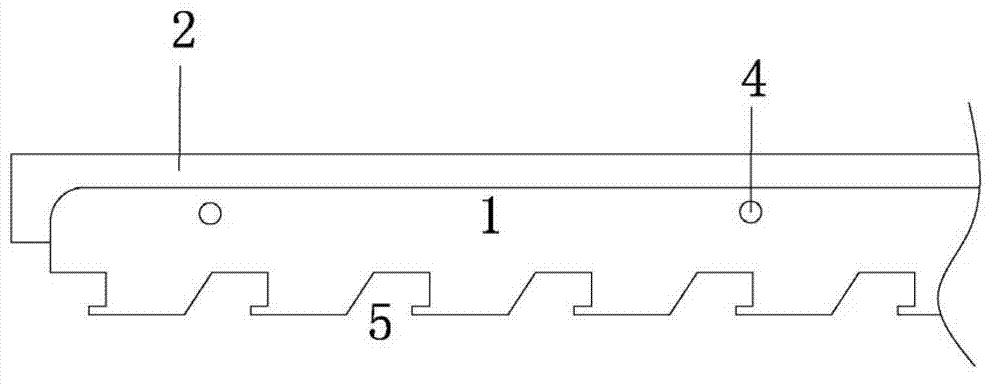

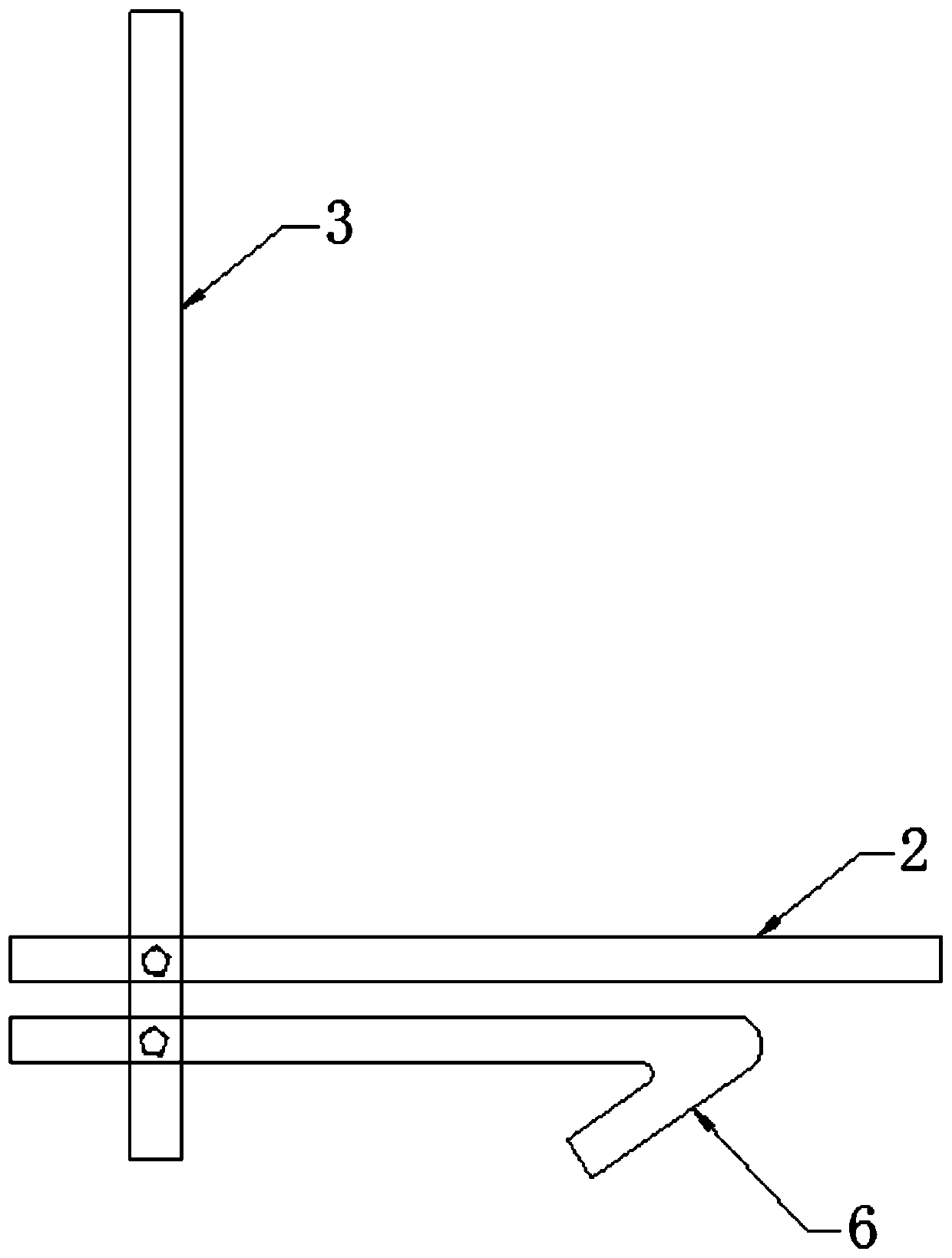

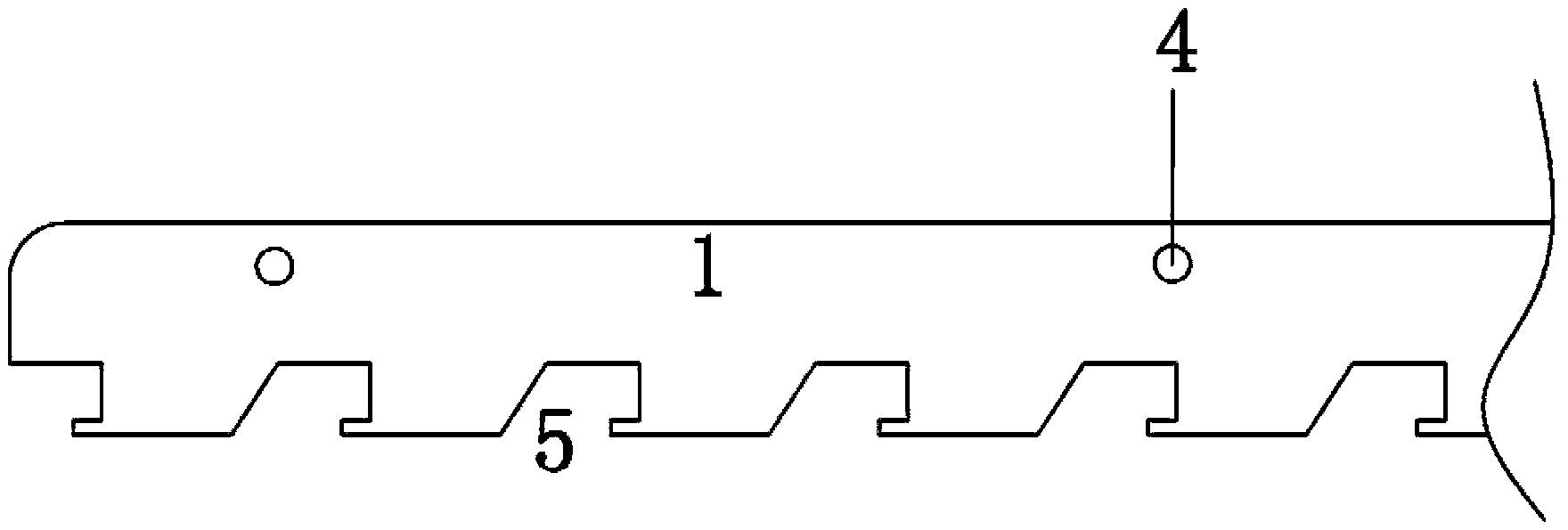

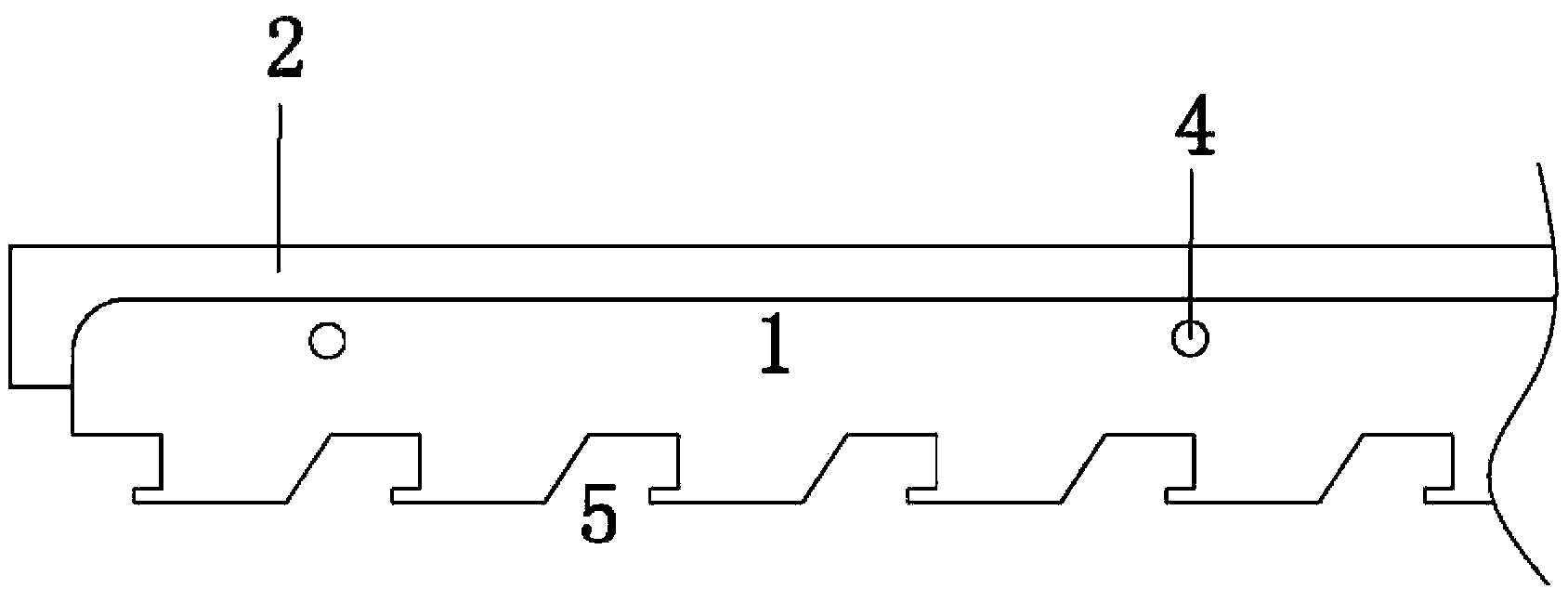

String-up switching mechanism of winding machine

The invention provides a string-up switching mechanism of a winding machine, and relates to the field of textile machinery. The string-up switching mechanism comprises a move-down silk plate and a shoveling plate, wherein a slideway is arranged on the shoveling plate, and a sliding head matched with the slideway is arranged on the move-down silk plate; a groove for hooking and pulling a silk beam is formed in one side of the move-down silk plate; and a bending way opposite to the one side of the groove is arranged at the slideway. The string-up switching mechanism of the winding machine has high string-up switching success rate, the waste silk quantity can be greatly reduced, and meanwhile the product quality is increased. As the improvement cost is low, the string-up switching mechanism is also suitable for large-range popularization and application.

Owner:JIANGSU CHALLEN FIBER S&T

Washing device and process of PET (polyethylene terephthalate) liquid-phase tackifying kettle

The invention relates to a washing device of a PET (polyethylene terephthalate) liquid-phase tackifying kettle and a washing process using the washing device for washing the tackifying kettle, and belongs to the technical field of polyester fiber production. The washing device comprises a segmented heater, a solvent injection pipe, a circulation pipe, a buffer tank, a condenser and a liquid seal tank, wherein the segmented heater is arranged in an outer wall jacket of the tackifying kettle; the solvent injection pipe is arranged at the top of the tackifying kettle; one end of the buffer tank is connected with the tackifying kettle through the circulation pipe, and the other end of the buffer tank is connected to the top of the condenser through a steam pipe; a circulative pipe is arranged at the bottom of the condenser and divided into two branch pipes, one branch pipe is connected to the bottom of the buffer tank, and the other branch pipe is connected to the bottom of the liquid seal tank; and the upper part of the liquid seal tank is connected to the top of the condenser, and control valves are arranged on two branch pipes of the circulative pipe respectively and used for controlling connection and disconnection of corresponding pipelines. The washing device has the advantages of high washing efficiency, low cost and the like.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Method and device for reducing waste wires of glass fiber wire drawing machine

ActiveCN110655320AReduce tanglingMachine yarn reductionGlass making apparatusGlass productionYarnManufacturing engineering

The invention discloses a method for reducing waste wires of a glass fiber wire drawing machine. The method comprises the steps: step S1, the wire drawing machine is started for yarn feeding; step S2,yarns are pushed into the inner side of a machine head; step S3, a yarn arranging machine arm of the wire drawing machine is folded to arrange the yarns; step S4, after yarn arrangement is finished,the yarns are pushed out of the inner side of the machine head; step S5, the machine head is subjected to creeling, and whether an end signal is received or not is judged; if the end signal is not received, the operation returns to the step S2; and if the end signal is received, the wire drawing operation is finished, and the wire drawing machine is closed. Compared with the prior art, yarn arrangement does not need to be started after a groove in one end of the machine head is full of the yarns, winding of the yarns in the groove of the machine head is reduced, and thus the machine head yarnsare reduced, yarn waste is reduced, and the yield of the finished product is increased; meanwhile, the winding time of the yarns in the groove in one end of the machine head is avoided, so that the production efficiency is improved. The invention further discloses a device for implementing the method for reducing the waste wires of the glass fiber wire drawing machine.

Owner:CHONGQING POLYCOMP INT

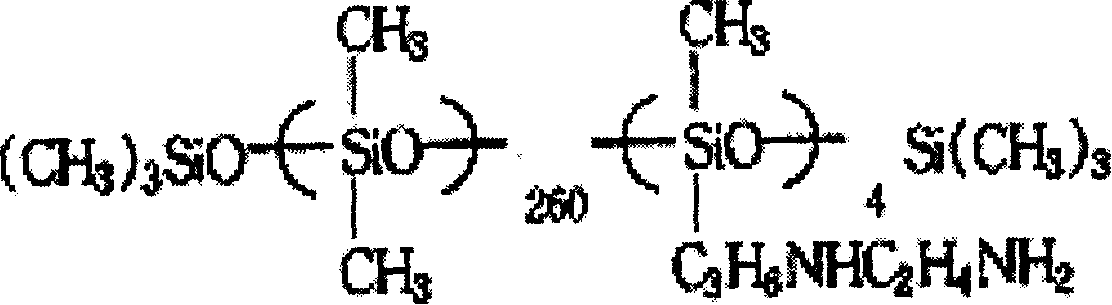

Auxiliary agent in use for regenerated fiber

The present invention discloses an ajuvant for producing regenerated fibre; in particular, it is an adjuvand for producing regenerated polyester fibre. Said adjuvant composition includes bundling agent, smoothing agent, antistatic agent and water. The described bundling agent is one kind of polyvinyl alcohol whose average degree of polymerization is 600-1500 and degree of alcoholization is 80%, polyethylene glycol whose average molecular weight is 400-8000, polyethylene glycol 400 monostearate and polyethylene glycol stearate or their mixture. The weight ratio of said bundling agent, smoothing agent, antistatic agent and water is 1:0.05-0.5:1-5:1.5-8.

