Patents

Literature

44results about How to "Improve load bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

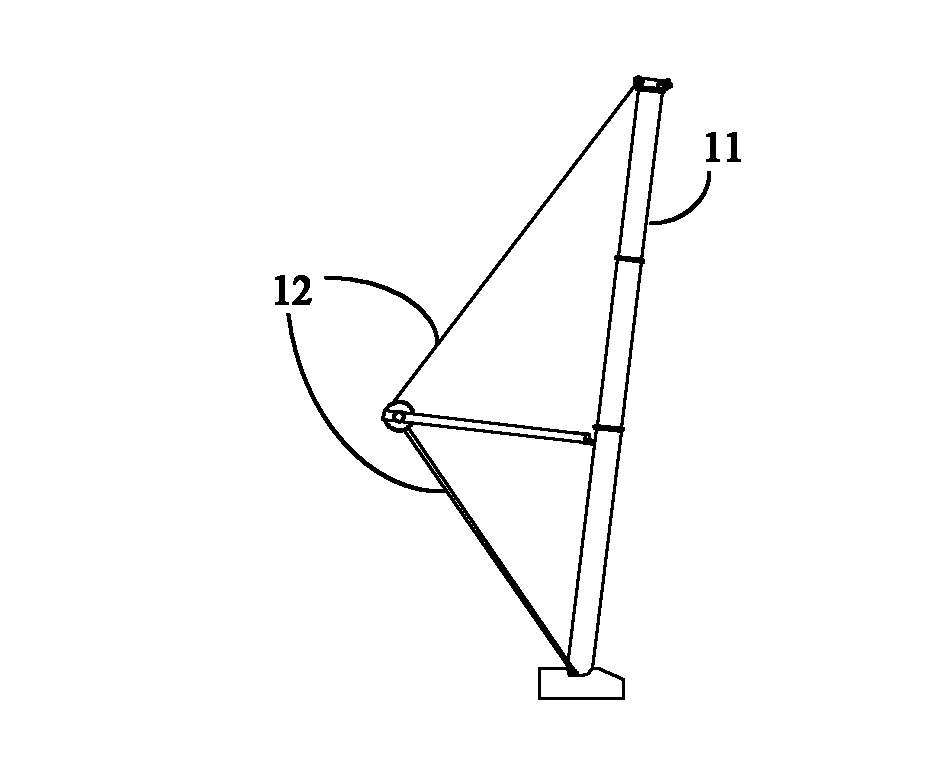

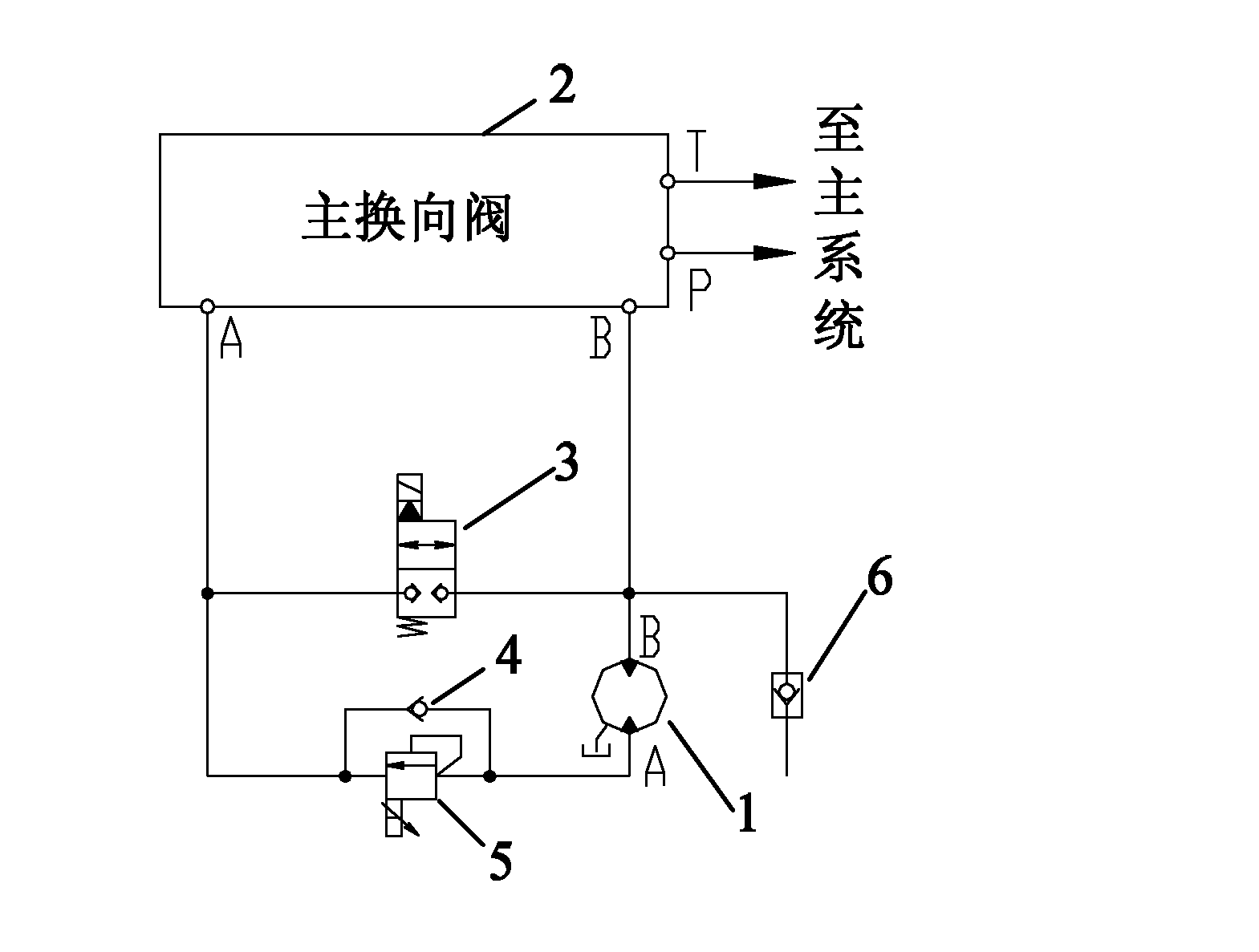

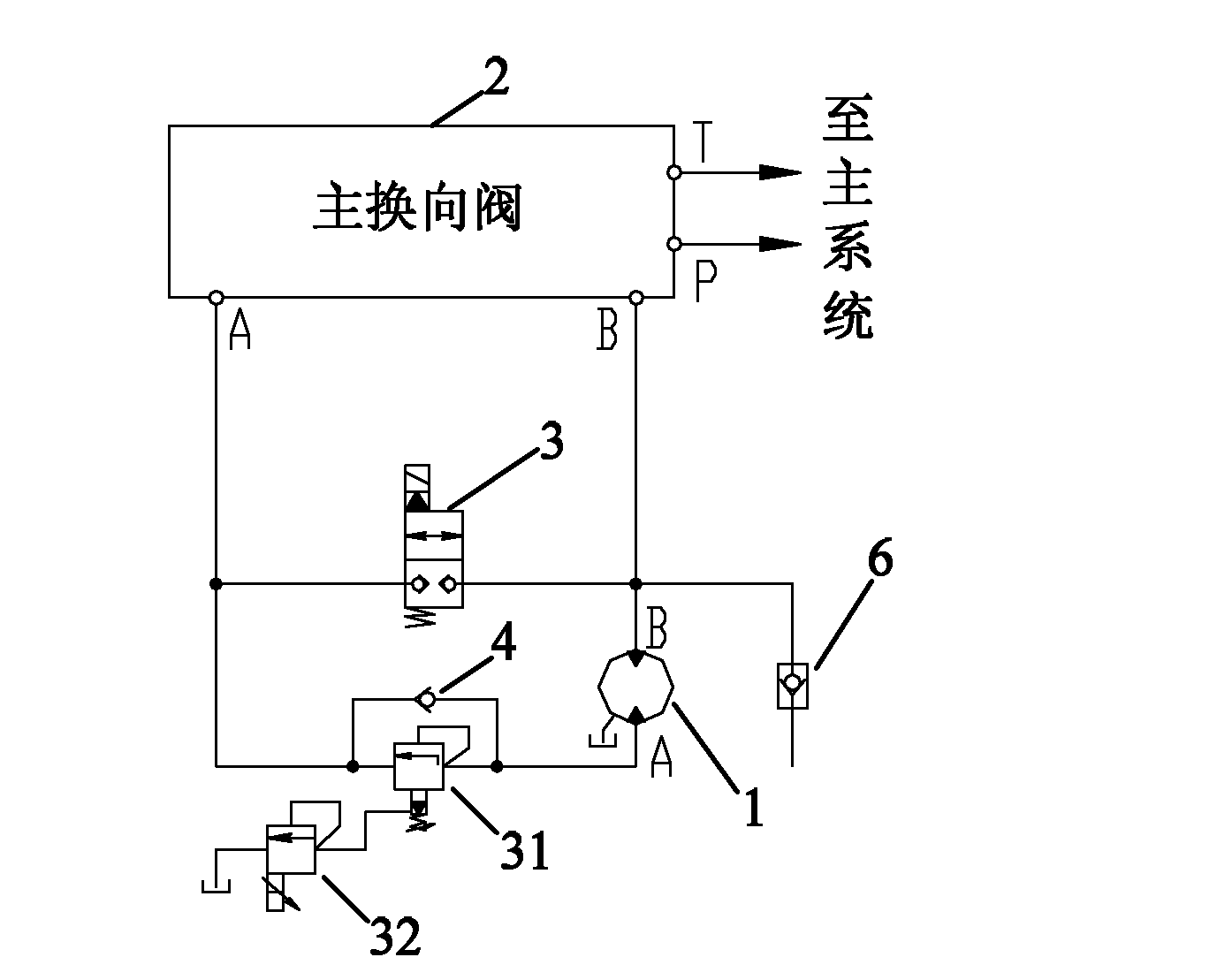

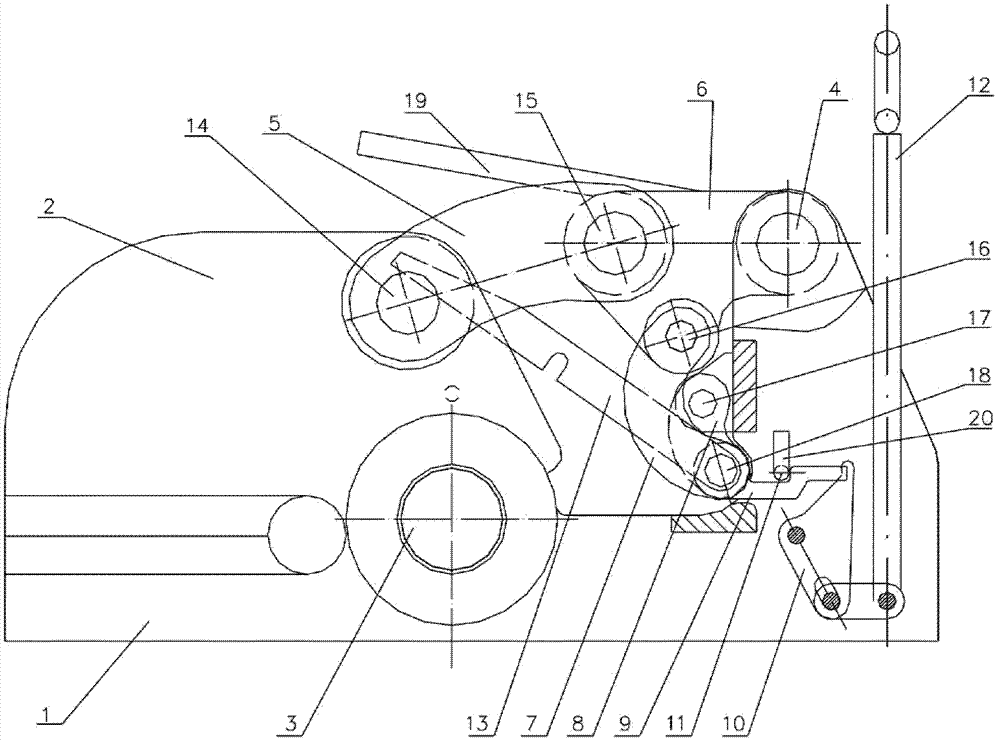

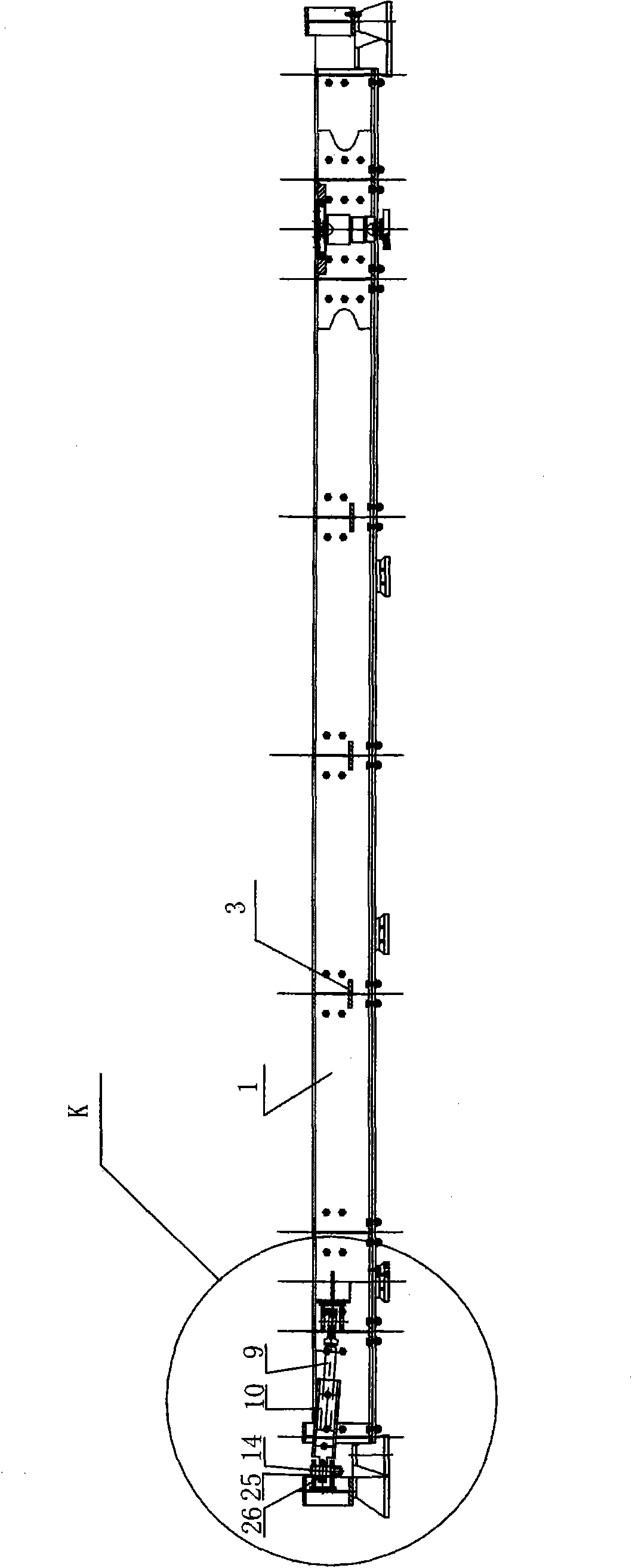

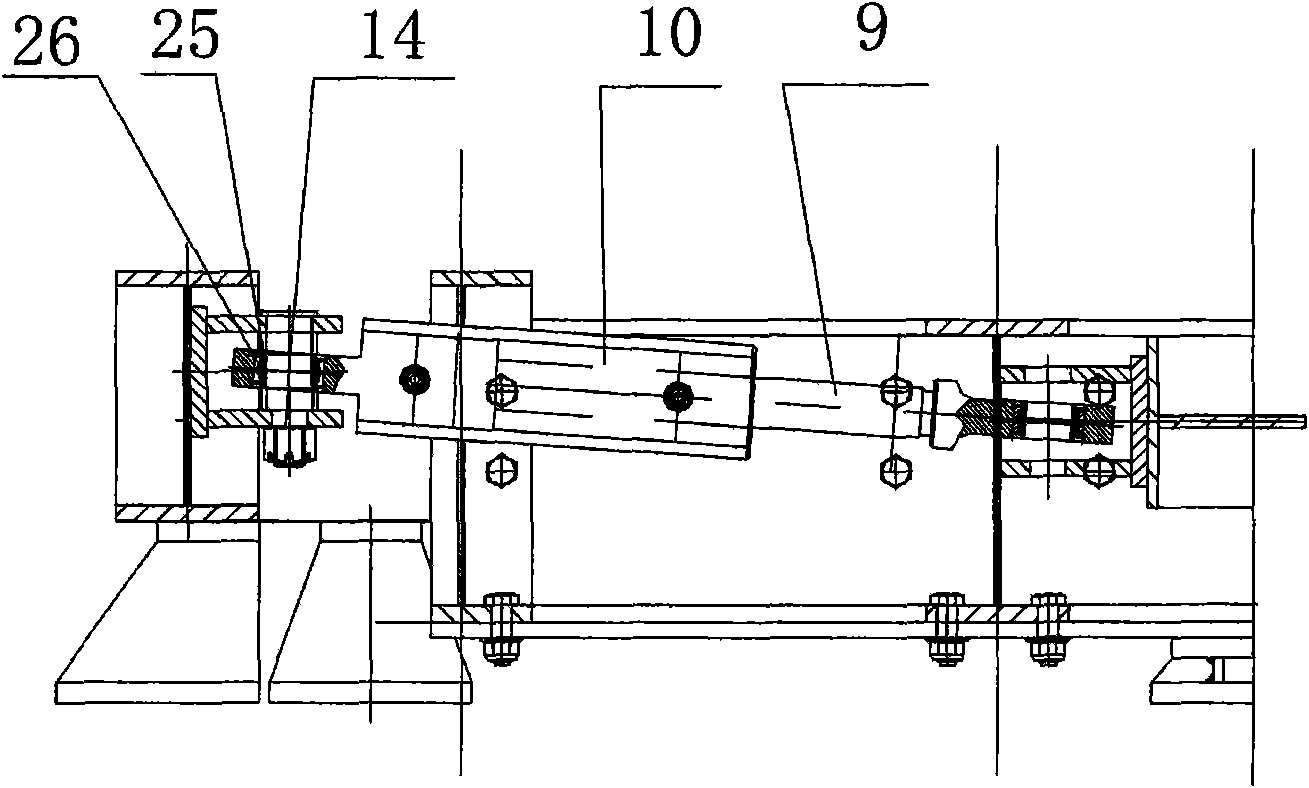

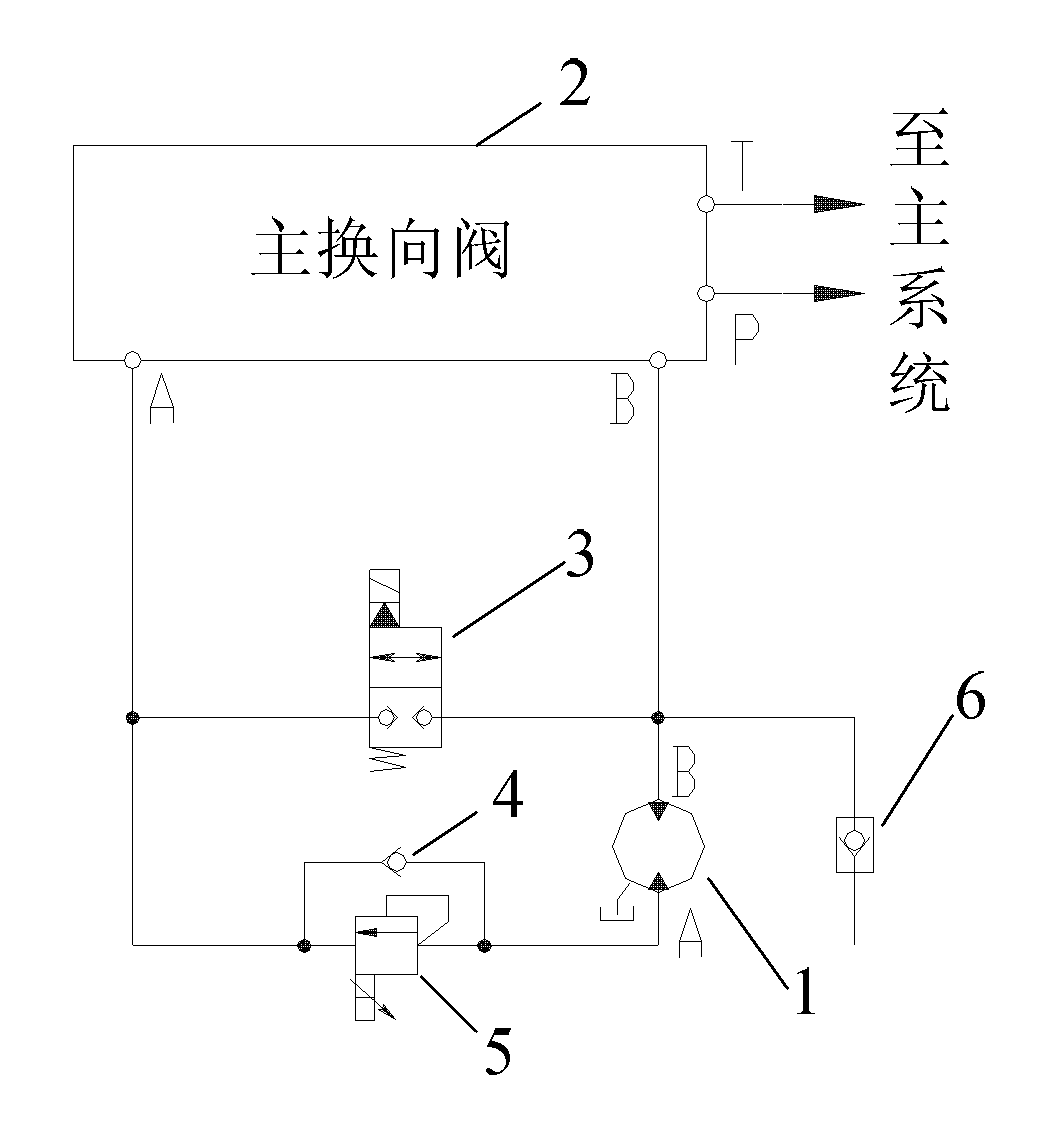

Crane, method for controlling tension of steel wire rope and hydraulic system

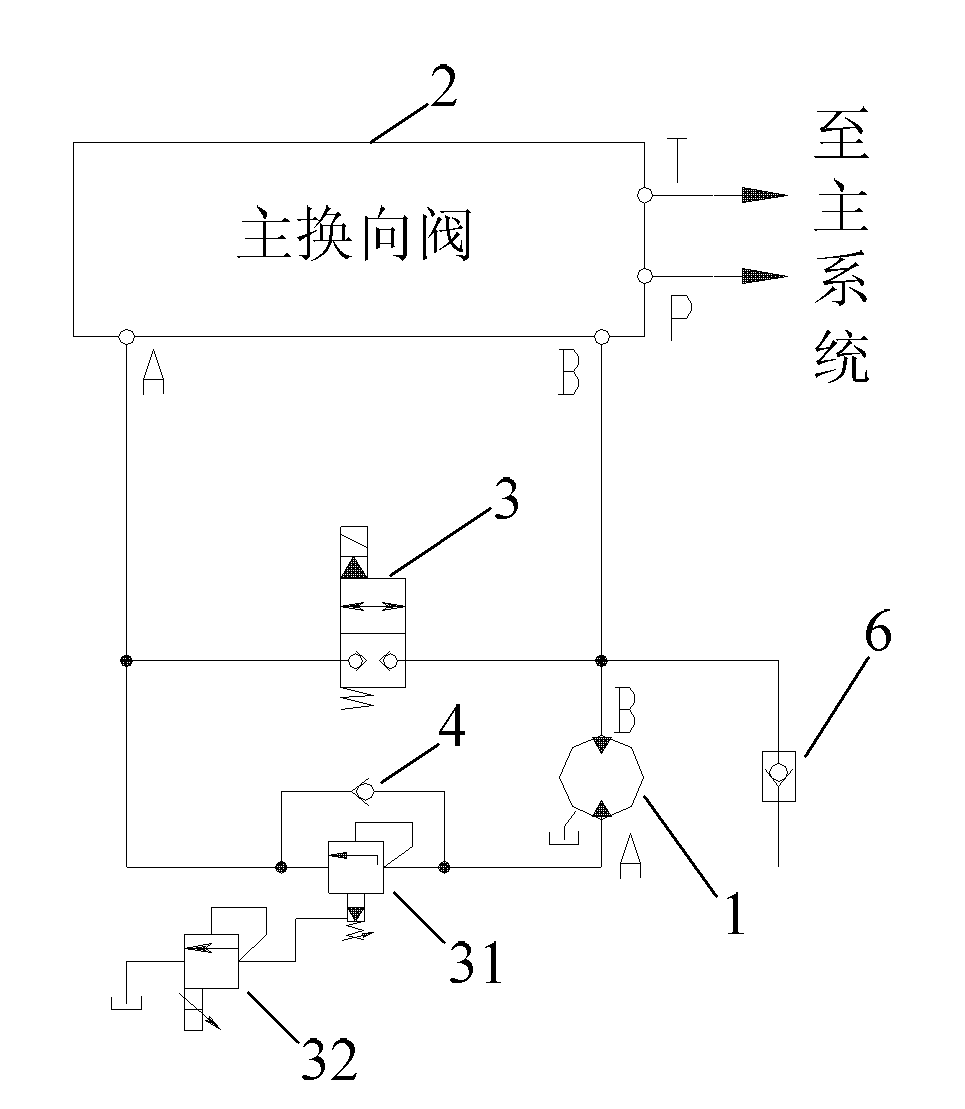

ActiveCN102491174AAdjustable tensionAchieve floating controlServomotor componentsWinding mechanismsHydraulic motorCheck valve

The invention provides a crane, a method for controlling the tension of a steel wire rope and a hydraulic system, and the crane, the method and the system can be used for solving the problems of low stability and low work efficiency of the conventional stretchable arm type crane with a super-lifting winding mechanism during stretching of a lifting arm in the prior art. The hydraulic system comprises a master reversing valve, a switching valve, a check valve, a backpressure valve and a hydraulic motor, wherein the master reversing valve is used for leading hydraulic oil into or out of the hydraulic system; the hydraulic motor is used for outputting power to a traction device of the steel wire rope; a first end of the switching valve is communicated with a first oil outlet of the master reversing valve; the inlet of the check valve is communicated with the outlet of the backpressure valve; a second end of the switching valve is communicated with the second oil outlet of the master reversing valve and a first end of the hydraulic motor; and the inlet of the backpressure valve is communicated with the outlet of the check valve and a second end of the hydraulic motor.

Owner:ZOOMLION HEAVY IND CO LTD

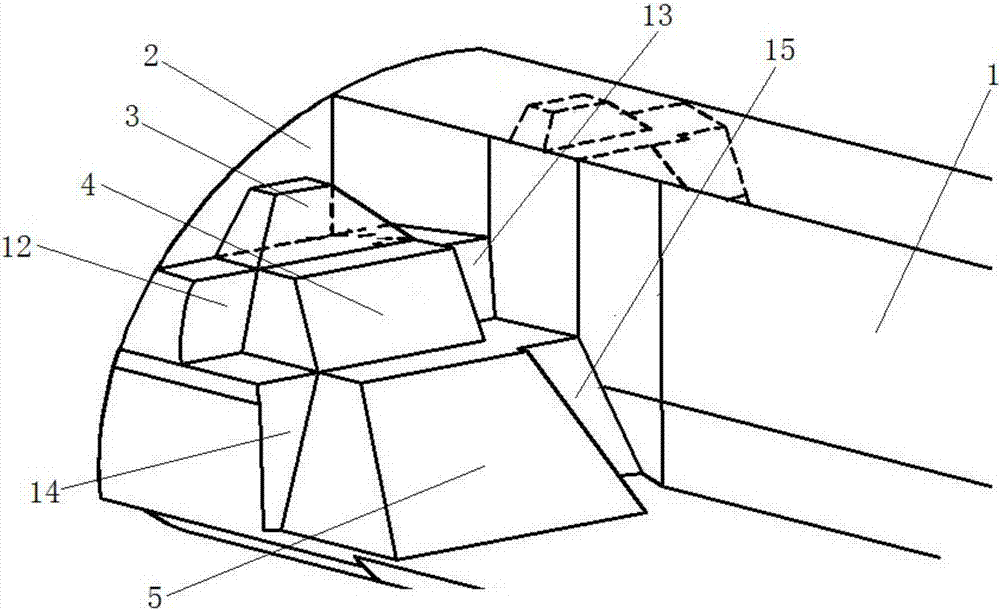

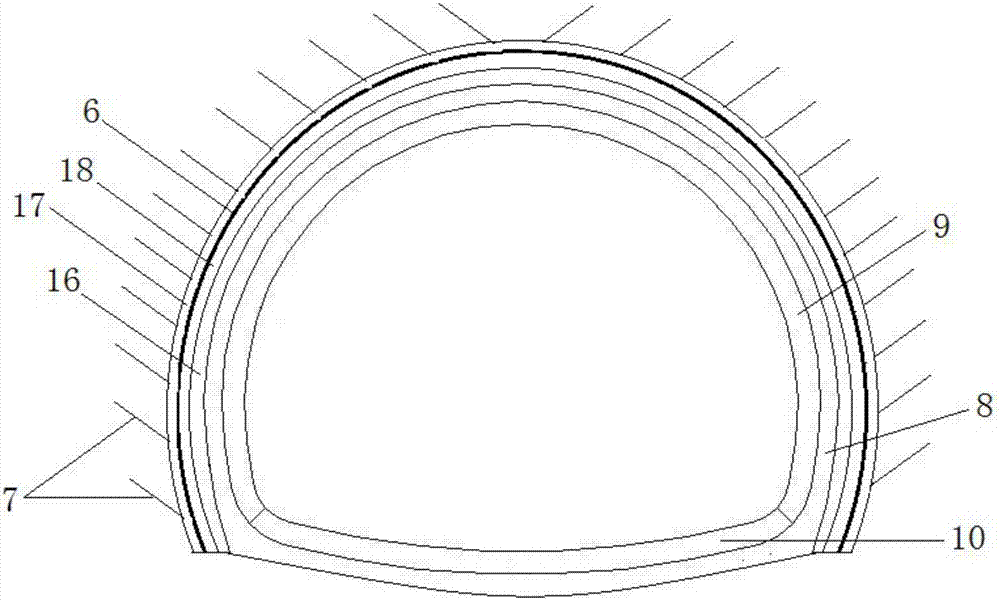

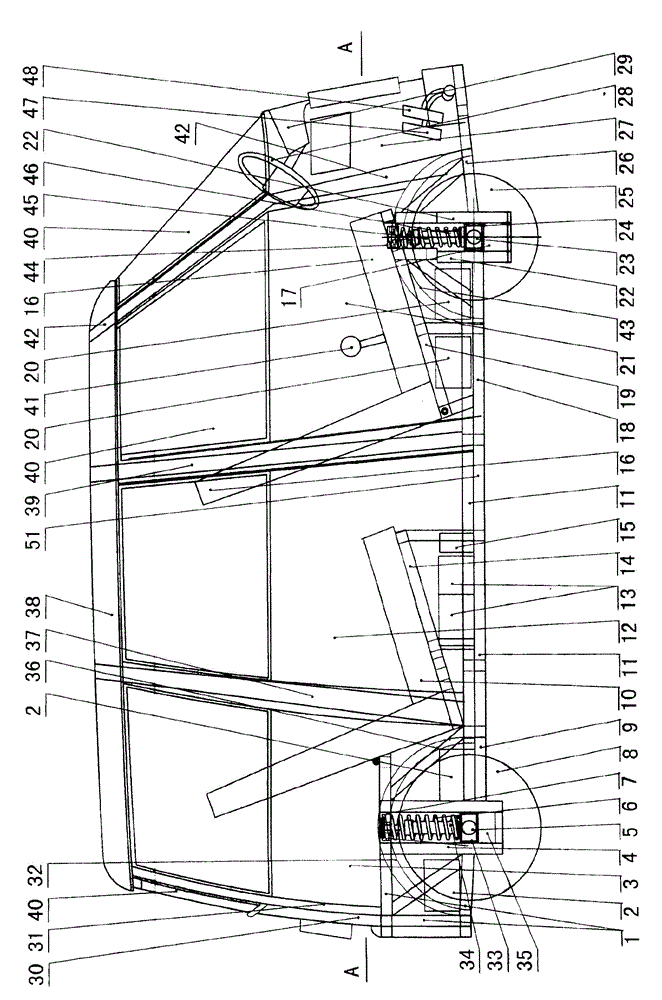

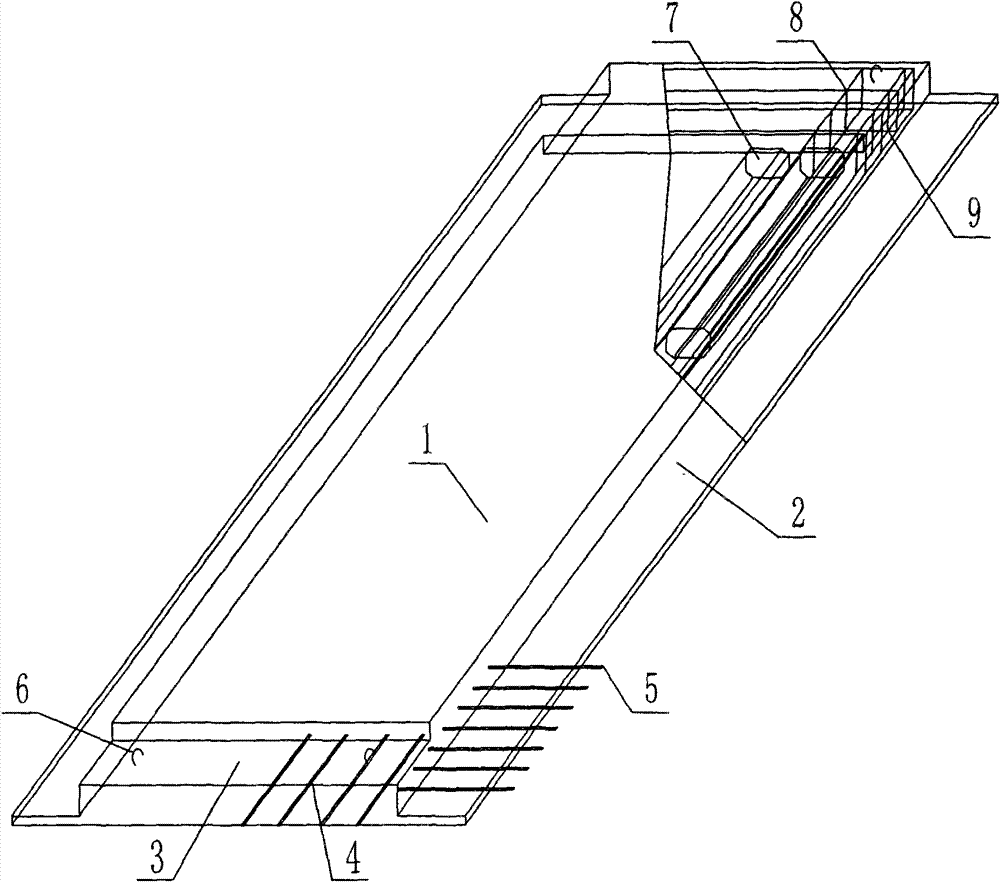

Excavation construction method for super large cross section tunnel of bias shallow buried weak surrounding rock

InactiveCN106979013AShorten the construction periodSimple stepsTunnelsProps/chocksEnvironmental geologyStructure of the Earth

The invention discloses an excavation construction method for a super large cross section tunnel of bias shallow buried weak surrounding rock. A temporary median lamella wall is adopted to divide a tunnel face into a left part and a right part; and the left part and the right part are excavated simultaneously through a three-bench-five-step method. According to the three-bench-five-step excavation method of the median lamella, when the geological condition changes, construction processes can be converted flexible and timely, the construction method is adjusted, and the construction period is shortened. The excavation method is simple in process and reliable in excavation, excavation of the super large cross section tunnel of the bias shallow buried weak surrounding rock is provided an important guarantee, the failure rate is low, and the project profitability is enhanced. A locking anchor pipe replaces a traditional locking anchor rod, the stability of the structure is also improved, meanwhile, steel pipes are adopted to fix steel frames, so that the steel frames form a whole through the connected steel pipes, the system bearing load is improved, the fixing effect of the steel frames is better, and control of tunnel deformation is very favorable.

