Washing device and process of PET (polyethylene terephthalate) liquid-phase tackifying kettle

A liquid phase thickening and cleaning device technology, applied in the field of polyester fiber production, can solve the problems of clean carbon deposition, uneven heating of the melt, affecting the viscosity increasing effect, etc., and achieves good heat transfer effect and heat transfer performance. The effect of reducing the amount of waste wire and unqualified wire and improving the melt quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

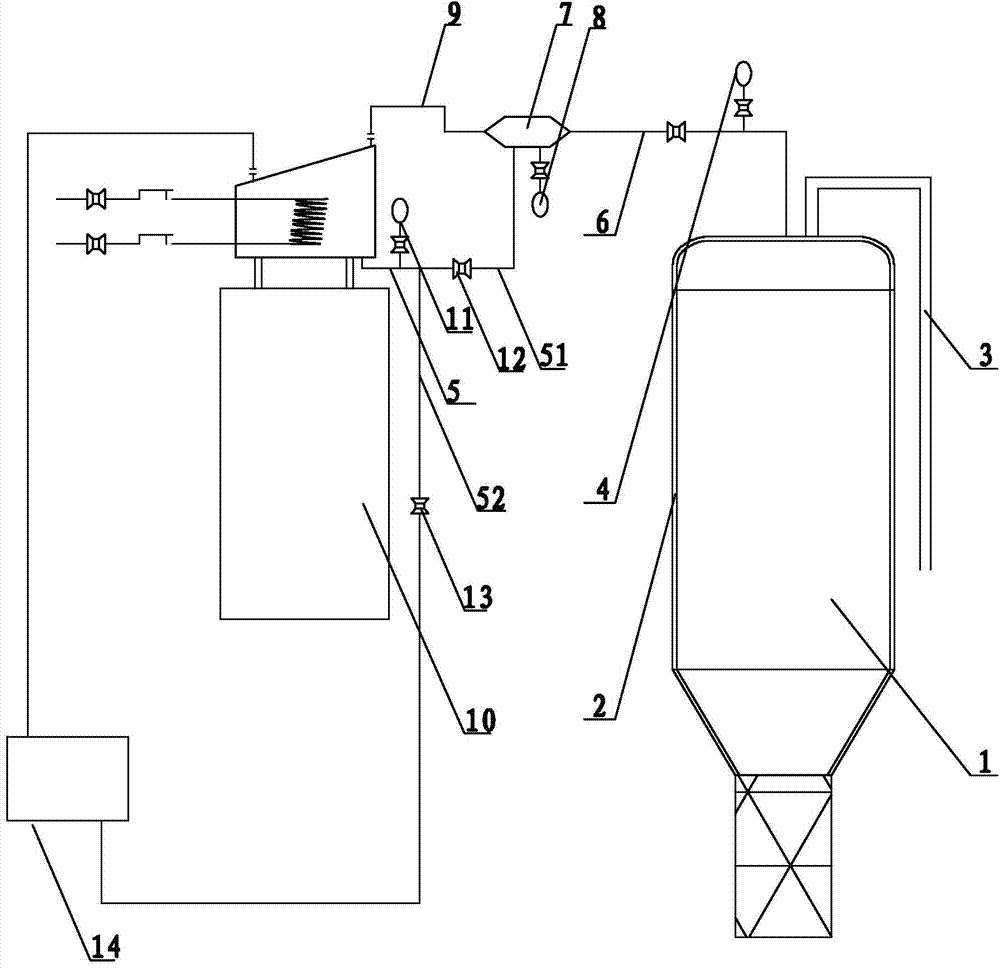

[0032] The cleaning device of the PET liquid phase thickening still of the present invention, combines figure 1 , comprising a sectional heater 2 arranged in the outer wall jacket of the thickening kettle 1, a solvent injection pipe 3 arranged at the top of the thickening kettle 1, and a circulation pipe 6, a buffer tank 7, a condenser 10 and a liquid seal tank 14, One end of the buffer tank 7 is connected to the thickening tank 1 through the circulation pipe 6, and the other end is connected to the top of the condenser 10 through the steam pipe 9; the bottom of the condenser 10 is provided with a circulation pipe 5, and the circulation pipe 5 is divided into two branch pipes , that is branch pipe one 51 and branch pipe two 52, branch pipe one 51 is connected to the bottom of buffer tank 7, branch pipe two 52 is connected to the bottom of liquid seal tank 14; the top of liquid seal tank 14 is connected to the top of condenser 10, branch pipe one 51, branch pipe Control valve o...