Owner:黄山市强力化工有限公司

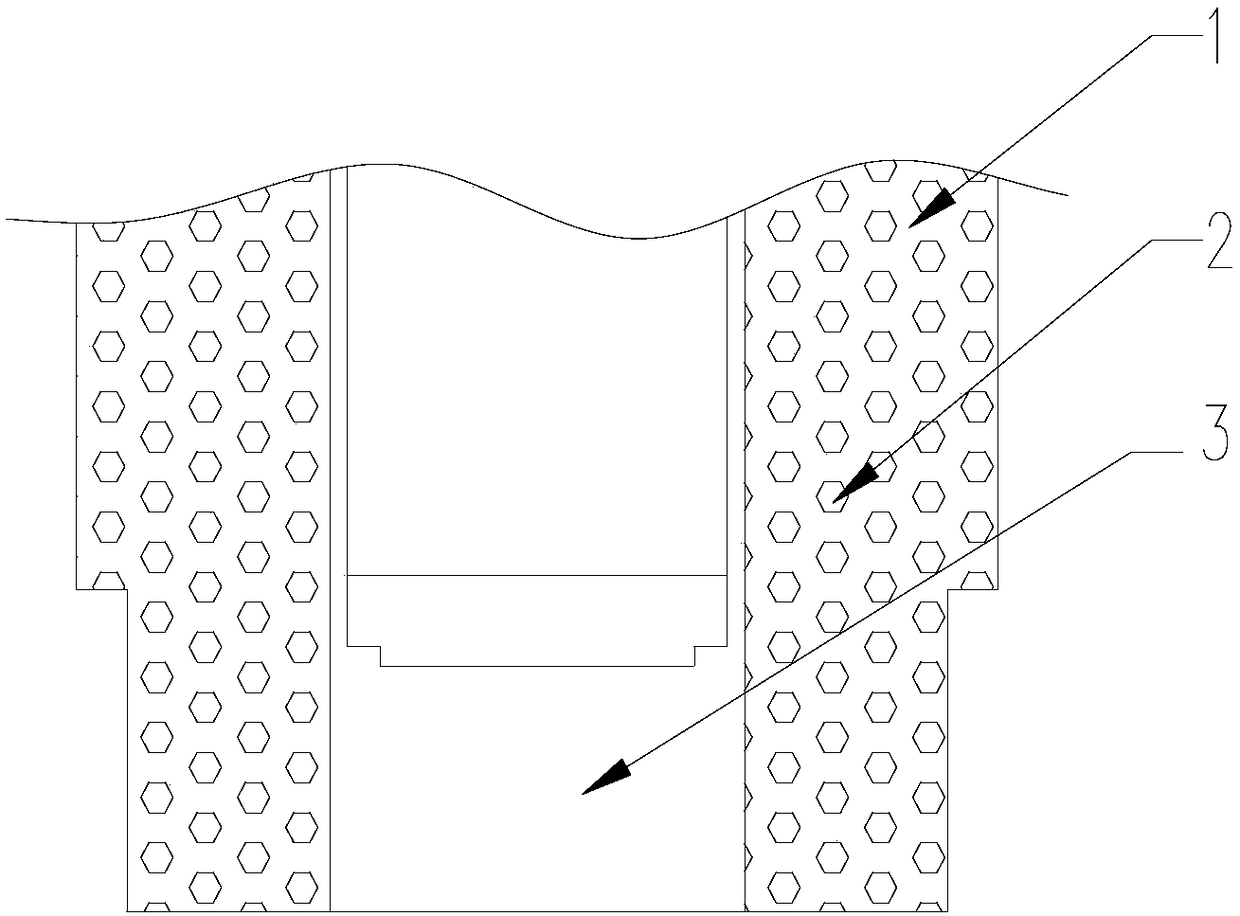

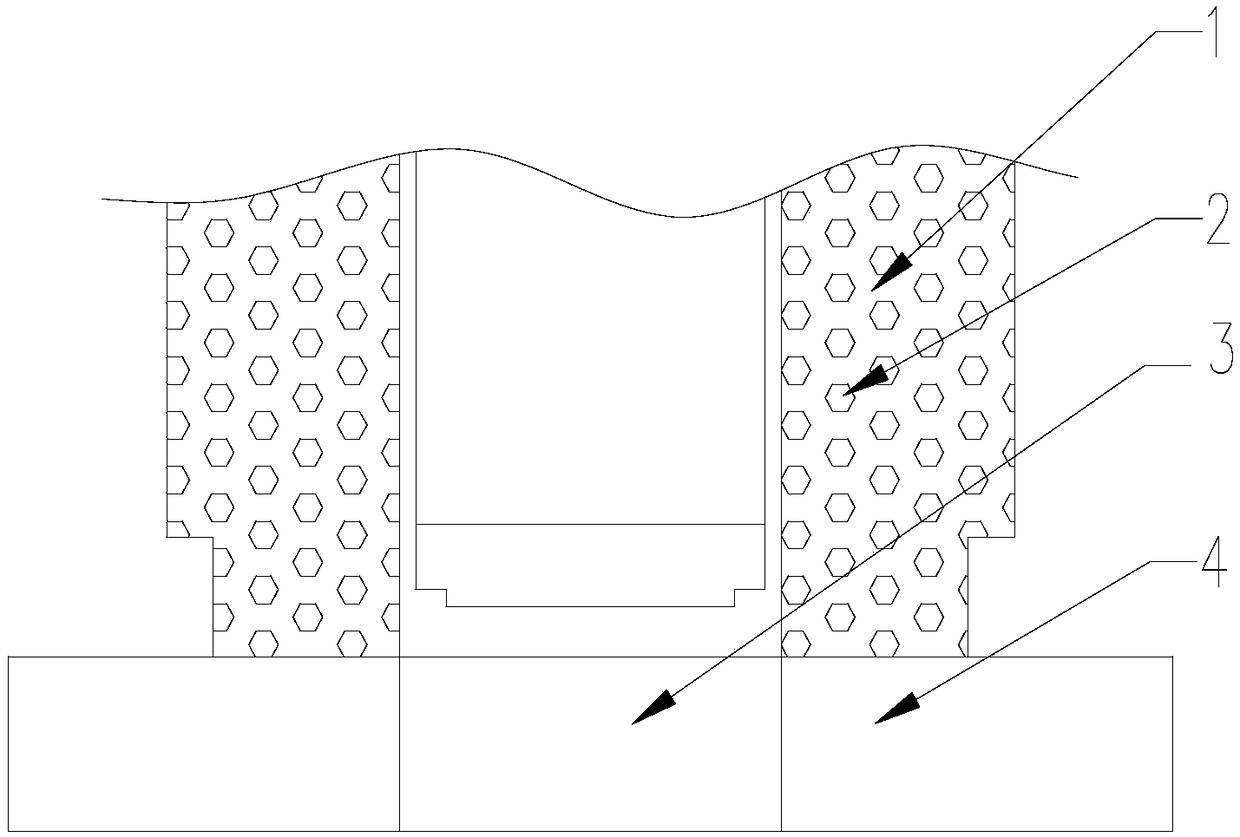

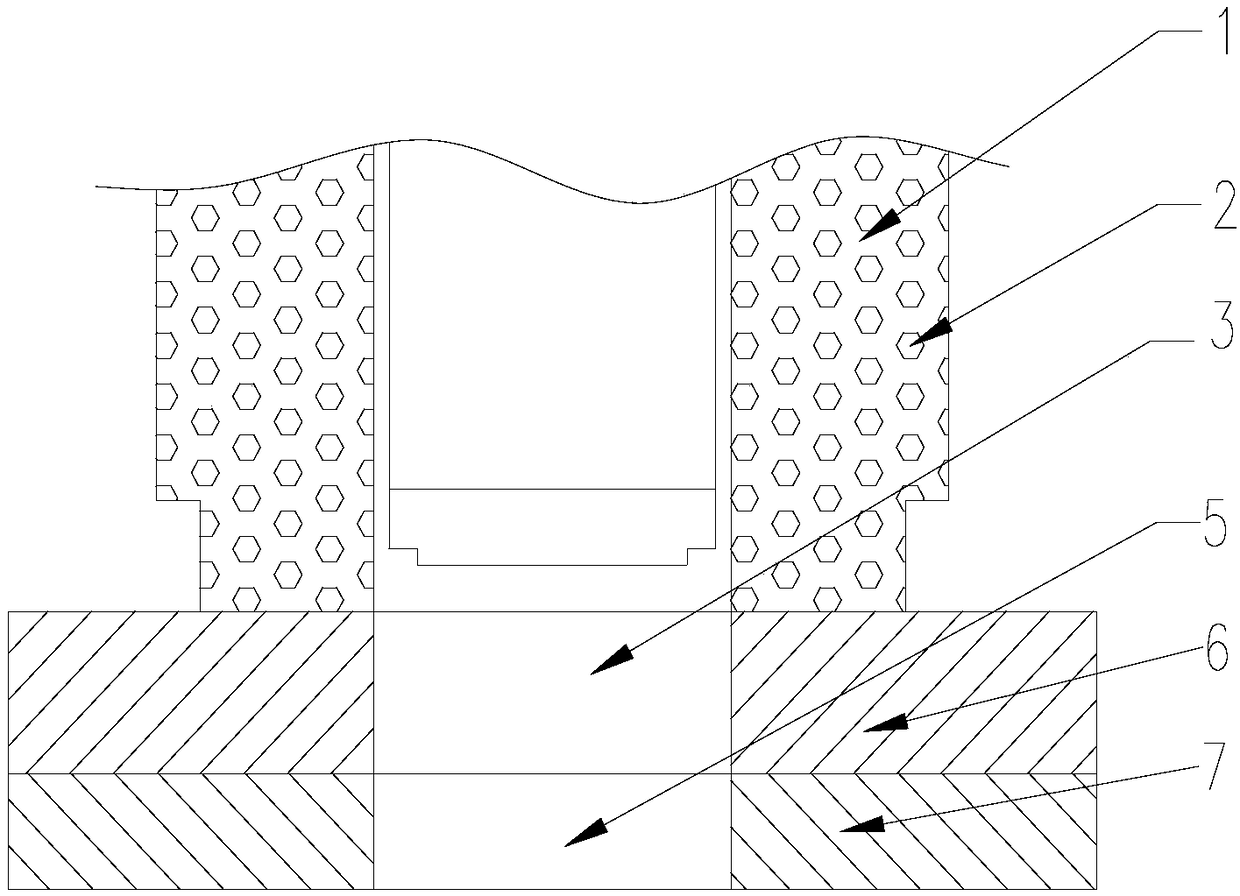

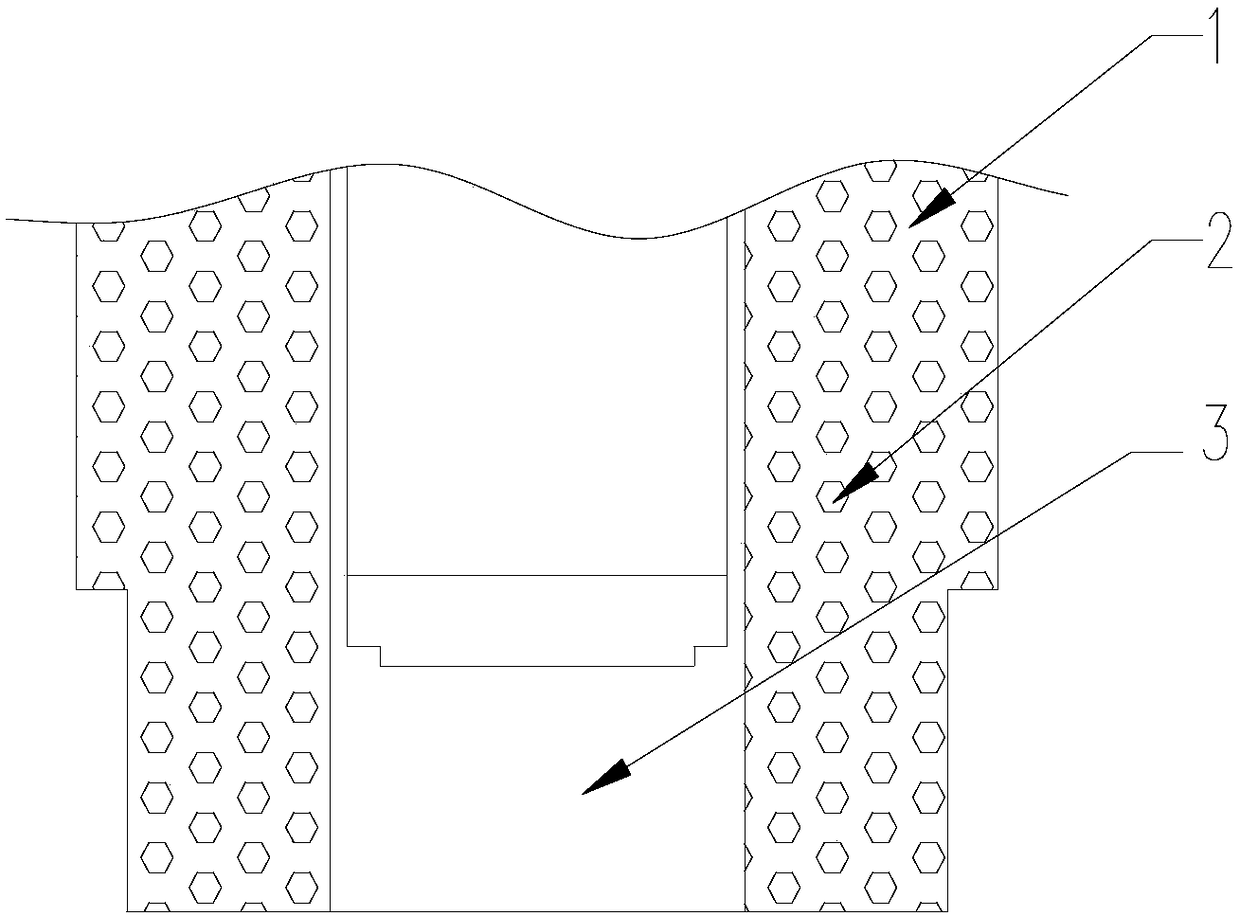

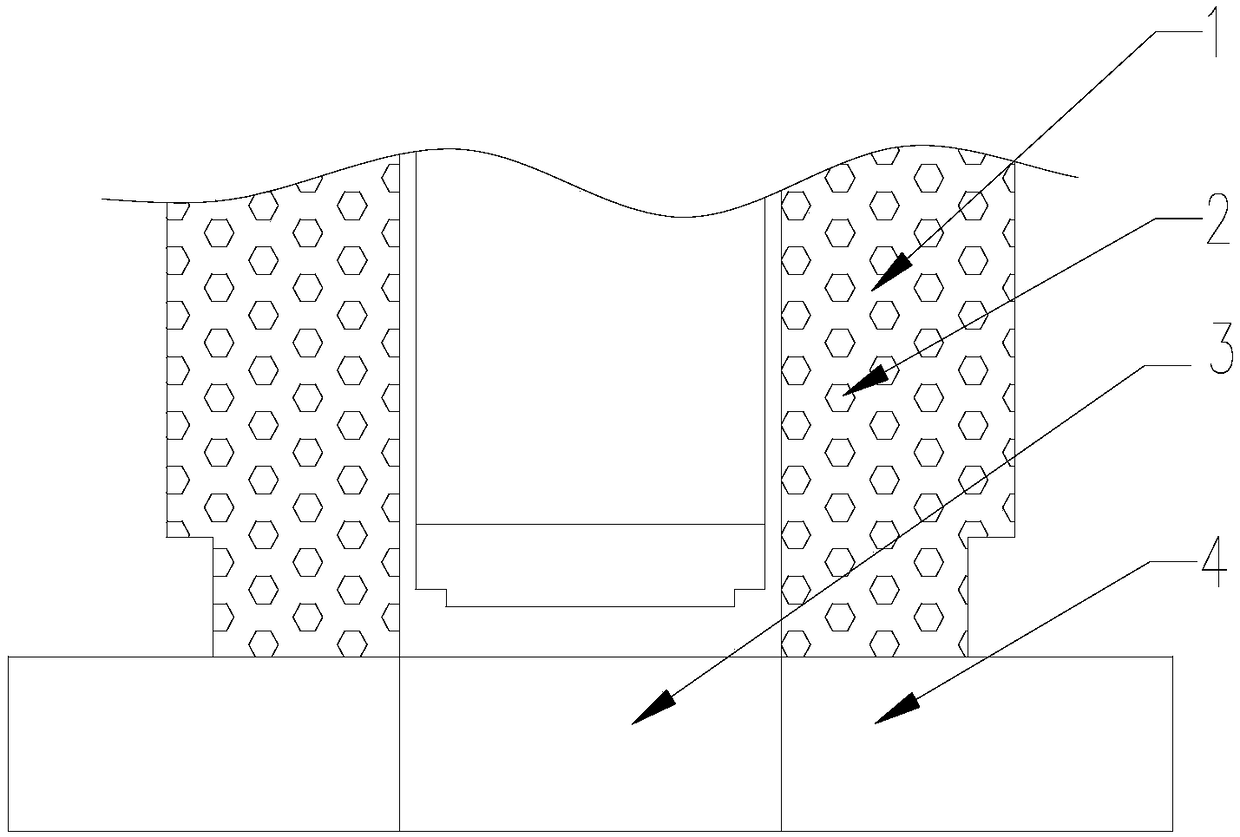

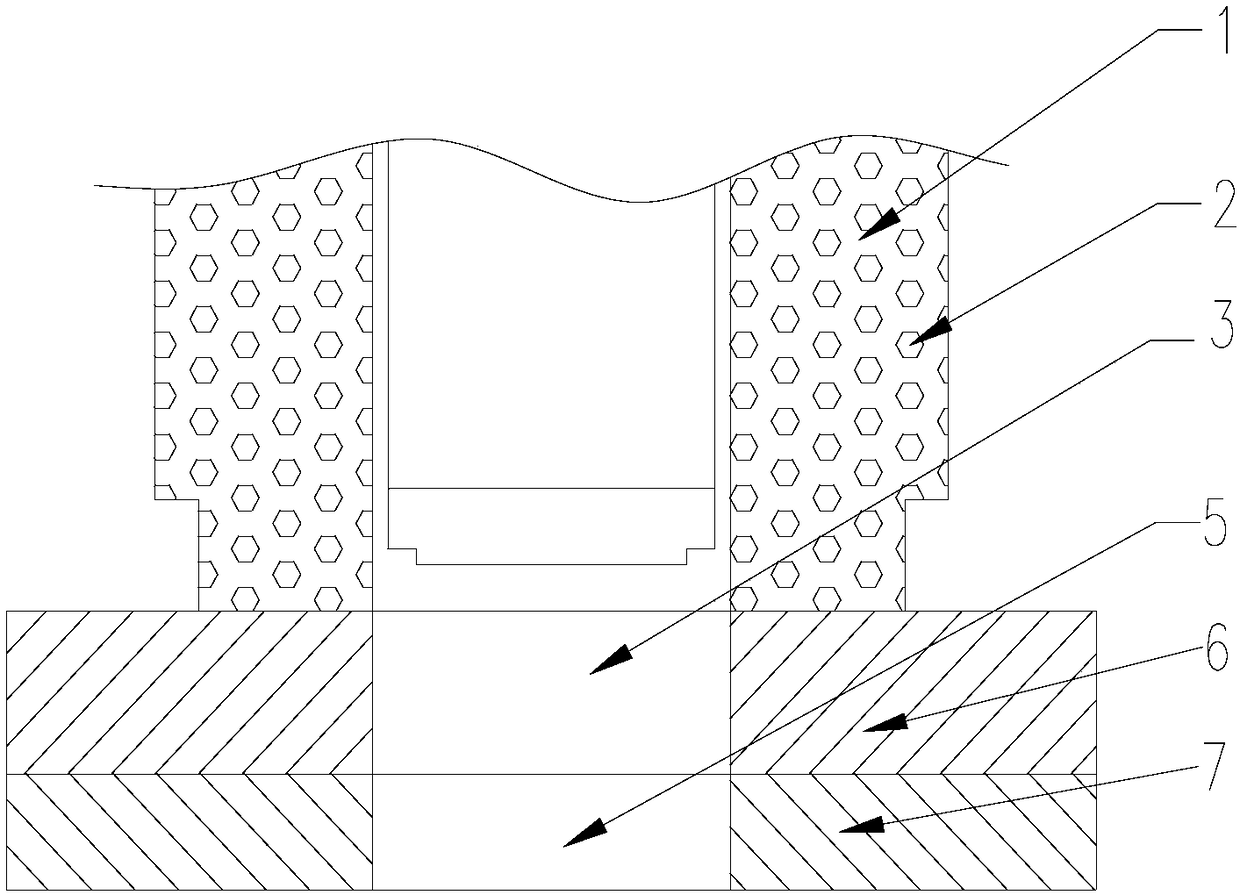

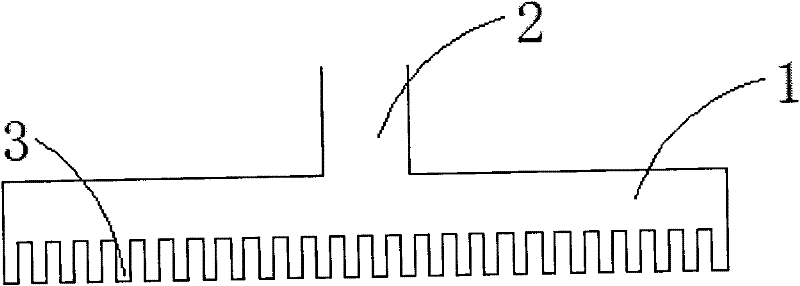

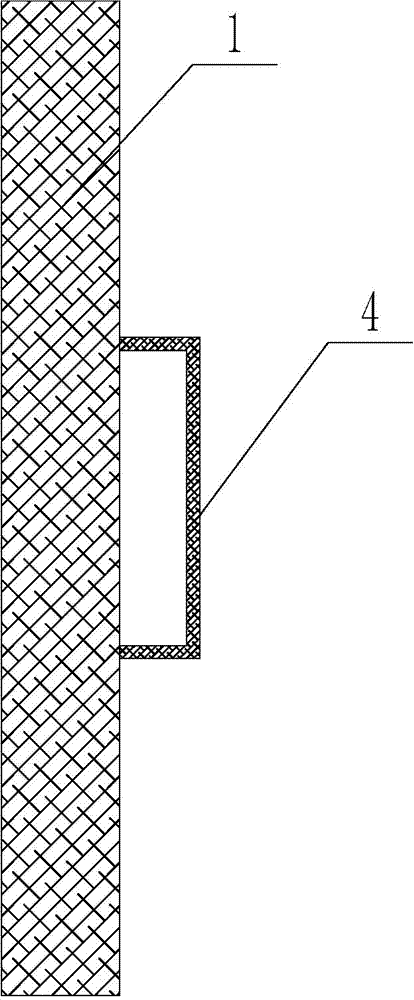

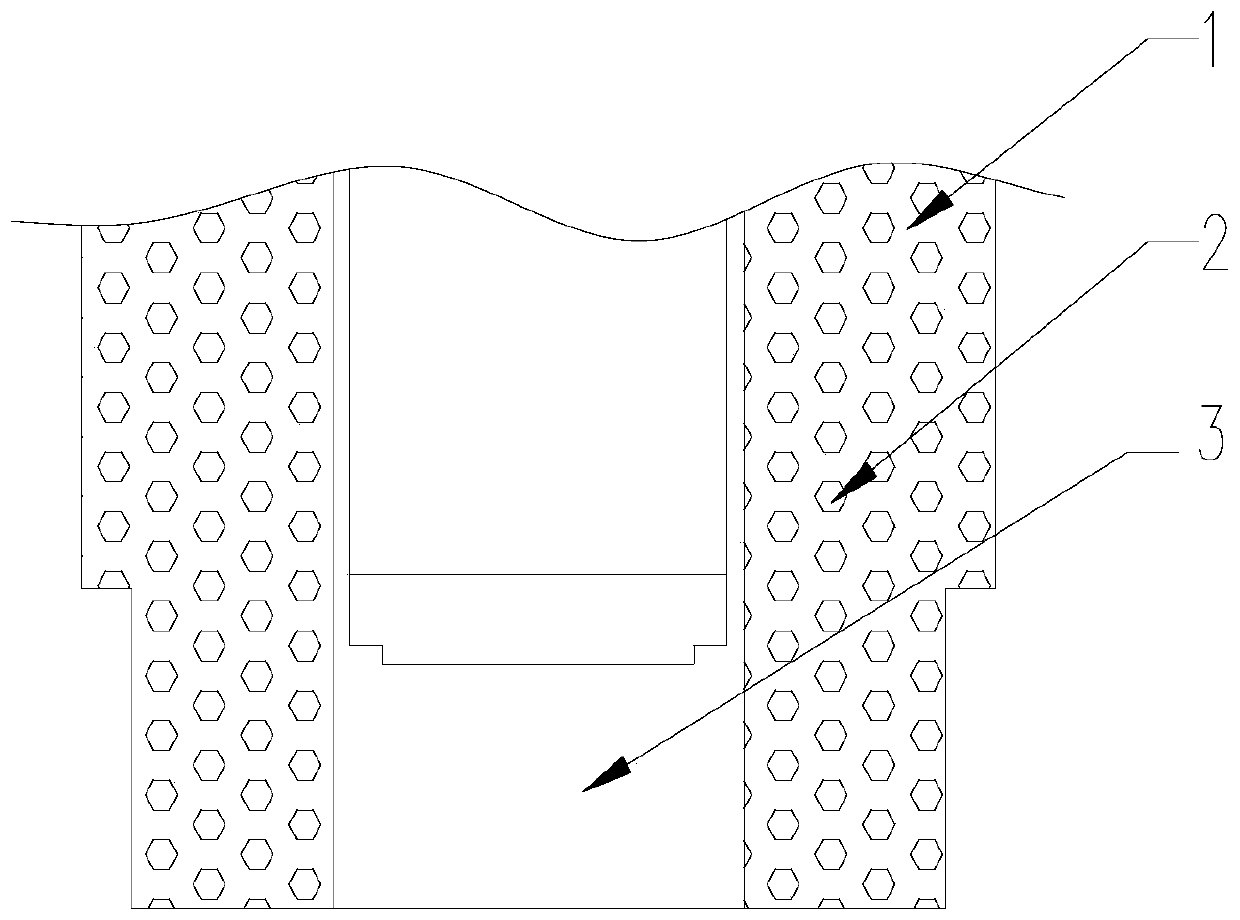

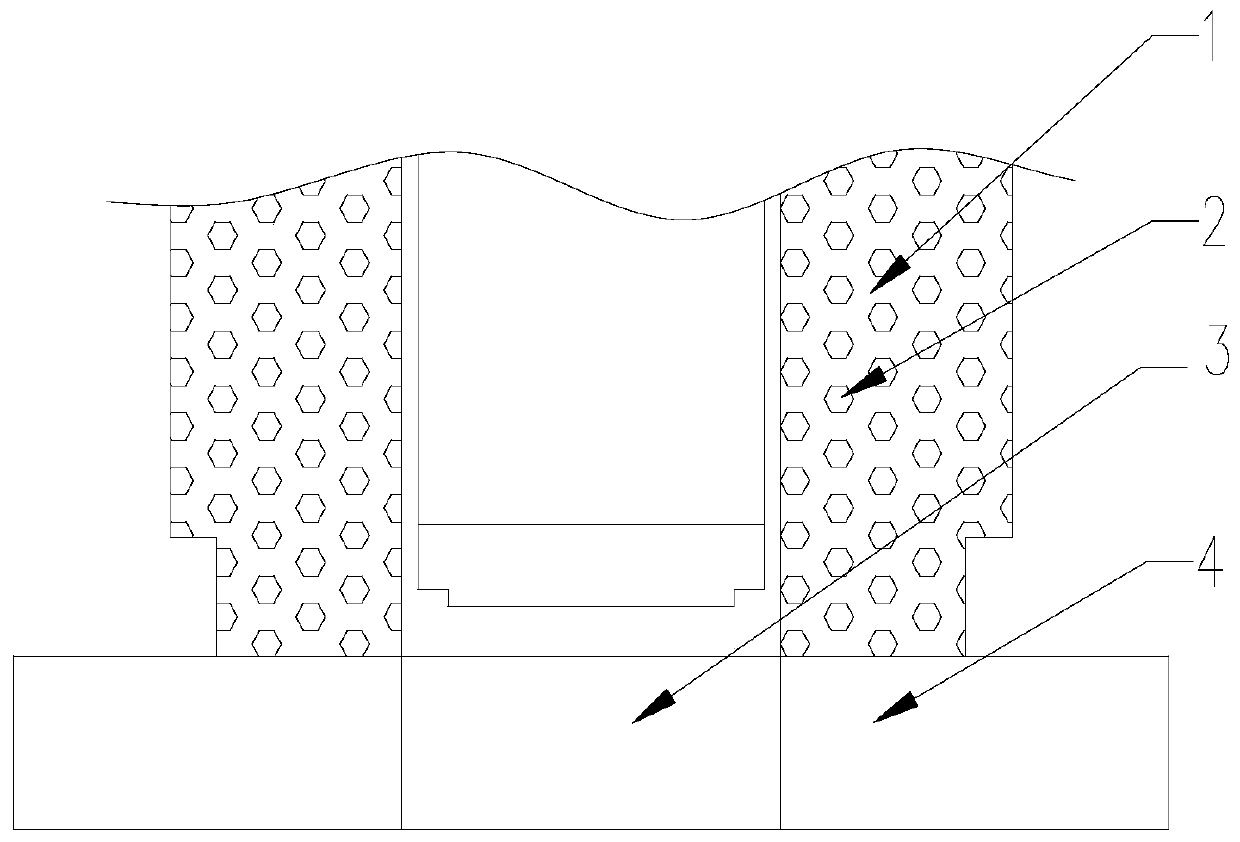

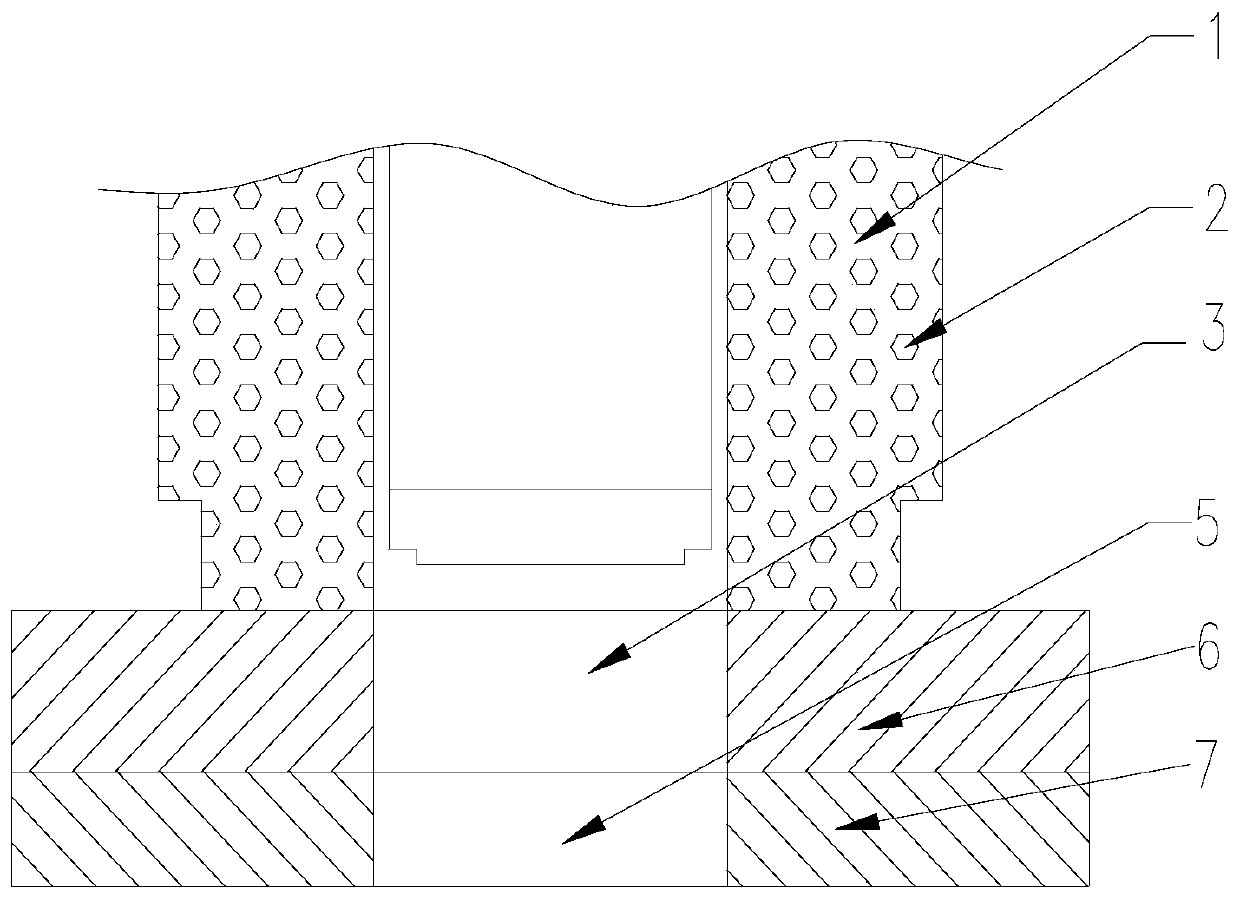

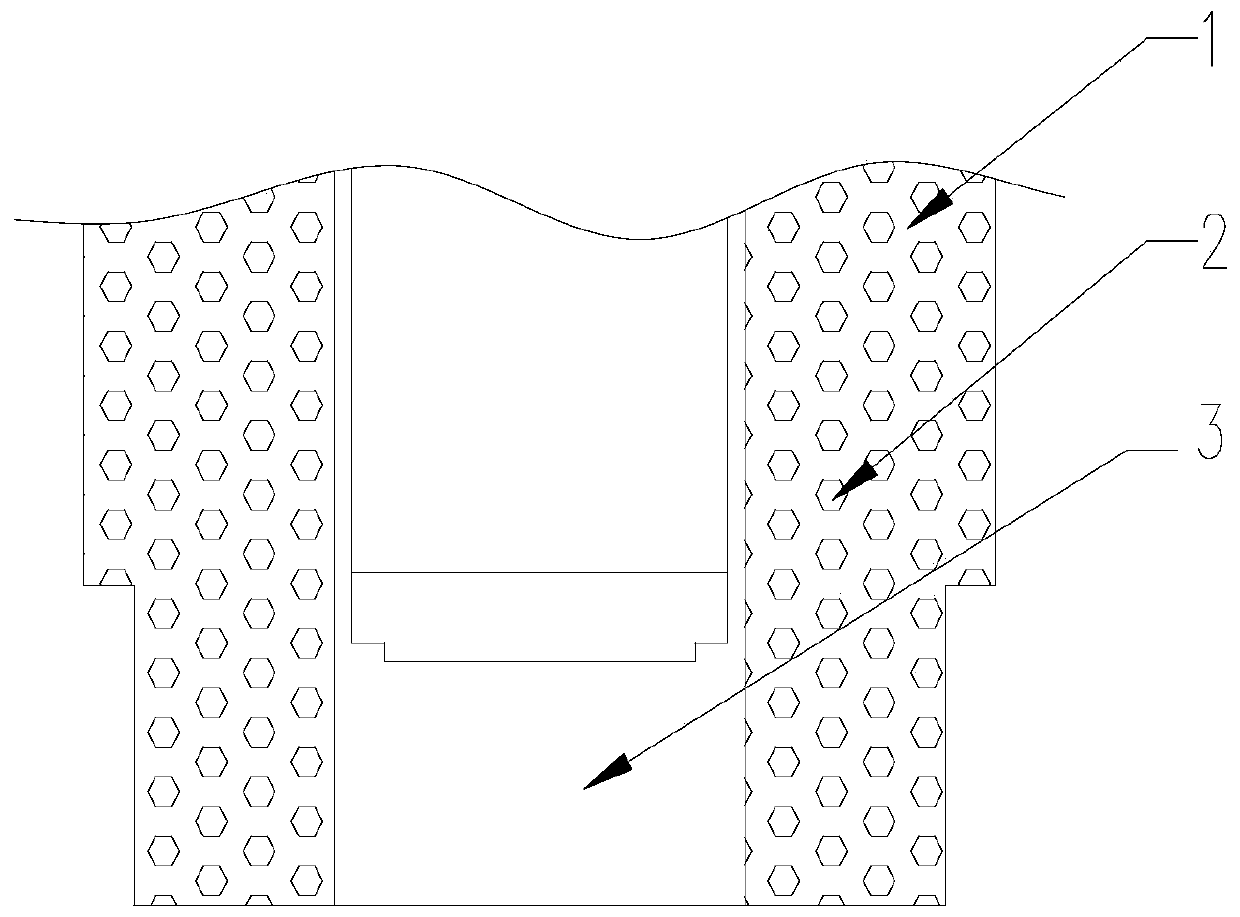

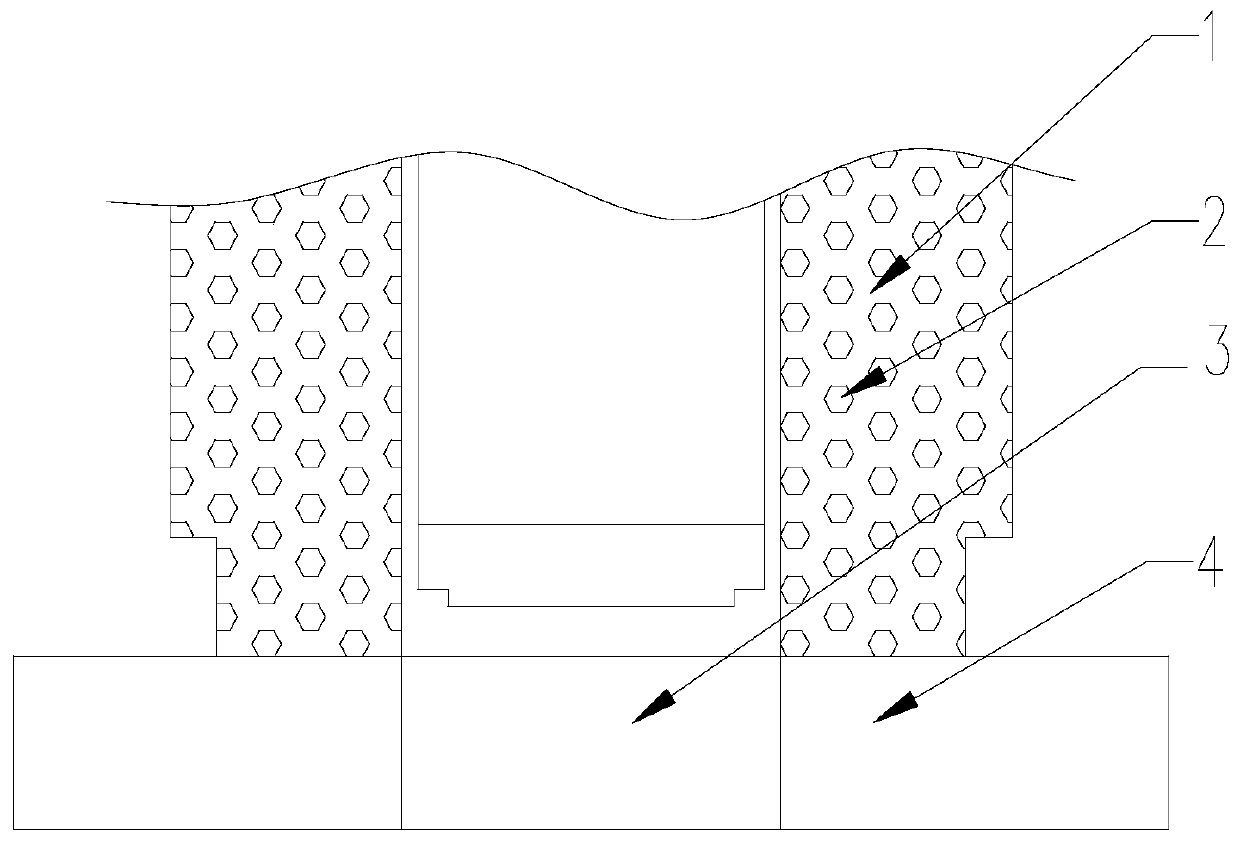

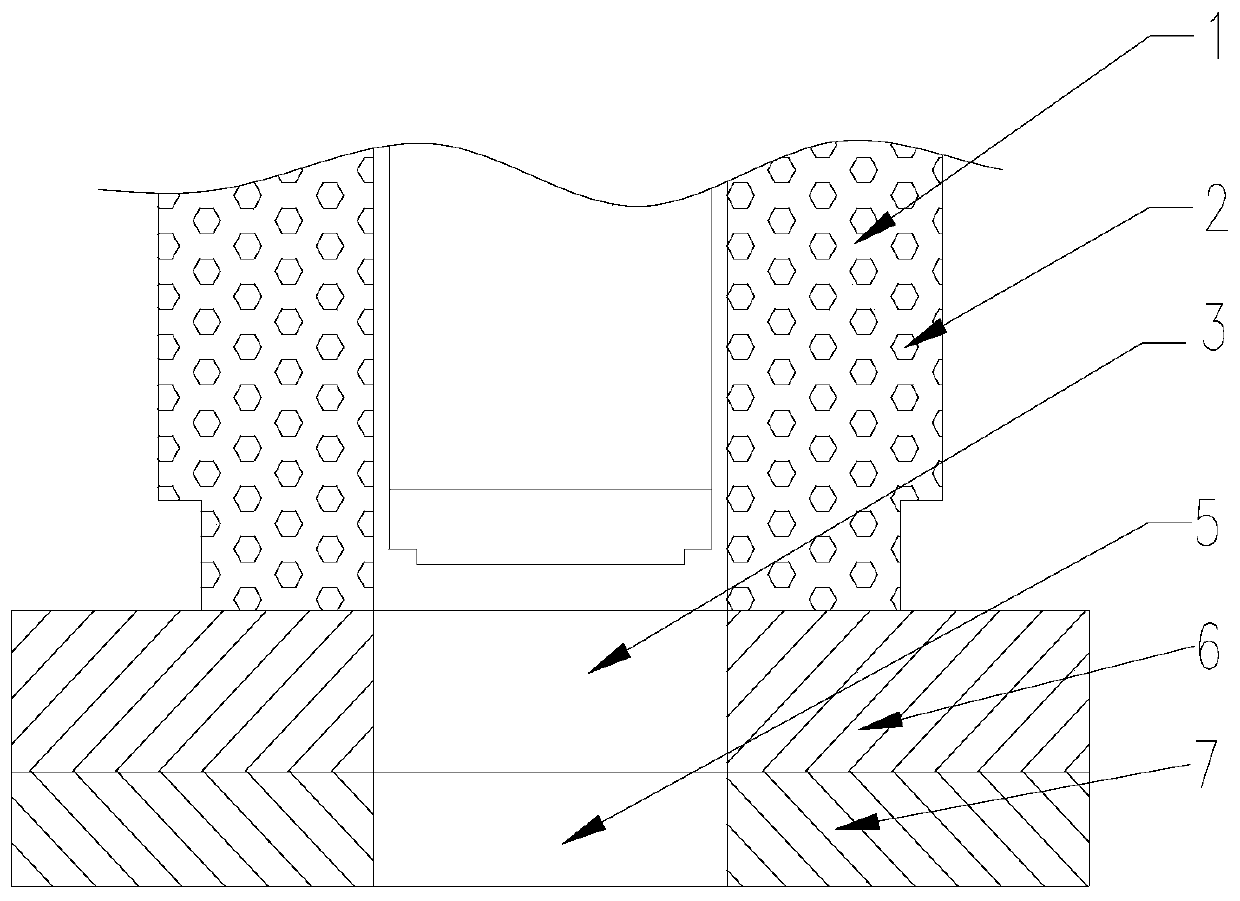

Heat preservation plate in cross air blow device

InactiveCN102926011ASimple structureEasy to useArtificial thread manufacturing machinesArtificial filament heat treatmentYarnPolyester

The invention relates to a heat preservation plate in a cross air blow device. The heat preservation plate comprises a heat preservation plate body, wherein the length of the heat preservation plate body is matched with the width of the cross air blow device, the heat preservation plate body is internally provided with a plurality of grooves, the cross sections of the groove are semi-circular, the sizes of the grooves are matched with the diameters of spinneret plates, and the quantity of the grooves correspond to that of the spinneret plates. The heat preservation plate is simple in structure, convenient to use, and low in cost. In the high-speed coiling of spinning fine denier or superfine denier polyester drawn yarn, the heat preservation plate plays a part in stably producing, reducing disconnecting heads, reducing waste yarns, reducing the