Owner:CCCC SECOND HARBOR ENG

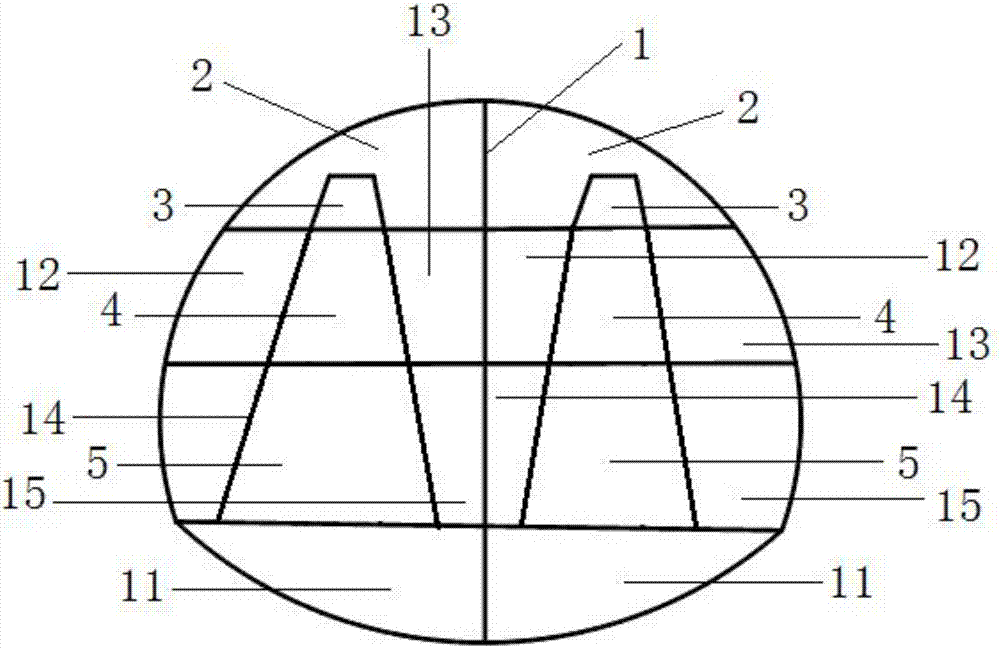

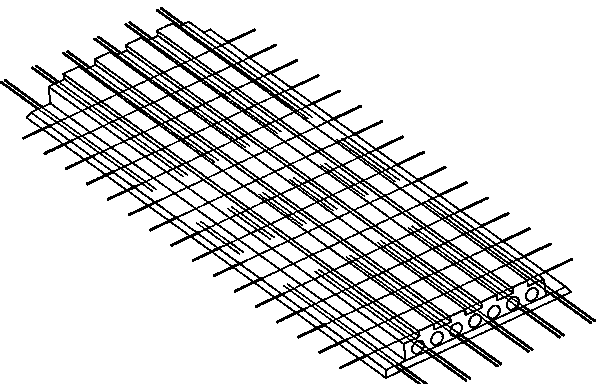

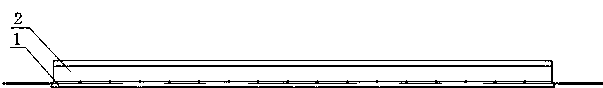

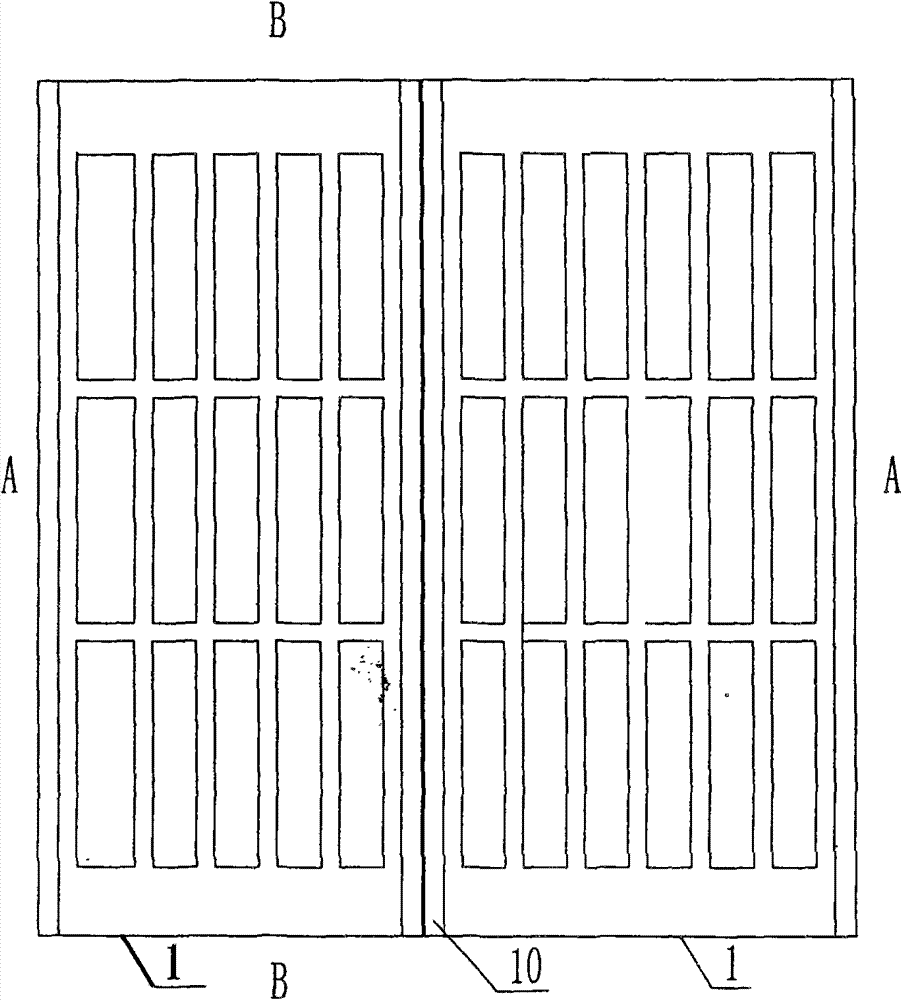

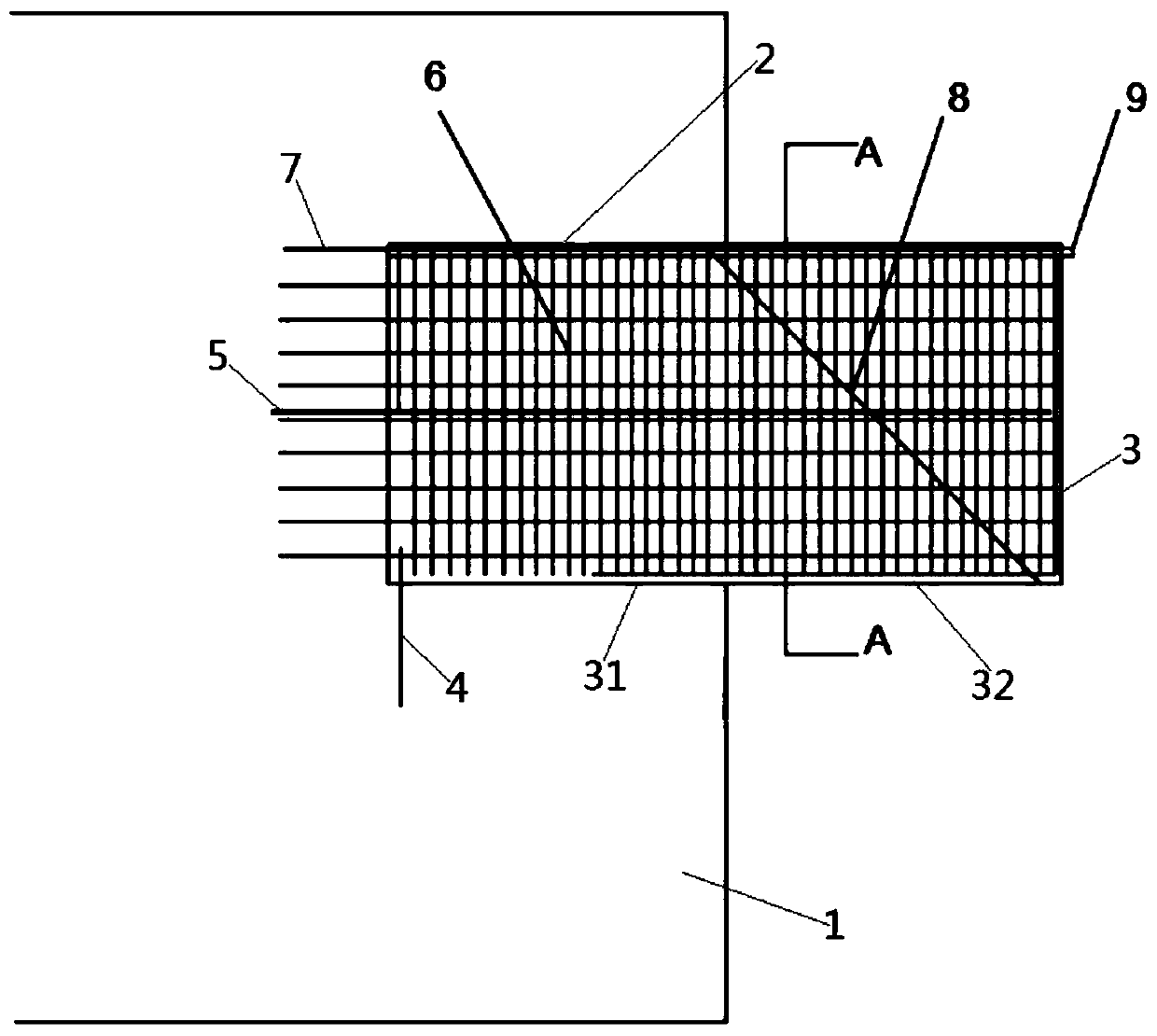

Hollow composite floor slab and construction method thereof

InactiveCN103981987AOptimize the force structureHigh strengthConstruction materialFloorsFloor slabReinforced concrete

The invention provides a hollow composite floor slab and a construction method of the hollow composite floor slab. The hollow composite floor slab is convenient to transport, low in breakage rate, small in self-weight, low in cost, large in rigidity and good in anti-seismic property. To achieve the aim, according to the scheme, the hollow composite floor slab comprises a prefabricated hollow slab body and a rear pouring reinforced concrete layer, and the prefabricated hollow slab body comprises a base board reinforced concrete layer and a porous concrete layer; a plurality of long through holes are longitudinally formed in the porous concrete layer at intervals; the two sides or the single side of the porous concrete layer are concaved in the two side faces of the base plate reinforced concrete layer, and a rear pouring portion is formed on the prefabricated hollow slab body; the rear pouring reinforced concrete layer is arranged above the prefabricated hollow slab body, and the porous concrete layer and the rear pouring reinforced concrete layer are meshed through a groove and beads. The construction method comprises the steps of manufacturing the prefabricated hollow slab body and mounting the hollow composite floor slab.

Owner:王睿敏

Conveying device for heavy load conveyor belt

Owner:上海林春万向轮制造有限公司

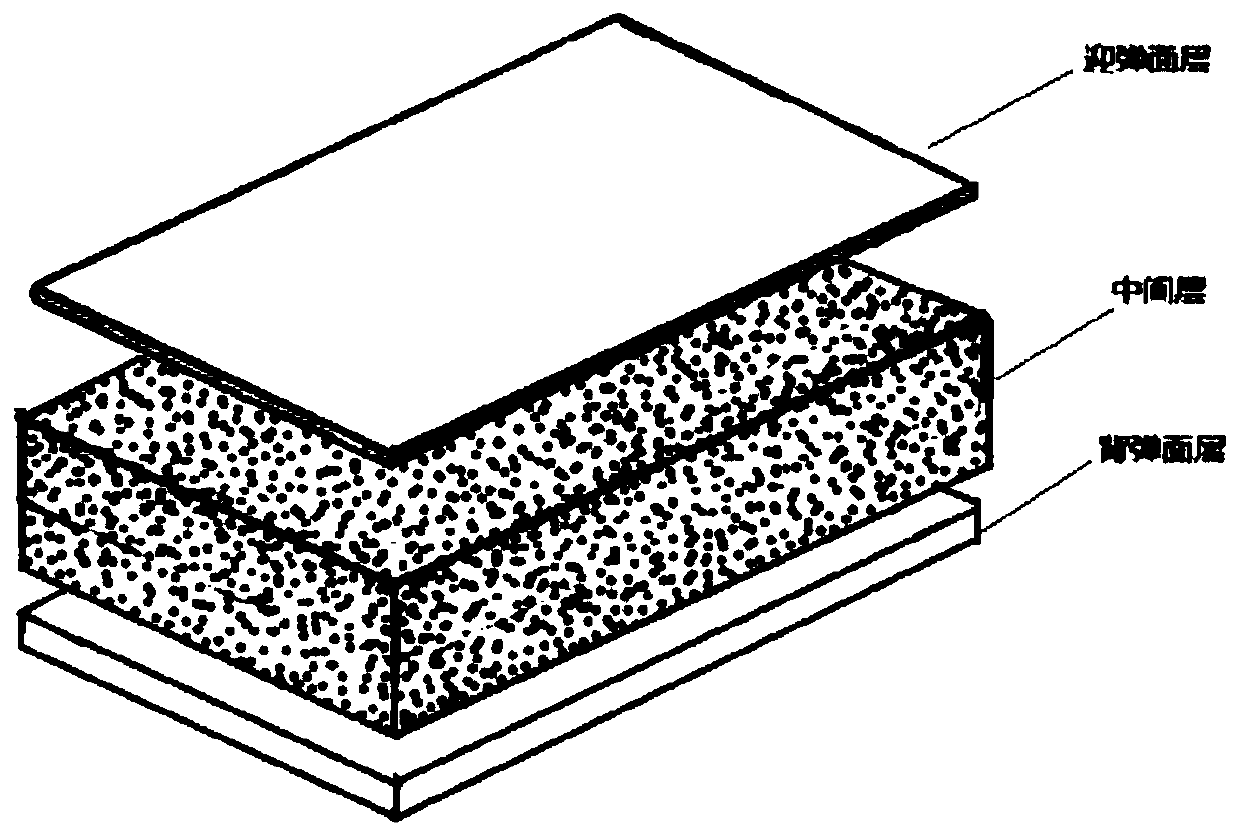

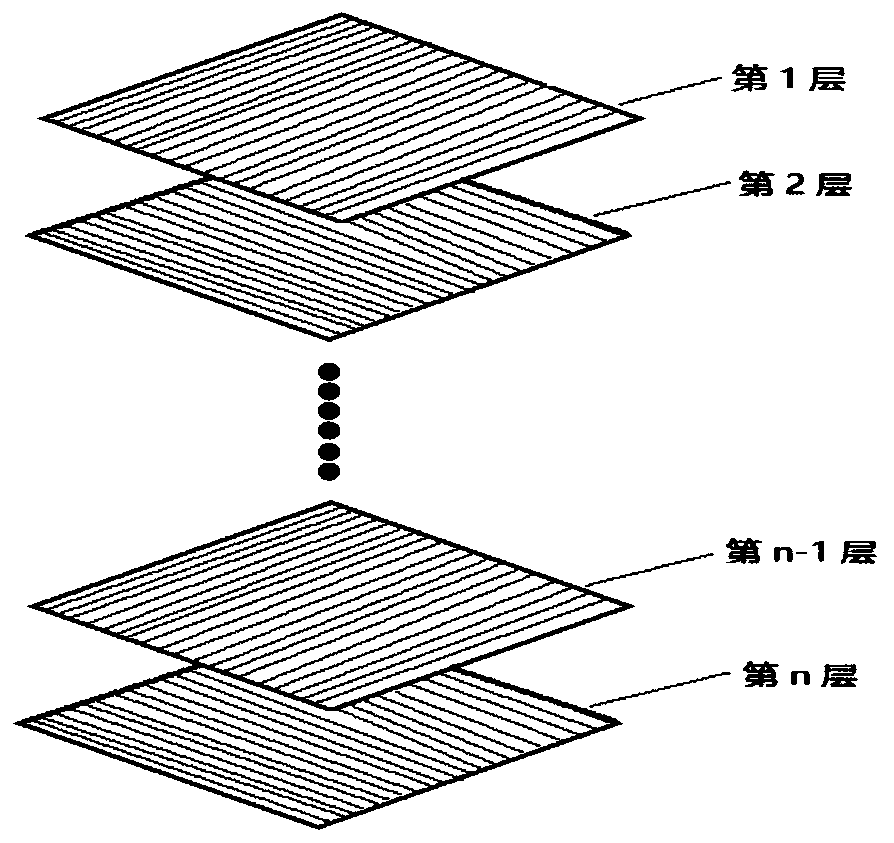

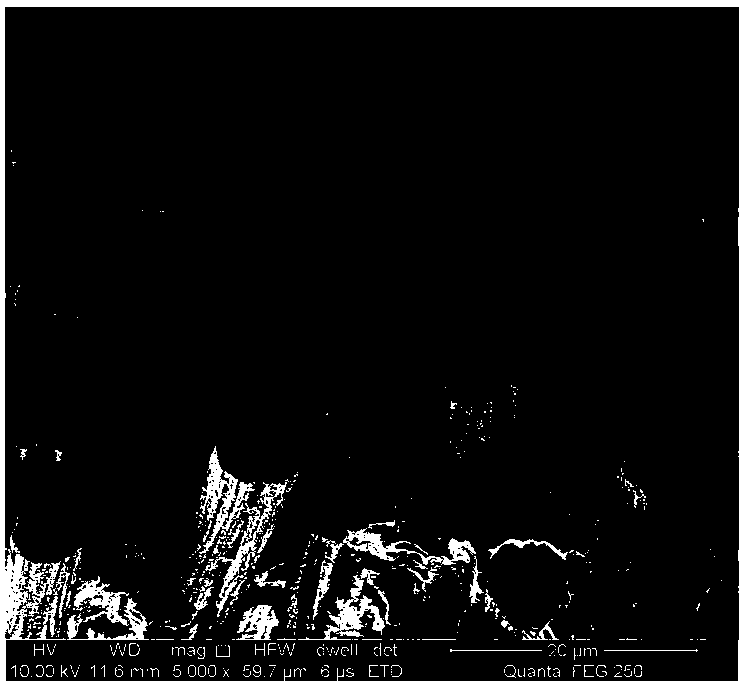

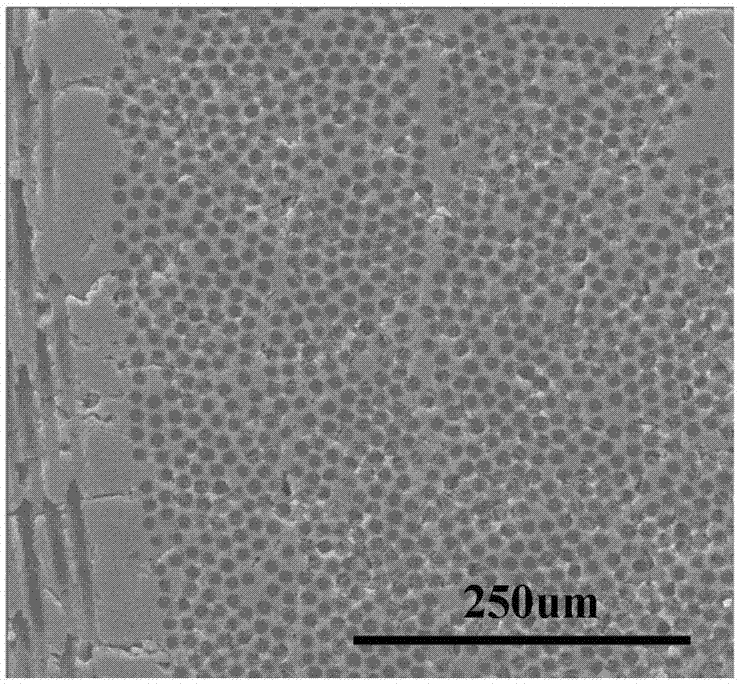

UHMWPE fiber reinforced resin-based soft bulletproof material

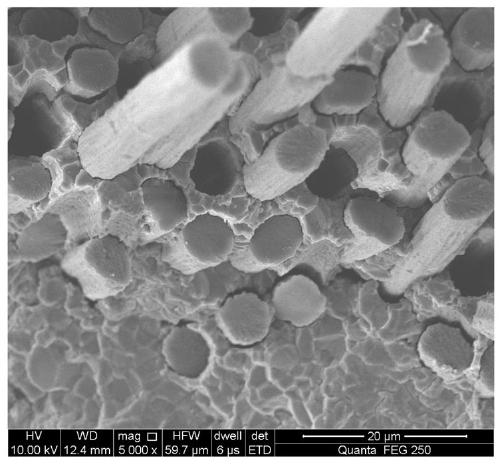

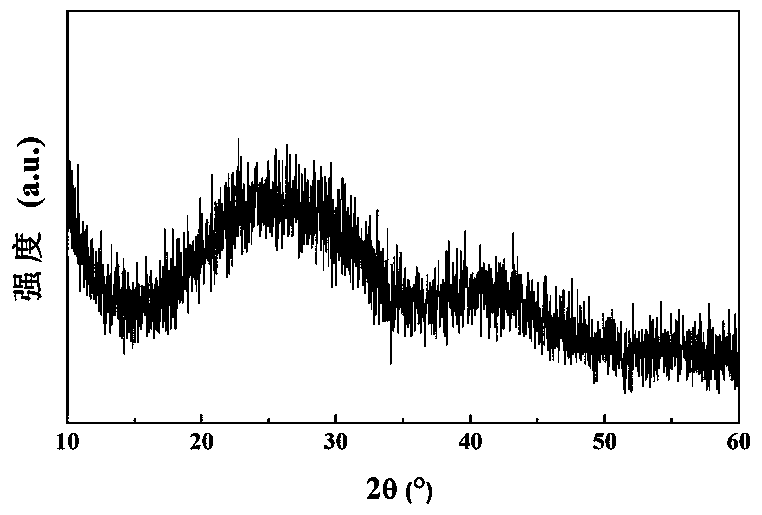

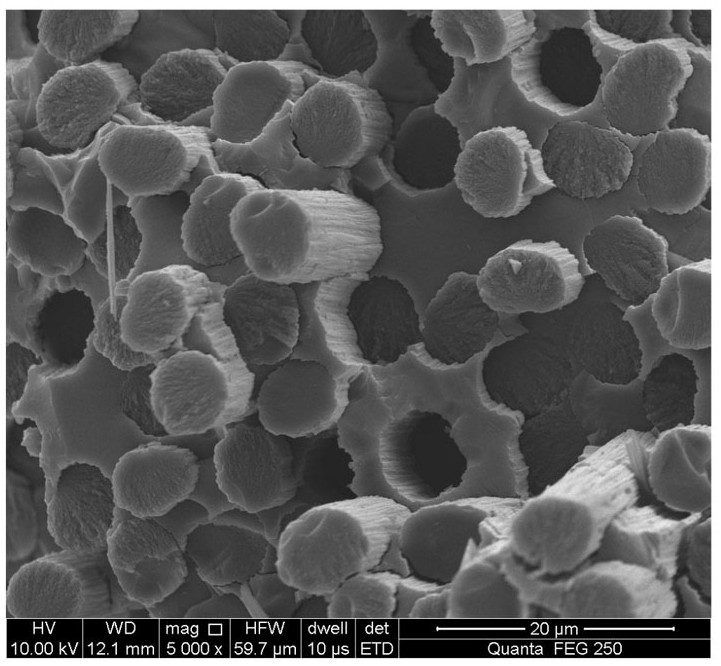

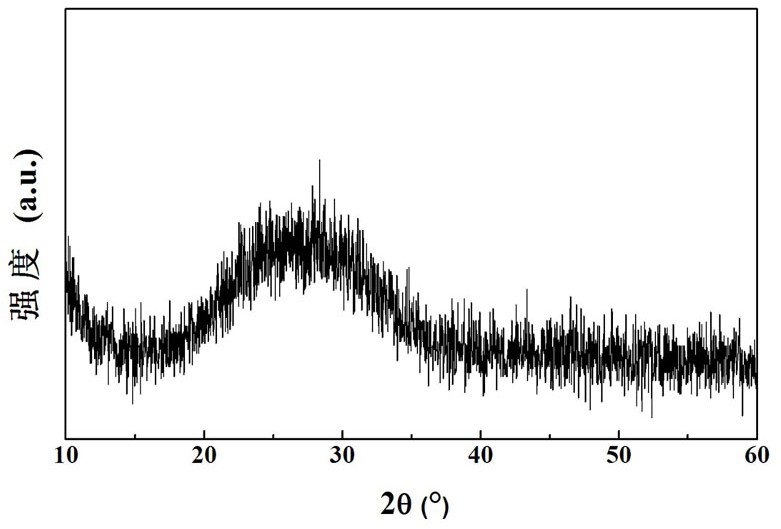

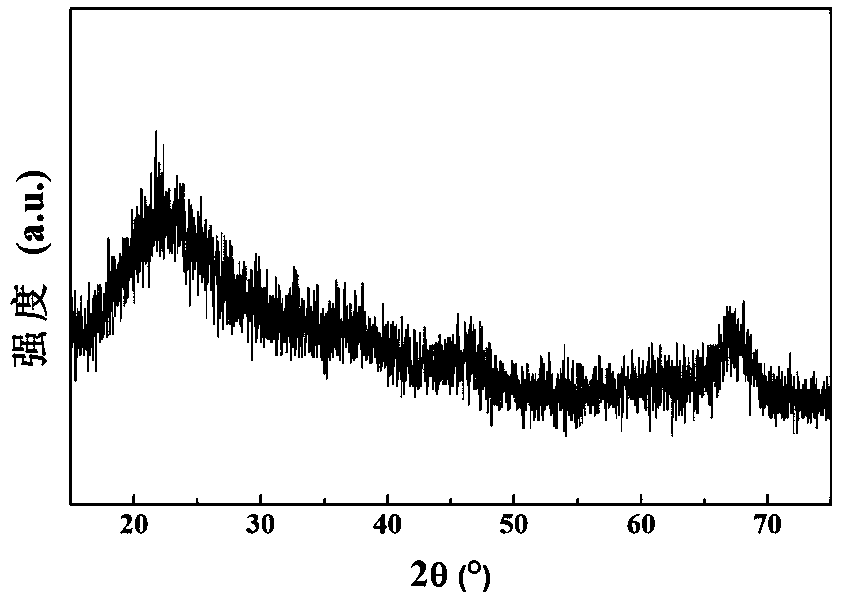

PendingCN111267429AGood bulletproofBack convex depth is smallProtective equipmentSynthetic resin layered productsFiberPolymer science

The invention provides a UHMWPE fiber reinforced resin-based soft bulletproof material, and relates to the technical field of protective equipment. The soft bulletproof material comprises a middle layer, a bullet facing surface layer overlaid on the surface of one side of the middle layer, and a bullet backing surface layer overlaid on the surface of the other side of the middle layer. The woven composite material is used as a bullet-facing surface layer material and a bullet-backing surface layer material of the soft bulletproof material, and the woven composite material is formed by making UHMWPE fibers into plain cloth or twill cloth and then hot-pressing and compounding the plain cloth or twill cloth and a hot-melt resin adhesive film. A plurality of UD sheets are used as middle layermaterials, each UD sheet is formed by hot-pressing and compounding a plurality of layers of UD single sheets, every two adjacent layers of UD single sheets are orthogonally arranged, and each UD single sheet is prepared from UHMWPE fibers and thermoplastic resin according to a UD cloth forming method. The soft bulletproof material is light in weight and has excellent bulletproof performance.

