A spinning method for prolonging the cleaning period of special-shaped cross-section fiber production

A special-shaped cross-section and fiber technology, applied in the field of spinning, can solve the problems of reducing the number and hardness of oligomer aggregation, unreasonable heating mode and structure in the slow cooling zone, and prolonging the cleaning cycle of special-shaped cross-section fibers, so as to reduce the temperature. , Conducive to fiber quality, prolonging the effect of cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

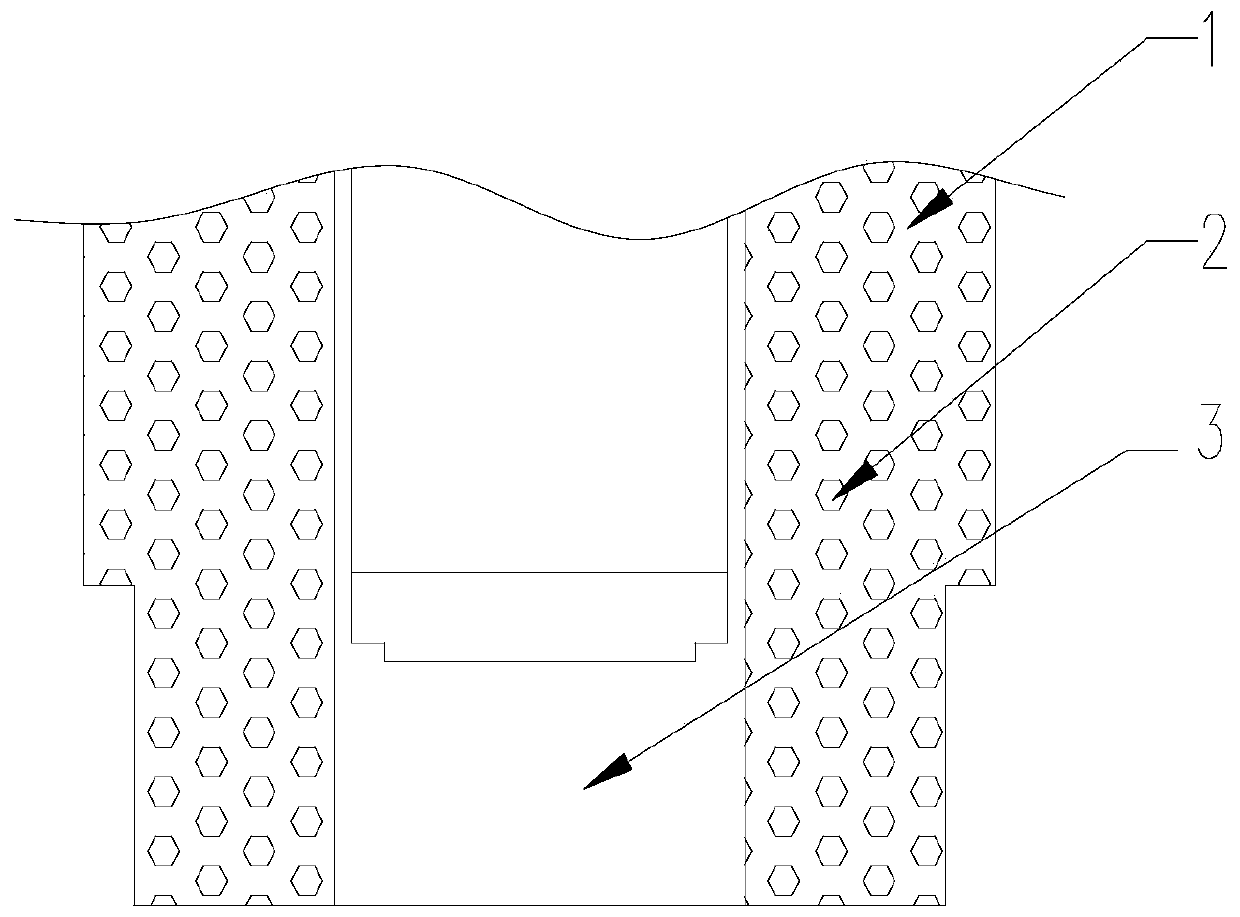

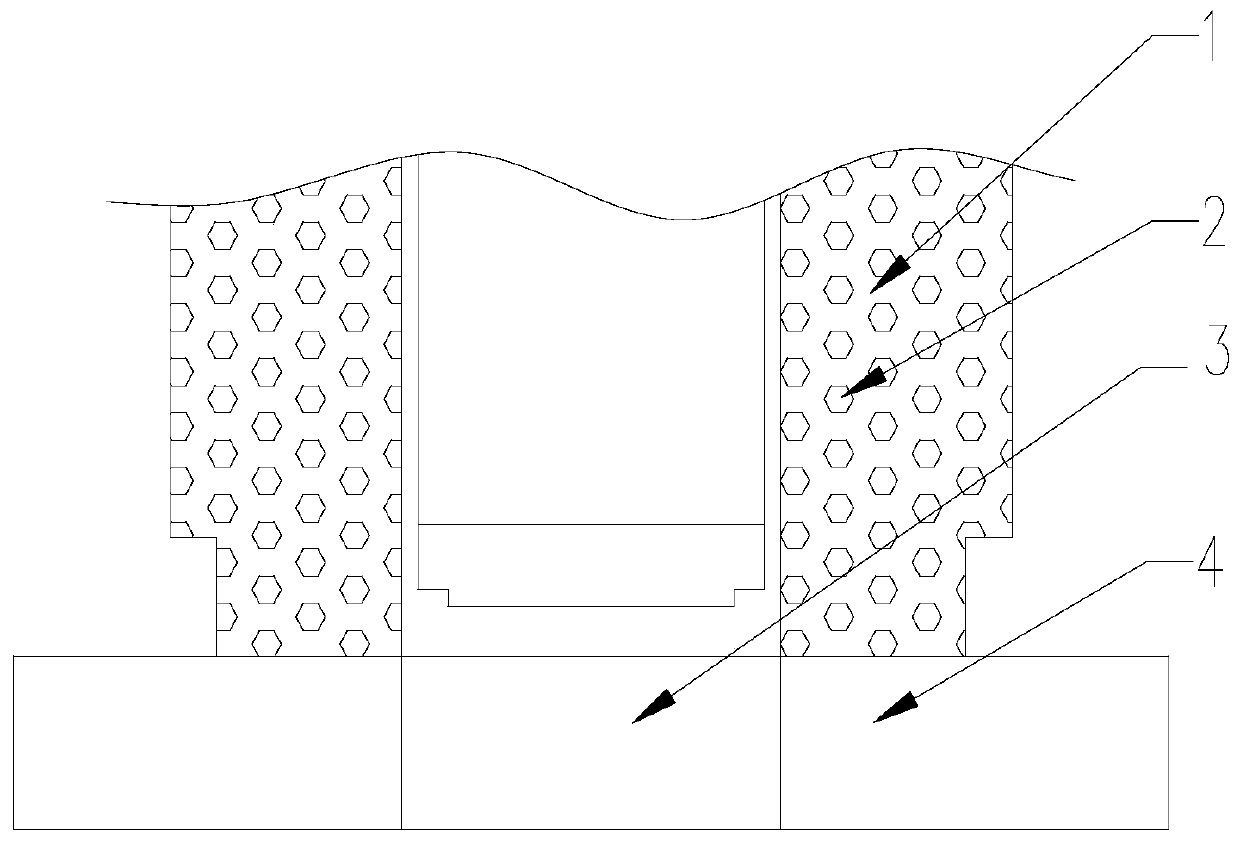

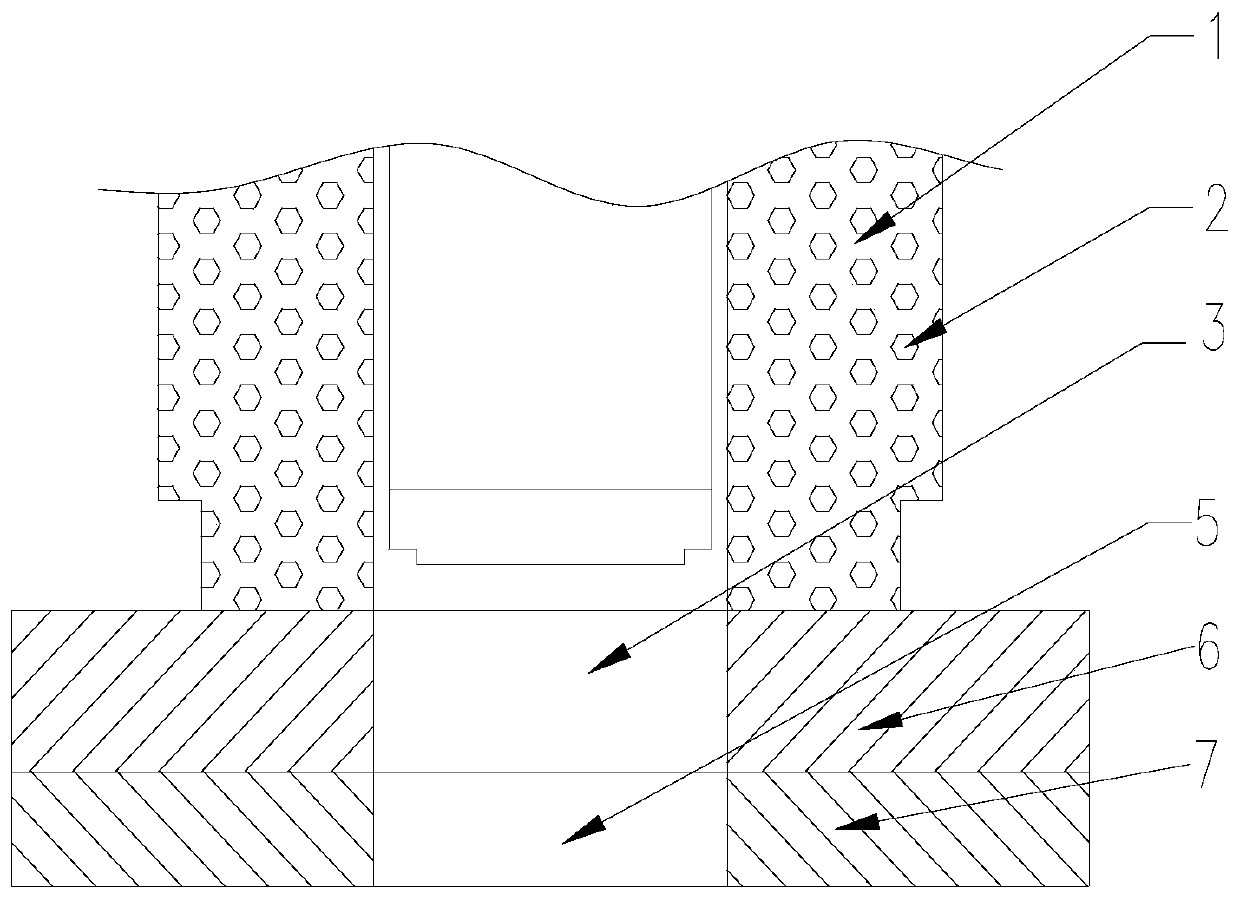

Embodiment 1

[0033] A spinning method for prolonging the cleaning period of special-shaped cross-section fiber production, its schematic diagram is as follows image 3As shown, the insulation board 6 is embedded and hung on the bottom of the spinning box 1. There is a gas-phase heat medium 2 in the spinning box 1. The inside of the insulation board 6 is hollow in a "back shape", and a hollow chamber I3 is set inside. The cross-section of the chamber is rectangular, with the side parallel to the line connecting the centers of the spinnerets as the long