evenness uneven rate of products, improving the M rate of coloration and the like, and particularly can effectively solve the broken filament of the special-shaped polyester drawn yarn in the process of production, so that the product quality can be improved.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

A high-modulus low-shrinkage hard wire rope and its preparation method

ActiveCN108385418BLow dry heat shrinkageSimple preparation processFibre typesFilament/thread formingYarnPolymer science

The invention relates to a high-modulus low-shrinkage stiff cord and a preparation method thereof. The preparation method comprises the following steps: performing solid-phase polycondensation-viscosity enhancement, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain high-modulus and low-shrinkage polyester industrial yarns; twisting to obtain a cord; making the cord into a high-modulus low-shrinkage stiff cord by a two-bath impregnation method, wherein during cooling, the longitudinal height is kept constant and the cross-sectional area of a slow cooling chamber is increased; meanwhile, the surface temperature of a spinneret plate is kept in a heat preserving way in the slow cooling chamber; an oiling agent contains 67.30 to 85.58 percent by weight of crown ether; during use of the oiling agent, 14 to 18 percent by weight emulsion is prepared with water. The preparation method disclosed by the invention is simple; the prepared high-modulus low-shrinkage stiff cord is made from modified polyester of which the molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain, is greater than or equal to 80N in breaking strength, and is greater than or equal to 37KN / m in cord bonding strength.

