Auxiliary agent in use for regenerated fiber

A technology of regenerated fibers and additives, applied in fiber types, fiber processing, textiles and papermaking, etc., can solve the problems of inability to increase the time of fiber falling into the barrel, winding rolls and wool, and loose fiber bundles, and achieve excellent bundling effect, The effect of increasing economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the present invention is:

[0028] 1. Add water into the chemical reaction kettle, heat up to 80-90°C, add sizing agent and stir for not less than 30 minutes to make solution A.

[0029] 2. Add a smoothing agent to solution A at 80-90°C and stir for not less than 60 minutes to make solution B.

[0030] 3. Add antistatic agent to solution B at 80-90°C and stir for not less than 120 minutes to make solution C.

[0031] 4. Cool down solution C to below 30°C, discharge and pack into finished product.

[0032] In the process of chemical fiber production, the detection method of cohesion is to detect the aggregation of detection aids by the time of fiber falling into the bucket. The fiber drop time refers to the time it takes for the fiber bundle to fill the fiber drum. The fiber drop time is generally controlled between 8 and 16 minutes. When the fiber drop time is less than 8 minutes, the fiber bundle appears. Phenomena such as looseness, roll w...

Embodiment 1

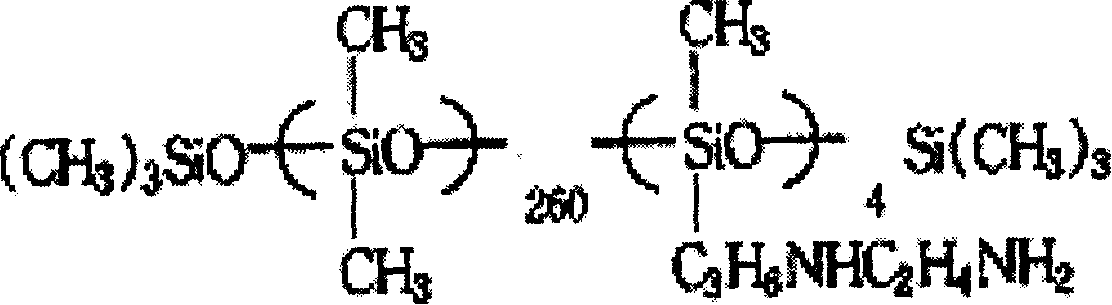

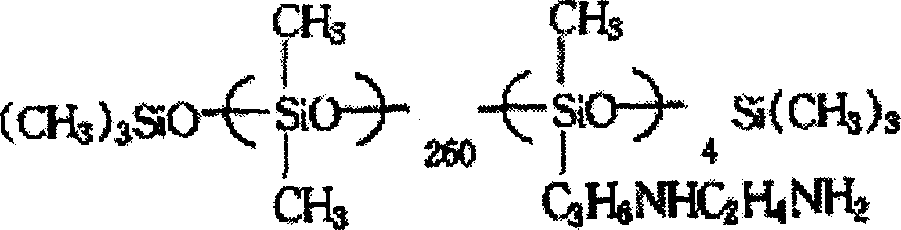

[0034]Example 1: Get 15kg of water and add it to the chemical reaction kettle, start the agitator, turn on the heating power, make the water warm up to 80-90°C, add 1kg of polyethylene with an average degree of polymerization of 900-1100 and a degree of alcoholysis of 80% Alcohol, stirred for 30 minutes, then added 0.04kg of amino-modified silicone oil emulsion with an average molecular weight of 10000-20000, continued to stir for 60 minutes, then added 0.8kg of dimethylaminoethanol methyl ammonium palmitate, and continued to stir for 120 minutes , cooled to below 30°C.

Embodiment 2

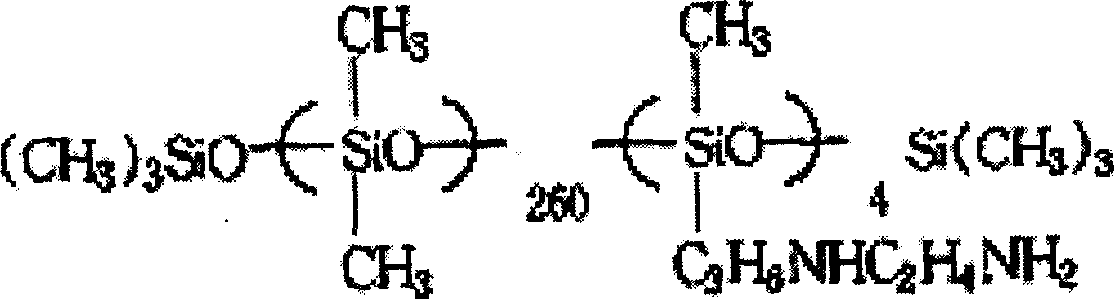

[0035] Embodiment 2: Get 15kg of water and add it to the chemical reaction kettle, start the agitator, turn on the heating power supply, make the water warm up to 80-90°C, add 1kg of polyethylene with an average degree of polymerization of 900-1100 and a degree of alcoholysis of 80% Alcohol, stirred for 30 minutes, then added 0.05 kg of amino-modified silicone oil emulsion with an average molecular weight of 10,000-20,000, continued to stir for 60 minutes, then added 1 kg of dimethylaminoethanol methyl ammonium palmitate, continued to stir for 120 minutes, and cooled To below 30 ℃, you can.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com