side direction, and the length of the long side is 1.2 times the sum of the diameters of the multiple spinnerets, and the direction perpendicular to the long side The length of the short side is 1.7 times the diameter of the spinneret, and a spacer with a thickness of 1 mm is inserted in the hollow chamber I3 to divide it into a plurality of slow cooling chambers. Each slow cooling chamber has A circular spinneret. The diameters of the spinn...

Embodiment 2

[0040] A spinning method for prolonging the board-cleaning cycle of special-shaped cross-section fiber production, its structure is basically the same as that of Example 1, the difference is that the thickness of the spacer is 2 mm, the insulation material filled in the insulation board is ceramic fiber, and its heat-resistant temperature is 405 ° C , The thickness of the insulation board is 40mm, the wall thickness of the stainless steel plate is 1.2mm, and the thickness of the heat insulation board is 35mm.

[0041] Use the above-mentioned device for super-bright special-shaped cross-section fiber spinning operation. After the temperature of the insulation board and the box are fully balanced, the temperature of the spinneret surface is detected. The measured temperature is 263°C, which is higher than the lowest temperature of 240°C for normal production. ℃, can spin smoothly, the average cleaning cycle is 31 hours, and the cleaning cycle is extended by 40%.

Embodiment 3

[0043] A spinning method for prolonging the board-cleaning cycle of special-shaped cross-section fiber production, its structure is basically the same as that of Example 1, the difference is that the thickness of the spacer is 3 mm, the insulation material filled in the insulation board is rock wool, and its heat-resistant temperature is 410 °C , The thickness of the insulation board is 50mm, the wall thickness of the stainless steel plate is 1.5mm, and the thickness of the heat insulation board is 45mm.

[0044] Use the above-mentioned device for super-bright special-shaped cross-section fiber spinning operation. After the temperature of the insulation board and the box are fully balanced, the temperature of the spinneret surface is detected. The measured temperature is 268 ° C, which is higher than the lowest temperature of 240 ° C for normal production. ℃, can spin smoothly, the average cleaning cycle is 30 hours, and the cleaning cycle is extended by 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com