Owner:JIANGSU HENGLI CHEM FIBER

One-step method for producing polyester and ammonia empty-covered yarn and changing yarn

ActiveCN110004537BReduce productionReduce the risk of accidents at workPiercing arrangementsYarnPolyester

The invention discloses a one-step method for producing polyester-spandex empty-covered yarn for yarn replacement, which includes the following content: the spandex yarn can be replaced without running out, and the polyester POY yarn is not cut. Once the spandex yarn runs out, the wire detector will send a signal to the cutter to cut off the polyester POY yarn at the same time. This is the normal protection program of the machine and cannot be changed, otherwise it will affect the normal operation of the machine. In this case, both the polyester yarn and the spandex yarn must be raised again, and there will be abnormal yarns on the surface of the finished empty-covered yarn, and this part of the abnormal yarn must be stripped to increase the consumption of waste yarn. Spandex is used to change the yarn without running out. When the spandex yarn is about to be finished and the thin skin is seen in the paper tube, first use the doffing suction gun at the three rollers to suck the yarn tow, and pull off the spandex yarn that is about to be finished. The one-step method for producing polyester / spandex air-covered yarn replacement produces less waste silk, shortens the empty spindle time of the machine, has higher production efficiency, is simple and convenient to operate, and can effectively reduce the risk of work-related injuries.