Owner:NANTONG UNIVERSITY

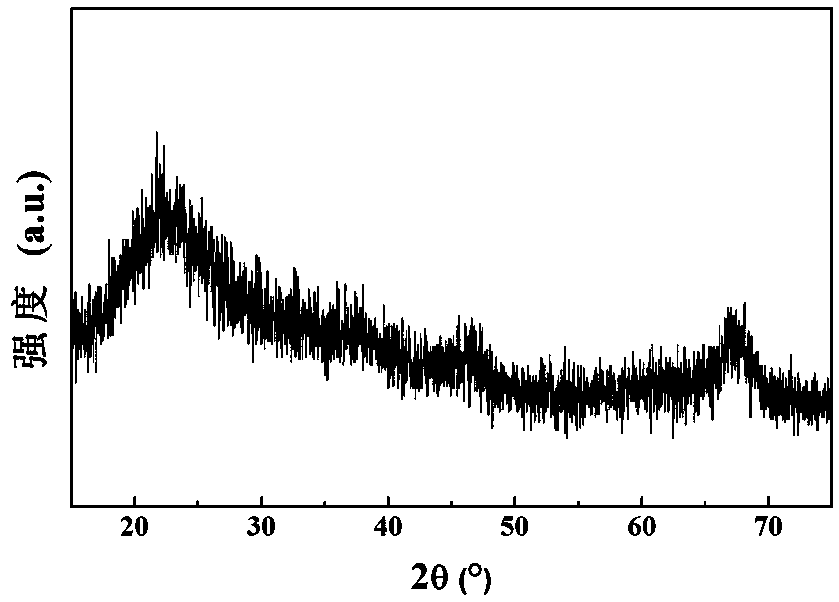

Three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material and preparation method thereof

ActiveCN107640976AImprove antioxidant capacityImprove high temperature resistanceCeramicwarePorosityFiber

The invention discloses a three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material. The composite material comprises a three-dimensional silicon carbide fiber preform and yttrium silicate, the yttrium silicate is a mixed crystalline phase of Y2Si2O7 and Y2SiO5, a crystalline phase of the Y2Si2O7 or a crystalline phase of the Y2SiO5, the pores of the three-dimensional silicon carbide fiber preform are uniformly filled with the yttrium silicate, and the porosity of the three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material is 10%-16%. A preparation method comprises the following steps: (1) preparing a Y2O3-SiO2 composite sol; (2) performing impregnating; (3) performing drying; (4) performing heat treatment; and (5)repeating processes including impregnating-drying-heat treatment in the steps (2)-(4). The three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material has the advantages of low porosity, a high compact degree, high-temperature resistance, oxidation resistance, excellent mechanical properties and the like; and the preparation efficiency of the preparation methodis high, and the compact degree and mechanical properties of the prepared composite material are remarkably improved.

Owner:NAT UNIV OF DEFENSE TECH

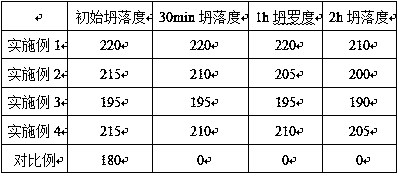

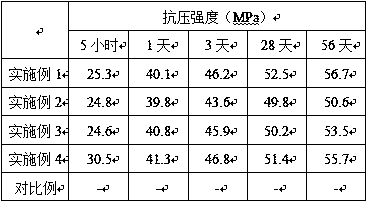

Admixture for marine engineering concrete and preparation method of admixture

The invention relates to the field of buildings, in particular to an admixture for marine engineering concrete and a preparation method of the admixture. The admixture is prepared from raw materials in parts by weight: 100-150 parts of a water reducing agent, 0.5-1 part of tetramethylammonium iodide, 1-5 parts of sodium ethoxide, 3-5 parts of polyacrylamide, 30-50 parts of a surfactant, 15-20 parts of a rust inhibitor, 30-50 parts of an expansion agent, 3-5 parts of a retarder, 6-10 parts of a deforming agent and 0-80 parts of water. The invention aims to overcome the shortcomings of the priorart and provide the admixture for the marine engineering concrete and the preparation method of the admixture, the effects of water reduction, rust resistance, defoaming and retarding are achieved, and the effects are improved; the admixture is added into the concrete, so that the flowability of concrete slurry is improved, retentivity is good, the water reduction rate is high, the density of theconcrete is improved, good flocculability is achieved, and the friction resistance between liquid can be reduced; and the grinding efficiency is improved, and the admixture has the characteristics ofexcellent anti-permeability, fast hardening and early strength, high later strength and the like.

Owner:广西云燕特种水泥建材有限公司

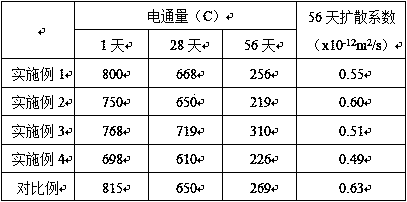

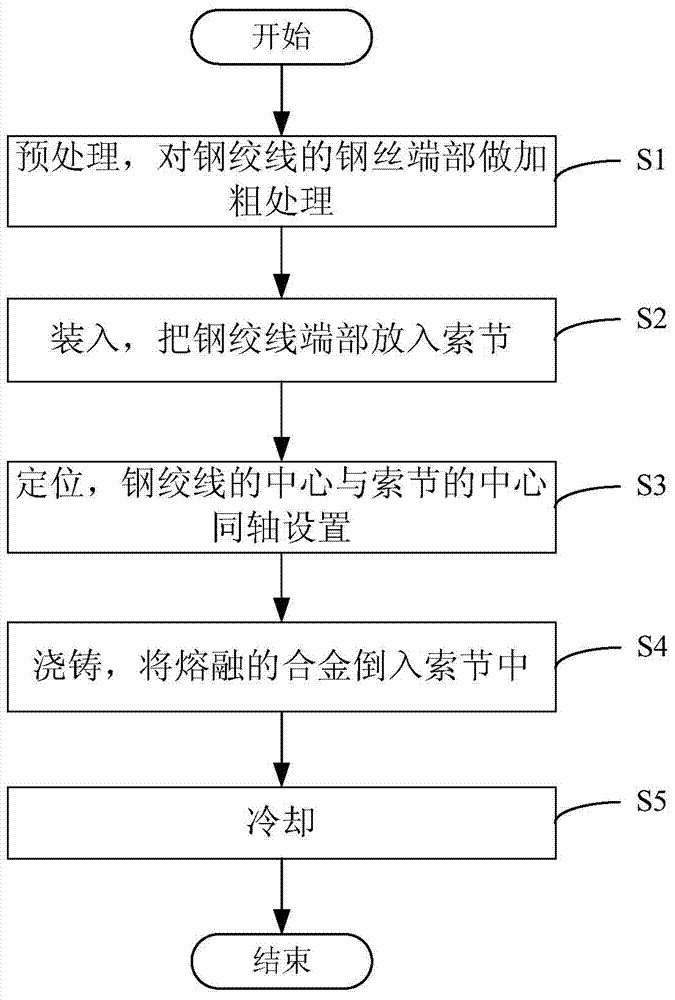

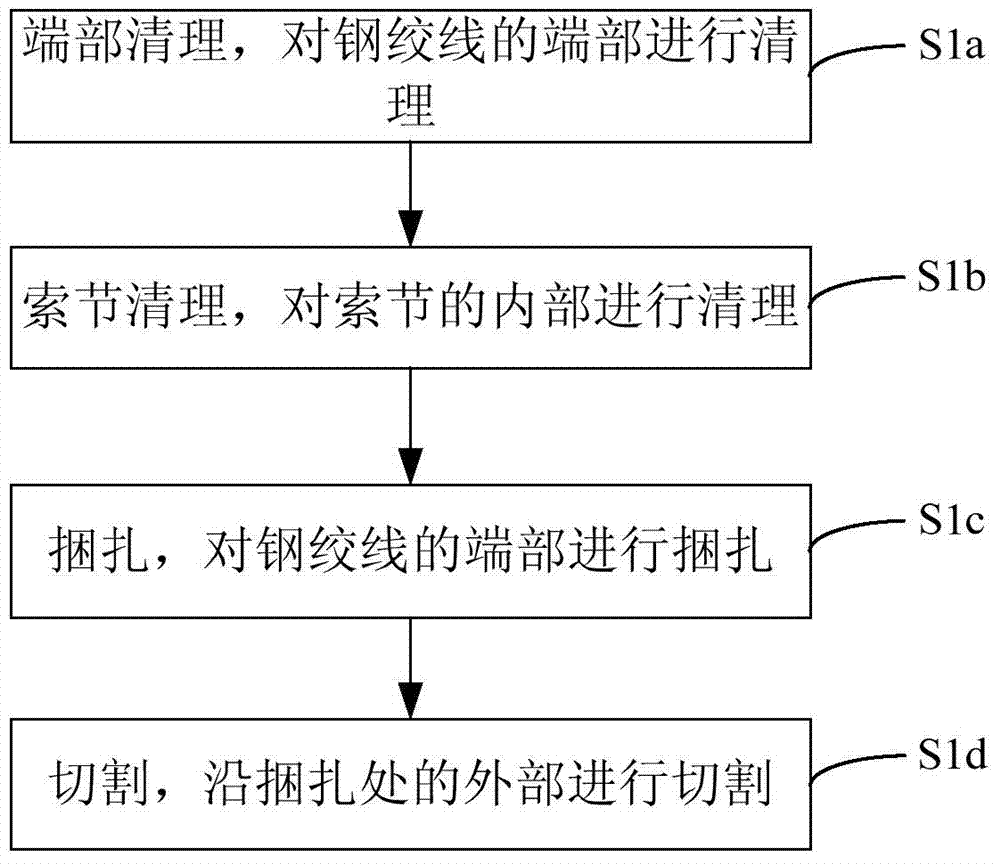

Hot-casting anchoring method of stainless steel cables

The invention relates to a hot-casting anchoring method of stainless steel cables. The method includes: pretreating, namely thickening one end of each steel wire in a steel strand; charging, namely putting the end of the steel strand into a cable joint; positioning, namely coaxially setting the center of the steel strand and that of the cable joint; casting, namely pouring molten alloy into the cable joint; cooling. According to the scheme, the ends of the steel wires are thickened and embedded in the cast alloy, so that end bearing capacity of the steel wires can be improved and connection is firmer. In addition, the center of the steel strand and that of the cable joint are coaxially set, the steel wires in the steel strand are evenly stressed, and the service life of the steel strand is prolonged.

Owner:GUANGDONG KIN LONG HARDWARE PROD CO LTD

Three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material and preparation method thereof

The invention discloses a preparation method of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The preparation method of the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material comprises the following steps of (1) stabilizing SiO2-ZrO2 composite sol; (2) impregnatingthree-dimensional carbon fiber prefabricated members into the stabilized SiO2-ZrO2 composite sol; (3) drying the impregnated three-dimensional carbon fiber prefabricated members; (4) performing thermal treatment; (5) repeating the impregnation-drying-thermal treatment process in the steps of (2) to (4) until the weight gain rate of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material intermediate in a current impregnation-drying-thermal treatment process relative to a previous impregnation-drying-thermal treatment process is smaller than 1% to obtain the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The prepared three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material has the advantages of being high in high-temperature resistance and antioxidant and mechanical performance and the like.

Owner:NAT UNIV OF DEFENSE TECH

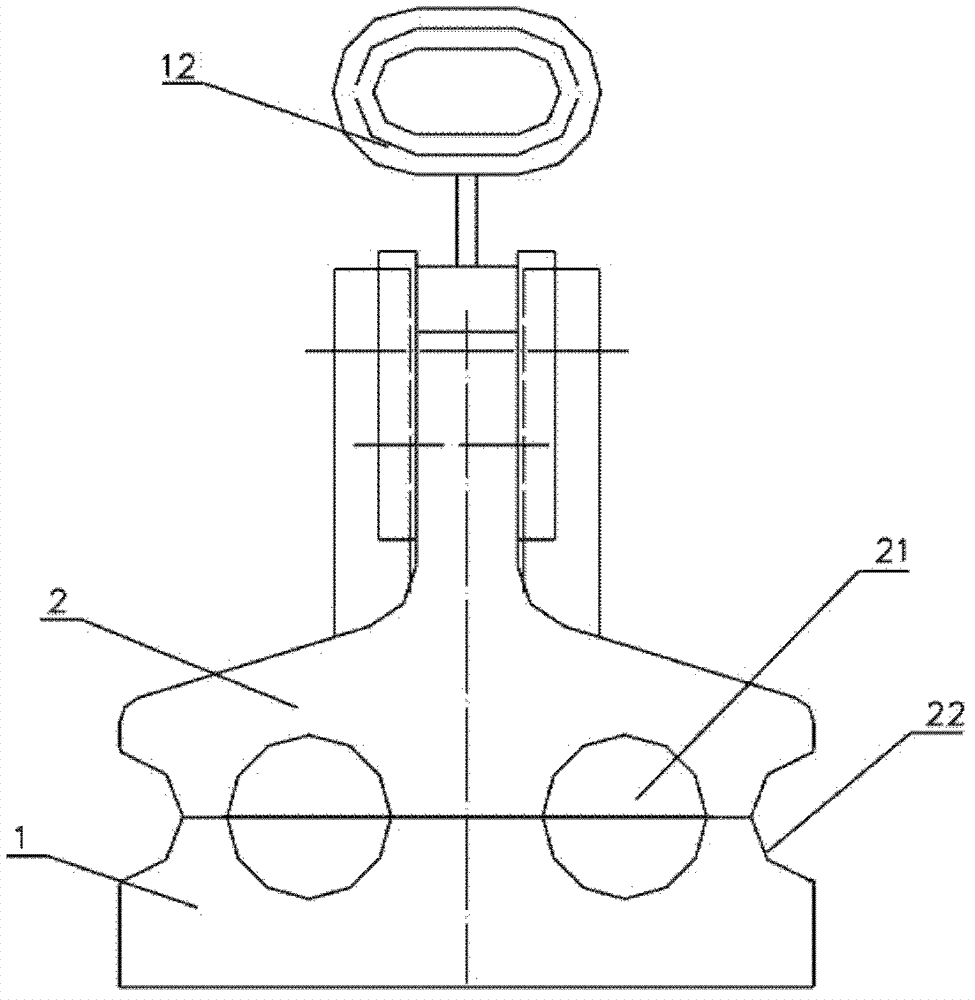

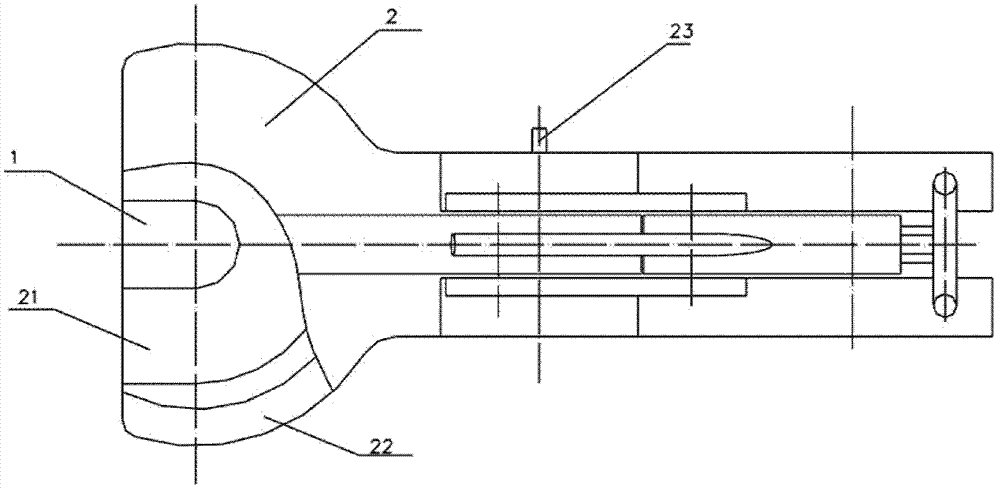

Chain cable securing device for ship

The invention relates to a chain cable securing device for a ship, which can be widely used for water drum mooring of the ship during defending against a hurricane. The chain cable securing device for the ship comprises a base and a manual opening and closing mechanism which is configured together with the base, wherein the manual opening and closing mechanism comprises a press cover with one end hinged with the base; an internal arc groove and an external arc groove are respectively formed inside and outside the press cover configured together with the base; the press cover is connected with a manual rocking bar by a connecting bar and the other end of the manual rocking bar is hinged with the base so that a double-rocking-bar type manual opening and closing mechanism; the manual rocking bar of the manual opening and closing mechanism is connected with a self-locking mechanism; and the self-locking mechanism is connected with a manual unlocking device. The chain cable securing device for the ship, provided by the invention has the advantages of compact and reasonable structure, high reliability, small appearance, light weight, high bearing load, strong hurricane defending mooring function, convenience in use, functions of rapidly clamping, automatically locking and rapidly unlocking hurricane defending chain cables and capability of being widely used for water drum mooring of the ship during defending against the hurricane.

