Conveying device for heavy load conveyor belt

A transmission device and conveyor belt technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of power device burden, conveyor belt deviation, heavy conveyor belt transmission quality, etc., to reduce power output, improve load bearing, and easy to solve The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0008] The present invention will be described in detail below with reference to the accompanying drawings.

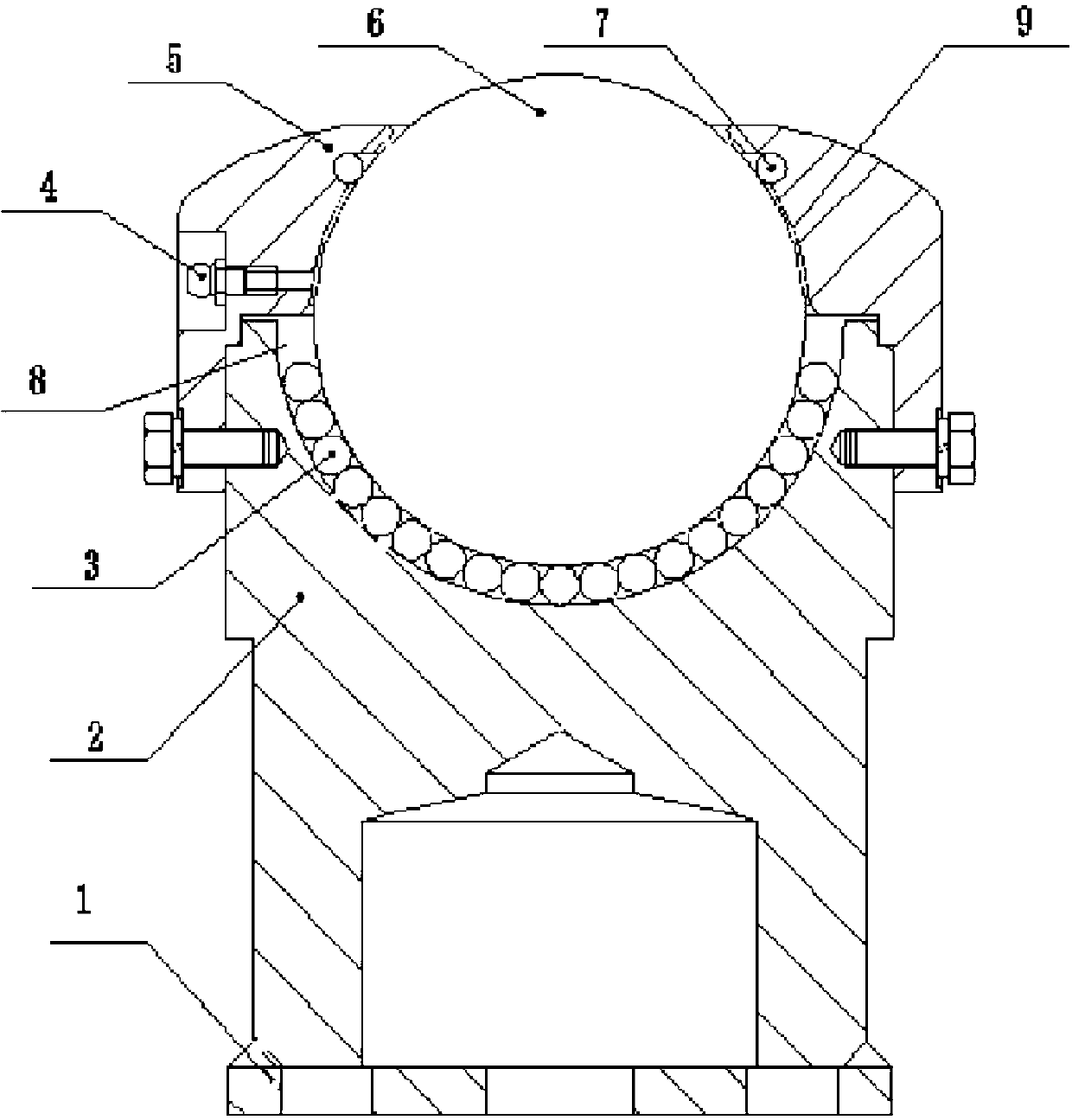

[0009] Such as figure 1 As shown, a conveying device for a heavy-duty conveyor belt includes a steel ball seat 2. The top of the steel ball seat 2 is provided with a hemispherical groove 8, and the surface of the hemispherical groove 8 is provided with evenly distributed C8 steel balls 3. The upper edge of the seat 2 is also provided with a steel ball cap 5, the top of the steel ball cap 5, the inner cavity, and the inner wall of the cap surround an arc-shaped hole 9 through which the C100 steel ball 6 can pass. The arc-shaped hole 9 is located on the top of the steel ball cap The diameter of the C100 steel ball 6 is smaller than the diameter of the inner cavity of the steel ball cap. One spherical surface of the C100 steel ball 6 protrudes from the top of the steel spherical cap 5, and the other spherical surface is slidingly connected with the C8 steel ball 3. The inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com