Owner:桐昆集团浙江恒盛化纤有限公司

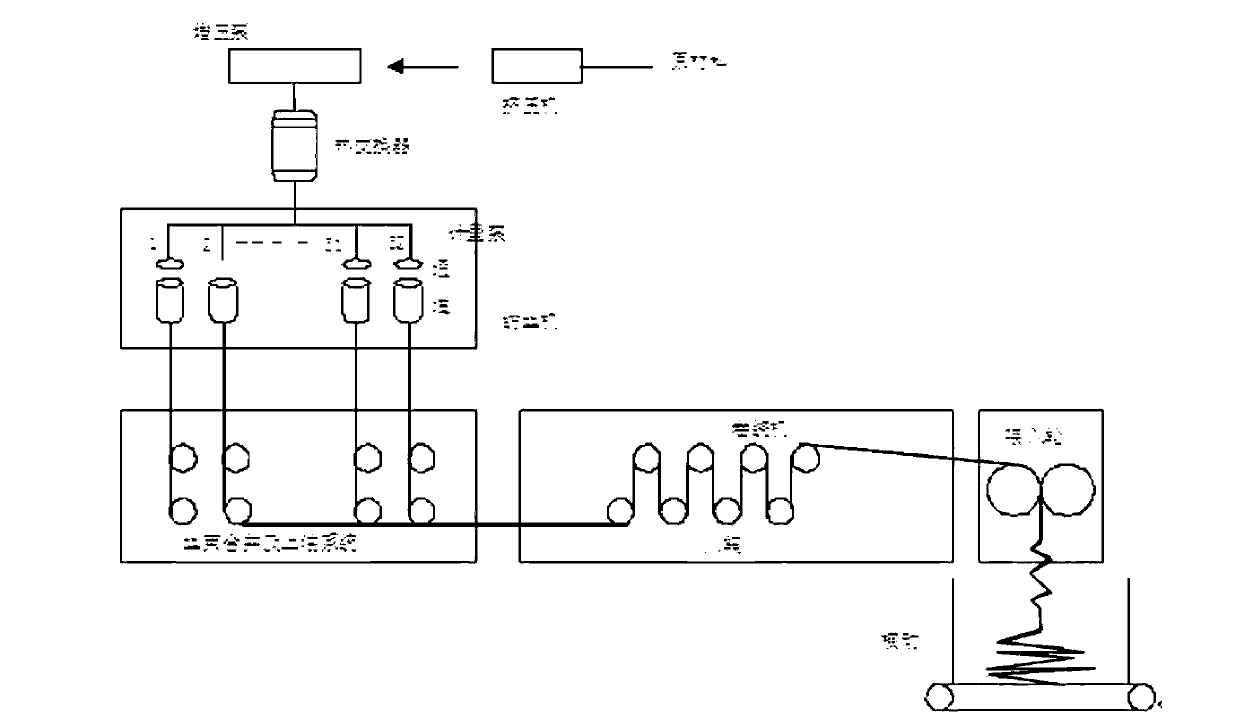

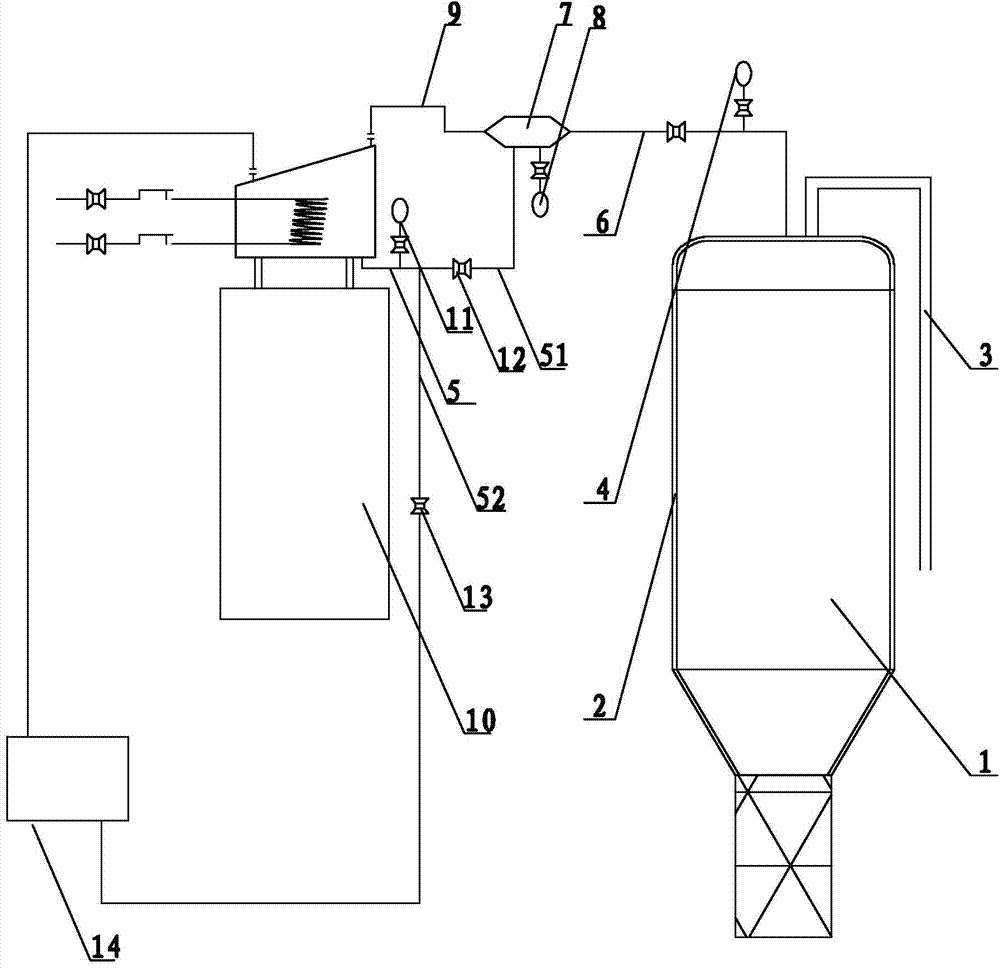

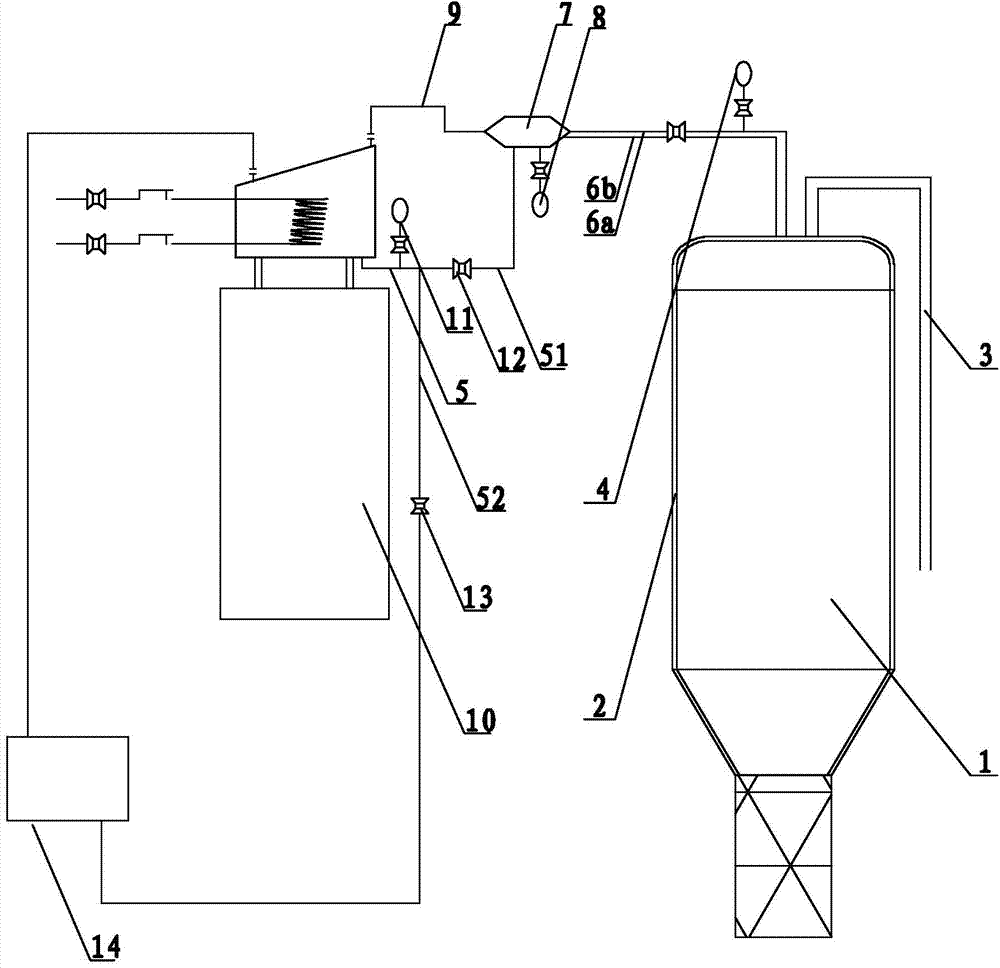

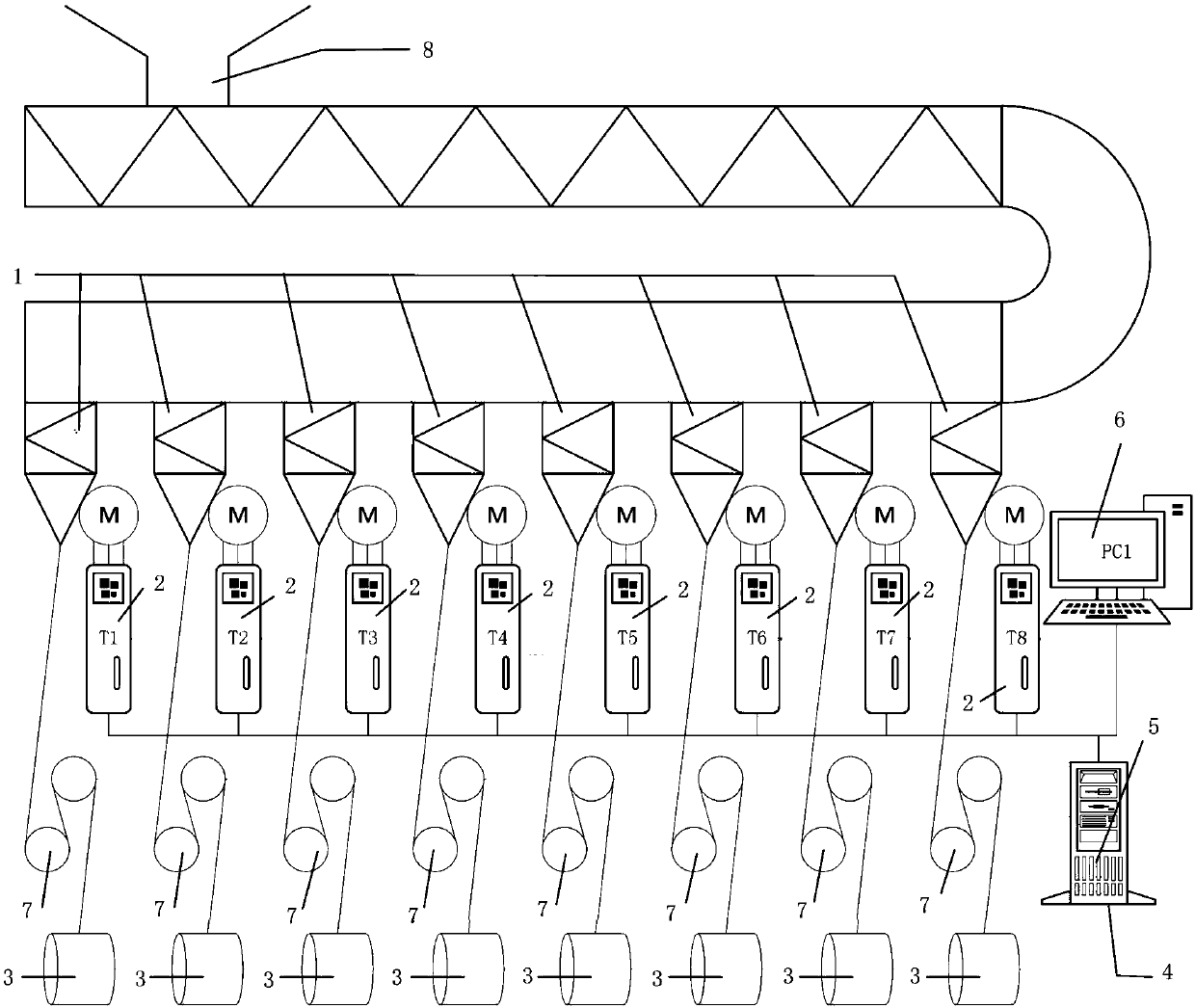

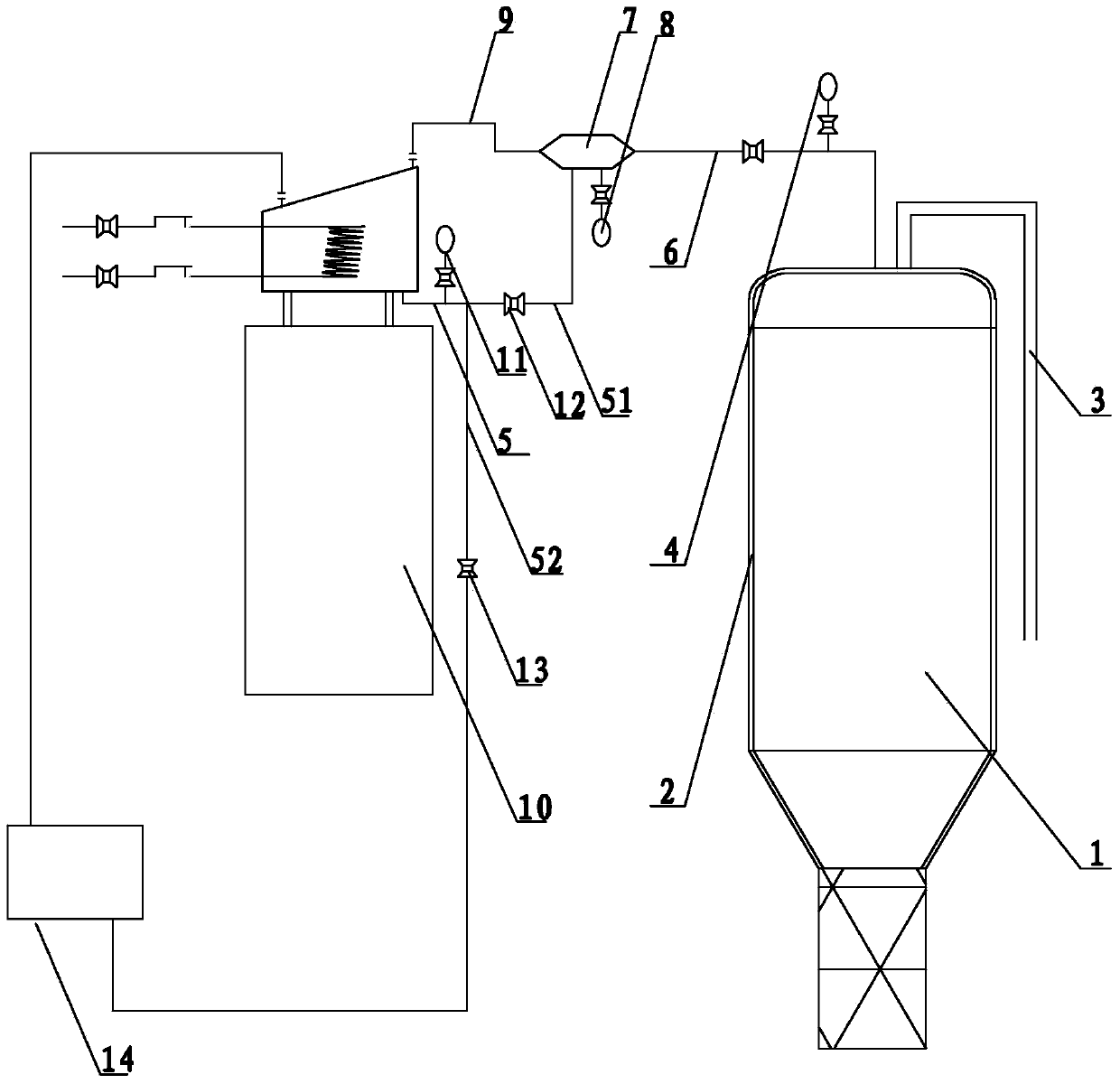

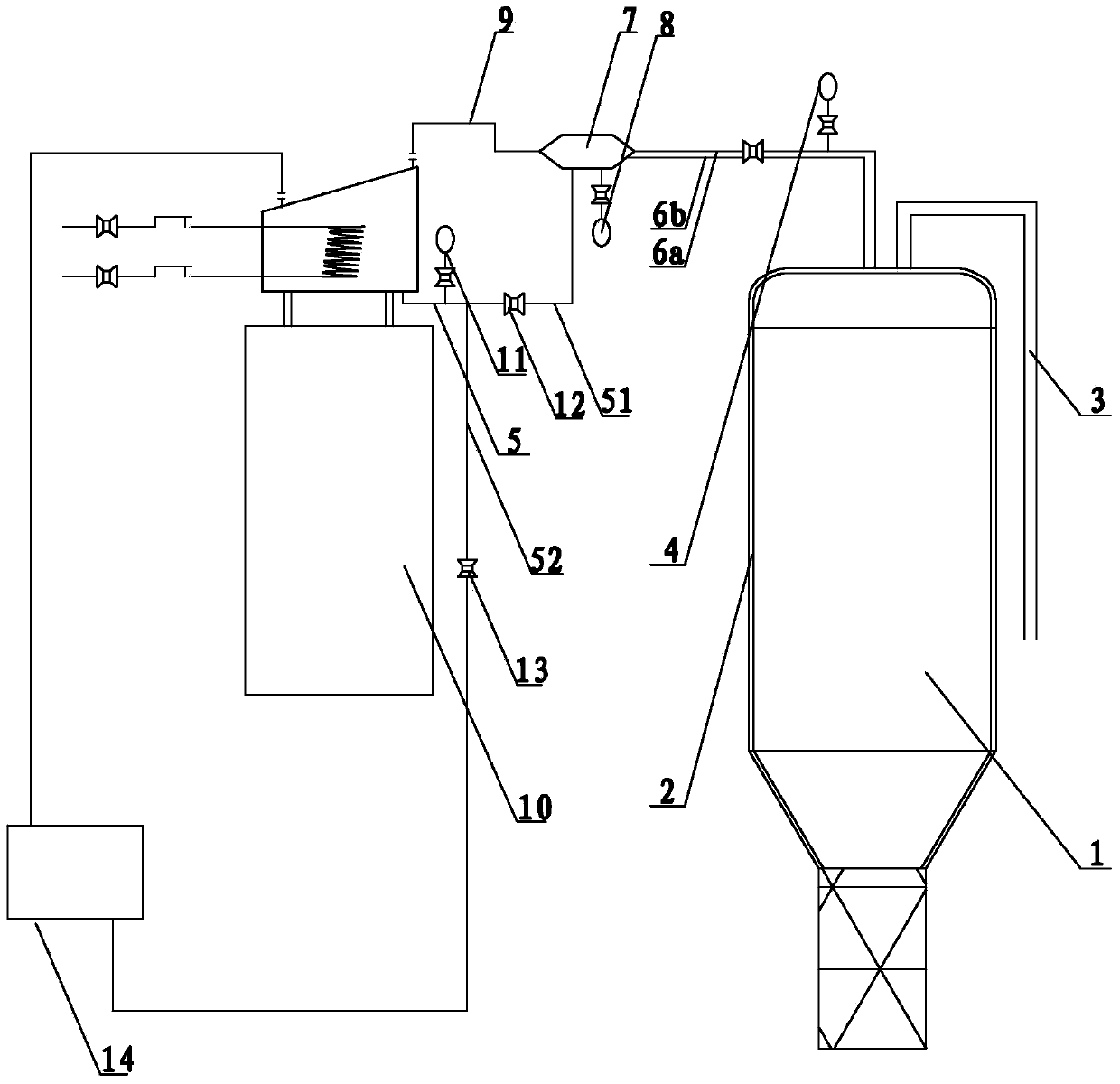

Automatic acceleration and deceleration control system and method for spinning metering pumps

PendingCN110396728AReduce generationReduce waste silkSpinning head liquid feederMultiple frequencyWinding machine

The invention discloses an automatic acceleration and deceleration control system and method for spinning metering pumps. The system comprises multiple metering pumps, multiple frequency converters, multiple winding machines and a control module. The winding machines are electrically connected with the control module and used for detecting the working states of the winding machines and judging whether or not the winding machines are in a halt state; the frequency converters are electrically connected with the control module and used for detecting the working states of the frequency convertersand counting the deceleration quantitative proportion of the frequency converters; the control module gives out speed adjustment signals to the frequency converters according to the logical judgment;the frequency converters are further connected with the metering pumps and used for controlling acceleration operation or deceleration operation of the metering pumps according to the speed adjustmentsignals. According to the automatic acceleration and deceleration control system and method for the spinning metering pumps, waste silk generation can be reduced, and the situation can be avoided that the pressure of a spinning melt exceeds the limit.

Owner:GUANGDONG XINHUI MEIDA NYLON

Network distributor gas supply pipeline network system

ActiveCN102345176BImprove uniformityStable air pressureConjugated synthetic polymer artificial filamentsMonocomponent polyesters artificial filamentBuffer tankEconomic benefits

The invention discloses a network distributor gas supply pipeline network system, comprising at least two levels of network air pressure air pressure stabilizing devices, wherein, each level of network air pressure air pressure stabilizing device is provided with a plurality of buffer tanks, one end of each buffer tank is communicated with an air inlet and the other end is communicated with at least two air outlets, the level one network air pressure air pressure stabilizing device is provided with a buffer tank, each air outlet of each buffer tank in each level of network air pressure air pressure stabilizing device is respectively communicated with the air inlet of one buffer tank in the next level of network air pressure air pressure stabilizing device, and each air outlet of each buffer tank in the last one level of network air pressure air pressure stabilizing device is respectively communicated with the network distributor. The network distributor gas supply pipeline network system is a multi-level multi-branch system, air flow is subject to buffer through multiple buffer tanks, so that the air pressure is more stable, the degree of network and network uniformity of filaments and mixed filaments are increased, the winding tension is stabilized, end breaking and waste filaments are reduced, the production state is improved, and the product quality, production efficiency and economic benefit are improved.

