POY pre-drafting and winding device

A winding device and pre-drawing technology, which can be used in textiles and papermaking, clustering of newly extruded filaments, and complete sets of equipment for the production of artificial threads, etc. It can solve the problems of large floor area, large device height, and long time , to achieve the effect of saving manpower, reducing the requirements of the workshop, and reducing waste silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

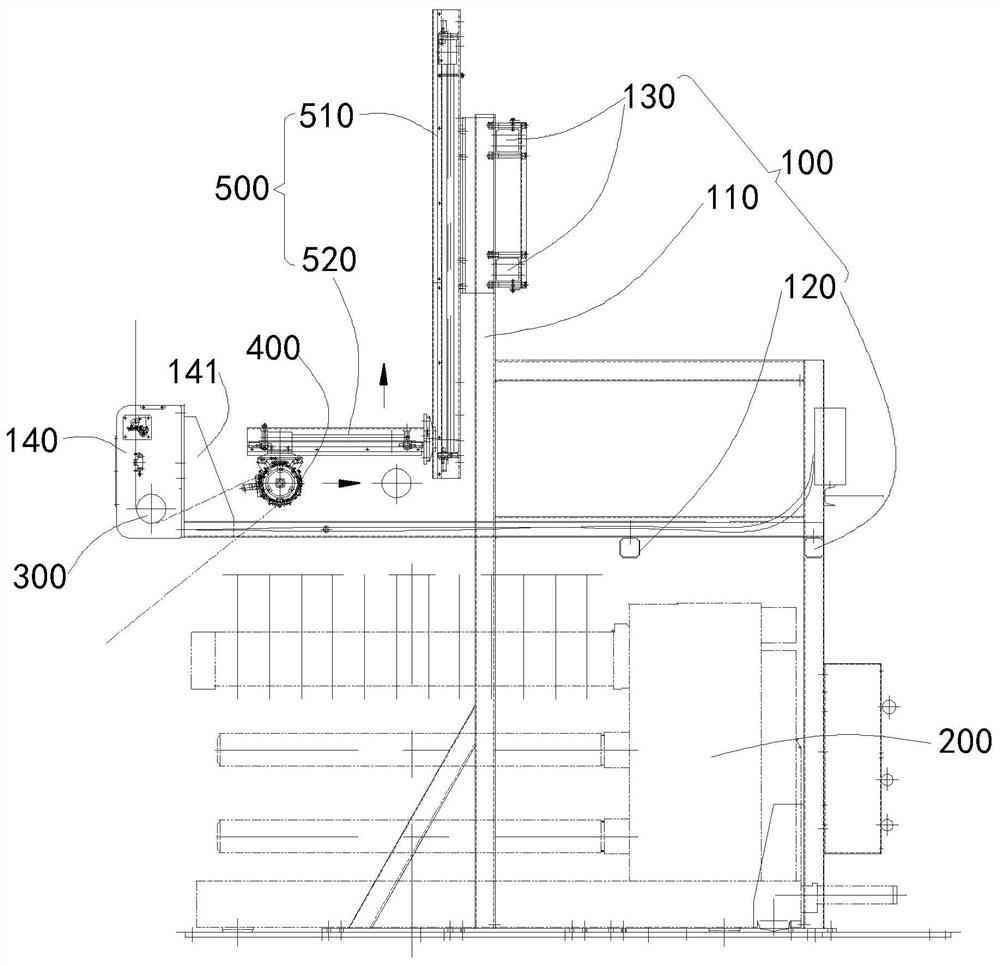

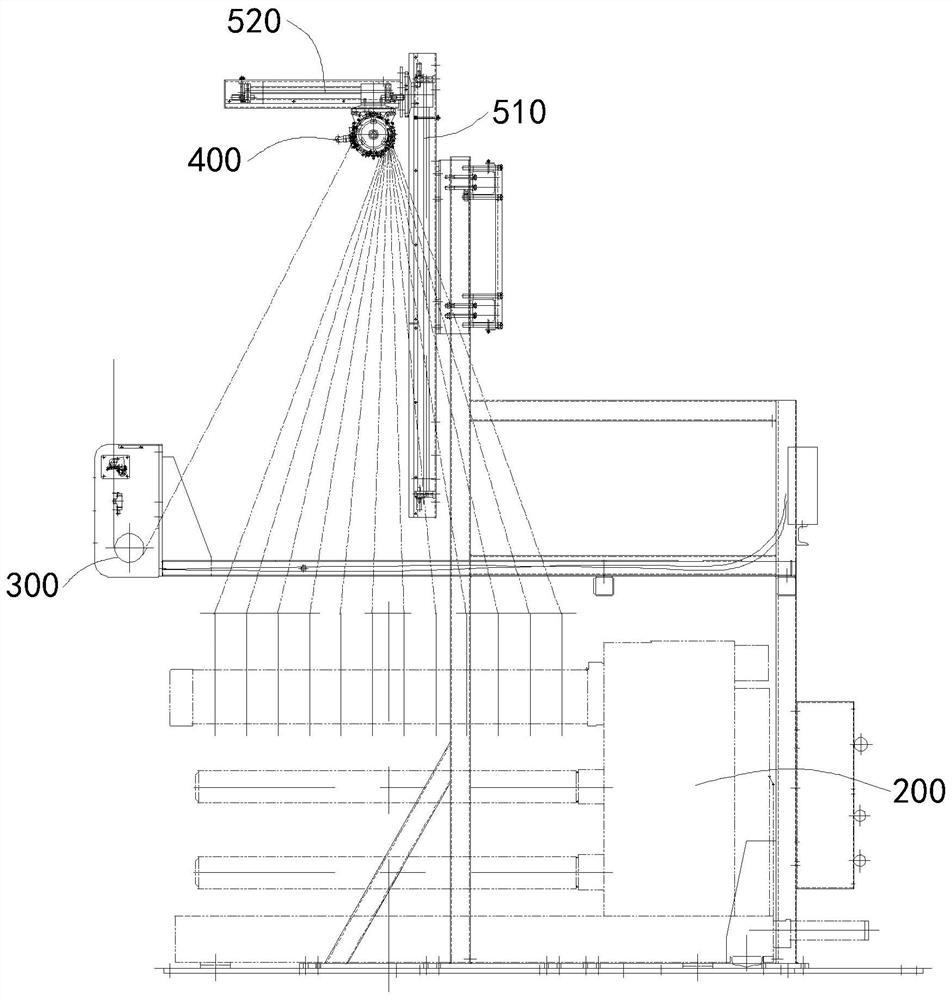

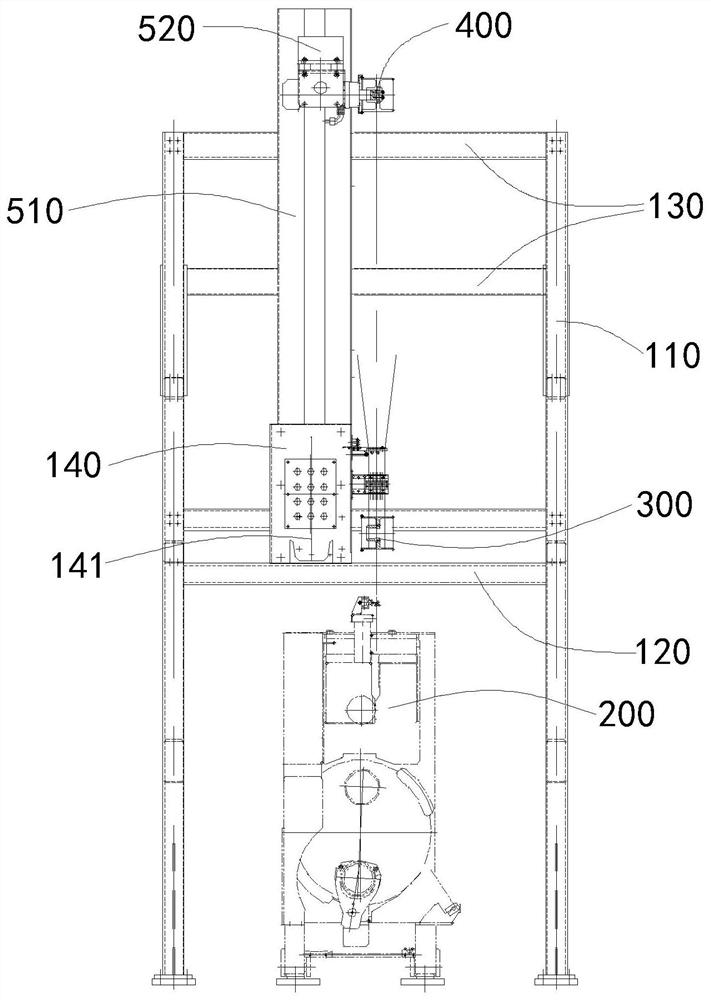

[0049] Please refer to Figure 1 to Figure 6 , the present embodiment provides a POY pre-stretch winding device, including a frame 100, a winding machine 200 relatively fixed to the frame 100, a first guide plate 300 fixed to the frame 100, and a movably disposed on the machine frame 100. The second guide plate 400 of the frame 100 and the vertical movement mechanism 500 provided on the frame 100, the vertical movement mechanism 500 drives the second guide plate 400 to move vertically, so as to hang the thread at the low position and thread the thread at the high position, Enter the subsequent normal spinning.

[0050] The first guide plate 300 is a fixed guide plate, which is specifically arranged at the front end of the winding machine 200 . The winding machine 200 can be fixedly installed on the machine frame 100, or relatively fixed by other means. By setting the vertical movement mechanism 500, the second guide plate 400 is controlled to move vertically, and the second ...

Embodiment 2