Owner:CHINA SHIPBUILDING INDUSTRY CORPORATION

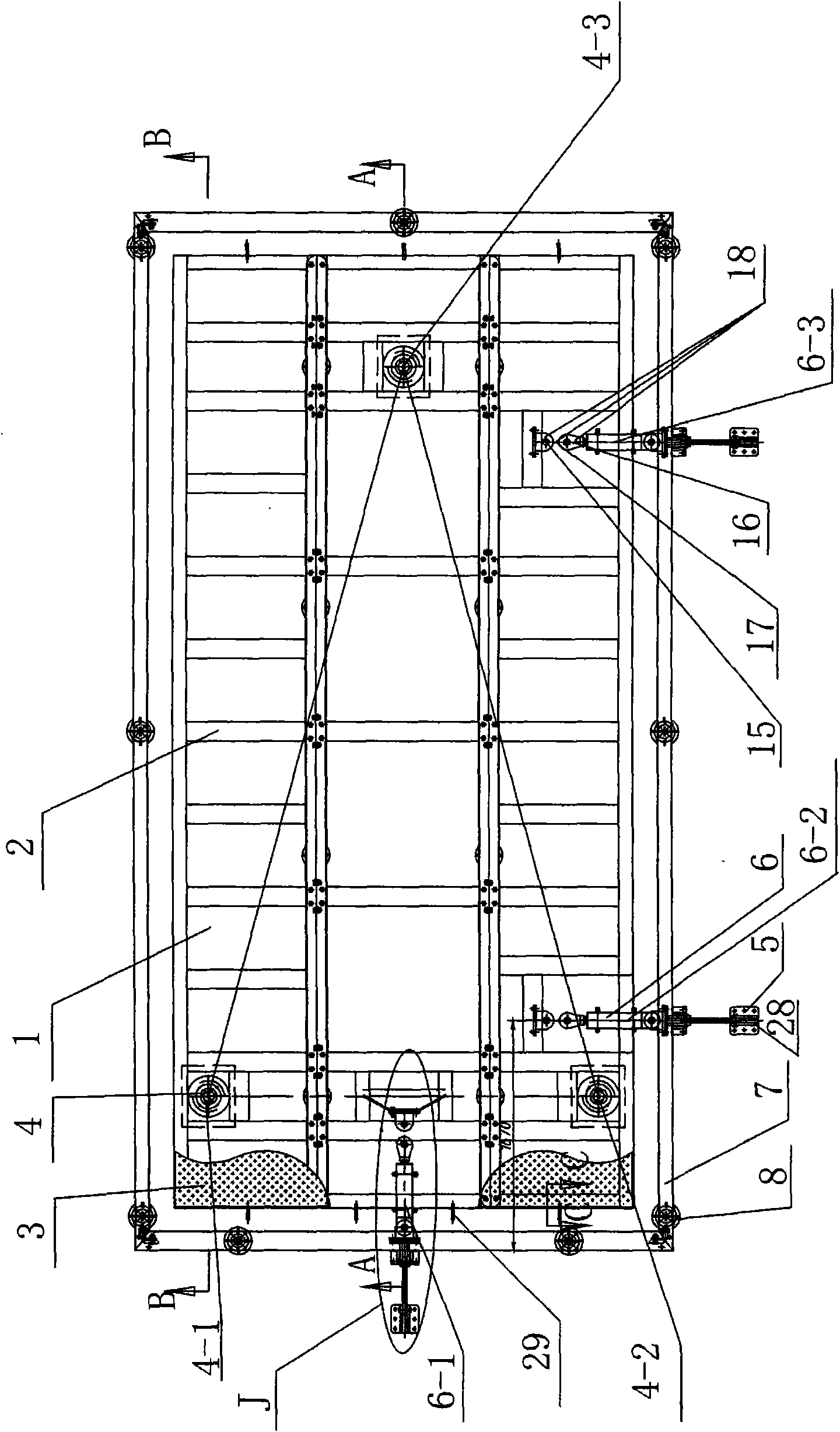

Platform with six degrees of freedom of motion

The invention relates to a device for controlling a platform to freely lift, translate and overturn, in particular to a platform with six degrees of freedom of motion. The platform is of a frame structure provided with a panel on the upper surface and is at least articulated with six drive parts; three of the six drive parts are lifting drive parts which are triangularly arranged below the platform, and two ends of the lifting drive parts are respectively provided with universal joint type hinges; the other three of the six drive parts are translation drive parts which are provided with jointbearing type hinges at two ends; the lifting drive parts are used for driving the platform to move along a Z-axis direction, and / or swing around an X-axis, and / or swing round a Y-axis; and the translation drive parts are used for driving the platform to move along the X-axis and / or Y-axis direction and / or swing around a Z-axis. The platform can be controlled to randomly move and / or rotate withinsix degrees of freedom and has the characteristics of small size, flexible running, high bearing capacity, easy assembly and disassembly, and the like.

Owner:JIANGSU HAIPENG SPECIAL VEHICLES

Three-dimensional carbon fiber preform reinforced yttrium silicate composite material and preparation method thereof

ActiveCN107640973AImprove high temperature resistanceOvercoming brittlenessLayered productsNon-woven fabricsFiberPorosity

The invention discloses a three-dimensional carbon fiber preform reinforced yttrium silicate composite material. The composite material comprises a three-dimensional carbon fiber preform and yttrium silicate, the yttrium silicate is a mixed crystalline phase of Y2Si2O7 and Y2SiO5, a crystalline phase of the Y2Si2O7 or a crystalline phase of the Y2SiO5, the pores of the three-dimensional carbon fiber preform are uniformly filled with the yttrium silicate, and the porosity of the three-dimensional carbon fiber preform reinforced yttrium silicate composite material is 9%-14%. A preparation methodcomprises the following steps: (1) preparing a Y2O3-SiO2 composite sol; (2) performing impregnating; (3) performing drying; (4) performing heat treatment; and (5) repeating processes including impregnating-drying-heat treatment in the steps (2)-(4). The three-dimensional carbon fiber preform reinforced yttrium silicate composite material has the advantages of low porosity, a high compact degree,high-temperature resistance, oxidation resistance, excellent mechanical properties and the like; and the preparation efficiency of the preparation method is high, and the compact degree and mechanicalproperties of the prepared composite material are remarkably improved