Owner:XUZHOU SILK FIBER TECH

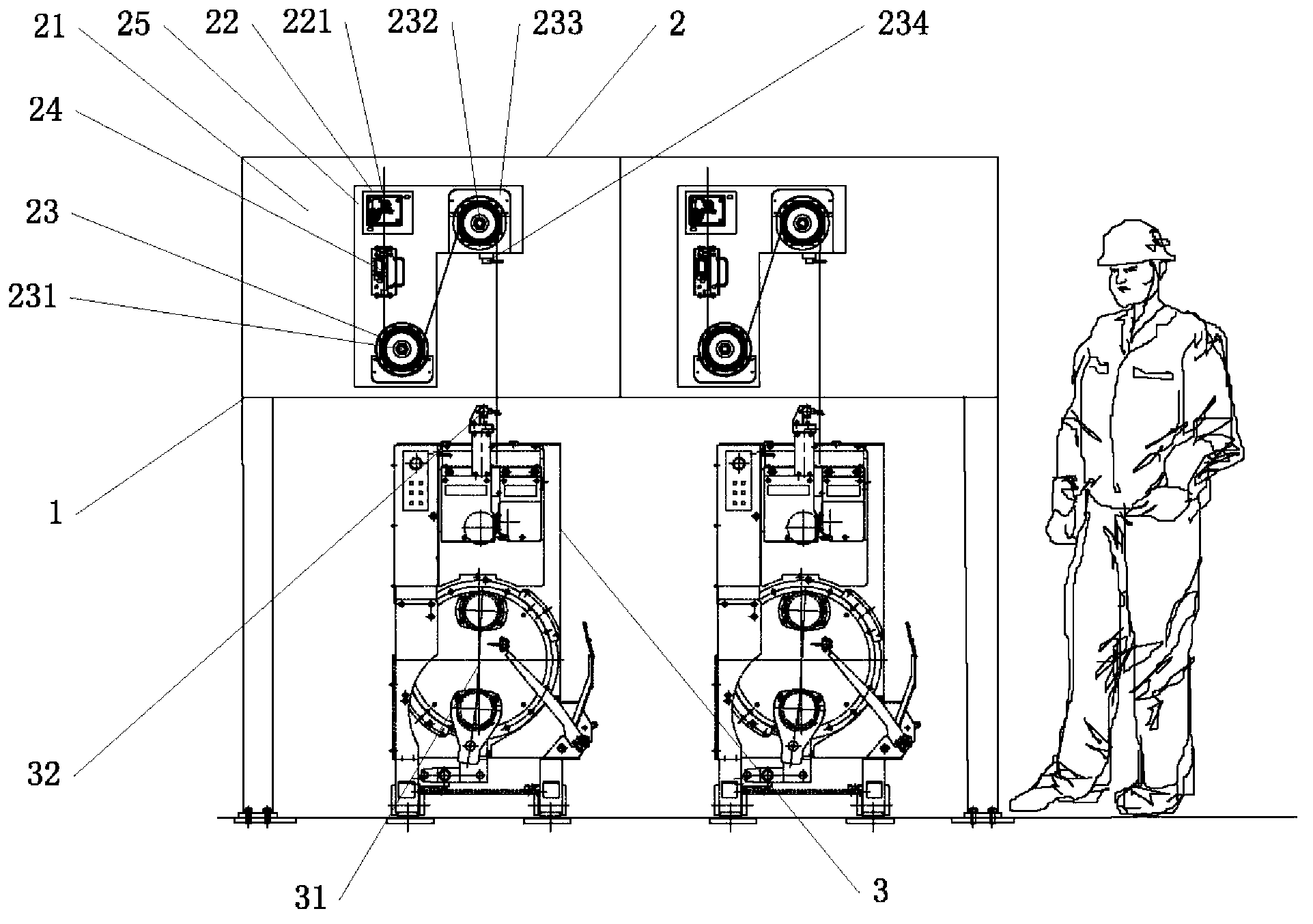

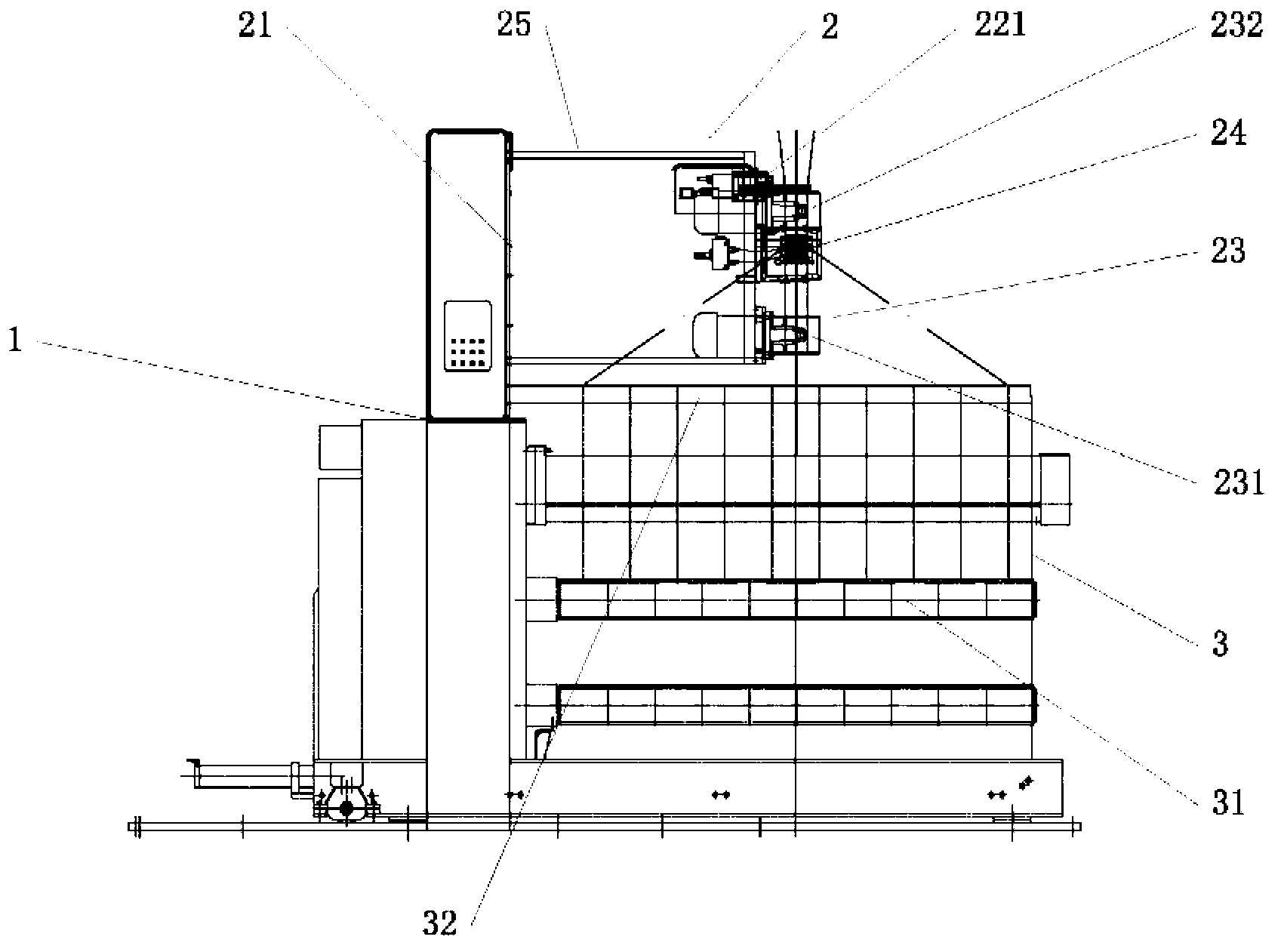

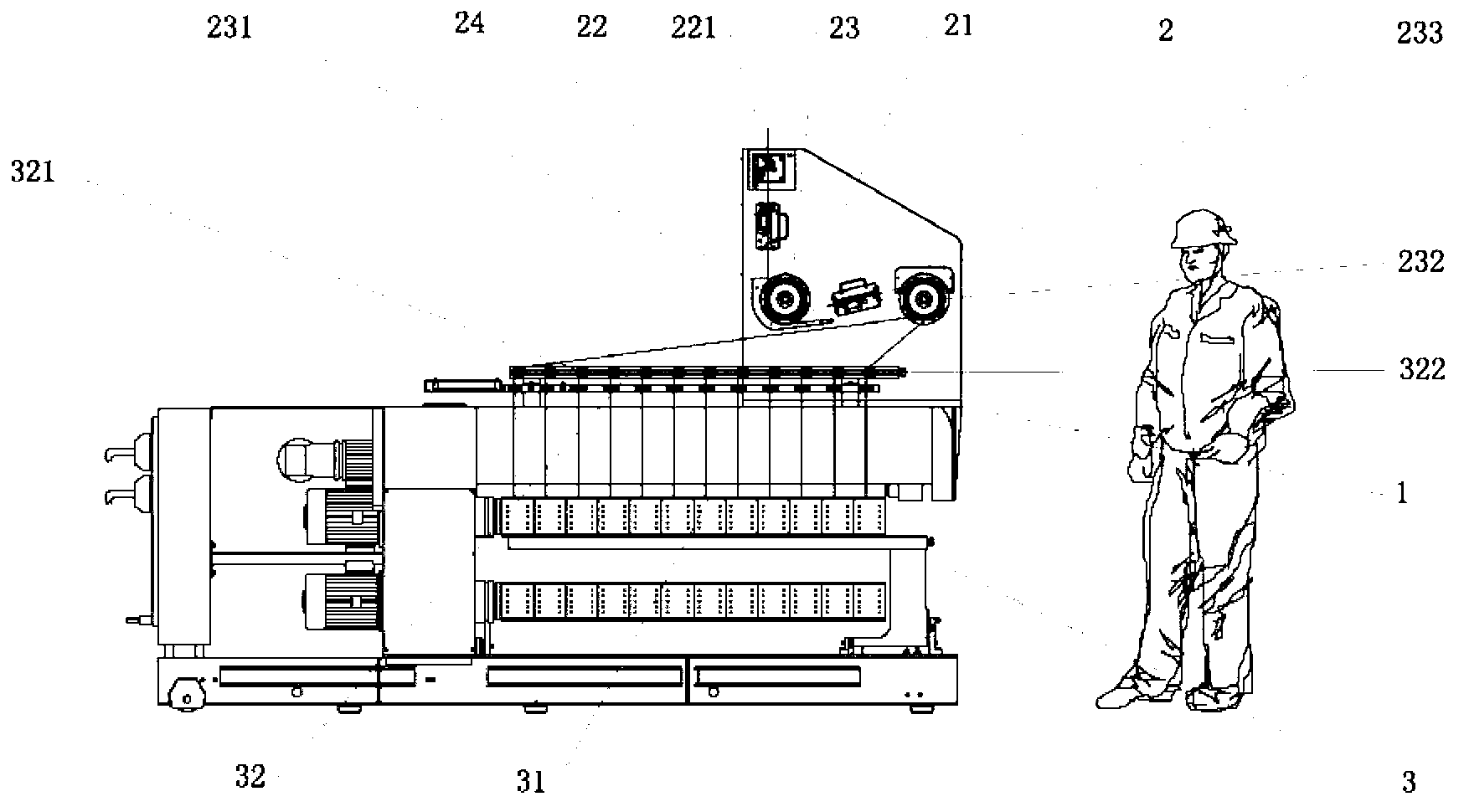

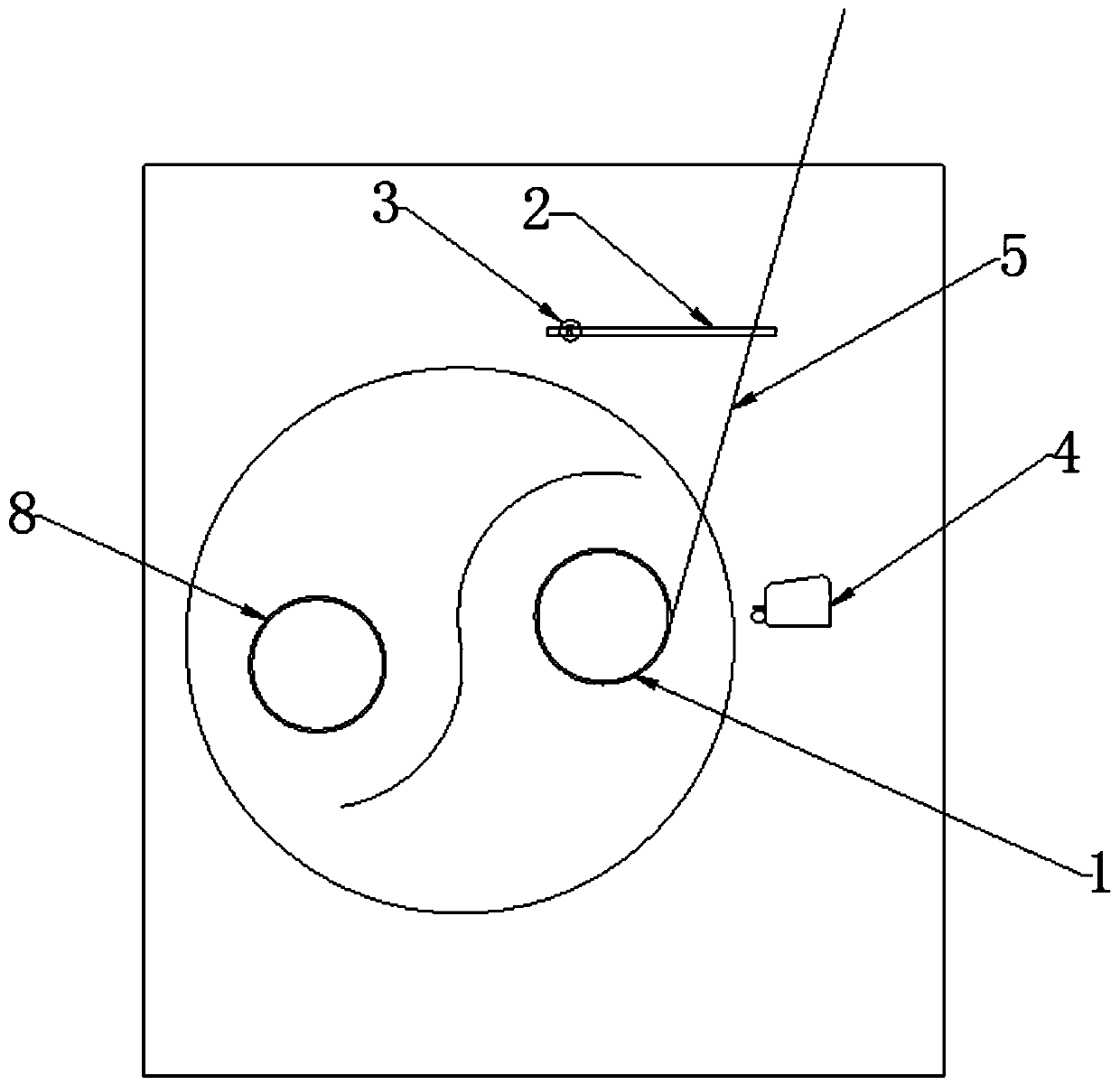

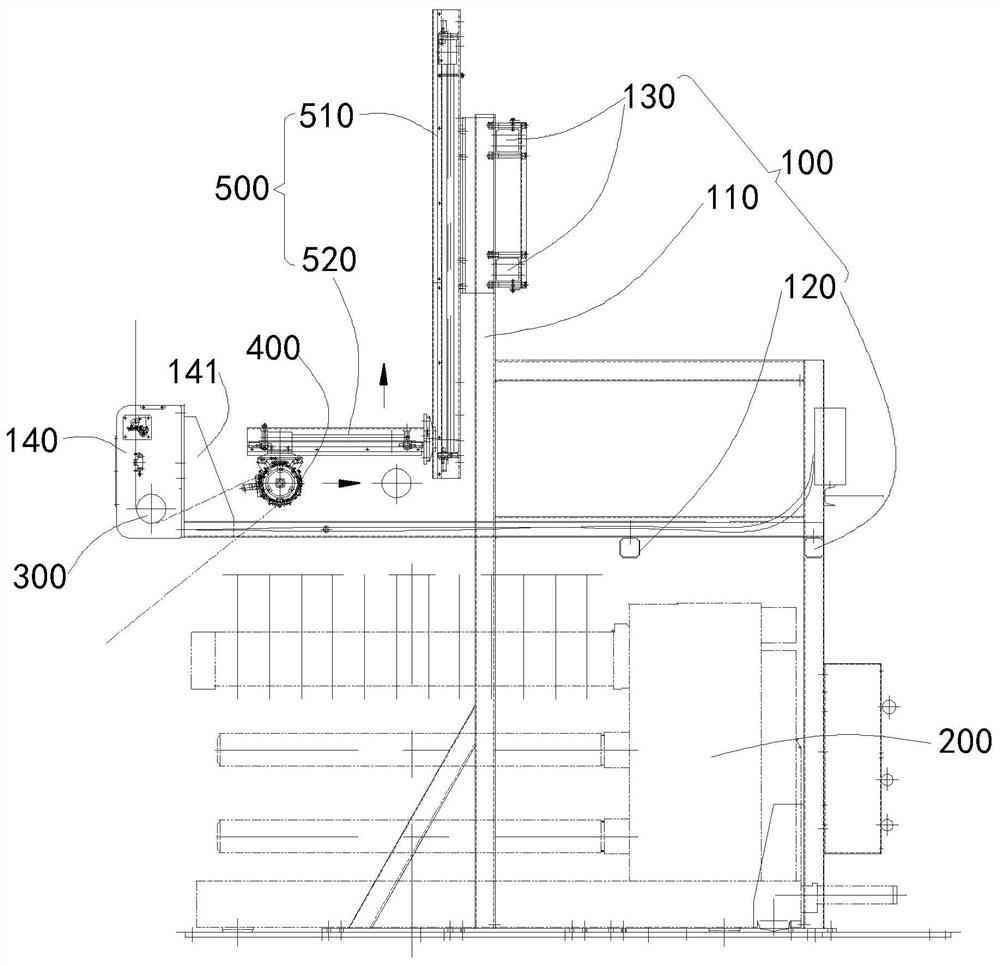

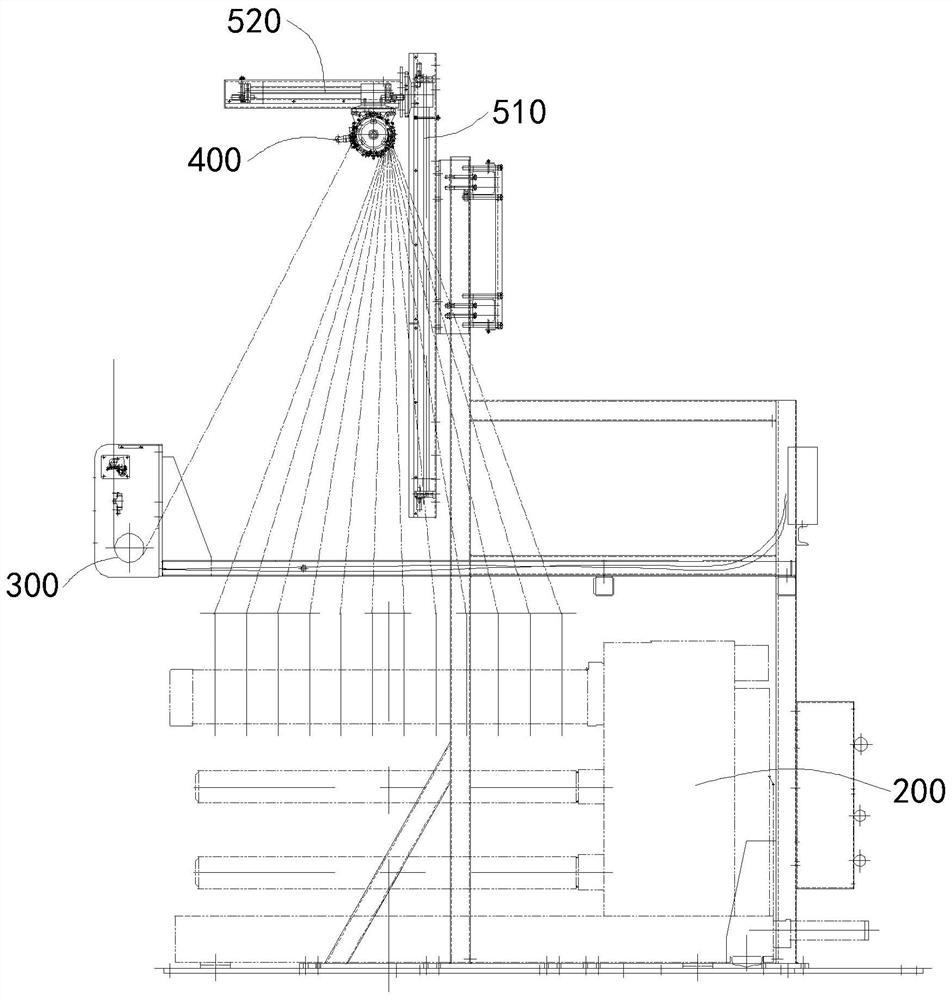

POY pre-drafting and winding device

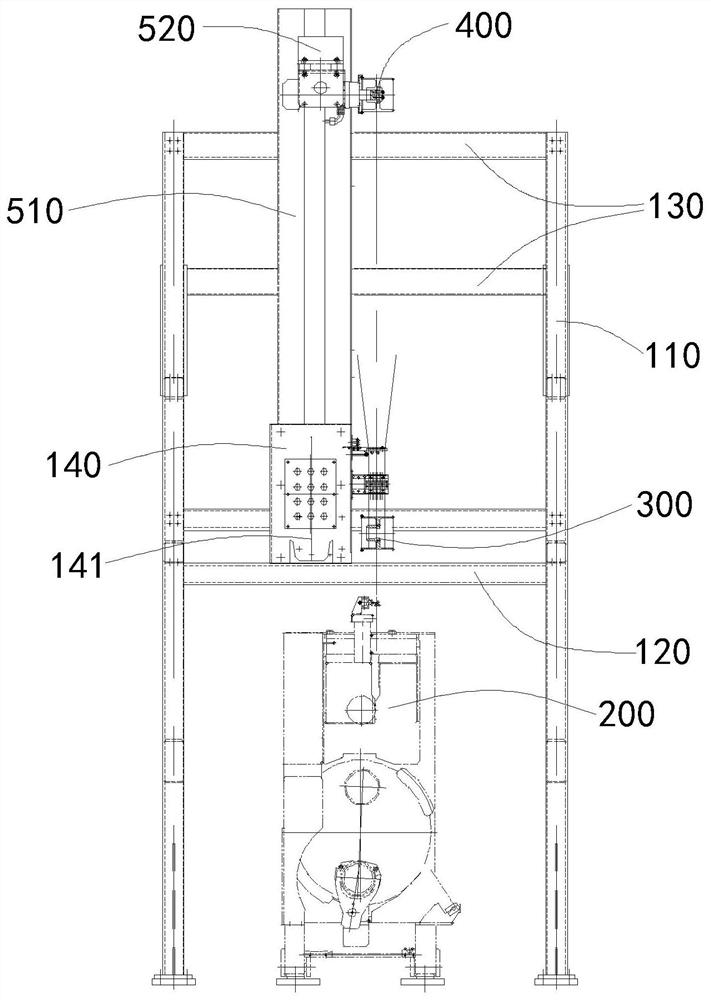

PendingCN113430659AImprove the defect of high structural heightReduce the height of the structureNew-spun product collectionArtificial thread manufacturing machinesWinding machineEngineering

The invention discloses a POY pre-drafting and winding device, relates to the technical field of spinning, drafting and winding, and solves the technical problems that spinning-in operation needs multiple persons, the time is long, the device height is large and the occupied area is wide in the prior art. The device comprises a rack, a winding machine fixed relative to the rack, a first guide disc fixed to the rack, a second guide disc movably arranged on the rack and a vertical moving mechanism arranged on the rack; and the vertical moving mechanism is used for driving the second guide disc to move in the vertical direction. By arranging the vertical moving mechanism, the second guide disc moves in the vertical direction, so that the defect that an original device for fixing the second guide disc is large in structural height is improved, the structural height is reduced, and the requirement for capital construction is lowered; the defect that in original spinning-in operation, an upper operator and a lower operator perform drafting and winding respectively can be overcome by unobstructed arrangement of the rack in the vertical direction; and the single operator can complete drafting and winding by holding a thread suction gun.

Owner:BEIJING CHONGLEE MACHINERY ENG

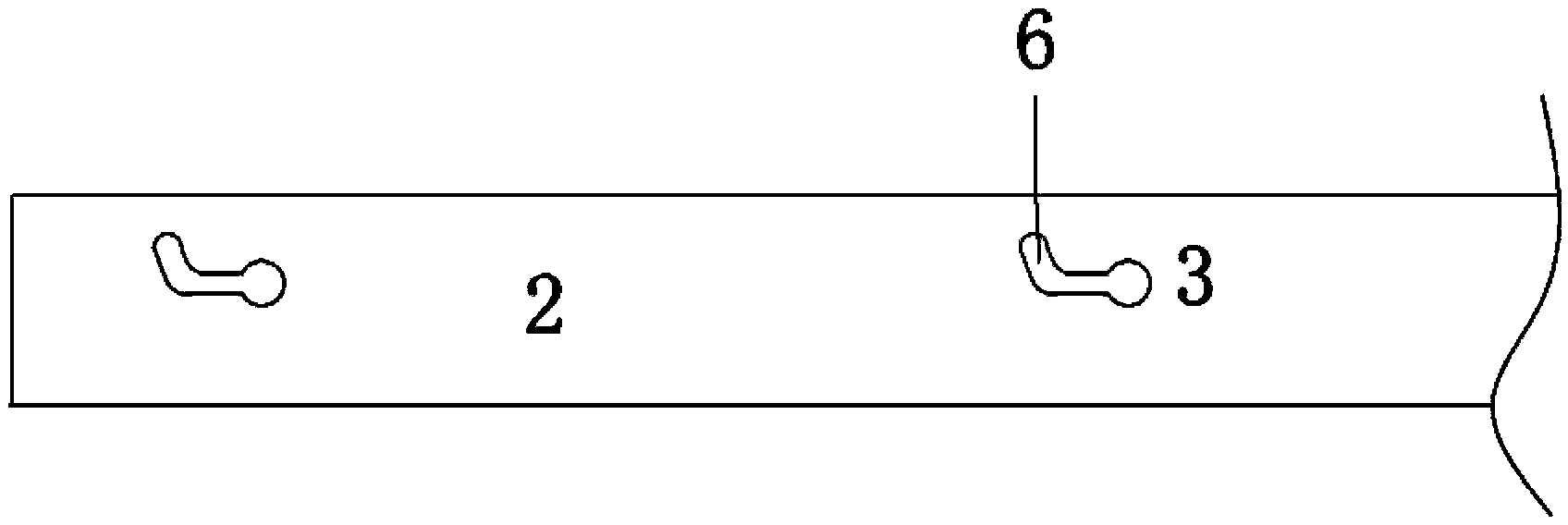