[0057] This embodiment provides a kind of POY pre-drawing winding device, based on the POY pre-drawing winding device of embodiment 1, such as figure 1 and figure 2 As shown, a mounting base 520 is also provided. The vertical movement mechanism 500 includes a third guide rail 510 arranged vertically, and the mounting base 520 is movably arranged on the third guide rail 510 . The mounting seat 520 is arranged between the first guide plate 300 and the second guide plate 400, and is arranged horizontally, and the second guide plate 400 is movably arranged on the mounting seat 520, so that the second guide plate 400 moves vertically under the driving and move horizontally.

[0058] When the vertical movement mechanism 500 drives the second guide plate 400 to move down vertically to hang the wire at a low position, the second guide plate 400 is also moved horizontally through the mounting seat 520, and the second guide plate 400 is moved toward the first guide plate. 300 moved c...

Embodiment 3

[0061] Please refer to Figure 4 to Figure 11 , this embodiment provides a POY pre-drawing and winding device, based on the POY pre-drawing and winding device in Embodiment 1, a hanging thread rod 600 and a horizontal movement mechanism 700 are also provided. Please refer to Figure 7 , Figure 8 and Figure 10 , the thread hanging rod 600 is configured to wind the tow coming from the first guide disc 300 to form a stretching line segment 641 .

[0062] Please refer to Figure 8 and Figure 11 , Figure 8 There are four positional states of the movement of the hanging screw 600 in the graphic summary, Figure 11 for Figure 8 The schematic diagram of the four position states of , the horizontal movement mechanism 700 is configured to drive the hanging thread rod 600 to reciprocate along both sides of the horizontal radial direction of the second guide plate 400 in the low position and to move axially along the second guide plate 400 to The development line segment 641 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com