Owner:NAT UNIV OF DEFENSE TECH

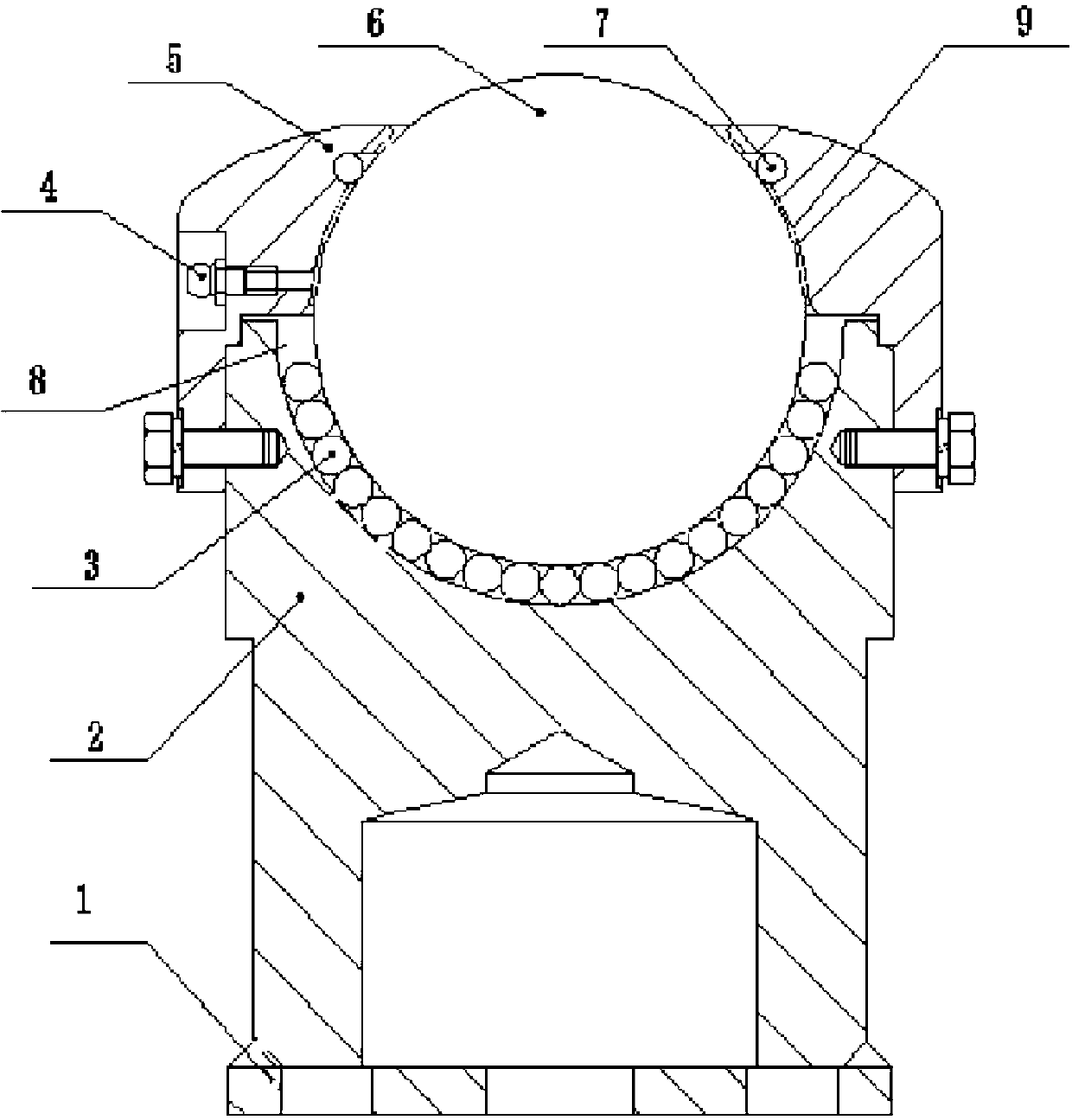

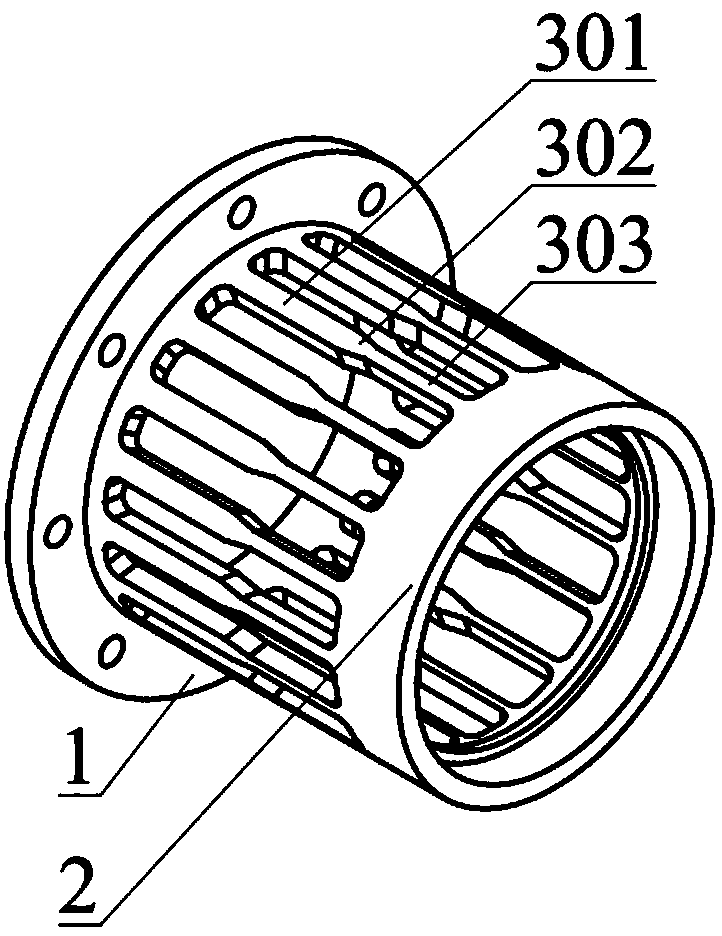

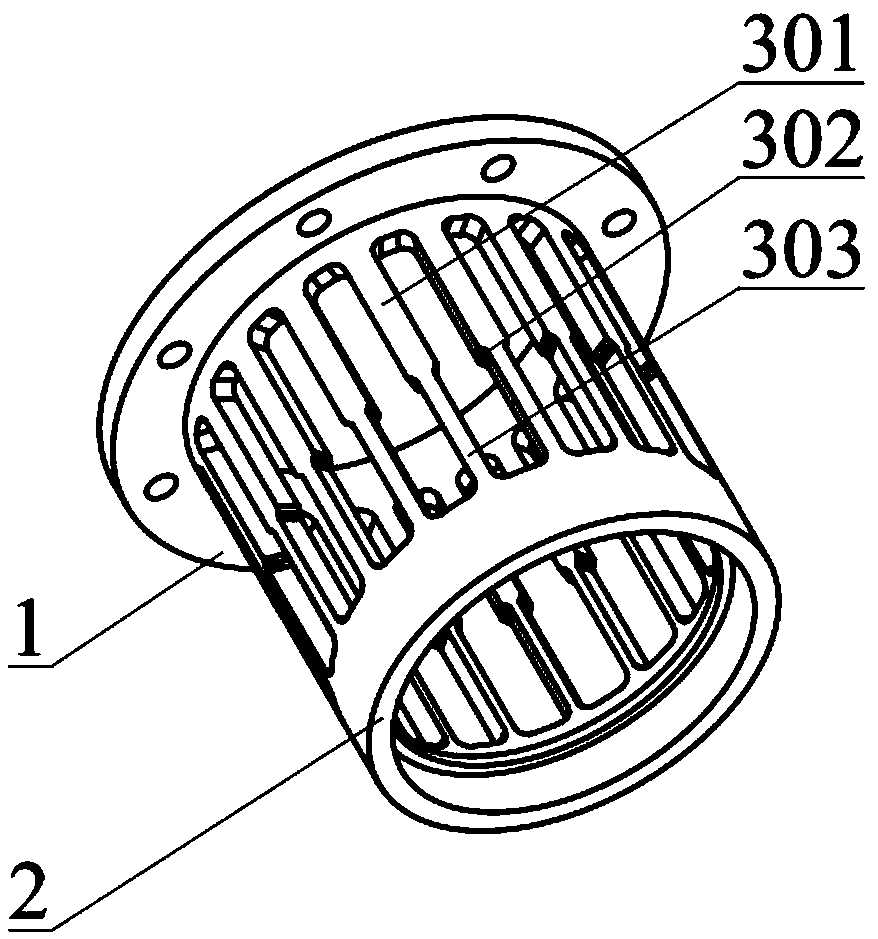

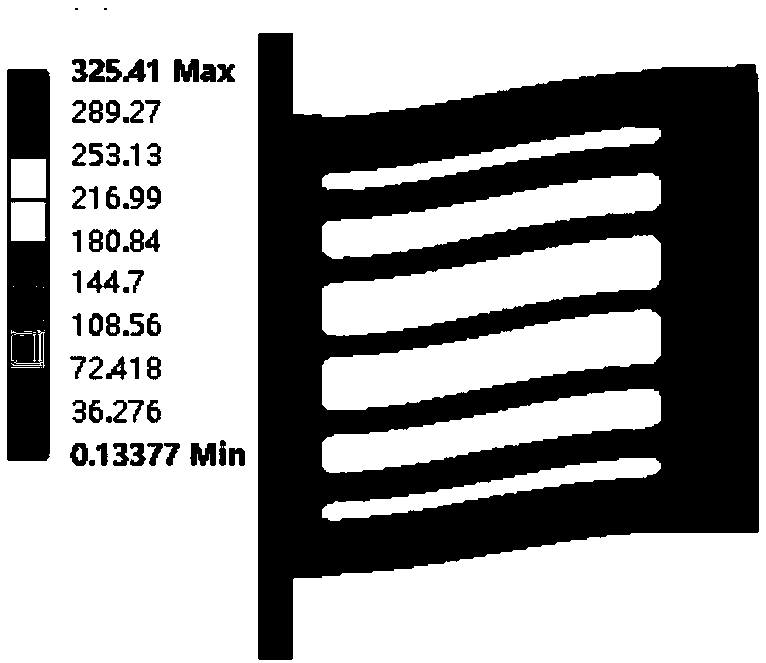

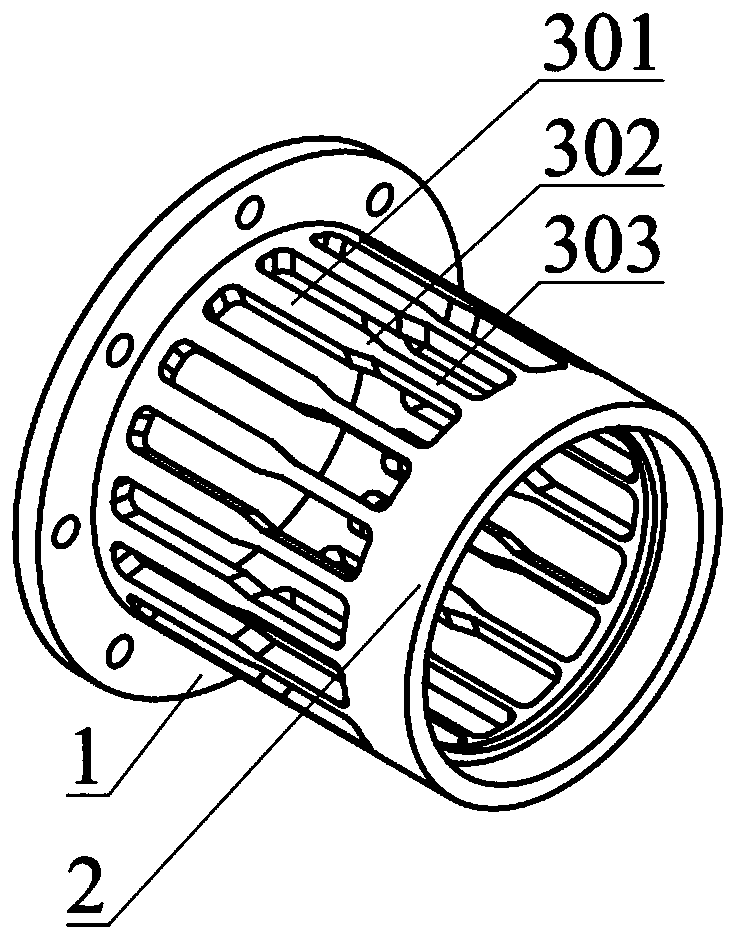

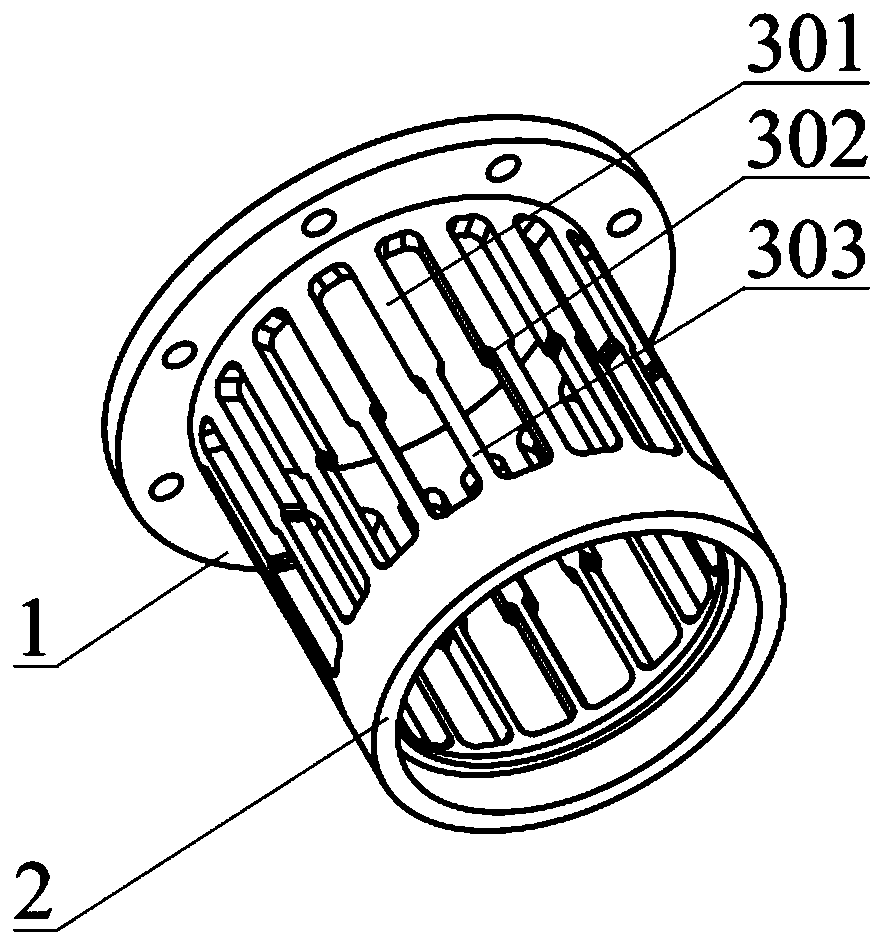

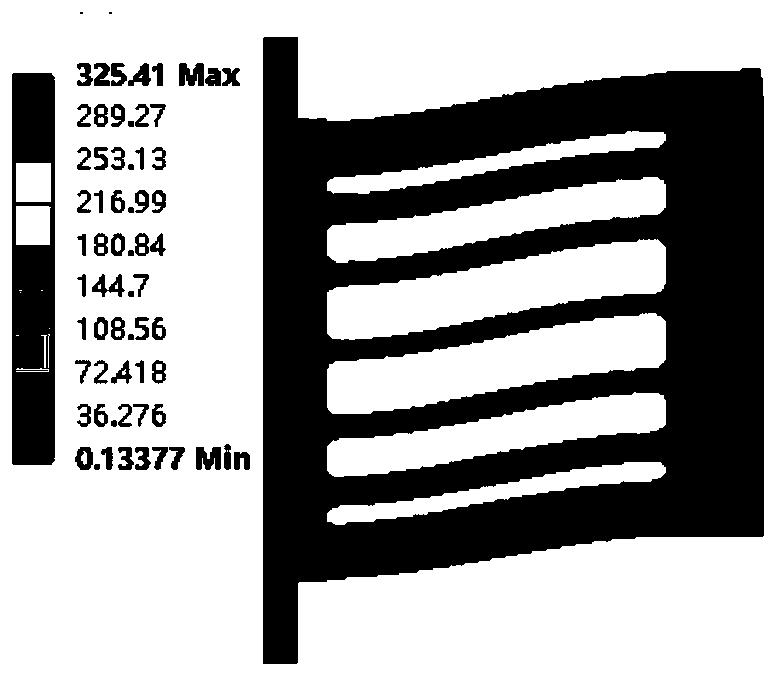

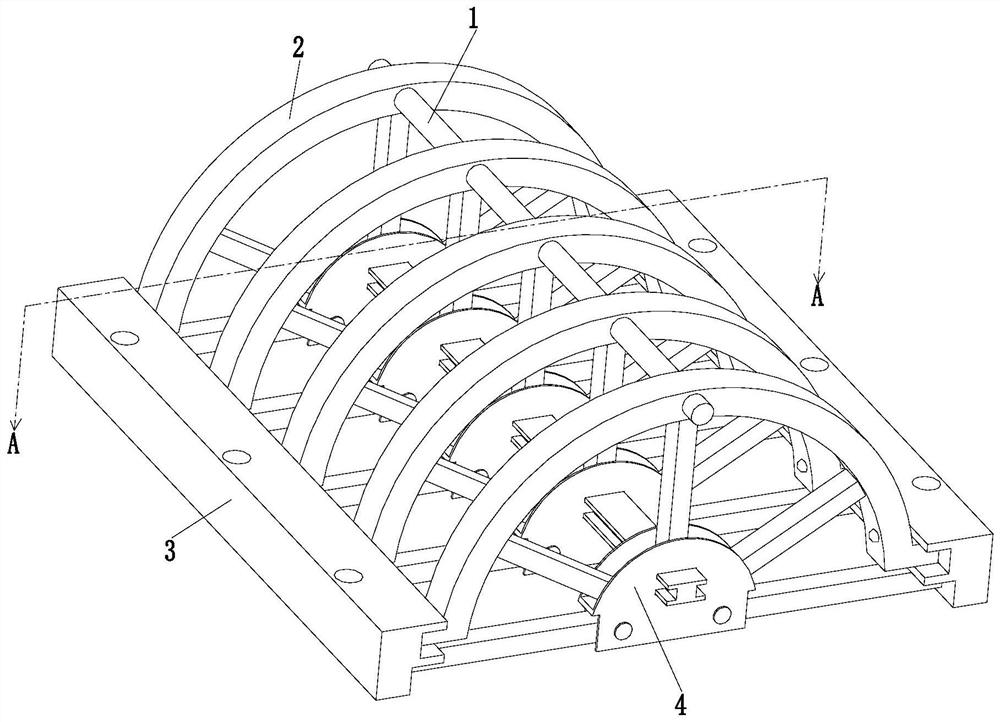

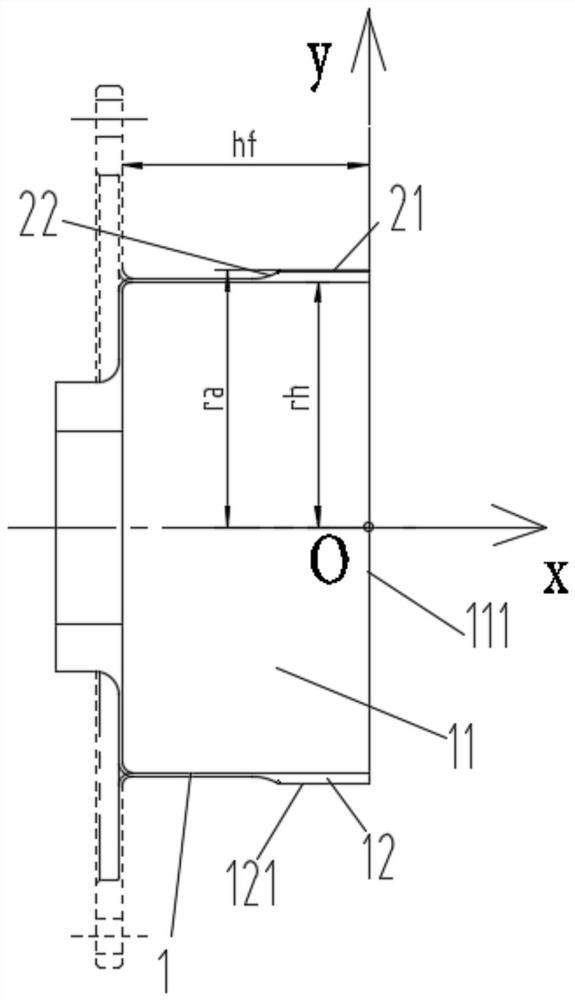

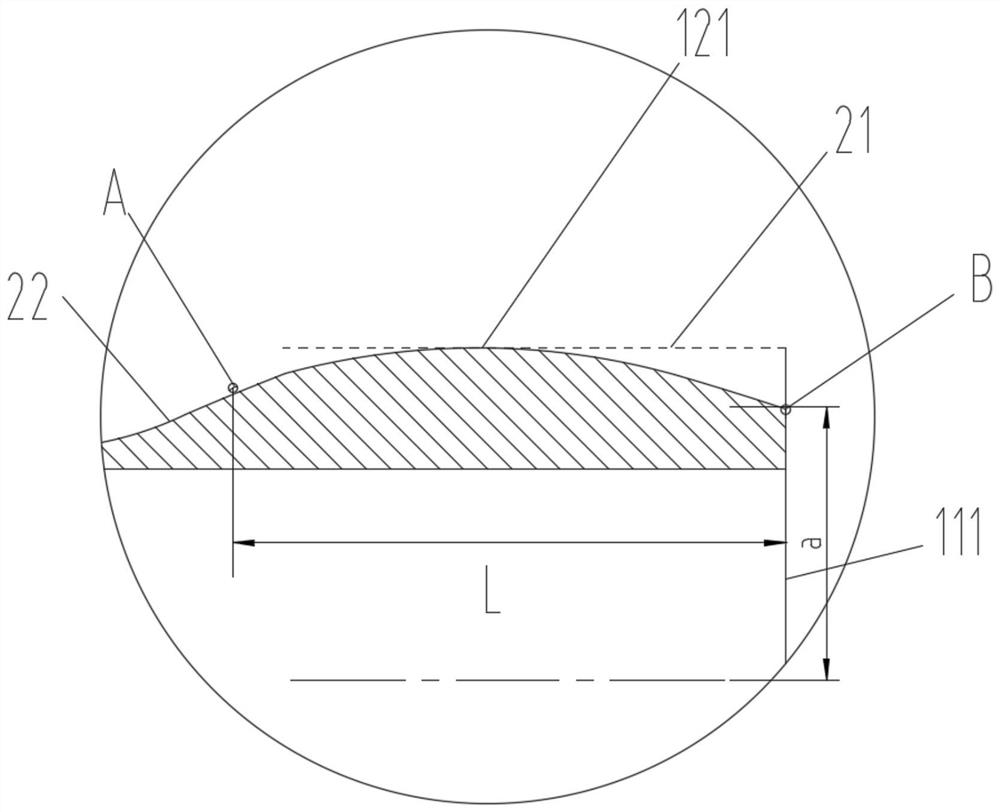

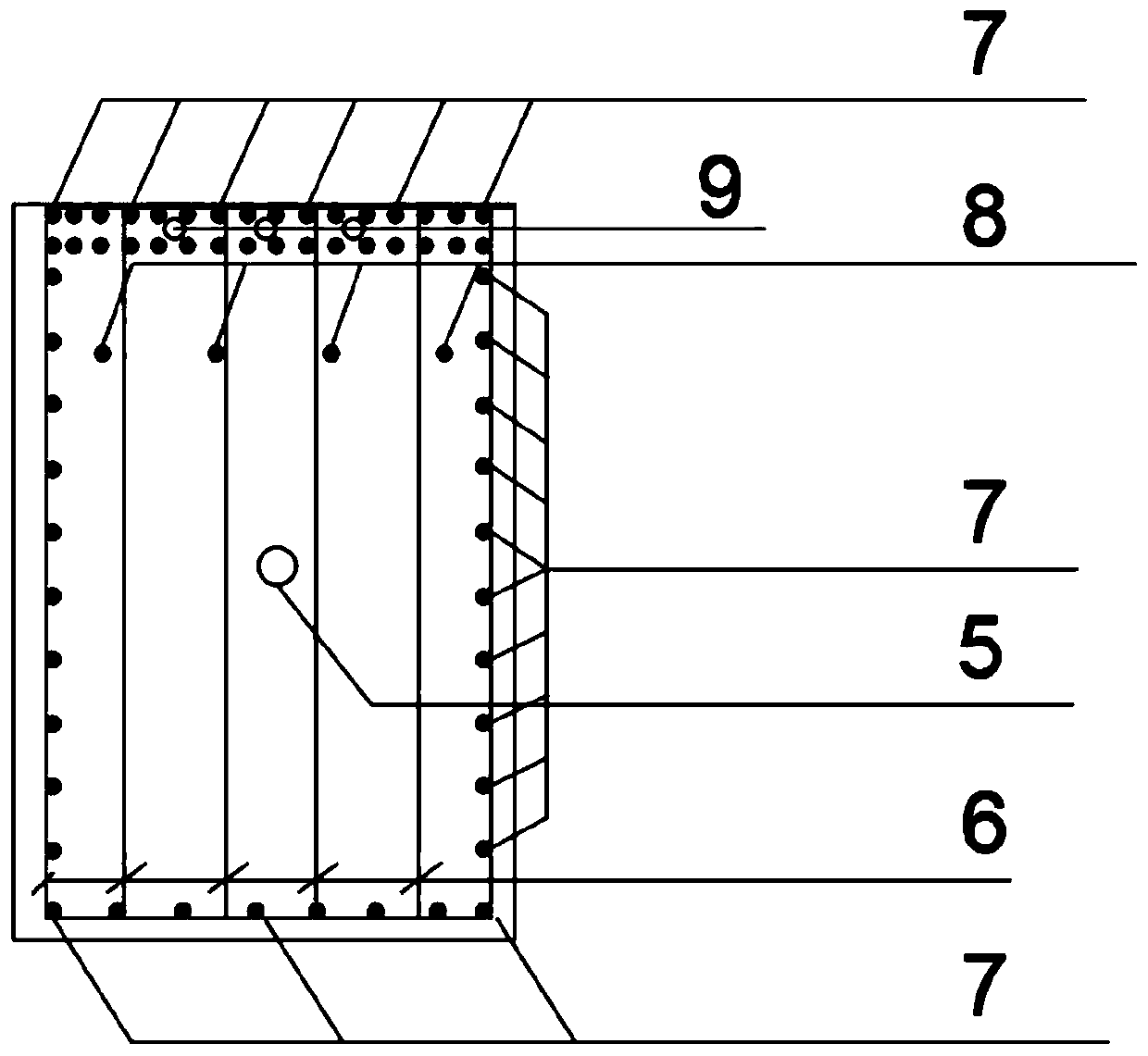

Squirrel cage type elastic support with rigid gradient

ActiveCN109026207AAdjust the critical speedImprove load bearingGas turbine plantsTurbine/propulsion lubricationStructural engineeringUltimate tensile strength

The invention discloses a squirrel cage type elastic support with a rigid gradient. The squirrel cage type elastic support comprises a fixing ring and a cylindrical bearing installation ring with oneend fixedly connected with the fixing ring. Multiple through grooves are formed in the cylinder wall of the cylindrical bearing installation ring, and multiple variable-section cage bars which are evenly distributed are correspondingly formed. By means of the squirrel cage type elastic support, a second cage bar part with the smaller section area is adopted at the end away from the fixing ring, and a first cage bar part with the large section area is adopted at the end close to the fixing ring. The rigidity of the squirrel cage type elastic support is adjusted by adjusting the relative size ofthe section area of the two parts of cage bars, and therefore the critical rotating speed of a rotor system is adjusted; and meanwhile, the bearing load and the bending moment capability of the squirrel cage type elastic support are improved, the cage bars are not likely to be fractured, the fatigue strength reservation is improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

Three-dimensional carbon fiber preform enhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material and preparation method thereof

ActiveCN107640975AImprove antioxidant capacityImprove high temperature resistanceCeramicwareFiberPorosity

The invention discloses a three-dimensional carbon fiber preform enhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material and a preparation method thereof. The composite materialcomprises a three-dimensional carbon fiber preform and yttrium oxide-aluminum oxide complex-phase ceramic, in the yttrium oxide-aluminum oxide complex-phase ceramic, the molar content of Al2O3 is 5%-95%, pores of a three-dimensional carbon fiber preform are uniformly filled with the yttrium oxide-aluminum oxide complex-phase ceramic, and the porosity of the three-dimensional carbon fiber preformenhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material is 10%-15%. The preparation method comprises the following steps; (1) preparing yttrium oxide-aluminum oxide composite sol; (2) carrying out dipping; (3) drying; (4) carrying out heat treatment; and (5) repeating a dipping-drying-heat treatment process in the step (2)-step (4). The composite material has the advantagesof low porosity, high compactness, high temperature resistance, oxidation resistance, excellent mechanical property and the like. The preparation method is high in preparation efficiency, and the compactness and mechanical property of the prepared composite material are improved remarkably.

Owner:NAT UNIV OF DEFENSE TECH

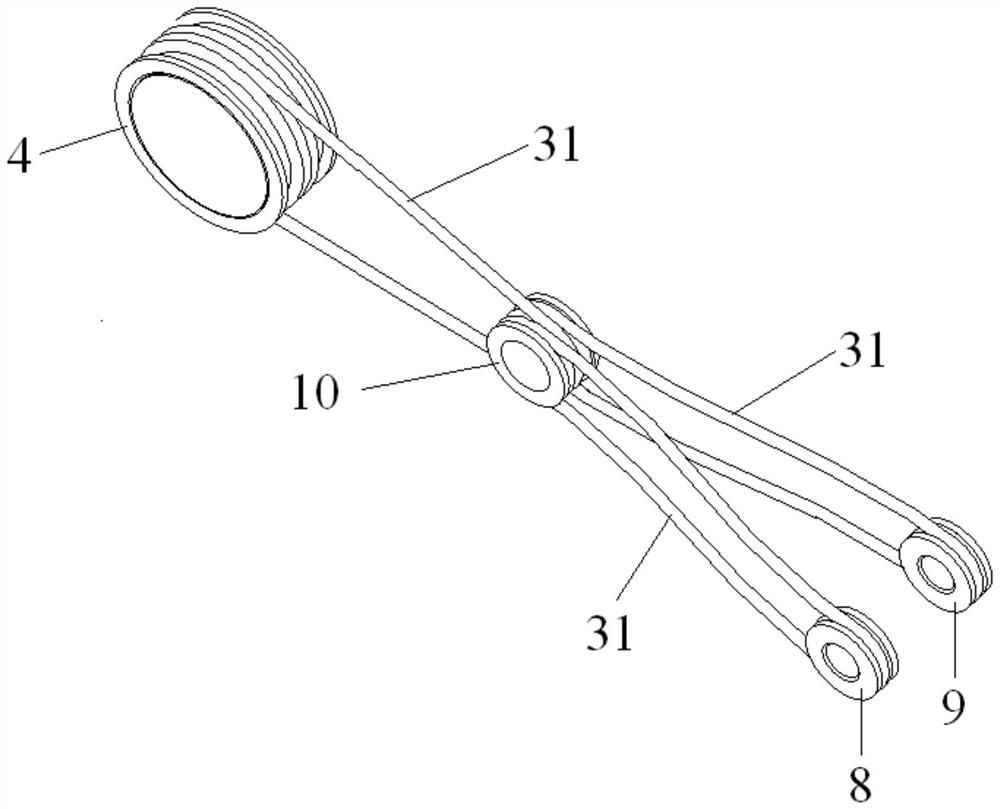

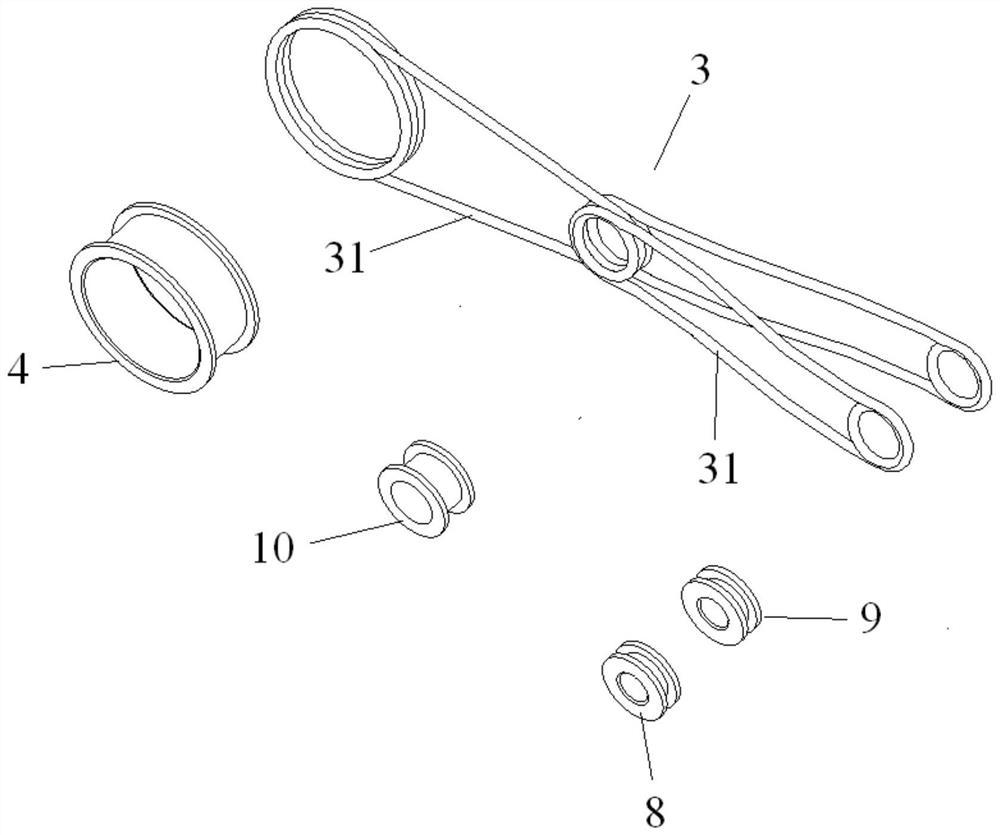

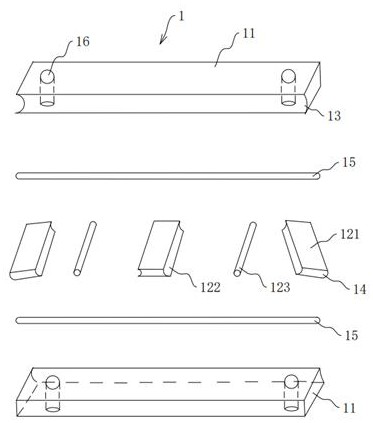

Light-weight large-load commercial vehicle stabilizer bar and suspender assembly and preparation method thereof

ActiveCN113815376AImprove load bearingEasy loadingInternal combustion piston enginesInterconnection systemsFiberInjection moulding