String-up switching mechanism of winding machine

The invention provides a string-up switching mechanism of a winding machine, and relates to the field of textile machinery. The string-up switching mechanism comprises a move-down silk plate and a shoveling plate, wherein a slideway is arranged on the shoveling plate, and a sliding head matched with the slideway is arranged on the move-down silk plate; a groove for hooking and pulling a silk beam is formed in one side of the move-down silk plate; and a bending way opposite to the one side of the groove is arranged at the slideway. The string-up switching mechanism of the winding machine has high string-up switching success rate, the waste silk quantity can be greatly reduced, and meanwhile the product quality is increased. As the improvement cost is low, the string-up switching mechanism is also suitable for large-range popularization and application.

Owner:JIANGSU CHALLEN FIBER S&T

Preparation method for polyethylene glycol terephthalate for industrial yarn

The invention discloses a preparation method for polyethylene glycol terephthalate for industrial yarn. Alkali metal acetate is added at a proportioning stage prior to an esterification reaction and exerts a modification action in the esterification reaction, and obtained polyester products have the advantages that broken filaments and broken ends are reduced in a subsequent spinning process, theanti-electrostatic property is high during wire drawing, the tensile strength of a finished product is high, and the volume of filament waste is lowered during spinning.

Owner:江阴赛胜新材料有限公司

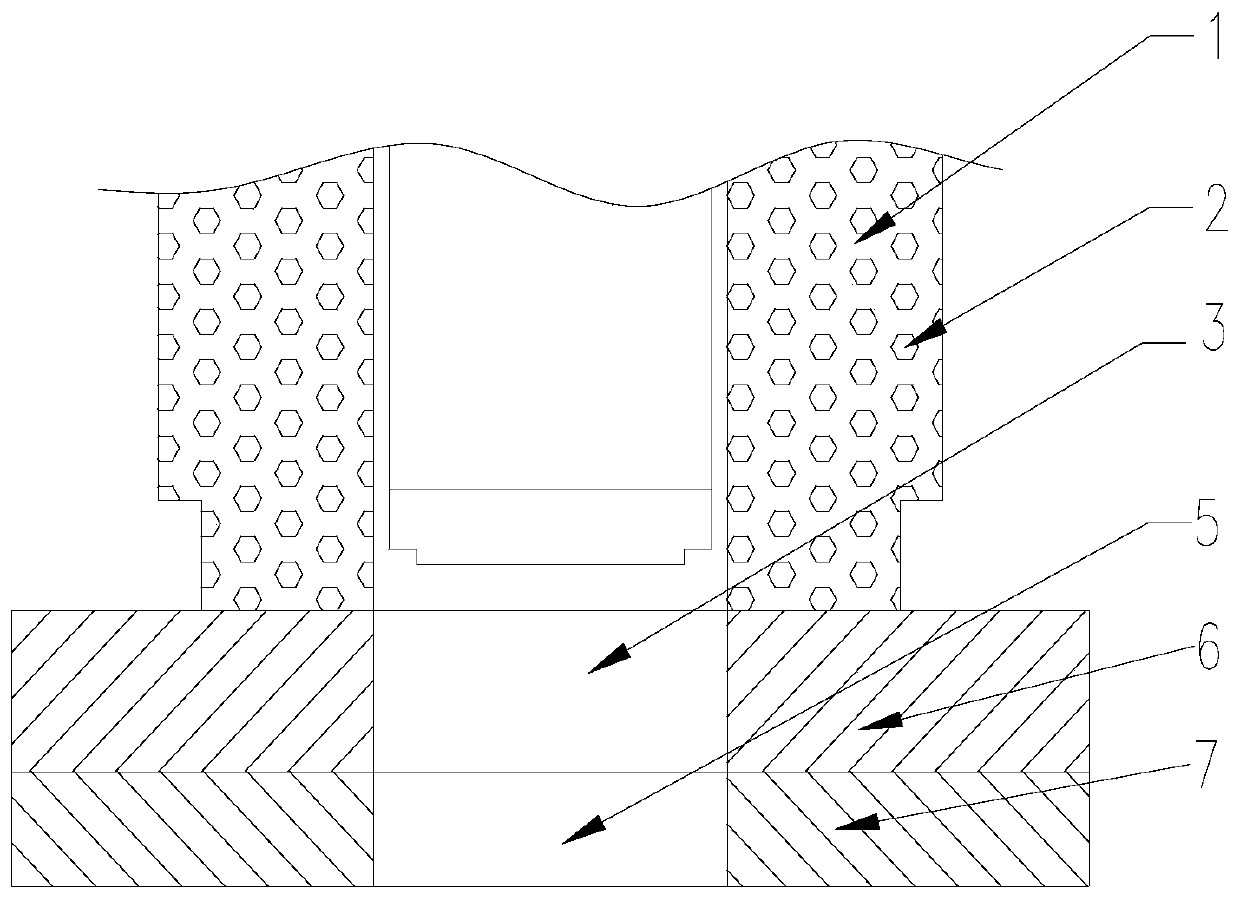

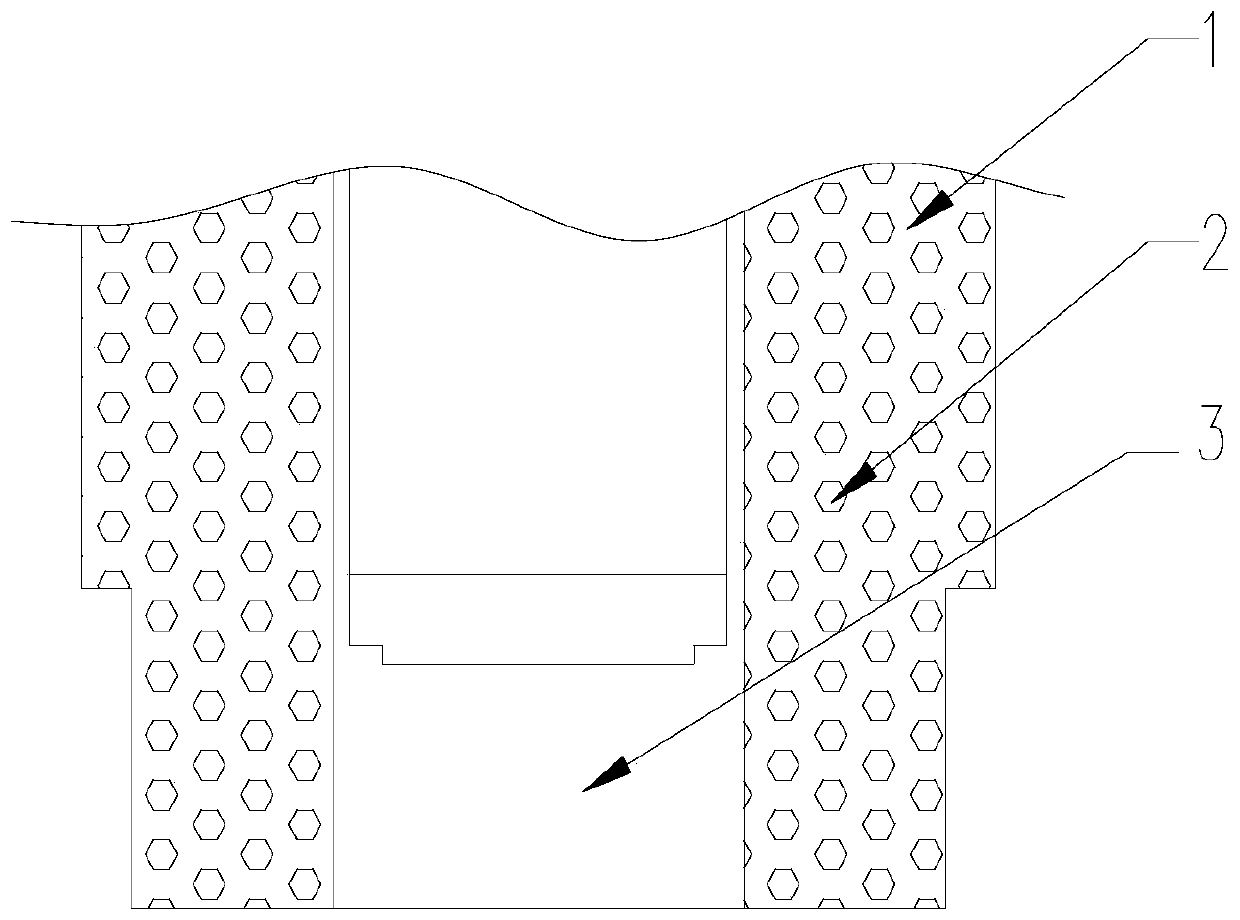

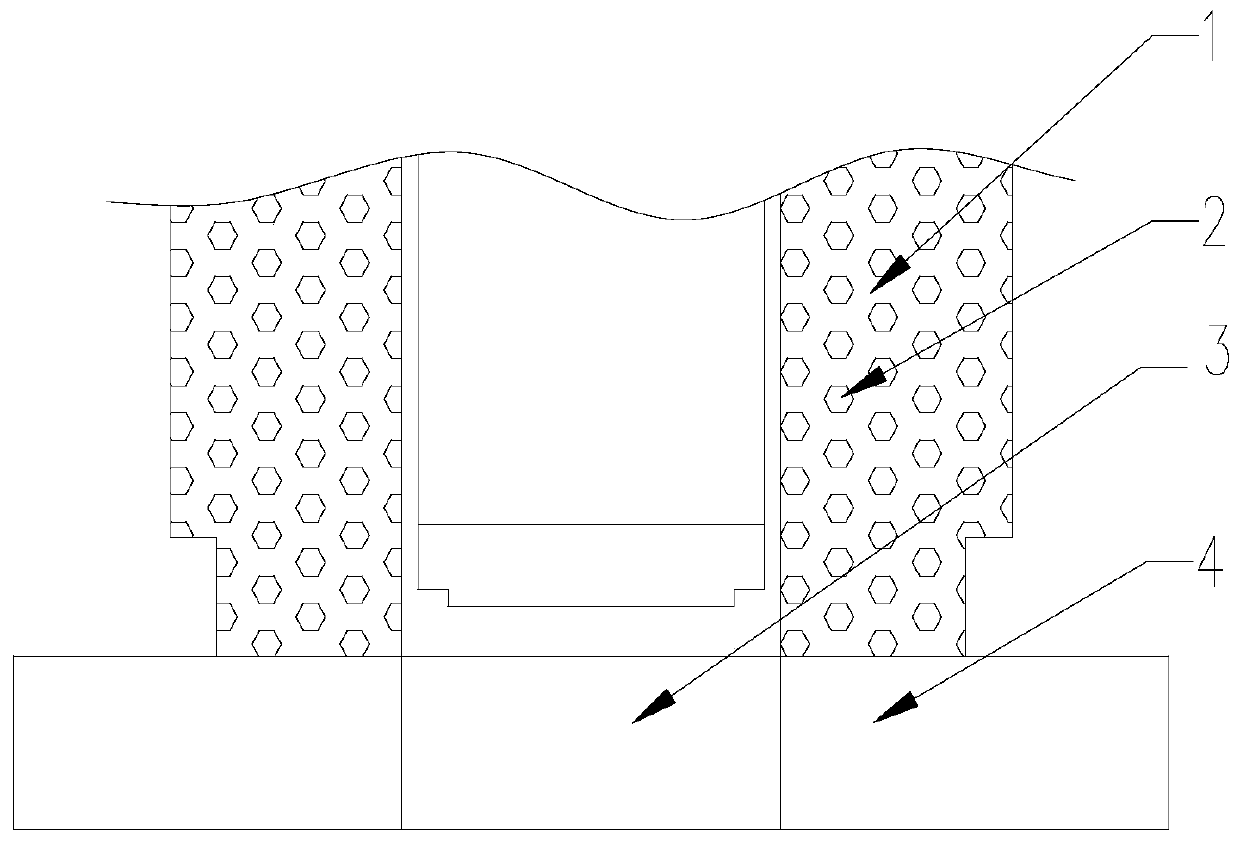

A spinning method for prolonging the cleaning period of special-shaped cross-section fiber production

