Network distributor gas supply pipeline network system

A technology for air supply pipes and distributors, applied in the direction of single-component polyester rayon, conjugated synthetic polymer rayon, etc., which can solve the problem that the uniformity of the network may not meet the requirements and cannot meet the production of mixed fiber yarn Requirements, network pressure instability and other problems, to achieve the effect of improving network uniformity, air pressure stability, improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

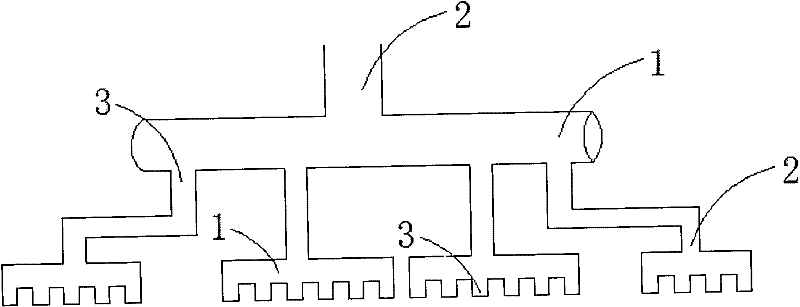

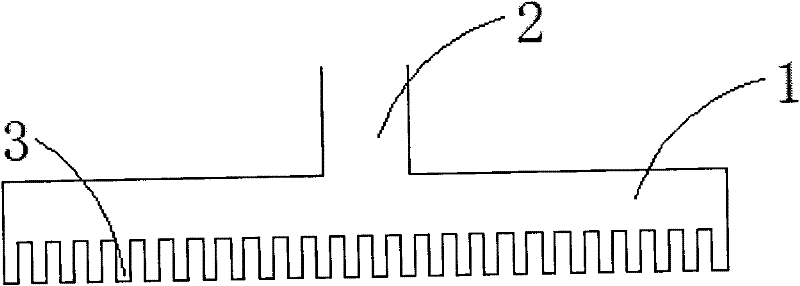

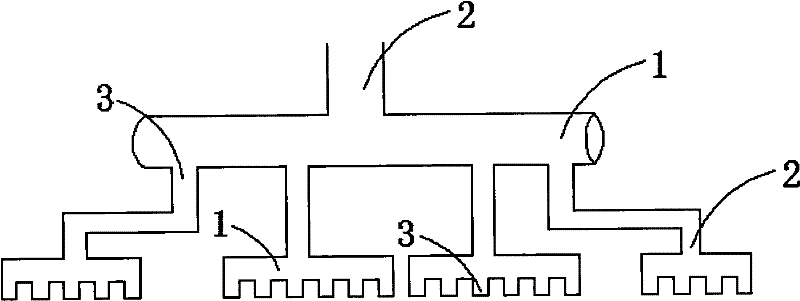

[0014] Embodiment: a network distributor air supply pipeline network system, with 2 to 4 levels of network air pressure stabilizing devices, each level of the network air pressure stabilizing device has several buffer tanks 1, the volume of each of the buffer tanks Depending on the network pressure, one end of each buffer tank is communicated with an inlet pipe 2 and the other end is communicated with 2 to 8 outlet pipes 3, the first-stage network air pressure stabilization device has a buffer tank, and each stage Each outlet pipe of each buffer tank in the network air pressure stabilizing device is respectively connected with the inlet pipe of a buffer tank in the next-level network air pressure stabilizing device, and each outlet pipe of each buffer tank in the last stage network air pressure stabilizing device The outlet pipes are respectively connected to the network distributor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com