The invention discloses a light-weight large-load commercial vehicle stabilizer bar and suspender assembly and a preparation method thereof. The stabilizer bar and suspender assembly comprises a composite material rod body and a reinforcement body, wherein the reinforcement body is fiber or metal wires and comprises a plurality of reinforcement body sections, a first sleeve is arranged at one end of the rod body, and a second sleeve and a third sleeve are arranged at the other end of the rod body; a bushing is arranged in each sleeve, at least one fourth bushing is arranged in the rod body, when the number of the fourth bushing is one, a reinforcing body section is wound between the first bushing and the fourth bushing, reinforcing body sections are wound between the second bushing and the fourth bushing, reinforcing body sections are wound between the third bushing and the fourth bushing, and when the number of the fourth bushings is more than two, reinforcing body sections are also wound between two adjacent fourth bushings. The preparation method comprises injection molding or pouring molding. The stabilizer bar assembly has the advantages of being light in weight, high in bearing load, high in design freedom degree and the like, and can be suitable for rod pieces with longer lengths and more complex structures.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

Squirrel Cage Elastic Support with Stiffness Gradient

ActiveCN109026207BAdjust the critical speedImprove load bearingGas turbine plantsTurbine/propulsion lubricationStructural engineeringEngineering

The invention discloses a squirrel cage type elastic support with a rigid gradient. The squirrel cage type elastic support comprises a fixing ring and a cylindrical bearing installation ring with oneend fixedly connected with the fixing ring. Multiple through grooves are formed in the cylinder wall of the cylindrical bearing installation ring, and multiple variable-section cage bars which are evenly distributed are correspondingly formed. By means of the squirrel cage type elastic support, a second cage bar part with the smaller section area is adopted at the end away from the fixing ring, and a first cage bar part with the large section area is adopted at the end close to the fixing ring. The rigidity of the squirrel cage type elastic support is adjusted by adjusting the relative size ofthe section area of the two parts of cage bars, and therefore the critical rotating speed of a rotor system is adjusted; and meanwhile, the bearing load and the bending moment capability of the squirrel cage type elastic support are improved, the cage bars are not likely to be fractured, the fatigue strength reservation is improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

Three-dimensional carbon fiber prefabricated part enhanced yttrium oxide-zirconium oxide multiphase ceramic composite material and preparation method thereof

The invention discloses a three-dimensional carbon fiber prefabricated part enhanced yttrium oxide-zirconium oxide multiphase ceramic composite material and a preparation method thereof. The compositematerial is prepared from a three-dimensional carbon fiber prefabricated part and Y2O3-ZrO2 multiphase ceramic, wherein in the Y2O3-ZrO2 multiphase ceramic, the molar content of ZrO2 is 5%-95%, the Y2O3-ZrO2 multiphase ceramic is uniformly arranged in pores of the three-dimensional carbon fiber prefabricated part, and the porosity of the composite material is 8%-15%. The preparation method comprises the following steps: (1) preparing Y2O3-ZrO2 composite sol; (2) performing soaking; (3) performing drying; (4) performing heat treatment; and (5) repeating the processes of soaking, drying and heat treatment from the step (2) to the step (4). The composite material has the advantages of low porosity, high density, high temperature resistance, oxidation resistance, good mechanical properties and the like; and the preparation method has high preparation efficiency and obviously enhances the density and the mechanical properties of the prepared composite material.

