Hollow composite floor slab and construction method thereof

A technology of stacking floors and hollow-core slabs, applied in floors, building materials, building components, etc., can solve the problems of heavy and heavy floor static load, difficult to transport, and floor slabs without reinforced connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

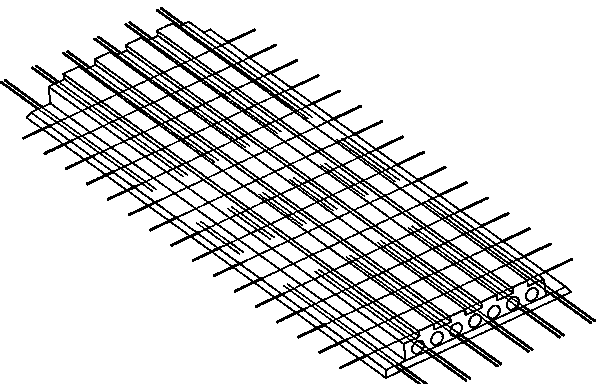

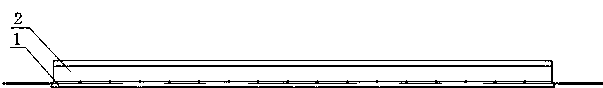

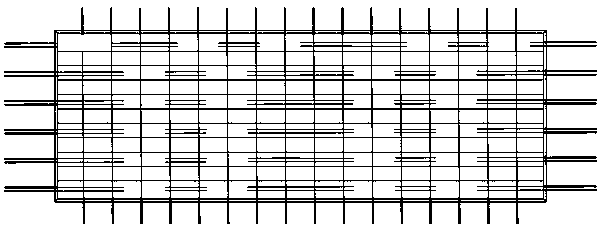

[0052] Reference attached figure 1 to attach Figure 5 , a hollow laminated floor slab, comprising a prefabricated hollow slab, the prefabricated hollow slab includes a bottom slab reinforced concrete layer 1 and a porous concrete layer 2; the porous concrete layer 2 is provided with a plurality of long through holes 3 at longitudinal intervals; the two sides of the porous concrete layer 2 or One side is concave on both sides of the reinforced concrete layer 1 of the bottom plate, so that the reinforced concrete layer 1 of the bottom plate forms a post-cast part 6; a post-cast reinforced concrete layer 7 is arranged above the porous concrete layer 2, and the porous concrete layer 2 and the post-cast reinforced concrete layer 7 are interlocked with each other by grooves and ribs.

[0053] The upper surface of the porous concrete layer 2 is provided with long grooves 4 arranged in parallel and at intervals along the length direction of the prefabricated hollow slab; and long co...

Embodiment 2

[0069] Reference attached Figures 6 to 10 , The section of the long groove 4 is a semicircular structure, and the others are the same as in Embodiment 1.

Embodiment 3

[0071] Reference attached Figures 11 to 15 , the cross-section of the long groove 4 is a trapezoidal structure, and the others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com