ActiveCN107904684BExtended cleaning cycleExpand escape spaceArtificial thread manufacturing machinesFilament manufactureFiberThermodynamics

The invention relates to a spinning method for prolonging the plate-clearing period of special-shaped cross-section fiber production. The longitudinal height is kept unchanged, and the area of the cross section of a slow cooling cavity is increased; meanwhile, the slow cooling cavity keeps the plate surface temperature of a spinneret by utilizing natural heat preservation and additionally arranging a heat insulation plate on the lower portion of a heat preservation plate to extend a wind-free region; the plate-clearing period of special-shaped cross-section fiber production is prolonged by 35-55%; increase of the cross section area of the slow cooling cavity means that the cross section of the slow cooling cavity is changed from round to rectangular on the premise that the spinneret connected with the slow cooling cavity is kept unchanged. A cylindrical slow cooling cavity is changed into the rectangular cylindrical slow cooling cavity, the spinning oligomer escape space is expanded, an active heating type slow cooling area is changed into a non-heating heat preservation type, the gathering quantity and hardness of oligomers on the high-temperature spinneret are reduced, special-shaped cross-section fiber plate-clearing period is greatly prolonged, the production efficiency is improved, the energy consumption is reduced, waste fibers are reduced, the spinning quality is improved, and the labor intensity of workers is reduced.

Owner:JIANGSU HENGLI CHEM FIBER

Washing device and process of PET (polyethylene terephthalate) liquid-phase tackifying kettle

The invention relates to a washing device of a PET (polyethylene terephthalate) liquid-phase tackifying kettle and a washing process using the washing device for washing the tackifying kettle, and belongs to the technical field of polyester fiber production. The washing device comprises a segmented heater, a solvent injection pipe, a circulation pipe, a buffer tank, a condenser and a liquid seal tank, wherein the segmented heater is arranged in an outer wall jacket of the tackifying kettle; the solvent injection pipe is arranged at the top of the tackifying kettle; one end of the buffer tank is connected with the tackifying kettle through the circulation pipe, and the other end of the buffer tank is connected to the top of the condenser through a steam pipe; a circulative pipe is arranged at the bottom of the condenser and divided into two branch pipes, one branch pipe is connected to the bottom of the buffer tank, and the other branch pipe is connected to the bottom of the liquid seal tank; and the upper part of the liquid seal tank is connected to the top of the condenser, and control valves are arranged on two branch pipes of the circulative pipe respectively and used for controlling connection and disconnection of corresponding pipelines. The washing device has the advantages of high washing efficiency, low cost and the like.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

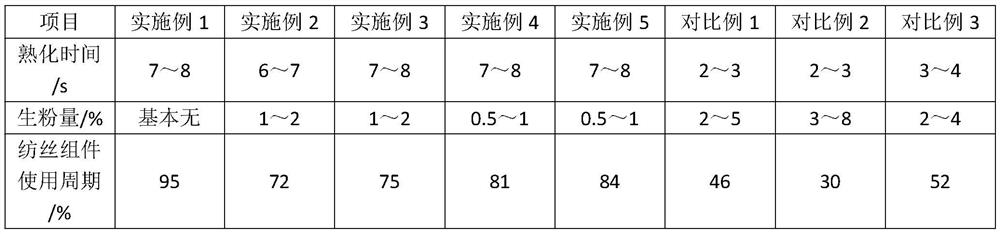

A kind of polypropylene raw material with fully dispersed red pigment and its preparation method

ActiveCN110511483BFully dispersedExtend the life cycleMonocomponent polyolefin artificial filamentPigment addition to spinning solutionPolymer scienceSpinning

The invention belongs to the technical field of polypropylene fiber production. Aiming at the problem that the existing red pigment is not easily dispersed in the polypropylene raw material mixture, which causes the color difference of the polypropylene fiber, the invention provides a polypropylene raw material mixture in which the red pigment is fully dispersed and a preparation method, which consists of the following The composition of each component in mass percentage: polypropylene powder ≥ 48%, red pigment 27-30%, polyethylene wax ≥ 17%, electrostatic agent 0.95-1%, silicone powder 0.05-0.1% and zinc stearate 2.5% ~3%, the sum of the mass percentages of the above-mentioned components is 100%, the softening point of polyethylene wax is ≥120°C, first rotate and mix at low speed during preparation, and then fully rotate and mix at high speed. The permanent brilliant red in the polypropylene raw material is fully dispersed, no raw powder is produced, the aging time is prolonged, and the service life of the spinning assembly is improved. The color of the obtained polypropylene fiber is good, there is basically no color difference, and the amount of waste yarn is also greatly reduced.

Owner:ZHEJIANG SITONG NEW MATERIAL TECH CO LTD

A method for reducing oligomer content in polyester fiber

ActiveCN108130615BLow polymer contentChange bond angleArtificial thread manufacturing machinesMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a method for reducing the content of oligomers in polyester fibers. Firstly, a diol chain segment with a branched chain is introduced into a molecular chain of polyester to obtain modified polyester, then in a cooling step of spinning preparation of the polyester fibers by the modified polyester, the vertical height is kept unchanged and the cross section area of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the way of heat preservation; diol with the branched chain has the following structural formula defined in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3 , R3 is selected from alkyl with the carbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5. The method is simple, the content of cyclic oligomers in the polyester fibers is less than or equalto 0.6 wt%, and the content of linear oligomers is less than or equal to 0.3 wt%; the polyester fibers has highly promising application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Wire drawing machine spiral mold box structure

Owner:WUXI CHANGXIN TECH

A control method for preventing variation of poy silk fineness on the way

ActiveCN103488119BReduce the problem of denier shrinkageIncrease the full volume rateArtificial thread manufacturing machinesProgramme control in sequence/logic controllersWinding machineYarn

The invention provides a control method for preventing POY (Pre-Oriented Yarn) fineness from generating midway variation. The method provides a control system for preventing the POY fineness from generating the midway variation. The system comprises a melt metering pump frequency converter for controlling a rotary speed of a melt metering pump, a winding machine controller for controlling a winding machine to operate and a PLC (Programmable Logic Controller), wherein the melt metering pump frequency converter is connected with the melt metering pump for spinning POY; the winding machine controller is connected with the winding machine for spinning the POY; the melt metering pump frequency converter and the winding machine controller are connected with the PLC respectively. According to the control method, the problems that the POY metering pump has faults and manual faulty operation is not found in time to cause that the POY middle fineness becomes small can be reduced greatly; therefore, the problem that the dyeing is not uniform, caused by the fineness, and the amount of waste silks are reduced.

Owner:JIANGSU CHALLEN FIBER S&T

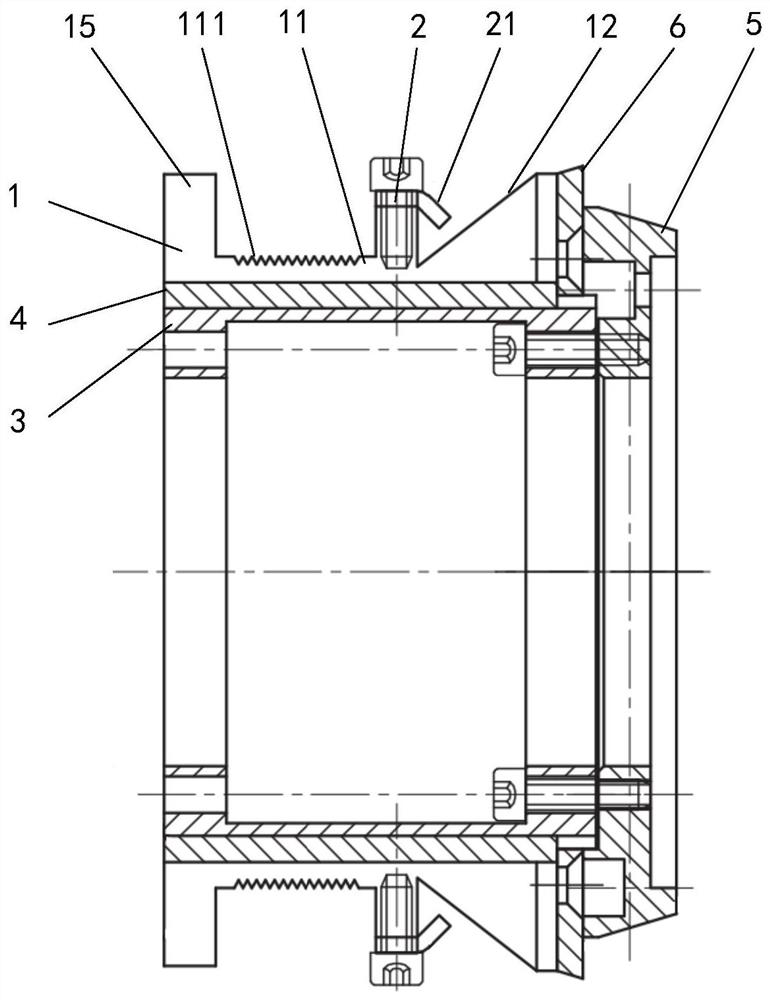

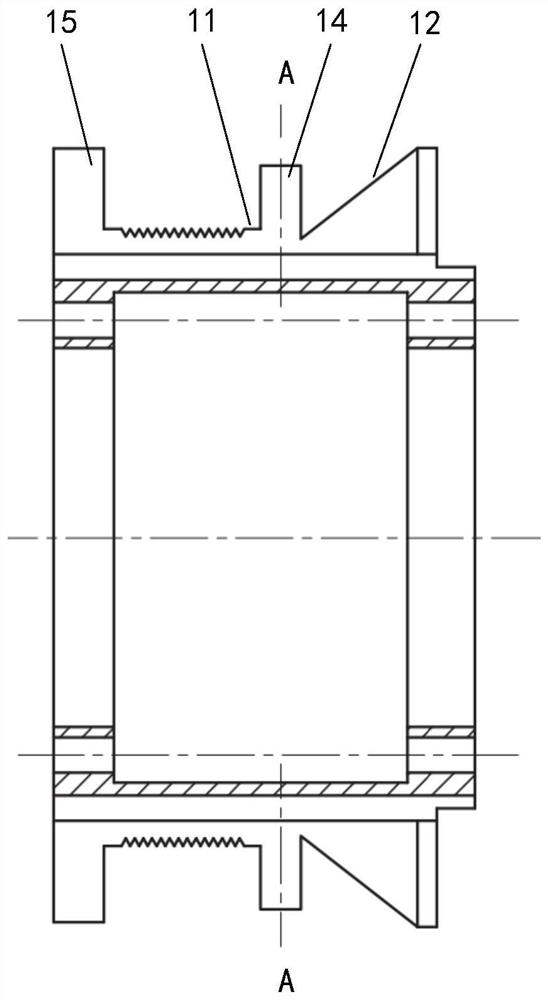

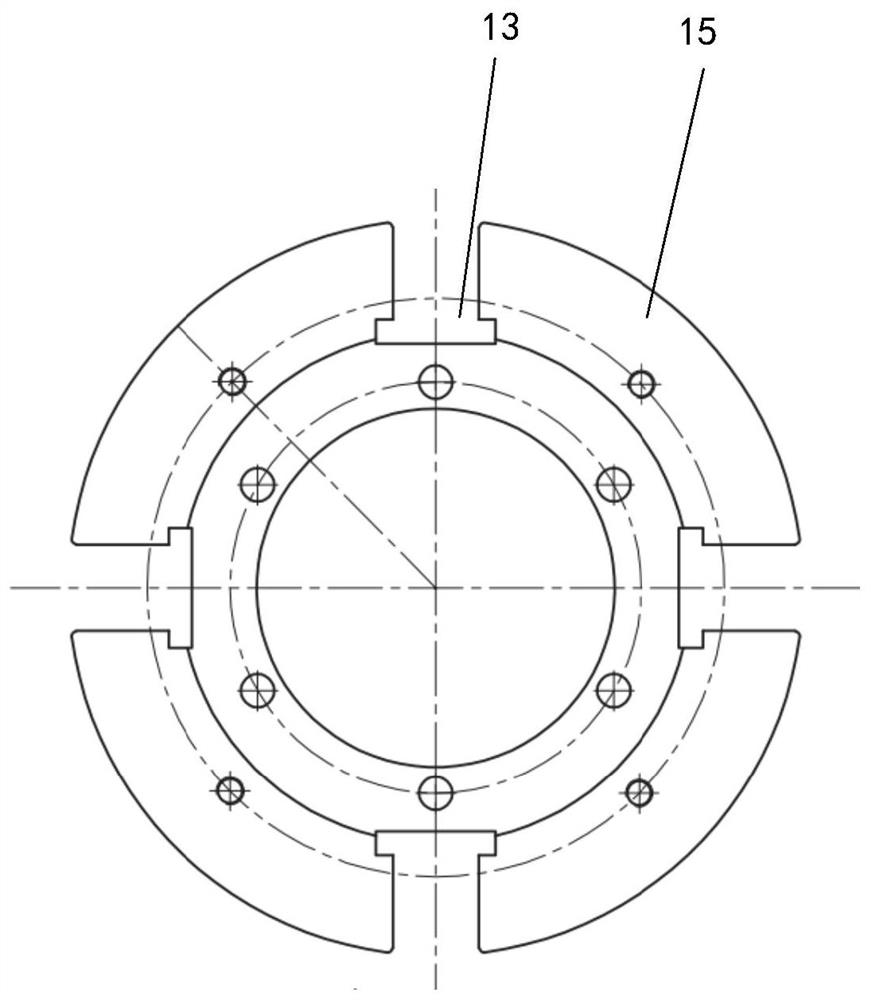

A glass fiber drawing machine and its breaking device

ActiveCN111646690BFast windingAvoid wastingGlass making apparatusGlass productionGlass fiberWire cutting

The invention discloses a glass fiber wire drawing machine and a wire breaking device. The wire breaking device comprises a wire cutting ring and at least one wire cutting block fixed on the outer periphery of the wire cutting ring in the circumferential direction to cut the glass fiber. The wire block is conducive to fast wire cutting; the outer circumference of the wire cutting ring has a circular groove for glass fiber winding and a conical groove whose small diameter end is adjacent to the circular groove to guide the glass fiber to be wound to the head. The setting of the conical groove can be adjusted. The glass fiber can be wound quickly, avoiding excessive winding of the glass fiber in the annular groove, which is conducive to reducing the amount of waste wire; all cutting blocks are located between the annular groove and the conical groove, and the outer circumference of the cutting ring has several axially extending And through the broken wire groove of the annular groove and the conical groove, the broken wire groove is used to cut the glass fiber. The glass fiber is cut by two ways of cutting wire block and wire breaking groove, so as to avoid excessive entanglement of glass fiber in the cutting ring, avoid wasting glass fiber, reduce the amount of waste wire, and help reduce production cost.

Owner:CHONGQING POLYCOMP INT

Preparation method of polyethylene terephthalate for industrial yarn

The invention discloses a preparation method of polyethylene terephthalate for industrial yarn. In the batching stage before the esterification reaction, alkali metal acetate is added, and the alkali metal acetate plays an important role in the esterification reaction. The obtained polyester product has less fuzz and broken ends in the subsequent spinning process, strong antistatic performance during drawing, strong tensile strength of the finished product, and reduced amount of waste yarn in the spinning process.

Owner:江阴赛胜新材料有限公司

Spinning-winding apparatus and spinning-in method therein

The invention provides a spinning-winding apparatus and spinning-in method and a spinning-in method therein which may reduce the amount of waste yarns. In the spinning-winding apparatus with a drawing-out device (10), a godet roller group (20), a first winding device (30) and a second winding device (40), the first winding device (30) and the second winding device (40) are provided with first bobbin support shafts (31, 41) on which bobbins (31B, 41B) for spinning in are mounted, and second bobbin support shafts (32, 42) on which bobbins (32B, 42B) for switching silk yarns from the bobbins (31B, 41B) of the first bobbin support shafts (31, 41) are mounted, respectively; the first winding device (30) is at a spinning-in rotating speed (L) while spinning in to the bobbin (31B) of the first bobbin support shaft (31), and at a production rotating speed (H) after completing spinning-in of the bobbin (31B); and the second winding device (40) is at the production rotating speed (H) while spinning in to the bobbin of the first bobbin support shaft (41).

Owner:TMT MACHINERY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com