Owner:NAT UNIV OF DEFENSE TECH

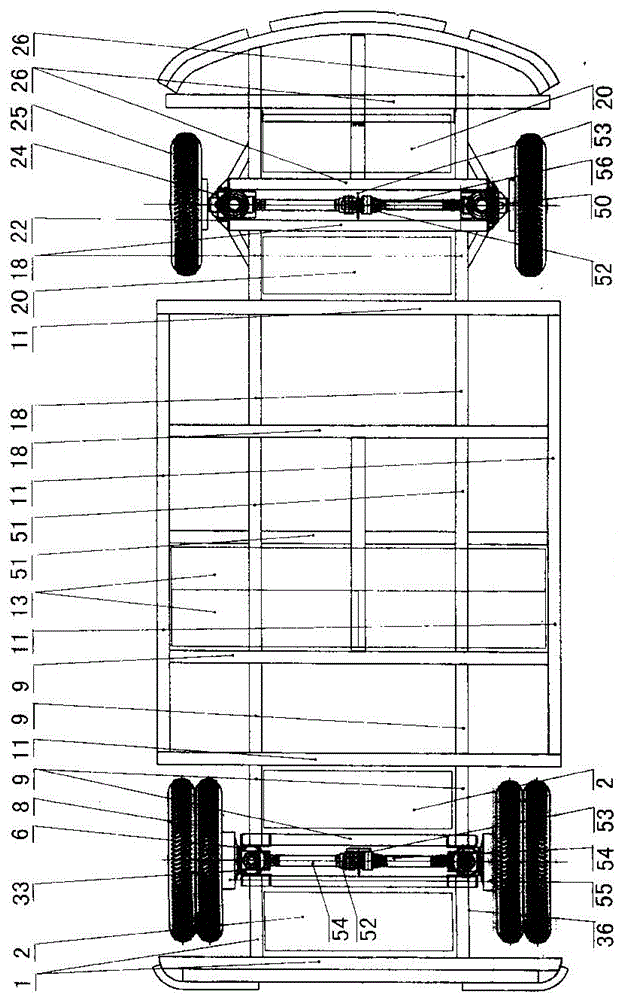

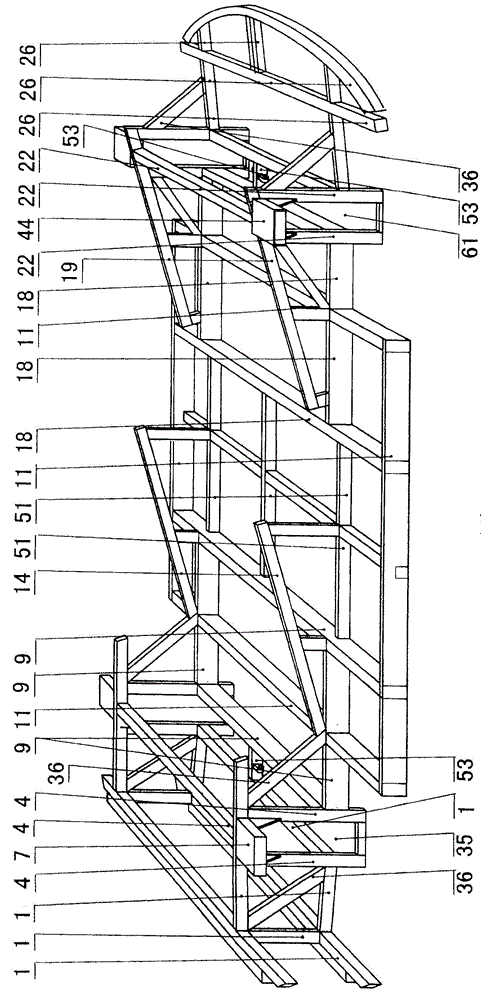

Hub-motor-driven miniature electromobile

InactiveCN104589999ALow priceSave installation spaceUnderstructuresMotor depositionMotor driveTransfer case

The invention provides a hub-motor-driven miniature electromobile. According to the hub-motor-driven miniature electromobile, two hub drive motors are adopted to drive rear wheels directly, a cumbersome internal combustion engine is omitted, a traditional central electromotor applying a centralized driving mode is replaced, the middle conversion and transmission links of a reduction gear, a transfer case, a steering transmission device and the like are omitted, and an electronic control system replaces a traditional mechanical differential system; the weight of the electromobile is lowered greatly, the mounting space of a motor is saved, the whole weight of the electromobile is reduced, the structure is simplified, the cost is reduced, the drive efficiency is improved, and the hub-motor-driven miniature electromobile has the advantages of being simple in structure and capable of saving energy and protecting the environment.

Owner:河南超微电动汽车有限公司

A spliced steel structure truss

ActiveCN110644674BEasy to adjust the positionImprove load bearingGirdersBridge erection/assemblyMechanical engineeringSystems engineering

Owner:黄山浙工绿色建筑科技有限公司

High-hardness steel ball and preparation method thereof

InactiveCN107312922AHigh hardnessImprove load bearingFurnace typesPolishing compositions with abrasivesBall bearingSlag

The invention discloses a high-hardness steel ball and a preparation method thereof. The preparation method comprises: melting raw materials in a vacuum environment, removing slag and deoxidizing to obtain alloy liquid; cooling the alloy liquid to 1400-1420°C After adding into a mold for molding, a steel ball green body is obtained; the steel ball green body is subjected to the first annealing treatment to obtain a steel ball green body M, and the steel ball green body M is subjected to a second annealing treatment to obtain a steel ball green body The ball blank N is obtained by cooling the steel ball blank N to room temperature to obtain a high-hardness steel ball; the problem that the ball bearing cannot bear a large heavy load due to the limitation of the hardness of the inner steel ball is solved.

Owner:WUHU YUHENG SPECIAL STEEL BALL

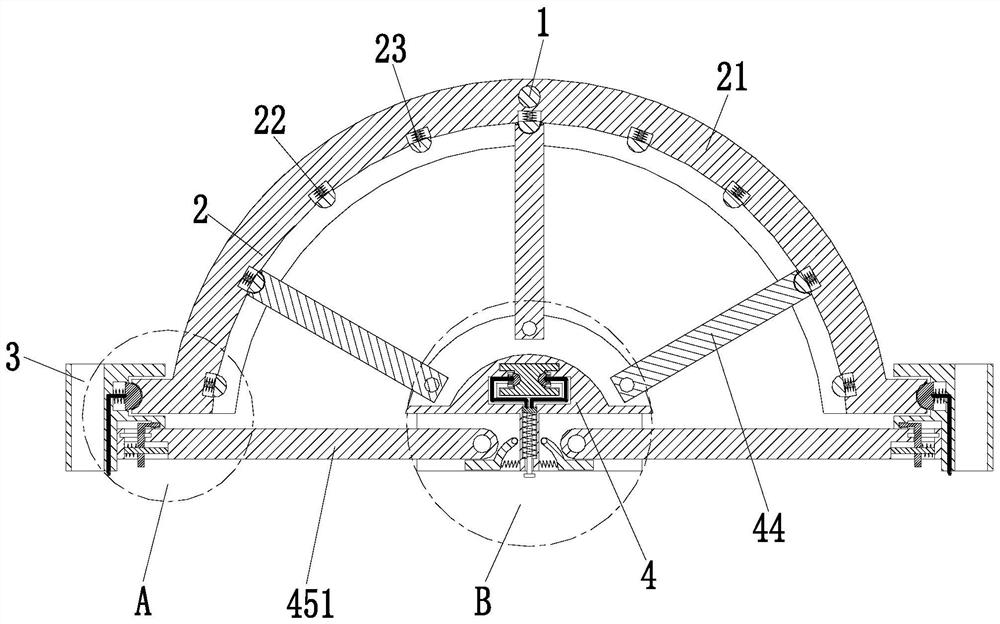

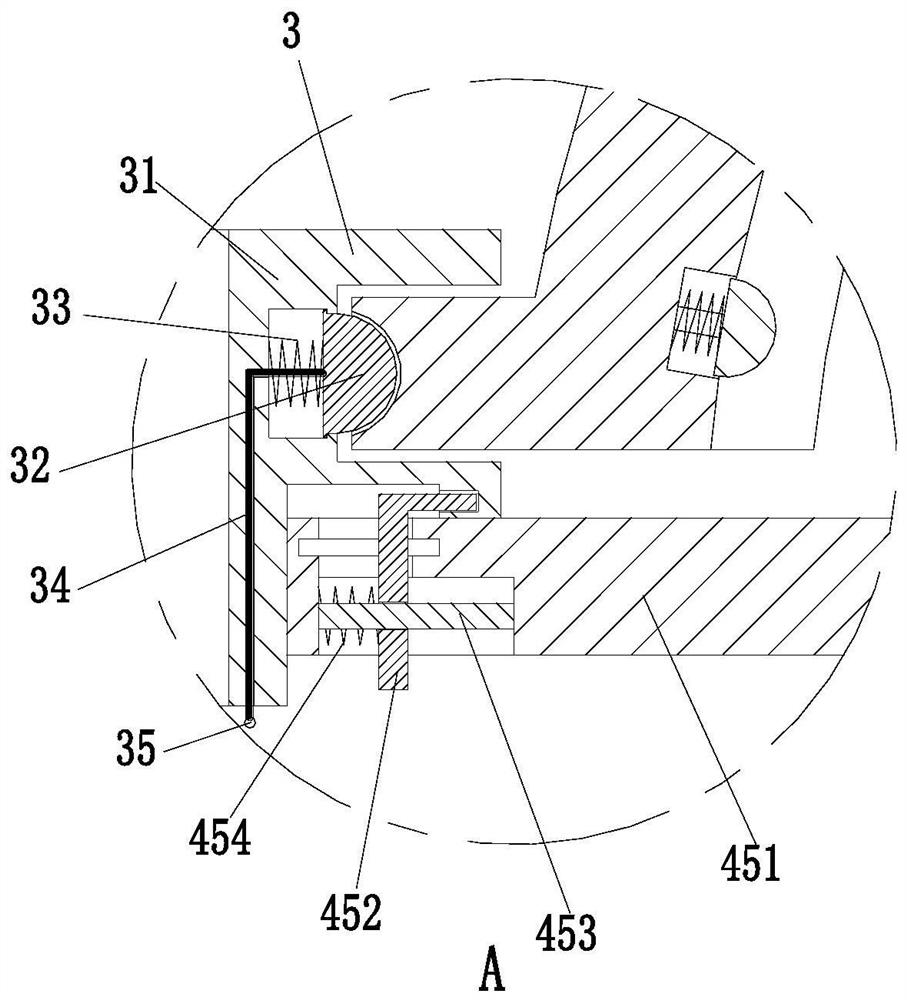

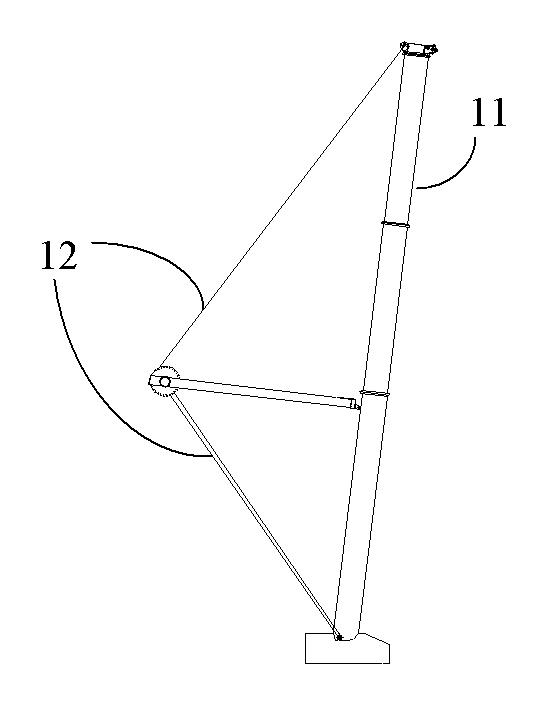

Crane, method for controlling tension of steel wire rope and hydraulic system

ActiveCN102491174BImprove load bearingStrong pullServomotor componentsCranesHydraulic motorEngineering

A hydraulic system for controlling tension of a steel wire rope comprises a master reversing valve (2), a switching valve (3), a check valve (4), a backpressure valve (5), and a hydraulic motor (1). The master reversing valve (2) is used for leading hydraulic oil into or out of the hydraulic system; the hydraulic motor (1) is used for outputting power to a traction device of the steel wire rope; a first end of the switching valve (3) is in communication with a first oil outlet (A) of the master reversing valve (2), an inlet of the check valve (4), and an outlet of the backpressure valve (5); a second end of the switching valve (3) is in communication with a second oil outlet (B) of the master reversing valve (2) and a first end (B) of the hydraulic motor; and an inlet of the backpressure valve (5) is in communication with an outlet of the check valve (4) and a second end (A) of the hydraulic motor (1). The present invention provides a crane having the hydraulic system and a method for controlling tension of a steel wire rope. The system and the method can solve the problems in the prior art that a telescopic-boom crane with a super-lift winding mechanism has low stability and low work efficiency during stretching of a lifting boom.

Owner:ZOOMLION HEAVY IND CO LTD

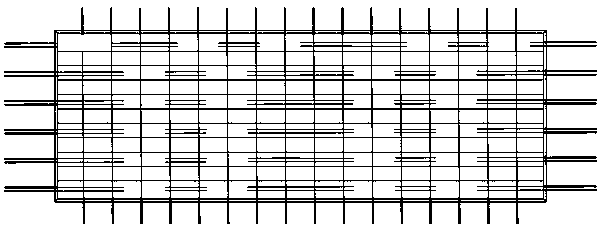

Steel bar concrete precast floor slab

InactiveCN101787760BImprove seismic performanceImprove anti-seepage performanceFloorsEarthquake resistanceSurface layer

The invention relates to improvement of the traditional steel bar concrete precast floor slab, which is characterized in that the upper surface layer and the lower surface layer of a precast concrete hollow floor slab are internally provided with a two-way steel bar framework, an upper and lower layer connecting steel bar concrete ribs consisting of a vertical steel bar connecting steel bars of the upper surface layer and the lower surface layer and wrapping concrete is arranged between the upper surface layer and the lower surface layer; heat insulation and sound insulation materials are filled between the two steel bar concrete ribs; two sides and two ends of the floor slab in an axial direction are both provided with connecting steel bars and side wings of the extending thickness less than the thickness of the floor slab; and shelf beams at two end parts of the floor slab are internally provided with transverse steel bar frameworks forming beam structures and anti-shearing diagonalsteel bars connecting the steel bars at the lower surface layer. The precast floor slab integrates the advantages of the precast floor slab and the cast-in-place floor slab, overcomes all defects of the precast floor slab and the cast-in-place floor slab, especially has small cast-in-place construction workload and high construction speed, can meet requirements of the construction for rapid operation, materials saving and no pollution in an assembled building, accords with the development direction of the building industrialization production, and has high earthquake resistance of the cast-in-place floor slab.