Embodiment 2

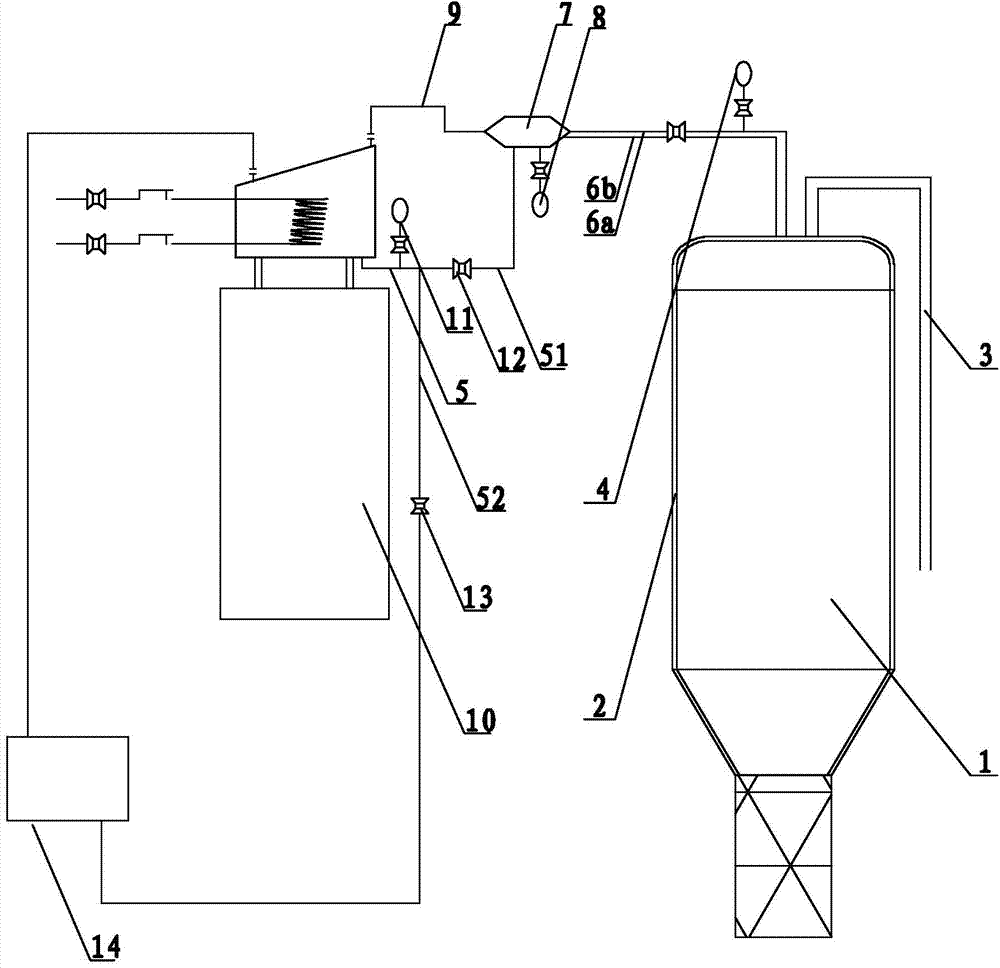

[0040] The settings and workflow of this embodiment are the same as those of Embodiment 1, the difference is that: combined figure 2 , the circulation pipe is provided with a gas circulation pipe 6a and a liquid circulation pipe 6b, the pressure detector 4 is installed on the gas circulation pipe 6a, and the two pipes of gas and liquid carry out the transportation of the vapor solvent and the liquid solvent respectively, which improves the transportation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com