Owner:张吉华 +1

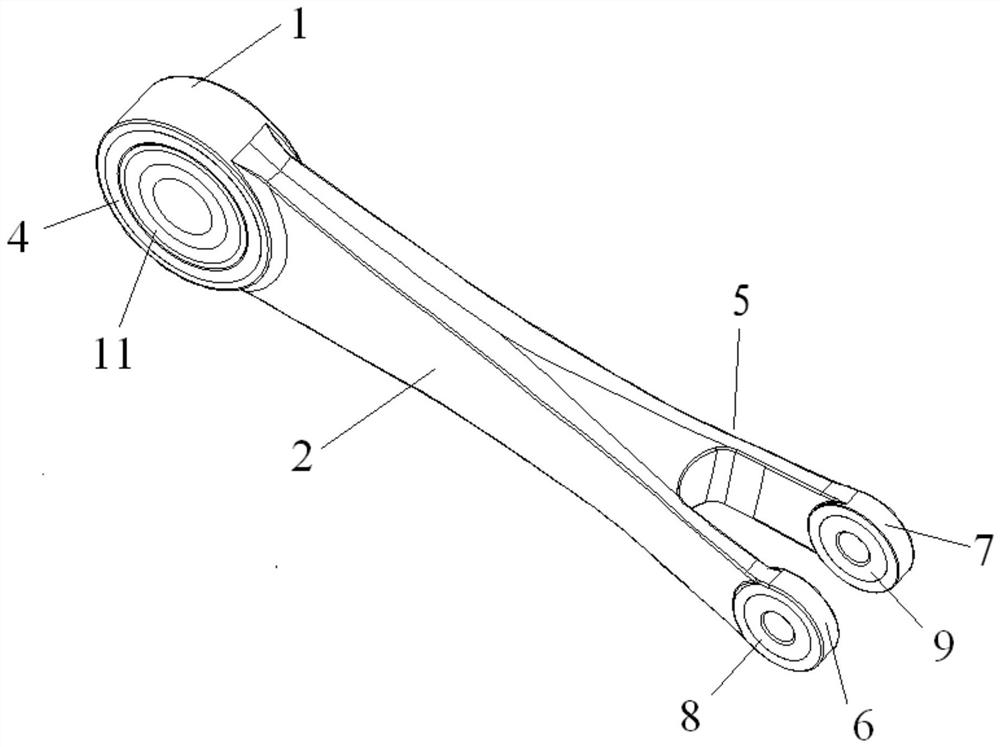

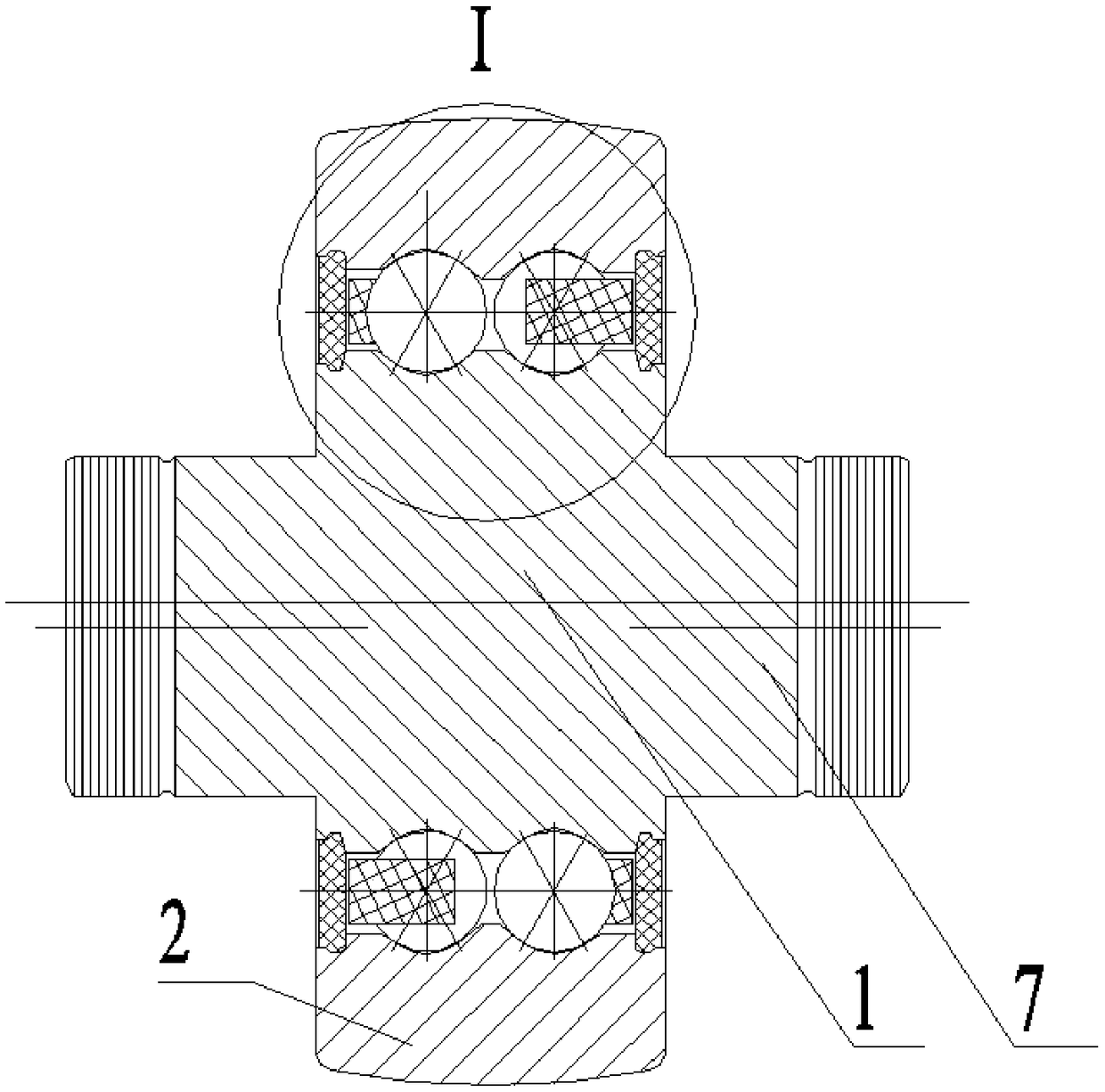

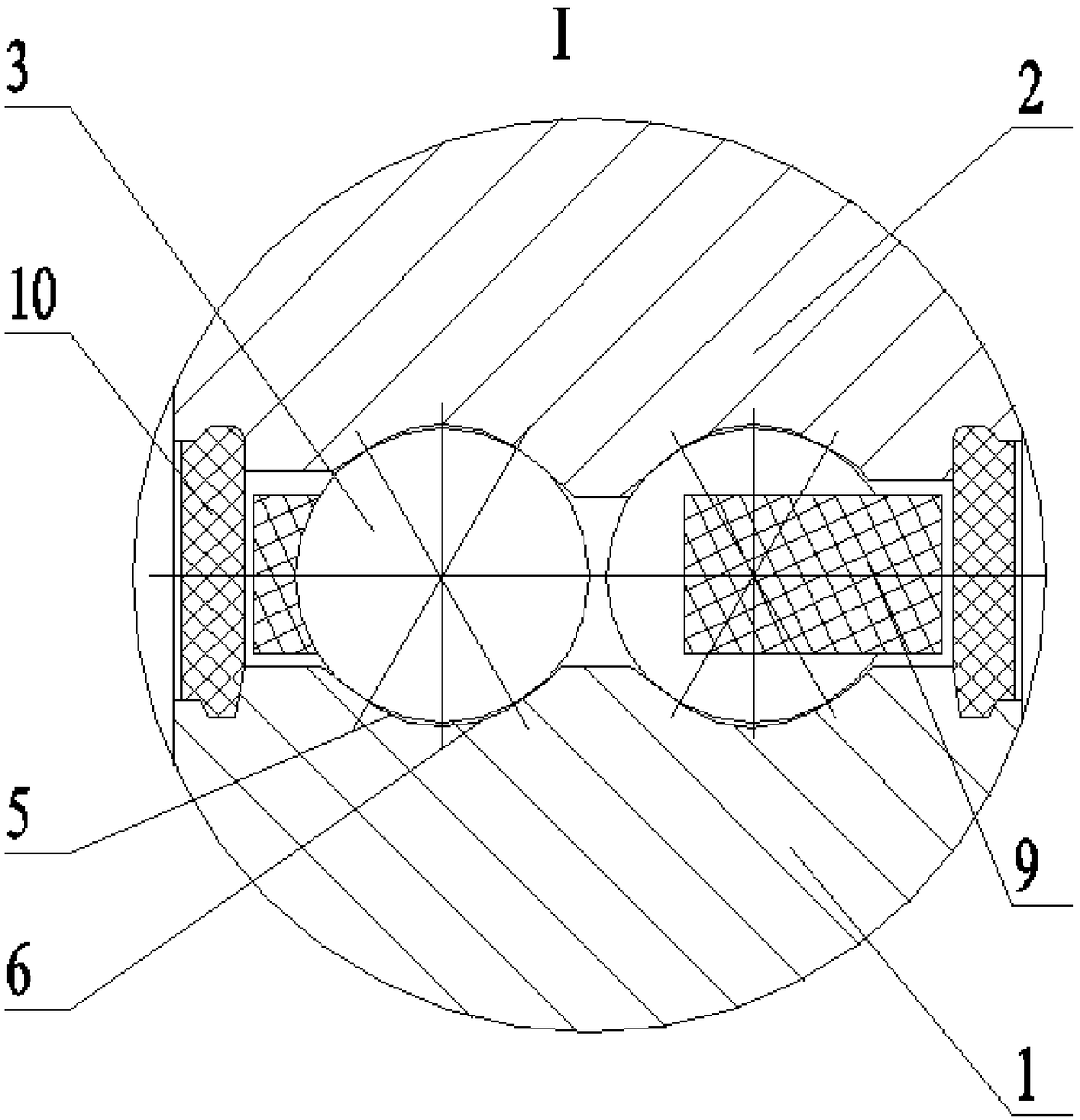

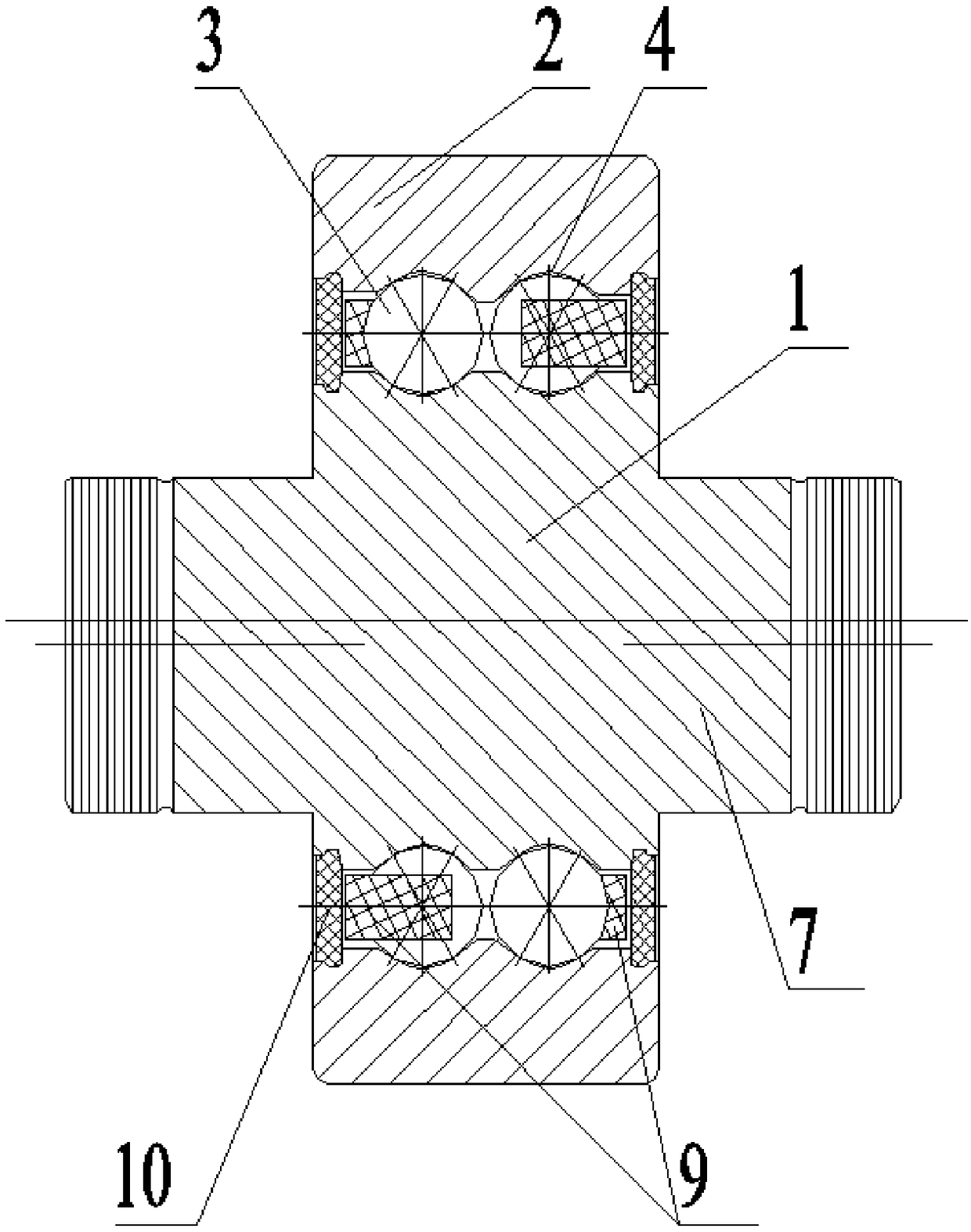

Bearing for robot arm

PendingCN109488682AImprove load bearingIncrease the range of the rotation areaRolling contact bearingsBearing componentsMechanical engineeringSpherical form

The invention discloses a bearing for a robot arm. The bearing comprises an inner ring, an outer ring arranged out of the inner ring in a sleeving manner and a spherical rolling body. Two parallel chutes are formed in the outer circumferential face of the inner ring and the inner circumferential face of the outer ring, the chutes of the inner ring and the chutes of the outer ring are formed oppositely, the rolling body is arranged between the chutes of the inner ring and the chutes of the outer ring, the axial sections of the chutes comprise first arcs and second arcs, the radiuses of curvature of which are greater than the radius of the rolling body, and the rolling body is in contact with the first and second arcs, so that the rolling body and the chutes have four contact points, and therefore, the bearing not only can bear the radial load, but also can bear the axial load, and the bearing load of the bearing is improved; one of the inner and outer ring is fixedly connected to a large arm of the robot while the other one is fixedly connected to small arm, and the rotating axis of the inner ring is deviated from the rotating axis of the outer ring, so that the moving track of theend part of the small arm is changed and the rotating area range between the small arm and the large arm is enlarged.

Owner:临清市海瑞轴承制造有限公司

Three-dimensional carbon fiber reinforced alumina-zirconia composite material and preparation method thereof

The invention discloses a three-dimensional carbon fiber reinforced alumina-zirconia composite material and a preparation method thereof. The preparation method comprises the following steps: (1) stabilizing an alumina-zirconia composite sol; (2) under vacuum immersing a three-dimensional carbon fiber preform in the alumina-zirconia composite sol; (3) drying the impregnated three-dimensional carbon fiber preform; (4) performing heat treatment; (5) repeating the impregnation, drying, and heat treatment process from the step (2)-the step(4) for the until weight gain of a three-dimensional carbonfiber reinforced alumina-zirconia composite material intermediate is less than 1% compared with that of the three-dimensional carbon fiber reinforced alumina-zirconia composite material intermediatetreated after last impregnation, drying, and heat treatment process to obtain the three-dimensional carbon fiber reinforced alumina-zirconia composite material. The three-dimensional carbon fiber reinforced alumina-zirconia composite material has the advantages of high temperature resistance, oxidation resistance and excellent mechanical properties and the like.

Owner:NAT UNIV OF DEFENSE TECH

Three-dimensional carbon fiber reinforced silica-zirconia composite ceramic composite material and preparation method thereof

The invention discloses a preparation method of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The preparation method of the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material comprises the following steps of (1) stabilizing SiO2-ZrO2 composite sol; (2) impregnatingthree-dimensional carbon fiber prefabricated members into the stabilized SiO2-ZrO2 composite sol; (3) drying the impregnated three-dimensional carbon fiber prefabricated members; (4) performing thermal treatment; (5) repeating the impregnation-drying-thermal treatment process in the steps of (2) to (4) until the weight gain rate of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material intermediate in a current impregnation-drying-thermal treatment process relative to a previous impregnation-drying-thermal treatment process is smaller than 1% to obtain the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The prepared three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material has the advantages of being high in high-temperature resistance and antioxidant and mechanical performance and the like.

Owner:NAT UNIV OF DEFENSE TECH

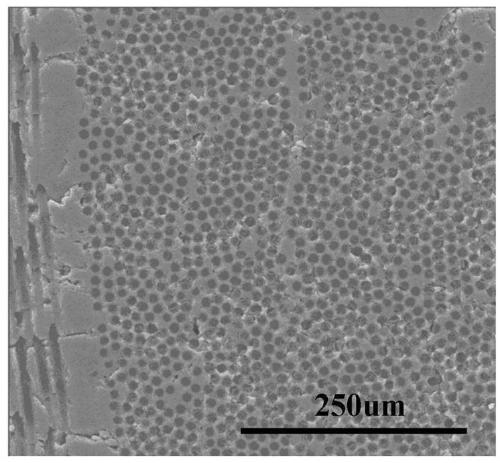

Flexible gear and harmonic reducer suitable for heavy load working condition

PendingCN113446376AImprove load bearingGuaranteed stabilityGearingPortable liftingReduction driveReducer

The invention provides a flexible gear and a harmonic reducer suitable for heavy load working condition. The flexible gear comprises a cylinder body, an inner hole of the cylinder body is used for installing a wave generator, a plurality of flexible gear teeth are arranged on the outer circumferential wall of the cylinder body, the flexible gear teeth are evenly arranged in the circumferential direction of the cylinder body at intervals and extend in the axial direction of the cylinder body, the tooth profiles of the flexible gear teeth are symmetrical about a first plane, the first plane is a plane passing through the axial extension line of the top points of the tooth profiles of the flexible gear teeth and the central axis of the cylinder body, and on the first plane, along the direction from the cylinder opening to the cylinder bottom of the cylinder body, the tooth-direction modification curve of the flexible gear teeth is a continuous smooth curve, and the distance between the tooth-direction modification curve and the central axis is increased firstly and then decreased. According to the flexible gear, the phenomenon of inter-tooth interference in the meshing process can be reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Three-dimensional silicon carbide fiber preform reinforced yttria-zirconia composite ceramic composite material and preparation method thereof

The invention discloses a three-dimensional silicon carbide fiber preform reinforced yttrium oxide-zirconium oxide multiphase ceramic composite material and a preparation method thereof. The compositematerial comprises a three-dimensional silicon carbide preform and an Y2O3-ZrO2 multiphase ceramic, in the Y2O3-ZrO2 multiphase ceramic, molar content of ZrO2 is 5-95%, the Y2O3-ZrO2 multiphase ceramic is uniformly filled in pores of the three-dimensional silicon carbide fiber preform, and porosity of the composite material is 9-16%. The preparation method comprises the following steps: (1) preparing Y2O3-ZrO2 composite sol; (2) impregnating; (3) drying; (4) carrying out heat treatment; and (5) repeating the impregnation-drying-heat treatment process in the steps (2)-(4). The composite material disclosed by the invention has the advantages of low porosity, high density, high temperature resistance, oxidation resistance and good mechanical properties, the preparation method has high preparation efficiency, and the density and mechanical properties of the composite material are obviously improved.

Owner:NAT UNIV OF DEFENSE TECH

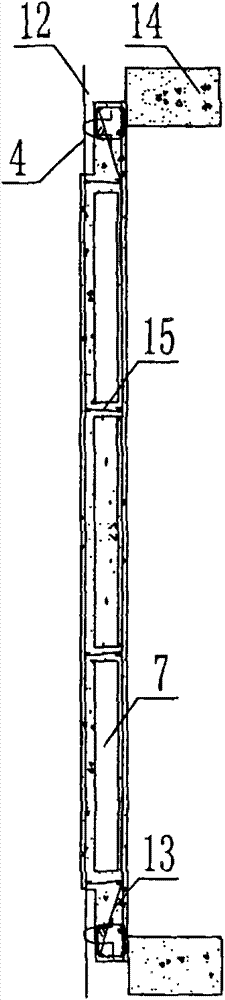

Novelbridge crane beam bearing platform structure of underground power house and construction method of novel bridge crane beam bearing platform structure

PendingCN111424880ALower requirementImprove stabilityGirdersJoistsCantilevered beamArchitectural engineering

The invention discloses a novel bridge crane beam bearing platform structure of an underground power house and a construction method of the novel bridge crane beam bearing platform structure. The novel bridge crane beam bearing platform structure comprises a rock mass and a cantilever beam, wherein the cantilever beam is divided into an embedding section and a cantilever section; an embedding groove is excavated in the rock mass; an embedding section of the cantilever beam is embedded in the embedding groove; the cantilever beam comprises longitudinal ribs and stirrups; the longitudinal ribs are sleeved with the stirrups, are distributed in the periphery of the cantilever beam and extend out of the end face of the embedding section of the cantilever beam; a plurality of first embedding channels are formed in the end of the embedding section, and the longitudinal ribs are embedded in the first embedding channels. The embedding grooves embedded in the embedding section of the cantileverbeam is excavated in the rock mass, and by embedding the cantilever beam in the rock mass, stability of the bridge crane beam bearing structure is improved, and the problem of structural instability of the rock anchor beam due to plastic damage between the rock wall and an inclined platform when quality of the rock wall is poor in the prior art is solved.

Owner:中国葛洲坝集团第三工程有限公司

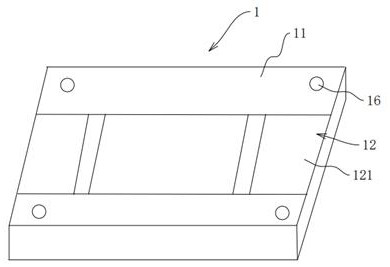

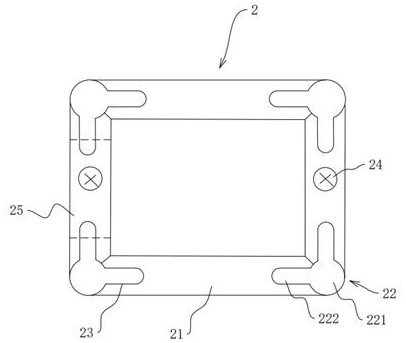

High-rigidity dust-free assembled laboratory

PendingCN114809304AReduce pollutionLess consumablesConstruction materialWallsExperimental laboratoryMechanical engineering

The invention relates to the technical field of precision equipment laboratories, in particular to a high-rigidity dust-free assembled laboratory which comprises a wall and a ground. The ground comprises two side edge buckling beams and a unit plate located between the two side edge buckling beams, first arc-shaped long grooves are formed in the side faces, close to the unit plate, of the two side edge buckling beams correspondingly, and second arc-shaped long grooves are formed in the two side faces, close to the side edge buckling beams, of the unit plate correspondingly. Cylindrical long grooves are formed between the first arc-shaped long grooves and the corresponding second arc-shaped long grooves, and core columns used for fixing the side edge buckling beams and the unit plates are arranged in the cylindrical long grooves. A fixing piece used for fixing the two wall plates is arranged between the two adjacent wall plates. The assembled type floor is adopted, consumables are saved, the construction period is greatly shortened, and cyclic disassembly and utilization can be achieved; in addition, the laboratory wall body is a prefabricated semi-finished product field assembly type, so that the field installation time is greatly saved, procedures are few in interpenetration, and construction is convenient; and meanwhile, the possibility of environmental pollution to a laboratory in the construction process is reduced.

Owner:CHINA CONSTR EIGHTH ENG DIV

Three-dimensional silicon carbide fiber preform reinforced yttrium oxide-zirconium oxide multiphase ceramic composite material and preparation method thereof

The invention discloses a three-dimensional silicon carbide fiber preform reinforced yttrium oxide-zirconium oxide multiphase ceramic composite material and a preparation method thereof. The compositematerial comprises a three-dimensional silicon carbide preform and an Y2O3-ZrO2 multiphase ceramic, in the Y2O3-ZrO2 multiphase ceramic, molar content of ZrO2 is 5-95%, the Y2O3-ZrO2 multiphase ceramic is uniformly filled in pores of the three-dimensional silicon carbide fiber preform, and porosity of the composite material is 9-16%. The preparation method comprises the following steps: (1) preparing Y2O3-ZrO2 composite sol; (2) impregnating; (3) drying; (4) carrying out heat treatment; and (5) repeating the impregnation-drying-heat treatment process in the steps (2)-(4). The composite material disclosed by the invention has the advantages of low porosity, high density, high temperature resistance, oxidation resistance and good mechanical properties, the preparation method has high preparation efficiency, and the density and mechanical properties of the composite material are obviously improved.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com